Landlords` Guide to Electrical Safety

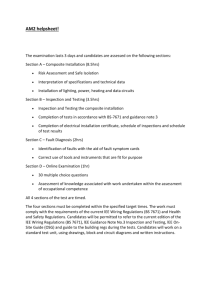

advertisement