Quantifying the Impact of a Non-Ideal Return Path

advertisement

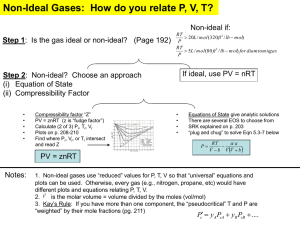

Intl. Journal of Microcircuits and Electronic Packaging Quantifying the Impact of a Non-Ideal Return Path Andrew Byers and Melinda Piket-May University of Colorado at Boulder Campus Box 425 Boulder, Colorado 80309 Phone: 303-492-7891 Fax: 303-492-5323 e-mails: byersa@maori.colorado.edu, mjp@maori.colorado.edu Stephen H. Hall Intel Corporation JF2-54 2111 NE 25th Ave. Hillsboro, Oregon 97124 Phone: 503-264-8695 Fax: 503-264-6053 e-mail: stephen.h.hall@intel.com Abstract Non-ideal return path issues can pose several significant problems for high-speed digital system designers. Occurring in many different forms, non-ideal return paths can cause detrimental effects such as ground bounce, increased signal delays, signal disruption, and electromagnetic incompatibility. In an ideal system, the return current travels through the reference plane directly beneath the transmission line carrying a signal. A non-ideal return path occurs when there is a discontinuity in the reference plane that causes the return current to diverge away from the ideal path. Experiment and simulation were used to quantify the timing and signal quality impacts of a transmission line passing over a slot in the ground plane. This ground slot structure represents the simplest example of a non-ideal return path, and is well suited to evaluate the impact that a poor return path will have on the performance of a digital system. Although the specifics of this particular return path problem will differ from more complicated situations, many of the signal quality and timing trends can be generalized to return path problems of a more complex nature. Subsequently, this study will help identify the performance degradation trends that can be expected in a digital system design when the engineer is not able to provide a perfect path for the return currents. Additionally, the use of bypass capacitors to shorten the return current path length and thereby reduce the non-ideal effects on signal integrity is presented in this paper. Key words: 1. Introduction Signal Integrity, Timing Budget, Coupling, Return Current Path, Finite Difference Time Domain, Time Domain Reflectometry, Ground Gap, and Decoupling Capacitors. Non-ideal return paths manifest themselves in several different ways in high speed interconnect systems. A few common examples are signal lines passing over split power planes used to facilitate dual voltages, a line changing reference planes, a meshed or slotted ground plane, and package/connector power and ground return pins. Essentially, any situation where the return current is forced to diverge from its ideal path directly beneath the signal trace can be considered a non-ideal return path. Regardless of the form, these The International Journal of Microcircuits and Electronic Packaging, Volume 22, Number 3, Third Quarter 1999 (ISSN 1063-1674) 262 © International Microelectronics And Packaging Society Quantifying the Impact of a Non-Ideal Return Path non-ideal situations have detrimental effects on signal integrity and timing reliability. Any reflected or transmitted disturbance caused by a non-ideal current return path can distort the waveforms, and if severe enough, can cause system failures due to excessive ringing or overshoot on the bus. Furthermore, nonideal return paths tend to cause timing pushouts. A timing pushout is an increase in the flight time of a signal compared to an ideal interconnect. Often seen as a ledge in the rising/falling edge or a diminished rise time at the receiver, these pushouts consume valuable interconnect timing budgets allocated to a designer. This paper highlights three major problems associated with a ground slot non-ideal return path: A large inductive disruption seen at the driver, a timing pushout at the receiver, and an unusually high coupling coefficient between lines that traverse the same gap. The non-ideal effects measured were dependent on the return current divergence path and gap width. Any type of non-ideal return path will introduce additional timing uncertainties into the system and degrade timing budgets and signal integrity. Therefore, the ability to identify and model the specific mechanisms that contribute to the performance degradations is essential to a good design methodology. Simulation techniques using Finite Difference Time Domain (FDTD) algorithms, as well as traditional circuit simulators were developed and compared to measurements. The sensitivity of the signal disruption and timing pushout due to physical parameters such as gap width and length is described in this work. This paper quantifies the signal degradation caused by a specific return path discontinuity, explores different modeling techniques and gives insight into the performance impact trends that can be expected for other return path problems. 2. Background 3. Measurement and Simulation Techniques To quantify the impact of this return path problem, a test board was built that consists of two parallel microstrip lines traversing a slot in the ground plane. The layout of this test board is shown in Figure 1. Lines traversing gaps with two different widths, 25 mils and 100 mils, were measured. The two ground plane sections are connected with 5 mil traces at the edges of the gap to provide a DC connection. The microstrip lines are 6 mils wide on FR-4 dielectric, and the line impedance is 65 ohms. All other relevant dimensions are indicated in the Figure. It is important to note that although this slot is placed in a ground plane for this study, slots or gaps in any plane referenced by a transmission line will affect the return current present on that plane. There are instances when a microstrip line is referenced to a power plane, and the imperfections in the return path have the same effects on a signal as seen in a corresponding groundreferenced line. Ground planes shorted together 0.7” Microstrip 1.4” Bypass capacitor cap landing pads pads g a p 5.2” 0.7” Ground planes shorted together Microstrip Figure 1. Ground gap test board layout used for TDR/TDT measurements. Time Domain Reflectometry and Time Domain Transmission techniques (TDR/TDT) were used to measure the effects of the gap There has been some work done in the development of equivaon flight time and signal quality. A TDR measures the Time Dolent circuits for the reference plane gap structure. A transmission main waveform at the driver, while a TDT is measured at the reline model for the diverging return current is designed by increasing ceiver. A TDR/TDT system uses a digital oscilloscope for measurethe length of the signal line after taking into account the microstripment and a step-pulse function generator for a source. The stepto-slotline transition1. Another model of equivalent SPICE circuit is pulse is placed on one port of the transmission line under test using also presented and compared to experimental results, along with fulla coaxial feed attached to a matched contact probe. The TDR syswave time domain simulations2. This model uses separate nets for tem used in this study consisted of a Tektronix 11801B Digital Samthe lines passing over the gap and for the slotline created by the gap pling Oscilloscope meter using a sampling head extender (cable) itself, linking the nets through controlled current and voltage sources. and a SD-24 TDR sampling head. Cascade Michtotech 250 micron A more complete full-wave analysis of a line over a ground plane GSG microprobes were used to achieve clean signal transition from slot is also derived, and expressions for the reflection and transmisthe coaxial cable to the microstrip on the test board. sion factors from the slot are developed along with an equivalent YSimulations were done with conventional circuit-simulator tools parameter pi-network model3. and a FDTD full-wave three-dimensional solver. The circuit simuThis paper provides a more extensive review of the measurable lators used were QUAD by Viewlogic and HSPICE. Both of these signal characteristics due to the ground gap and highlights the trends tools use lumped and distributed models based on standard electroand sensitivities seen in both measured and simulated structures. magnetic transmission line and lumped element equations. Although Simple modeling techniques are suggested, and FDTD simulations the ability to model complex geometries is sacrificed for the relaare used to augment the measurements in order to develop more tively fast simulations, tools such as these are used to simulate large achievable robust design guidelines. interconnect systems with a good degree of accuracy. The FDTD method4 directly solves Maxwells curl equations in The International Journal of Microcircuits and Electronic Packaging, Volume 22, Number 3, Third Quarter 1999 (ISSN 1063-1674) © International Microelectronics And Packaging Society 263 Intl. Journal of Microcircuits and Electronic Packaging the Time Domain. These are given in differential form as follows, 4. Disruptions Due to the Ground Slot (1) A. Inductive Spike on Signal Line (2) In the case of the ground gap depicted in Figure 1, the most immediate effect on a digital signal carried on a transmission line traversing the gap is a significant inductive spike, as seen in the measured TDR pulse in Figure 3. This disruption is caused by the increase in the current loop, which corresponds to an increased inductance from the following basic relation, where E and H are the electric and magnetic fields, respectively, and e and µ are the permittivity and the permeability of the material. Since FDTD solves the basic physics of the problem, arbitrary geometries and materials can be modeled, and boundary conditions are automatically enforced at material interfaces. In the numerical implementation of equations (1) and (2), central differences are used in place of the temporal and spatial derivatives, giving second order accuracy. This yields a three dimensional grid of electric and magnetic field points, with the magnetic fields displaced by ½ of the lattice spacing, as shown in Figure 2. The field quantities are solved in a leap-frog fashion with a half time-step between the solution of the electric and magnetic fields. The electric field is found from the magnetic field using equation (1), and the magnetic field is found from the resulting electric field using equation (2). The FDTD simulations performed for this project were used to augment the existing measured data in order to uncover sensitivity trends in the data, or how a measured electrical parameter is affected by a change in a physical model parameter. (3) where L is the inductance, v is the flux defined by the magnetic field and the area between the line and the ground plane, and I is the current. As the gap forces the return current to diverge, the flux loop defined by the signal line current and the ground plane current increases, thus increasing the inductance. Figure 3 shows measured results for two different gap widths. The impedance levels shown on this plot correspond to transitions that the TDR signal sees. The 50 ohm level is the coaxial feed line, the 65 ohm level is the microstrip before the gap, and the 97 ohm and 115 ohms levels are the peak impedances seen at the driver due to the gap reflections. A larger gap width translates to a larger inductance loop, thus explaining the higher inductive spike seen in the TDR data. -0.11 -0.13 Z= 115 100 mil gap voltage (V) -0.15 -0.17 Z= 97 -0.19 -0.21 Z= 65 -0.23 25mil gap Z= 50 -0.25 0 Figure 2. A single FDTD grid cell showing the location of the electric and magnetic field points. 2.5E-10 5E-10 7.5E-10 1E-09 1.3E-09 1.5E-09 1.8E-09 Time (s) Figure 3. Measured TDR inductive spike for two different gap widths: 100 mils and 25 mils. The International Journal of Microcircuits and Electronic Packaging, Volume 22, Number 3, Third Quarter 1999 (ISSN 1063-1674) 264 © International Microelectronics And Packaging Society Quantifying the Impact of a Non-Ideal Return Path The inductive spike in the digital signal can pose a serious problem since it will degrade the signal integrity at the driver and receiver, filter the edge rate and increase inter-symbol interference. If the degradation of signal integrity is severe enough, it is possible to cause a false trigger at the receiver or to push out the timings enough to violate the setup or hold times. Furthermore, increased overshoot at the buffers can exacerbate oxide stress and subsequently affect reliability. FDTD simulations were performed on scaled-down versions of the test board in order to avoid numerical instabilities associated with memory-intensive models due to high grid density. Also, by running many simulations of smaller versions of the problem, the basic performance trends and the significance of the physical variables could be identified and verified against the measured data trends. A typical simulation of a ground-gap model run on a SGI Origin 200 Server took about 2 hours of CPU time and 30 Mbytes of memory. FDTD TDR simulation results for test boards with different gap widths are shown in Figure 4. Four different gap widths were simulated: 100mils, 50 mils, 20 mils, and 10 mils. The important trend to notice is the proportionality between the gap width and the spike magnitude. A comparison of the spike magnitudes for the measured data and FDTD is favorable. In the 20 mil and 25 mil cases, both exhibited inductive spike magnitudes of nearly 20% of the input step voltage. In both the measured and simulated 100 mil cases, the relative spike magnitudes were closer to 30% of the input step voltage. inductor in a traditional circuit simulator would sufficiently account for the inductive spike caused by the ground plane discontinuity. The values for the inductors used in these simulations were chosen using a first order approximation equation given by Johnson and Graham5, as follows, (4) Gap Inductance pre-gap line post-gap line Figure 5. Equivalent ground gap model. 0.1 0 10nH -0.1 voltage 1.2 1.15 1.1 100mil gap TDR Voltage 1.05 -0.2 5nH -0.3 nominal 1 -0.4 0.95 0.9 -0.5 0.85 0 0.8 0.75 0.7 1E-10 1.5E-10 2E-10 2.5E-10 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2 time (ns) 10mil gap 3E-10 3.5E-10 Time(seconds) Figure 4. FDTD simulations of TDR data for ground gap encounter: inductive disruption on the signal line. The inductive spike seen in the measured and FDTD data indicates that the phenomenon should be able to be modeled with a series inductor inserted into a transmission line5, depicted in Figure 5. Figure 6 shows the results of QUAD circuit simulations performed with 5nH and 10nH series inductors, along with the nominal (no inductor) simulation. The spike magnitude scales with the inductance, as expected. In this respect, using an appropriately sized Figure 6. QUAD simulations of series inductor inserted into microstrip line; modeling ground gap. In this equation, a microstrip line passing over a symmetric gap to both sides is assumed, where D is the return current diversion distance, w is gap width, and Lgap is the series inductance caused by return current diverging around the gap. However, two very significant secondary effects of the ground gap, namely timing pushout and unusually high line to line coupling, are more difficult to model using this simple lumped element model. B. Receiver Edge Rate Degradation The next consequence of passing a digital signal line over a The International Journal of Microcircuits and Electronic Packaging, Volume 22, Number 3, Third Quarter 1999 (ISSN 1063-1674) © International Microelectronics And Packaging Society 265 Intl. Journal of Microcircuits and Electronic Packaging 0.00E+00 25 mil gap voltage (mV) -5.00E-02 100 mil gap -1.00E-01 -1.50E-01 -2.00E-01 first ledge area -2.50E-01 -3.00E-01 0 2E-10 (s) 4E-10 6E-10 8E-10 time (sec) Figure 7. Measured receiver edge rate degradation due to ground gap encounter; 100 mil and 25 mil gap cases. The causes of this timing pushout are not as intuitive as the reasons behind the inductive spike. The measured TDT data in Figure 7 show that a wider gap results in a more severe timing pushout. Not only is the edge rate degraded, but there is also a ledge-type shape occurring about halfway between the low and high voltage levels of the pulse. Due to its severity, the ledge seen in the data threatens the timing budget even more than the degraded edge rate. As the signal reached the ground plane gap, a portion of the ground current jumps the gap through the inherent capacitance, while the rest of the ground current diverges around the gap. This splitting of the ground current explains the existence and location of the ledge in the TDT waveform. The idea of a capacitance across the gap also explains why the start of the ledge occurs earlier in the rising edge of the waveform for a wider gap. A wider gap indicates a smaller capacitance, which in turn would support a smaller amount of ground current passing directly across the gap and more ground current diverging around the gap, thus causing a more significant ledge. Identifying this problem is an important step since it helps the designer mini- mize the effect during the initial design and provides insight into how to develop sufficient modeling strategies. This curious ledge effect at the receiver is an example of a phenomenon that a simple simulation with an inductor in the middle of a transmission line cannot model. However, a fullwave solver with relatively free geometrical modeling ability, such as FDTD, will be able to predict such an effect. Results from a TDT simulation are shown in Figure 8 for the two different gap widths, along with the nominal case of a microstrip over a continuous ground plane. Although the FDTD simulation shows a definite ledge effect that depends on the gap width, the exact shape of the timing pushout is not quite the same as is seen in the measured data in Figure 7. The FDTD ledges are more prominent than their measured counterparts, stemming from the fact that the FDTD solver makes a lossless approximation and the model is a scaled-down version of the test board. However, the sensitivity of the ledge location and timing impact on the gap physical parameters is consistent between the FDTD simulations and the measurements. Note that for the 100 mil gap, the ledge starts at an earlier point on the rising edge of the waveform than it does for the 25 mil gap. This supports the idea of a capacitance existing across the gap, through which a portion of the ground current passes. A set of FDTD simulations shows that the point during the rising edge (defined as a percentage of the final voltage level) where the ledge begins depends on the gap width, as plotted in Figure 9. Another relationship is verified in Figure 10 between the timing pushout caused by the ledge and the return current diversion path length around the gap. The independent axis of this Figure is length the gap extends away from the microstrip, while the dependent axis is the receiver rise time, with a 50ps rise time on the input signal providing the ideal case. Understanding the relationships between the physical characteristics of the gap and their impacts on the waveforms is a good step towards developing appropriate modeling strategies. Currently, there are no lumped-element and transmission line models that show this important ledge effect at the receiver. 1.2 no gap 1 25 mil gap 0.8 Voltage (V) gap, or slot, in the ground plane is a significant degradation of the edge rate at the receiver. Figure 7 is a TDT measurement showing this degradation in the edge rate, a timing pushout, for the two gap widths. The actual amount of the timing pushout will depend on the particular threshold voltage level of the receiver. CMOS systems typically have a threshold region that can vary between 35% and 65% of Vcc. The actual threshold voltage varies due to process variation and system noise. In this case, a receiver switching at 65% of Vcc would see a much larger pushout than one switching at 35%. The timing impact ranges from approximately 50ps at the 35% level to 150ps at the 65% level, which is costly in any modern high-speed design. To gauge the significance, it should be noted that modern high-speed digital designs have typical setup and hold interconnect skew budgets between 100 and 300ps. 0.6 0.4 100 mil gap 0.2 0 1E-10 1.5E-10 2E-10 2.5E-10 time (seconds) 3E-10 Figure 8. FDTD simulation depicting ledge effect in receiver waveforms. The International Journal of Microcircuits and Electronic Packaging, Volume 22, Number 3, Third Quarter 1999 (ISSN 1063-1674) 266 © International Microelectronics And Packaging Society Quantifying the Impact of a Non-Ideal Return Path energy sourced on the driving line is coupled onto the passive line in a mutual inductive manner, as seen in the measured results in Figure 11. This coupling has harmful repercussions since independent signals on separate lines will be adversely affected. The amount of coupled energy depends on the magnitude of the inductive spike, which in turn depends on the gap width. Receiver Ledge Dependence on Gap Width 80 ledge start (% final voltage) 75 70 65 60 55 -1.00E-01 50 driver line inductive disruption -1.50E-01 45 0 10 20 30 40 50 60 70 gap width (mils) voltage (V) 40 -2.00E-01 -2.50E-01 Figure 9. FDTD simulation: TDT ledge start, defined as the starting point of the ledge normalized to the final receiver voltage, verses the ground gap width. -3.00E-01 passive line coupled -3.50E-01 0 2E-10 4E-10 6E-10 8E-10 1E-09 1.2E-09 1.4E-09 time (s) Receiver Risetime Dependence on Gap Length Figure 11. Measured disruption on the signal line due to ground gap and the subsequent coupling on both ends of the passive line. 140 10%-90% risetime (ps) 120 100 80 60 40 20 0 0 200 400 600 800 1000 gap length (mils) Figure 10. FDTD simulation: TDT timing pushout versus gap length. The timing pushout is a combination of degraded edge rate and a distinct ledge, while the gap length defines return curent diversion distance. C. Ground Slot Coupling FDTD simulations produced results similar to the measured data. These results are plotted along with the simulation bypass capacitor results in Figure 13. The main difference between the FDTD simulations and the measurements was that FDTD predicted a higher coupling factor. This may be due again to the lossless approximation and to the fact that the microstrip lines were physically closer in the scaled-down model of the test board. Although the simulations did not exactly match the measurements, both the FDTD simulations and the measurements indicated that the coupling coefficient is dependent on the gap width. Circuit simulators such as QUAD and HSPICE also are able to model the general coupling mechanism by using a mutual inductance between two series inductors placed in separate transmission lines. This simple representation models the effect of the gap on the driver line with the inductor and the actual coupling mechanism along the gap with the mutual inductance. Although this rough approximation of the problem works for first-pass designs, several of the finer nuances of the gap are ignored, such as the receiver rise time degradation and the coupling delay from one line to the other. Another side effect of routing over a gap is an abnormally high coupling factor to other transmission lines traversing the same gap. The coupling mechanism is the gap itself, with the coupled energy traveling in the slotline mode to the victim microstrip line. At a distance of 1.4 inches away, nearly 15% of the pulse The International Journal of Microcircuits and Electronic Packaging, Volume 22, Number 3, Third Quarter 1999 (ISSN 1063-1674) © International Microelectronics And Packaging Society 267 Intl. Journal of Microcircuits and Electronic Packaging 5. Use of Bypass Capacitors to Mitigate Effects There are two basic approaches for mitigating the effects of the reference plane gap on signal integrity. The first is to simply avoid routing lines over a gap. In the past, the gap presence was not an issue, as the effects were hard to see with the slower rise times on digital pulses and the timing pushouts were small compared to the required setup and hold times. Currently, that is not the case, and digital designers must find alternative methods to separate power or ground planes without creating return path discontinuities. The second approach is the use of bypass, or decoupling capacitors6. The return current will naturally follow the path of least inductance. Therefore, by providing bypass capacitors to shorten the path length, the long divergence around the gap and increased inductance is avoided. Figure 12 shows measured results of placing two bypass capacitors across the gap, one on each side of the sourced line. Standard surface-mount capacitors were soldered across the gap on the cap landings, as indicated in Figure 1. Surface-mount caps are used here mainly since they present the least amount of lead inductance to the ground current. Note that not only is the coupling to the neighboring line avoided, but also the magnitude of the inductive spike is limited as the ground current loop is shortened. Placing a decoupling capacitor between the two lines, the inductive spike is reduced in magnitude by about half and the coupling is virtually eliminated. Decoupling capacitors also reduce the timing pushout by shortening the return current diversion distance, which in turn decreases the delay seen by the portion of the current that is forced around the gap. The use of lumped bypass capacitors is available to the FDTD model through a SPICE-FDTD interface, where the H fields in the FDTD grid are transferred to current in the SPICE program during runtime7, 8. This interface allows for SPICE capacitors to be placed across the gap in the FDTD model. A simulation result exhibiting the correct operation of the bypass capacitors is shown in Figure 13. A 0.1:F SPICE capacitor placed between the lines reduces the size of the inductive spike by about 50%, while also reducing the amount of coupling by nearly 75%. 1 0.8 0.6 no bypass cap driver line 0.4 bypass cap no bypass cap 0.2 passive line 0 bypass cap -0.2 -0.4 1E-10 1.5E-10 2E-10 2.5E-10 Time (seconds) Figure 13. The use of lumped SPICE bypass caps in the FDTD grid to mitigate the inductive disruption and coupling caused by the ground plane gap. 0.05 no caps 6. Conclusions passive line 0 two caps The multiple problems posed by non-ideal return paths limit the speed and reliability of high-speed digital designs. Three distinct effects of a typical ground slot non-ideal return path were identified -0.1 in both measurements and simulations. The reflected spike at the driver and the start of the timing pushout ledge at the receiver are -0.15 no caps both strongly dependent on the gap width. The spike at the driver and the duration of the timing pushout are sensitive to the gap length, -0.2 or the return current diversion distance. Coupling to quiet lines dedriver line pends on a combination of gap width and length, and good decoupling two caps -0.25 capacitor placement generally alleviates all of the above problems. 0.00E+ 1.00E- 2.00E- 3.00E- 4.00E- 5.00E- 6.00E- 7.00E- 8.00E- 9.00E- 1.00E00 10 10 10 10 10 10 10 10 10 09 Finite Difference Time Domain simulations were shown to produce time (sec) the same performance trends as measured TDR data, thereby equipping the designer with another tool with which to identify and remove signal integrity roadblocks. Future work includes extending Figure 12. Measured TDR: Use of decoupling caps to mitigate the understanding of this simple return path case to more compligap effects on signal and victim lines. cated situations, as well as developing more accurate lumped-element models of the ground gap disruption. The International Journal of Microcircuits and Electronic Packaging, Volume 22, Number 3, Third Quarter 1999 (ISSN 1063-1674) voltage (V) -0.05 (s) 268 © International Microelectronics And Packaging Society Quantifying the Impact of a Non-Ideal Return Path References 1. E. Tuncer, C.-W. Lam, F. Yuan, Modeling Ground Plane Cuts Using Transmission Line Theory, IEEE 5th Topical Meeting on Electrical Performance of Electronic Packaging, EPEP 96, Napa, California, October 28-30, pp. 229-231, 1996. 2. H.-J. Liaw and H. Merkelo, Signal Integrity Issues at Split Ground and Power Planes, IEEE CMPT 46th Electronic Components and Technology Conference, ECTC 96, pp. 752-5, 1996. 3. A.K. Bhattacharyya, et al., Full wave analysis for the equivalent circuit of an inclined slot on a microstrip ground plane, IEE Proceedings, Part H, Microwaves, Antennas and Propagation, Vol. 139, pp. 245-50, June 1992. 4. Allen Taflove, Advances in Computational Electrodynamics: The Finite Difference Time Domain Method, Artech House, Norwood, Massachusetts, Chapter 8, 1998. 5. Johnson and Graham, High Speed Digital Design, Prentice Hall PTR, New Jersey, pp. 194-197, 1993. 6. D. Brooks, Bypass Capacitors: A conversation with Todd Hubing, Printed Circuit Design, Vol. 15, No. 3, pg. 30, 1998. 7. M. Piket-May, V. Thomas, et.al., The Use of SPICE Lumped Circuits as Sub-grid Models for FDTD Analysis, IEEE Microwave and Guided Wave Letters, Vol. 4, No. 5, pp. 141-143, May 1994. 8. C.-N. Kuo, T. Itoh, et.al., Modeling of microwave active devices using the FDTD analysis based on the voltage-source approach, IEEE Microwave and Guided Wave Letters, Vol. 6, No. 5, May 1996, pp. 199-201. About the authors applications in high speed analog and digital design, EMC/EMI, solar cell design, and wireless communication. She serves on the Administrative Committee of IEEE Antennas and Propagation Society. Professor Piket-May is also very active in engineering education. Her focus is on moving towards an interactive environment where the student is in charge of the learning. She works on undergraduate engineering design issues and incorporating research into the classroom in an interactive and meaningful way. She received a 1996 URSI Young Scientist Award and was named a Sloan New Faculty Fellow in 1997. Professor Piket-May was awarded an NSF CAREER award in 1997 for her research and teaching activities. She is currently mentoring an NSF PSFMETE Post-Doc Fellow in Engineering Education. More information is available at http://maori.colorado.edu Stephen H. Hall is a Senior Design Engineer at Intel Corporation. He is currently working in the Intel Architecture Laboratory designing high speed systems, enabling technologies, developing simulation methodologies and performing research in the area of high speed signaling. He has 6 years of experience in the area of high speed digital design. Before coming to Intel, he worked in the Special Purpose Processor Development Group at the Mayo Foundation developing extremely high speed optical and electrical systems. Andrew Byers is pursuing a combined B.S./M.S. Degree in Electrical Engineering at the University of Colorado at Boulder, focusing in computational electromagnetic simulations and measurements. He has worked an internship at Brookhaven National Laboratory in New York designing digital radiation monitor units. Two internships at Intel have led to his current research, which involves high-speed digital interconnect measurements and modeling. Melinda Piket-May (S89 , M92) received her BSEE Degree from the University of Illinois - Champaign in 1988 and her MSEE and Ph.D. Degrees in Electrical Engineering from Northwestern University in 1990 and 1993, respectively. Her work experience includes internships at Fermi National Accelerator Lab, Naval Research Lab, and Cray Research. She joined the ECE Department at the University of Colorado Boulder in 1993 where she is currently an Assistant Professor. Professor PiketMay has an active research program in computational electromagnetics. Her work includes development of general methods to extract information from the numerical simulation, as well as work on higher order FDTD schemes to reduce phase error in FDTD simulations. Her research is industrial based with The International Journal of Microcircuits and Electronic Packaging, Volume 22, Number 3, Third Quarter 1999 (ISSN 1063-1674) © International Microelectronics And Packaging Society 269