Reactor Sampling System Model PV

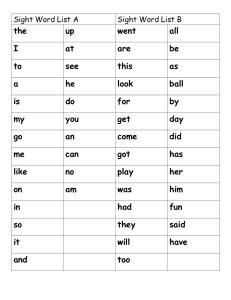

advertisement

NEOTeCHA Reactor Sampling Type PV A safe and reliable sampling device to meet the demands of the chemical and pharmaceutical industry Features General applications Technical data To take a sample from reactors or vessels containing: • poisoned media’s • biological media’s • corrosive media’s • environmental unfriendly media’s • liquids with high viscosities Additionally the PV reactor sampling unit allows the operator to view the reaction process stage via an integrated sight glass. Pressure (bar): Temperature (°C): Sample volume (ml): max. 10 max. 200 150 / 250 / 500 / 1000 • Extracts a representative sample from a reactor under process conditions without stopping the process or opening the reactor. • Safe and simple operation. • Sample is transferred pressure less. • Different sample volumes are available. • All wetted parts are PTFE, PFA, perfluor or glass. • Direct mounting of all auxiliary valves via integrated mini mounting flange. • If pH metering is required the top flange of the PV unit can be equipped with the required connection. • Unit can be connected to a continuous recirculation pump. • Unit can be integrated with vacuum, nitrogen and rinsing supply lines. • Liquid product can be added to the reactor via the PV unit. • Sample media can be returned to the reactor. • No contamination of the atmosphere. Displaced air in the bottle is returned into sight glass. • Soft seated check valve prevents entering media in the vacuum line. • Unit can be flushed and rinsed in situ. • All valves can be pneumatically actuated. • Numerous varieties of auxiliary valves and accessories. The unit can be integrated with various sensor devices to measure Redox, pH or temperature of the chemical process inside the reactor. www.pentair.com/valves © 2012 Pentair Inc. All Rights Reserved. NEOJV-0023-EN-1402 NEOTeCHA Reactor Sampling Type PV Main components (1) Upper sight glass flange (2) Valve seat (3) Vacuum auxiliary valve (4) Sight glass safety cylinder (13) Vent valve NTB DN15 PFA lined (5) Sight glass (14) Transfer device (6) Hollow ball (15) Drain valve NBT DN15 PFA lined (7) Lower sight glass flange (8) NTB/NTC DN20 PFA lined ball valve (16) Sample bottle (9) Mounting flange (10) Suction hose (11) Dip tube (12) Reactor tank Material specification Part name Ball valve type NTB/NTC Sight glass flanges and connecting flange Sight glass Ball support and check valve floor Hollow ball Ball check seat Suction hose Sight glass safety cylinder Flange seals Material PFA lined ductile iron PFA lined stainless steel Borosilicate Virgin PTFE Virgin PTFE Perfluor elastomer PFA 12/9 or 19/16 mm dia. Acryl glass Virgin PTFE 2 NEOTeCHA Reactor Sampling Type PV Description of operation Process Step A: All valves are closed: (3), (8), (13) and (15). Process Step B: By opening valves (3) and (8), the liquid from the reactor is lifted with vacuum through the suction hose (10) inside the dip tube through the open ball valve (8) into the sight glass (5). The PTFE hollow ball (6) floats on the rising liquid level till the ball will interrupt the vacuum on valve seat (2). This will prevent the liquid entering the vacuum line. Process Step C: As soon as the sight glass is full, the main shut off valve (8) can be closed, thereafter also ball valve (3) can be closed to interrupt the applied vacuum. In this stage the media is separated from the reactor and can now be transferred from the sight glass into a bottle (16). There are several options available to do that. The most common is by means of the transfer device (14) including the drain valve (15) and vent valve (13). It connects the middle flange to the top flange. Process Step D: In the lower end of the transfer device the bottle (16) can be connected by an ISO GL45 thread. The drain valve (15) mounted on the middle flange controls the flow of the media into the bottle. A vent valve (13) on top of the sight glass will permit the displaced air from the bottle to be returned into the sight glass. With this type of transfer device no emission of toxic or foul smelling gases occurs during the transfer of the sample. Process step A The dip tube will be selected according to the type of reactor and operating conditions, i.e. size of reactor flange, shape and length of dip tube. These parameters are being decided by the customer. The flange on the end of the dip tube is a 2” ANSI 150 or a DIN DN 50. The PV is mounted and supported from this flange. The suction hose is mounted into the PFA lined connecting flange (9). The main shut-off valve (8) is a standard Neotecha ball valve type NTB. It is also possible to use the C-ball valve, a dead-spot free version. Process step B The lower sight glass flange (7) has two ports to connect valves or other auxiliary equipment (transfer device) by means of a 2-hole flange. The upper sight glass flange (1) is provided with four ports. The inside diameter of these ports is 8 mm. The cylindrical sight glass (5) is rated at 10 bar and is additionally protected by an acrylic safety cylinder (4). The valve seat (2) is equipped with a soft seat made from a Perfluor elastomer and insures a bubble tight shut off with the floating ball. The transfer unit can be equipped with a bottle sensing device. This sensing device requires that the bottle is connected properly before the sample can be transferred into the bottle. Accidental spilling of the media by human error is eliminated. Since there seldom are enough flange connections (nozzles) on reactors, the PV has been designed to connect a gas or liquid line to the mounting flange (9) which brings the gas or liquid into the reactor through the inside of the dip tube. Process step C Process step D 3 NEOTeCHA Reactor Sampling Type PV Auxiliary valves Accessories options PV reactor sampling unit Mounting flange Stainless Steel ball valves Spacer 2-way Stainless Steel ball valve Top flange suitable for In-Trac pH metering Stainless Steel braided hose Angle connectors Stainless Steel diaphragm valve Top flange c/w pH probe Tracing options PFA lined ball valve PVDF diaphragm valve PFA plug valve PFA plug valve Suction devices Manual vacuum pump Ball valves (TE 11) Reactor sampling unit PV PVDF diaphragm valve Stainless Steel/PFA diaphragm angle valve Diaphragm vacuum pump Stainless Steel diaphragm valve Eductor kit 4 NEOTeCHA Reactor Sampling Type PV Transfer device options PVDF diaphragm valves (TE 1) PVDF pneumatic operated diaphragm valves (TE 2) Indirect sample return units PFA lined ball valve Glass plug valves (TE 15) Stainless Steel/PFA diaphragm valves (TE 3) Stainless Steel ball valves (TE 7) Direct sample return unit Connected direct to transfer device Stainless Steel diaphragm valve 5 NEOTeCHA Reactor Sampling Type PV Modular conception The modular concept of the PV reactor can be tailored to virtually every customer sampling requirement. The volume of the sight glass is smaller or equal to the size of the sampling bottle to eliminate spilling by human error. 150, 250, 500 and 1000 ml samples volumes are available. We offer various solutions for heat tracing on auxiliary valves as well as to the main PV unit. The transfer device and auxiliary valves used for the vacuum or for rinsing media are available either manually or pneumatically operated. The unit can be utilized to a fully automated and remote controlled unit. Instead of using the transfer device a direct sampling method can be offered by means of the Neotecha Sapro® sampling valve. The Sapro® sampling valve will be mounted between the main shut off valve and the lower sight glass flange. The operation is achieved by a spring loaded lever which closes automatically when it is released. The handle can be locked by a pad-lock. The stroke of the lever is adjustable to regulate the flow to the bottle. The displaced air from the empty bottle can be released via a transfer hose back into the sight glass. 150 ml sight glass with heat tracing 150 ml 250 ml When the number one priority is to have total containment of the sampling media, Neotecha can provide a closed sampling system via a syringe. A sample can be taken without exposure to personnel or the environment. With the ever increasing concerns regarding fugitive emissions, the Sapro® sampling system with the syringe is an ideal solution when hazardous samples have to be taken. Once the sample is taken, the syringe can then be transported to the lab and can be converted to a needle syringe for easy sample transferring. After connecting the syringe, the lever can be operated to open both the sample container and the Sapro® sampling valve. Available in a variety of materials to handle highly corrosive media. Safety plug Syringe 500 ml Adaptor cap Needle adaptor 6 NEOTeCHA Reactor Sampling Type PV Rinsing and cleaning Two ports only is what it takes to completely rinse and clean the reactor sampler without dismounting any component. Connection port A allows rinsing: sight glass, transfer device, main valve and suction hose (yellow area). Connection port B allows rinsing: the area between the suction hose and dip tube (green area). Connection A Continuous flow circulation If a continuous or almost continuous metering is necessary like for instance temperature, pH or Redox metering, it is possible to equip the PV unit with a diaphragm pump, which produces a continuous flow through the suction hose and back through the mounting flange port. In this case the hollow ball is removed from the PV reactor in order to allow a continuous flow circulation. Operation principle with a continuous circulation pump Open the main valve (1) and the pump discharge valve (2). Open the air supply line valve to start the pump motion. The vacuum pump (3) raises the liquid through the suction hose mounted inside the dip tube, the main shut-off valve (1), sight glass (4) and enters the pump through the suction hose (5). The liquid will be returned via the discharge hose (6) and discharge valve (2), back into the dip tube inside the reactor. The modular concept allows a second PFA hose to be installed in the dip tube to allow a smooth discharge of the returned liquid in the reactor, without splashing. Connection B During the circulation, a measure probe can be inserted through the top sight glass flange. The many connecting ports of the reactor sampler allow an easy installation of a recirculation pump, transfer device and various auxiliary valves, all in one integrated, compact unit. (3) Vacuum pump (4) Sight glass (5) Suction hose (6) Discharge hose (1) Main valve (2) Pump discharge valve 7 NEOTeCHA Reactor Sampling Type PV Other lined products available from Neotecha Lined In-Line sampling valves • Dead space free design, to ensure representative sampling • Guaranteed safe and simple operation • As standard fail safe to close operation • Modular design • Suitable for open and closed ‘in line’ sampling Lined ball valves • Virgin PFA or PFA conductive lining offers high corrosion\resistance • Full bore design • One piece trunnion mounted: no possibility of damaging PFA lining on ball by the stem • Special C-ball design available to eliminate dead space and excellent control characteristics Lined butterfly valves • PFA / PTFE lining offers high corrosion resistance • Mechanically activated primary and secondary shaft seal • PFA, PTFE, conductive, exotic materials as well as UHMWPE trims are available • One piece disc stem design to ensure high Kv values. Lined check valves and sight glasses • PFA lining • Borosilicate glass • PTFE ball, guided with 4 ribs for vertical and horizontal applications • With integrated drop lip 8