Connecting Transient and Steady

advertisement

Connecting Transient and Steady-State Analyses

Using Heat Transfer and Fluids Examples

Washington Braga

Mechanical Engineering Department

Pontifical Catholic University of Rio de Janeiro, PUC-Rio

Rio de Janeiro, RJ, Brazil

wbraga@mec.puc-rio.br

ABSTRACT. In many undergraduate courses, emphasis is given to the

analysis of steady state situations, in spite of the fact that unsteady situations

are quite common in engineering problems. For instance, while discussing

heat transfer, unsteady state topics are introduced to students without

connection to steady state situations, as nature could handle unsteadiness

separately. This paper presents a few common situations, some of them often

treated only at their steady counterpart, that have been used to offer students an

interesting and pedagogically rich unsteady and steady analysis. The

methodology proposed herein, bridging unsteady to steady state situations,

helps subject integration, presents some criteria for model simplification and

allows further discussion on transient topics. The current paper is mainly

focused on Heat Conduction. However, similar analysis may be made for

situations involving Radiation and Convective Heat transfer.

Nomenclature

A

area, m2

coefficient, W/m2K

AR

aspect ratio, dimensionless

k

thermal conductivity, W/m.K

B

parameter, defined in Eq. (5), s-1

L

length, m

Bi

Biot number, dimensionless

m

fin parameter, m-1

C

parameter, defined in Eq. (5), K/s

P

Ct

Constant, defined in Eq. (19)

rate of energy generation inside

the sphere, W

c

specific heat, J/kg.K

Pe

fin perimeter, m-1

D

parameter, defined in Eq. (5), s-1

Q

rate of transfer of energy, W

E

parameter, defined in Eq. (5), K/s

q"

heat flux, W/m2

F

dimensionless parameter, Eq. (15)

h

Fo

Fourier number, dimensionless

convection

heat

transfer

coefficient inside the recipient,

W/m2.K; height of the channel, m

H

height, m

V

volume, m3

h

convective

R

radius of a cylindrical rod, m

heat

transfer

S

dimensionless parameter, Eq. (50)

Subscripts

T

temperature, K or C

b

base of an extended surface

t

time, s

c

characteristic

U

wall velocity, m/s

f

fluid

u

velocity component

H

relative to the height

x

coordinate, m

i

initial condition

L

relative to the length

R

radiation

thermal diffusivity, m /s

SS

steady-state

dimensionless length

s

surface; sphere

temperature difference, K

sup

superficial

mass density, kg/m3

t

transversal or cross sectional

∞

free stream conditions

Greek Letters

α

η

θ

ρ

φ

2

dimensionless temperature

Superscript

*

steady state condition

1. INTRODUCTION

Engineering problems occur both during unsteady and steady state situations. In

fact, experience indicates that many problems only occur or are more demanding during

transient situations. Nonetheless, in mechanical engineering courses, quite often, emphasis

is given to steady state analyses. Furthermore, most undergraduate heat transfer books

introduce steady and unsteady problems as two separate topics, perhaps because they

require different analytical methods: a simple one for steady situations and a quite

demanding one for unsteady problems. As it may be seen, most unsteady state examples

discussed leads to the same steady state solution: thermal equilibrium with the ambient, a

situation not always found.

Pedagogically speaking, the classical approach does not allow knowledge

construction, and does not help students to build up connections among the new material

and the many transient situations they met in their lives. To some students, this procedure

may indicate separate routes, solutions and physics and often, they end up believing that

there is no unsteadiness behind a steady state. Consequently, it may be concluded that a

more detailed analysis should be made linking both situations.

This paper intends to present a few classroom-type situations in which a simple and

yet interesting analysis may be made to introduce appropriately the path from unsteady to

steady situations: the lumped formulation cooling problem, the heat transfer problem in a 1D slab, a fin (extended surface), a couple of 2-D situations and the flow of fluid inside a

channel, the Couette problem.

In all such problems, the unsteady and steady parts are

analyzed in order to obtain the time necessary to reach steady state as function of the

relevant physical parameters, an important piece of information not only for many

2

industrial problems but also to an adequate understanding of the physical situation. It is

expected that following a similar analysis, students may start to visualize correctly that

steady state may occur in some situations, not always, but only at the end of an unsteady

situation. Sure, the transient phase may or may not be fast, depending on fluid thermal

properties and physical geometry, but now students may understand why.

2. SIMPLE COOLING PROBLEM

Usually discussed in an introductory heat transfer course, this problem describes the

cooling (or heating) of a small diameter, high thermal conductivity sphere (or cylinder),

initially at temperature Ti, that is dropped inside a pool, containing some non-identified

fluid, that far from the hot sphere is maintained at some uniform temperature. The heat

transfer coefficient, h, assumed to be uniform, takes care of convection and/or radiation

between the sphere and the inner walls of the recipient containing both the fluid and the

sphere.

A more interesting situation occurs when it is considered that the temperature of the

fluid may also change according to heat transfer not only to the sphere but also to an

external environment [1]. Considering the presence of some internal source of thermal

energy inside the sphere, Joule heating, for instance, say P , and taking into account some

thermal energy lost to that external environment1, QR , the lumped formulation balance of

energy for both fluid and sphere, neglecting the participation of the recipient walls, may be

written as:

( ρcV )f

•

fluid:

•

sphere:

dTf

= hAsup [ Ts − Tf ] − QR

dt

(1)

dTs

= P − hA sup [ Ts − Tf ]

dt

(2)

( ρcV )s

This system of equations must be solved considering as initial conditions:

•

Ts (t = 0) = Ts,i

(3)

•

Tf (t = 0) = Tf , i

(4)

To avoid solving the above system, one usually neglects the energy equation for the

fluid and considers only the thermal profile for the sphere. Naturally, such approximation

simplifies the problem but, on my account, it also reduces the chances of a better

understanding of its physics. Therefore, solving the system is recommended. Its solution

[2] is:

1

Actually, this term depends on the temperature difference between the recipient and the environment. It’s

taken herein as a fixed entity for simplicity.

3

B(Ts,i − Tf , i ) − ( B + D)t

CD − BE

e

=

− 1 +

T

(t)

t + Ts,i

s

B+D

B+D

T (t) = ( T − T ) D 1 − e − ( B + D)t + CD − BE t + T

f

s,i

f ,i

f,i

B+D

B+D

(5)

where the following definitions apply:

•

B=

•

D=

hAsup

(ρcV )s

hA sup

(ρcV )f

•

C=

P

(ρcV)s

•

E=

QR

(ρcv )f

Several interesting results may be found:

1. After some time, Ts (t) → Tf (t) , that is, whenever the non-linear drops to zero, the

temperature difference between sphere and fluid drops to zero, as it may be readily

verified.

2. The multiplier constant CD − BE , that appears on the linear term on the right hand

side of both equations, is in fact a relation between the internal source of thermal energy

inside the sphere, P , and the heat lost to the external environment, QR . Whenever

both terms are equal, we may have a steady state.

3. Whenever P = QR , the final, i.e. the steady state temperature may be obtained from

simple Thermodynamics arguments, and it is:

T* =

(ρcV )s Ts,i + (ρcV )f Tf ,i

(ρcV )s + (ρcV )f

(6)

or

T* =

BTf ,i + DTs,i

B+D

(7)

4. We often assume that the fluid has a much larger thermal inertia (or capacitance), that

is, a larger (ρ cV) than the corresponding value for the solid sphere. In this case, any

temperature variation for the fluid may be neglected to obtain:

•

D = 0 , therefore, T* = Tf , i = Tf

(8)

•

Ts (t) = ( Tf − Ts,i ) 1 − e − Bt + Ts,i

(9)

4

Critical to the present analysis is the evaluation of the time needed to allow body

and fluid to reach a common temperature that may or may not be, the final steady state

temperature (that is, provided P = QR ). Through observation of Equation (5), we may

conclude that such situation happens whenever the exponential term drops to zero. Noticing

the characteristic of the exponential function, a sufficient accurate estimate of the time

necessary to attain the desired situation is obtained assuming a large number for the

exponent. I usually consider 8, but any other suitable number may be obtained (see a more

thorough discussion on this below). Therefore, it may be concluded that steady state is

obtained whenever:

(B + D)t * = 8

(10)

or

8 ( ρcV )s D −1

t =

1+

hA sup B

*

that may be written as:

8

1

Fo* =

Bi

( ρcV )s

1 +

( ρcV )f

(11)

In the above equation, the Fourier Number, defined as

defined as

Bi =

Fo =

αs t

, and the Biot number,

L2c

hL c

, are introduced in terms of a characteristic length, Lc , defined as

ks

the ratio of the sphere’s volume to surface area. Considering the standard situation in

which the fluid is handled as having an infinite heat capacity, we obtain a simpler result:

t* = 8

( ρcV )s

hA sup

→ Fo* =

8k s

8

=

h(V / A sup ) Bi

(12)

As expected, the larger the thermal inertia (or the convective thermal resistance), the

longer it will take to reach steady state. In any event, with such expression, students may

observe clearly the influence of a large heat transfer coefficient or a small mass on the

attainability of a steady state situation, either for the cooling of thermal systems but also for

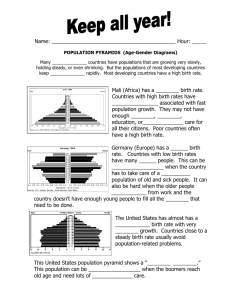

effective temperature measurement using a termocouple. Figures 1, 2 and 3 illustrate some

of the analysis that may be done. Figure 1 describes the temperature profiles for the fluid

and the sphere for the case in which the thermal capacitances of both bodies are of the same

order of magnitude (considered as equal, for simplicity). Figure 2 is obtained considering a

5

much larger thermal capacitance (taken as infinity) for the fluid than for the sphere. In such

situation, no significant temperature drop is observed for the fluid. Finally, Fig. 3 indicates

the situation in which the temperature difference between fluid and sphere drops to zero

after a while but no steady state is achievable. In such case, the heat generated inside the

sphere is larger than the heat lost to the external environment. Mathematically, this

indicates that the exponential term in Equation (5) drops to zero but not the linear one.

Fig.1. Temperature Profiles for same order thermal capacitance bodies.

Steady state is attainable,

Fig. 2 Temperature Profiles for Standard Cooling Problem. Fluid has

infinite thermal capacity. Steady state is attainable.

6

Fig. 3. Temperature Profiles for a situation in which no steady state is attainable

Temperature difference between bodies drops to zero.

Another way to pick a reasonable number involves the attainable precision on

temperature measurements. That is, assuming that it is reasonable to measure unsteady

temperature differences in the order of some small number, say 0.5% of the total variation,

but nothing less, it is sufficient to consider steady state whenever:

e − Bt = 0, 005 ≈ e −5

As it is seen, there is no significant difference between such approaches.

3. FLAT PLATE, LUMPED FORMULATION

Consider a flat plate, having a (relatively) small thickness

heat flux on the left surface,

q

"

R,

L , subjected to a radiant

and a convective heat transfer to an ambient fluid at

temperature T∞ and having a convective heat transfer coefficient, h , on the other surface.

At time t = 0, the initial temperature is Ti , considered constant. Assuming constant

thermodynamical properties, the First Law of Thermodynamics on such situation, may be

written as:

ρcV

∂T

= q"R − h(T − T∞ ) A sup

∂t

T = Ti

at

t=0≤x≤L

(13)

(14)

that has an exact solution, the following temperature profile:

7

φ(Fo) =

1

1

+ F − exp {− Bi Fo}

Bi

Bi

In such equation, Bi

=

(15)

hL

αt

T − T∞

T − T∞

, Fo = 2 , φ = "

and F = "i

. As it

k

L

qRL / k

qR L / k

may be seen, the assymptotic characteristic exponential function precludes a sharp

definition for the final condition, that is the steady state. To overcome such difficulty, one

may use the Ritz Integral Method [3], in which a trial profile such as:

φ% (Fo) = φSS f(Fo)

φ%

is an approximate profile, φSS is the steady state solution and f(Fo) is

arbitrary (usually polinomial) function such as a quadratic profile,

is used, where

some

(16)

f(Fo) = a1 + a 2Fo + a 3 Fo 2 ,

or

f(Fo) = a1 + a 2Fo + a 3Fo2 + a4 Fo3 .

a

The constants,

cubic

a1 ,a 2 ,a3

one,

and

a4

are

determined according to the conditions:

f(Fo = 0) = 0

f(Fo = Fo*) = 1

(17)

f '(Fo = Fo*) = 0

f ''(Fo = Fo*) = 0

In such equations, Fo * (or t* ) indicates the necessary time to reach steady state, the

only unknown remaining in Equation (16) subjected to Equation (17). According to the

% , written in terms of the unknown Fo * , must be

integral method, the trial profile φ

introduced in the dimensionless form of the integral equation obtained from the energy

equation:

Fo*

∫

0

∂φ

d ( Fo ) =

∂Fo

Fo*

∫ [1 − Biφ] d(Fo)

(18)

0

Depending on the order of the approximation, different results may be obtained, such as:

•

•

quadratic profile:

cubic profile:

3

3 L2

Fo* =

→ t* =

Bi

Bi α

4

4 L2

Fo* =

→ t* =

Bi

Bi α

Previous experience with integral methods does not allow us to conclude which

approximation gives better results. Other options may be chosen: for instance, considering

8

that the thickness of the boundary layer over a flat plate is arbitrarily defined as the height

in which the velocity reaches 99% of the external uniform velocity, we may use a similar

description to obtain a value such as:

•

5

5 L2

Fo* =

→ t* =

Bi

Bi α

As a matter of fact, the important fact is that all previous options indicate that the

correct answer may be generically represented as:

Ct

Ct L2

Fo* =

→ t* =

Bi

Bi α

in which the constant,

(19)

Ct , is to be determined following any suitable criteria.

In short,

higher Fo* indicates longer time to reach steady state. According to the previous analysis

given herein, I’ve been using a number such as 8.

4. FLAT PLATE, DISTRIBUTED FORMULATION

In the literature, the study of unsteady state in situations in which the internal

(conductive) resistance is not negligible compared to the external (convective) resistance is

usually introduced using a 1-D flat plate as model. The physical situation is such that the

initial condition is such that the plate has an uniform temperature, say Ti , and suddenly it

is dropped inside a non specified medium having uniform temperature

T∞ . The convective

heat transfer coefficient, h , is considered constant. In such situation, it is expected that

after some time, the wall reaches thermal equilibrium with the medium, having the same

final temperature.

The (classical) solution is obtained using the method of separation of variables, a

lengthy procedure that involves eigenvalues and eigenfunctions (sine or a cosine series

expansion - Fourier’s series - for a Cartesian slab). I have been using another problem,

with a better result, perhaps because of the students’ greater familiarity. Recognizing that

on the initial stages of a junior level heat transfer course, a steady state 1-D flat plate is

thoroughly studied, I have been discussing the unsteady state associated to it, trying to infer

how long it takes to develop. According to a balance of energy and Fourier’s law of heat

conduction, students learn fundamentals about a steady profile such as:

T(x) = c1x + c2

in which constants c1 and c2 will be determined following some boundary conditions. The

simplest case involves specified surface temperatures, at x = 0, T = T1 and

x = L, T = T2 2.

2

To analyze the unsteadiness of such problem, we may consider the

Most interesting cases involving convective or radiative heat flux boundary conditions are easily handled.

9

following model:

1 ∂T ∂ 2 T

=

α ∂t ∂x 2

(20)

subject to:

•

t = 0, T(x, 0) = Ti

(21a)

•

T(x = 0, t) = T1

(21b)

•

T(x = L, t) = T2

(21c)

Applying the superposition method, we may write that a tentative solution may be

found according to the temperature profile given by:

T(x, t) = TSS (x) + Tt (x, t)

(22)

For the case under analysis, the first term is simply the steady profile:

T2 − T1

x + T1

(23)

L

and the term Tt (x,t) indicates the unsteady part of our problem, that is expected to drop

TSS (x) =

to zero eventually. Doing so, our problem is reduced to:

1 ∂Tt ∂ 2 Tt

=

α ∂t

∂x 2

(24)

and the boundary conditions are: at

x = 0:

T(x = 0, t) = T1 → TSS (x = 0) + Tt (x = 0) = T1

However, by definition:

TSS (x = 0) = T1 , so we may say that

Tt (x = 0) = 0

and at x = L :

(25a)

T(x = L, t) = T2 → TSS (x = L) + Tt (x = L) = T2

Similarly,

TSS (x = L) = T2 , therefore, we have that:

Tt (x = L) = 0

The initial condition deserves a similar analysis. At

(25b)

t = 0,T(x, 0) = Ti . Therefore,

T(x, t = 0) = To → TSS (x) + Tt (x, t = 0) = Ti

(25c)

Consequently,

10

Tt (x, t = 0) = Ti − TSS (x) = (Ti − T1 ) −

T2 − T1

x

L

(26)

that may be written as:

t = 0, Tt (x, 0) = a + bx

Using the standard procedure for solving unsteady 1D problems [4,5], we obtain:

Tt (x, t) = exp( −αλ 2n t) d cos ( λ nx ) + e sin ( λ n x )

(27)

in which the eigenvalues are given by

λ n L = nπ

(28)

Applying the non-homogeneous initial condition yields

Tt (x, 0) = a + bx = e n sin ( λ n x )

d=0

and:

(29)

Using the standard procedure [3,4,5], we obtain that:

en =

2

−a + ( −1) n ( a + bL )

nπ

(30)

Consequently, the complete temperature profile, including both the unsteady and steady

solutions, is written as

T(x, t) = a + bx + ∑ e n sin ( λ n x ) e −αλ n t

2

(31)

n =1

This result may be presented graphically, as indicated in Fig. 4. The results were

obtained for the following set of conditions:

Ti = 25 C ; T1 = 100 C ; T2 = 30 C

and are displayed as function of the Fourier number, previously defined.

11

Fig. 4. Unsteadiness of 1-D temperature profile

The question remaining to be answered is again the time span necessary for the

steady state. Noticing the transient temperature profile, we may conclude that steady state

is reached whenever the exponential term drops significantly to zero. As we are aware, the

most critical eigenvalue is the first one [4,5]. Consequently:

exp( −αλ12 t) = exp[− Fo∗ ( λ1L) 2 ] ≈ exp[ −8]

(32)

In the present situation, λ1L = π , see Equation (28), and therefore, we may

conclude that steady state happens whenever:

Fo∗ ≈

8

8

8

= 2≈

= 0, 8

2

10

π

( λ1L)

in which it was considered that

(33)

ð 2 ≈ 10 .

It may be noticed in Fig. 4, that for Fo ≥ 0, 5 , the steady state (linear) profile is

visually obtained, indicating that this simple analysis is convenient. However, for smaller

Fourier numbers, the transient temperature profiles are far from the steady state profile,

clearly indicating the reason why the Fourier’s law of heat conduction may not be taken as:

q = − kA

∂T

∆T

= kA

∂x

L

(34)

before the steady state is achieved, a situation usually not clearly understood. Naturally,

the actual profiles depend on the data used as boundary and initial conditions and other

situations may be easily studied.

For students, it may also be interesting to compare transient times for different

material, to indicate the influence of the thermal diffusivity (or the length) as shown in

12

Table 1.

Table 1: Time for Steady State, considering a 1D flat plate

with thickness = 0,2 m

5. UNSTEADY PROFILE IN EXTENDED SURFACES

Extended surfaces is one of those topics that display an interesting unsteady profile,

often not discussed among students. An energy balance for a constant transversal area fin,

with constant thermal properties and convective heat transfer coefficient is given by:

∂2θ

1 ∂θ

2

−

θ

=

m

∂x 2

α ∂t

in which

θ(x) = T(x) − T∞ ,

(35)

is the fin excess temperature, m

2

=

hPe

kA T

is the fin

parameter and α is the thermal diffusivity of the material used on the fin. The initial and

the boundary conditions, chosen for the sake of simplicity, are expressed by:

•

t = 0, θ(x) = 0

(36a)

•

x = 0, θ(x = 0) = θb , the temperature at the root of fin

(36b)

•

x = L, θ(x = L) = 0

(36c)

A straight forward analysis similar to the one made for the previously discussed example,

uses:

θ(x, t) = θSS (x) + θt (x, t)

where

θSS (x)

is the steady state temperature profile for this type of fin (very long fin)3:

θSS (x) = θbe − mx

3

(37)

(38)

Other situations may be handled similarly.

13

and indicates that the eigenvalues are given by:

nπ

λ =

+ m2

L

2

2

(39)

Therefore, the complete temperature profile is given by:

θ(x) = θSS (x) + ∑ c ne −αλ n t sin ( λ n x )

2

(40)

in which the integration constants are given by:

−2

cn =

φSS sin ( nπx )dx

L ∫0

L

(41)

Repeating the previous analysis, we obtain that steady state is reached when

exp( −αλ12 t) = exp[− Fo∗ ( λ1L) 2 ] ≈ exp[ −8]

that is:

Fo∗ ≈

8

8

8

=

≈

( λ1L) 2 ( π 2 + mL2 ) (10 + mL2 )

(42)

It is now simpler to understand how the cooling rate is affected by a higher heat

transfer coefficient, obtained for instance increasing the velocity of the cooling fluid, but

also by the thermal conductivity, the cross section and the perimeter of the fin. See Fig. 5

for a graphical display of the transient behavior. It may be noticed the quick time evolution

of the dimensionless temperature profile, comparing for instance the solutions for Fo = 0,03

and Fo = 0,08 and then the solutions for Fo = 0,08 and Fo* = 0,42, that corresponds to the

steady state.

Fig. 5. Unsteady Temperature Profiles in Fins for m = 3,0.

14

6. A TWO DIMENSIONAL FLAT PLATE

2L , initially at a uniform temperature Ti . At

time t = 0, the wall is placed in a medium that is at some temperature T∞ , far from the

Consider a plane wall of thickness

wall. Heat transfer occurs by convection with a uniform and constant heat transfer

coefficient h. Mathematically, the problem may be defined according to the following

energy balance:

∂ 2 T ∂ 2 T 1 ∂T

+

=

∂x 2 ∂y 2 α ∂t

(43)

The standard procedure to obtain an analytical solution to this problem starts with

the proposition that variables can be separated:

T(x, y, t) = X(x, t)Y(y, t)

(44)

Generalizing previous results, we may write that the critical Fourier Number is

given by:

αt ∗

8

Fo = 2 =

L

(λ 1L)2 + (µ1H)2 / AR 2

∗

in which

AR =

(45)

2H

is the (geometrical) aspect ratio of the 2D plate and the two sets of

2L

eigenvalues are given by:

tan(λ1L) =

Bi L

λ1L

and

tan(µ1H) =

Bi H

µ1H

Naturally, it is interesting to have a general criteria to justify the usage of a 2D

problem instead of a much simpler 1D problem, as before. A simple one may be proposed

using Equation (45). For instance, it is obvious that whenever:

( λ1L) 2 >> (µ1H) 2 / AR 2

one may neglect the influence of the heat transferred along the horizontal surfaces and treat

the problem as a standard 1D vertical flat plate. For the present purpose, a ratio of 10 will

be considered reasonable for that. Therefore, whenever:

(µ H )

( λ1L ) = 10 1 2

( AR )

2

2

To make things easier, we may consider as before that

π ≈ 10 , resulting in:

15

λ 1L = π

µ 1H

AR

To generalize those concepts, we may define a physical aspect ratio (as it takes into

account the influence of the boundary conditions through the eigenvalues) as:

AR* =

( µ 1H )

( λ 1L )

(46)

Therefore:

αt ∗

8

Fo = 2 =

2

L

( λ1L)2 1 + ( AR*) / AR 2

∗

Consequently, whenever

(47)

AR > π ( AR*) , that is, the geometrical aspect ratio is

greater than π times the physical aspect ratio, the 2D problem may be reduced to a 1D

vertical plate problem, possessing a much simpler solution. Similarly, if AR* > πAR ,

the 2D problem may be treated as a 1D horizontal plate problem. For other values, the 2D

model becomes relevant.

To illustrate such effect, some results are shown in Table 2, in which the nondimensional temperature differences between the 2D and the 1D approximations are

displayed. The chosen geometrical aspect ratio is 2,0. The ambient temperature is 40 C

and the initial uniform temperature is 450 C. The thermophysical properties are the thermal

conductivity (= 1,3 W/mK) and the thermal diffusivity (= 1,1E-6 m2/s). The convective

heat transfer coefficient is assumed to be 100 W/m2K along the vertical surface. Along the

horizontal surface, the corresponding coefficient is treated as parameter and handled as the

Biot number defined as Bi H = h H H / k . The results are displayed as function of time.

Table 2. Temperature Differences between 1D and 2D

Approximations for a Flat Plate. Geometrical Aspect

Ratio (AR) = 2.0

As it can be seen, the temperature differences are reduced significantly whenever

16

AR* is small compared to AR (the geometrical one).

The temperature differences

increase with time but are reduced to zero as the steady state temperature is the same in

both cases.

7. Unsteady Profile for Short Cylinders

Following a similar analysis, we may conclude that, for a cylindrical rod of radius R

and height 2L, steady state is obtained whenever

αt ∗

8

Fo = 2 =

L

( λ1L)2 + (µ1R) 2 / AR 2

∗

L

and µ1 is the first eigenvalue obtained as root of the equation:

R

µ1J1 (µ1 ) + Bi J o (µ1 ) = 0

wherein

(48)

AR =

(49)

where J n indicates the Bessel function of n-th order. As before, a similar criteria may be

obtained to allow us to neglect the heat transfer through the horizontal surfaces (the infinite

cylinder case) or through the lateral surface (the infinite flat plate case).

8. Transient Couette Problem

A simple solution to the Navier-Stokes equation is obtained for the flow between

two parallel flat plates, one of which is at rest, the other is moving with constant velocity U.

This is the so-called Couette Problem [6]. The steady state solution is easily obtained as:

u

= η + Sη(1 − η)

U

(50)

in which the following definitions apply:

•

η=

y

, where h indicates the distance between the two plates, i.e. the channel

h

h 2 dP

• S=−

2µU dx

Typically, for S > 0 , that is, for a pressure decreasing in the flow direction, the velocity is

positive over the whole channel. For negative values of P, however, the velocity may

become negative, indicating the existence of a back-flow near the stationary wall.

Following a similar procedure close to the ones already shown, we obtain the following

profile as transient solution:

17

u(y,t)

= η + Sη(1 − η) + ∑ d n exp{ −Foς 2n }sin ( ς n η)

U

(51)

where:

νt

h2

•

Fo =

•

ς n , a dimensionless eigenvalue, is given by λ n h = ς = nπ

( − 1) n

• dn = 2

ς n

S

2S

2

1

S

2

+

+

−

ς

−

n

3

ς 2n

ς n

(

)

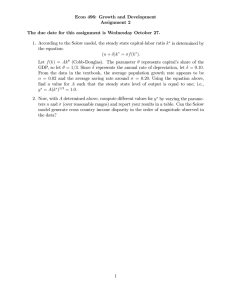

For the sake of demonstration, Fig. 6 indicates the transient velocity profile for the

special case that S = −2 . As it may be seen, it is obvious that the slip condition is a

localized effect while the pressure gradient is a bulk effect. The developing of a boundary

layer4 type of flow along the moving wall is clearly displayed. It is also shown the final

steady state profile, for comparison purposes. A similar analysis may be done for the

Hagen-Poiseuilli flow, as done originally by Szymanski [7].

Fig. 6 Transient Couette Flow, indicating the development of both

a back-flow and a positive flow regions with time.

4

that is, a region in which the moving wall affects the flow.

18

9. Conclusions

This paper presents a few discussions on how to investigate steady state situations

as a final stage for heat transfer problems, having in mind undergraduate engineering

students. In all the situations treated here, it is shown how thermal and geometrical

parameters affect the time necessary to reach steady state, allowing a deeper understanding

of transient effects.

Considering the standard approach used in most textbooks, the

procedure discussed here has at least two advantages: the sequential analysis of the

problems and the link between concepts, allowing a clearer view of the evolution.

Although not shown here, there are many other situations that may be handled accordingly,

allowing, perhaps, a fuller integrated engineering course.

Acknowledgements

I would like to thank the reviewers for suggesting improvements and helpful

comments to the original manuscript.

9. References

[1] PITTS, D.R. & SISSOM, L.E., Heat Transfer, Schaum Outlines, 1977,

[2] KAPLAN, W. Advanced Mathematics for Engineers, Addison Wesley, 1981

[3] ARPACI, V.S., Conduction Heat Transfer, Addison Wesley, 1966

[4] BRAGA, W., Heat Transfer, Thomson Learning Pub. Co., 2003, in portuguese

[5] INCROPERA F.P. & DEWITT D.P. Fundamentals of Heat and Mass Transfer, Wiley,

N.York, 1996

[6] SCHLICHTING, H., McGraw-Hill Book Company, 6th Edition, 1968.

[7] SZYMANSKI, F., Proc. Intern. Congr. Appl. Mech. Stockholm, 1930.

19