A cylindrical capacitive sensor (CCS) for both

advertisement

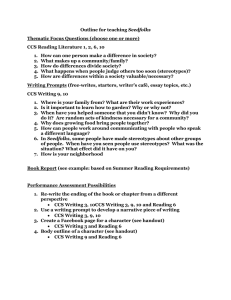

INSTITUTE OF PHYSICS PUBLISHING MEASUREMENT SCIENCE AND TECHNOLOGY doi:10.1088/0957-0233/17/7/049 Meas. Sci. Technol. 17 (2006) 2027–2034 A cylindrical capacitive sensor (CCS) for both radial and axial motion measurements Hyeong-Joon Ahn Department of Mechanical Engineering, Soongsil University, 511 Sangdo-dong, Dongjak-Gu, Seoul 156-743, Korea E-mail: ahj123@ssu.ac.kr Received 3 January 2006, in final form 12 April 2006 Published 21 June 2006 Online at stacks.iop.org/MST/17/2027 Abstract Conventional cylindrical capacitive sensors (CCS) are used only to measure the radial error motion of rotating machinery. However, axial error motion is also very important in rotating machines and it is very difficult to measure the axial motion due to the limited space. This paper presents a new CCS for both radial and axial motion measurements. The idea behind the new sensor is that the unused axial area of the CCS is exposed to measure the axial motion of a target. A theoretical model of the proposed CCS was derived. Based on the derived theoretical model, compensation methods to decouple the radial and axial motion measurements were proposed. In addition, an error analysis of the CCS was performed and a design rule was developed to guarantee the same accuracy in measuring both radial and axial motion measurements. Finally, a test rig and electronics for the proposed CCS were built and the effectiveness of the proposed CCS was verified through experiments and simulations. The developed CCS is expected not only to reduce the system complexity but also to afford a good balance between the radial and axial motion measurement accuracies. Keywords: capacitive sensor, displacement measurement, rotating machinery (Some figures in this article are in colour only in the electronic version) 1. Introduction Smart sensor systems, particularly position measurement systems, are expected to play a significant role in the high-precision intelligent manufacturing system. For example, a feedback control is inevitable to ensure sufficient repeatability for the high-resolution positioning of semiconductor manufacturing systems [1]. In addition, usage of active bearings like active magnetic bearings is being increased to achieve higher precision and productivity [2]. In these systems, the position measurement systems not only affect the system performance, but also the system size and complexity. Probe-type displacement sensors are highly sensitive to the surface quality of a target and these sensors require an additional algorithm to detect and compensate for the unnecessary signal induced by geometric errors [3, 4]. To 0957-0233/06/072027+08$30.00 analyse an air-bearing spindle error motion, a cylindrical capacitive sensor (CCS) was introduced by Chapman as an alternative to the probe-type sensors [5]. It was verified that the CCS showed much better performance in rejecting the geometric errors of a rotor than probe-type sensors [6], and it can minimize the effects of geometric errors by adjusting the sensor angular size [7]. Also, an extended analysis of a multi-segment CCS was performed [8] and a CCS was applied to the rotor motion measurement of a small air conditioning compressor [9]. The CCS is used only for measuring the radial error motion of rotating machinery. However, axial error motion is also very important in rotating machines such as hard disc and machine tools and it is very difficult to measure the axial motion due to the limited space. Moreover, it is very hard to balance the accuracies of both the radial and axial error motion measurements. © 2006 IOP Publishing Ltd Printed in the UK 2027 H-J Ahn New CCS Unused axial area Y Radial motion Z X Axial motion t δa (a) (a) (b) Figure 2. The main idea behind the novel CCS: (a) cross section of a CCS and (b) the proposed CCS. Figure 1. Types of CCS: (a) four-segment CCS and (b) eight-segment CCS. This paper presents a new CCS for both radial and axial motion measurements. There is no hardware difference of the new sensor from a conventional CCS, and the small axial area of the CCS is used to measure the axial motion of a target. A theoretical model of the new CCS was derived, which shows that there is a significant effect of the target radial motion on the axial measurement due to the intrinsic nonlinear nature of the CCS. The target radial motion effect was compensated using radial motion measurements based on the derived analytical model. In addition, a design rule was set to guarantee the same linearity of both radial and axial motion measurements. Finally, a test rig and electronics for the proposed CCS were built and the effectiveness of the proposed CCS was verified through experiments and simulations. 2. CCS Capacitive sensors are widely used in short-range ultraprecision and control applications because they have higher resolutions compared with other types of sensors. The existing four-segment CCS is designed to have the largest sensing area for a high resolution, as shown in figure 1(a). The rotor displacements can be approximated by equation (1) using the capacitances of four sensing electrodes (C1 , C2 , C3 , C4 ). XCCS4 = gain(C1 + C4 − C2 − C3 ), YCCS4 = gain(C1 + C2 − C3 − C4 ). (1) Although the four-segment CCS has a high resolution, it is sensitive to odd harmonic errors, especially the third harmonic component in the geometric errors of a rotor [6]. To overcome this shortcoming, Jeon et al [7] proposed a new configuration of CCS, the so-called eight-segment CCS. The eight-segment CCS consists of four shared and four unshared sensor segments, as shown in figure 1(b). The total angular size 2ζ of a sensor unit is the sum of two shared and one unshared sensor segments as follows: 2ζ = 2SS + SU . (2) Here, SS and SU are the angular sizes of the shared and unshared segments, respectively. Measured displacements of the rotor can be approximated by equation (3). The eight-segment CCS can have an arbitrary angular size of the sensor unit by adjusting the angular sizes 2028 (b) of the sensor segments, and a proper angular size of the sensor unit can minimize the effects of the geometric errors: XCCS8 = gain(C8 + C1 + C2 − C4 − C5 − C6 ), YCCS8 = gain(C2 + C3 + C4 − C6 − C7 − C8 ). (3) 3. A new CCS for both radial and axial motion measurements 3.1. Configuration Figure 2(a) shows the cross section of a CCS. There is a small axial area of the CCS. The main idea behind the novel CCS is that the small axial area of the CCS is used to measure the axial motion of the target, as shown in figure 2(b). If this concept is feasible, a more compact design and reduction of the system complexity can be achieved by removing the axial sensor. In the case of the proposed CCS, the capacitance of each electrode can be classified into the axial and radial capacitances: Ci = Cir + Cia . (4) Here, Cir is the capacitance of the radial area (radial capacitance) and Cia is that of the axial area (axial capacitance). Radial displacements can be approximated as equation (1) or equation (3) because the capacitances of the axial sensing area are removed by the differential configuration of the CCS. If the sensor thickness is t, the sensor inner radius is b and the axial gap is δa , the sum of the axial capacitances can be given by 2π(b + t/2)t Cia = ε , (5) δa i where is the permittivity of air and the axial area is expressed by the multiplication of the average radius of the axial area b + t/2, the thickness t and 2π. If the sum of the radial capacitances is constant irrespective of the target radial motion and the offset capacitance Coffset is properly removed, the axial motion would be approximated by the sum of all capacitances as shown in equation (6), Z≈ 1 1 = . CZ C − Coffset i i (6) r Here, Coffset = Ci + Cstray , which means the additional capacity due to radial and stray capacitances. A CCS for both radial and axial motion measurements C tr − C tr |α=0 Rotor ζ β b-δ b α 2πεbw 1 = α 2 − 1 . δ 1− δ (10) Hence, the additive nonlinearity can be compensated using the radial displacement measured with the CCS as 2 2 CZ = Ci − a XCCS + YCCS − Coffset . (11) i Figure 3. Measuring process of a CCS. 3.2. Total radial capacitance Small radial capacitance of the CCS can be approximated as [6] εbw θ. (7) C δ − α cos(θ − β) Here, w is the sensor axial width and θ is the angle variable for integration. Figure 3 shows the sensor radius b, the radial air gap between the sensor and the rotor δ, the rotor eccentricity α, the phase angle of the rotor eccentricity β and the sensor unit angular size ζ that will be used in the appendix. A nonlinear relationship between the rotor position and the total radial capacitance can be calculated by integrating equation (7) from 0 to 2π [10]. The resulting total radial capacitance can be given by 2π 2πεbw 1 C tr = Cir = C = (8) 2 . δ 0 1 − αδ The integration result shows nonlinear dependence of the sum of the radial capacitances on the radial position of the rotor. Since the total radial capacitance highly depends on the rotor eccentricity α, it was used to measure the minimum film thickness of a journal bearing [11]. For example, the radial clearance of the back-up bearing is assumed as 75% of the nominal clearance in an active magnetic bearing system, and the total radial capacitance varies over 150%. That is, we cannot use the total radial capacitance directly to represent the axial motion. 3.3. Compensation method The position dependence of the total radial capacitance can be compensated using the measured rotor displacements. The nonlinear radial measurement of the CCS can be expressed by a function of the normalized rotor eccentricity, α/δ [12], which is derived in the appendix, 1 εbw δ 1 XCCS = 8 2 − 1 sin ζ cos β. (9) δ α 1 − αδ The additive nonlinearity of the total radial capacitance can be expressed as capacitance variation due to the rotor eccentricity as shown in equation (10). The additive nonlinearity of the total radial capacitances is a function of the normalized eccentricity and it is very similar to the nonlinear mean gain of equation (9), Here, a is a compensation gain, and XCCS and YCCS are measured radial displacements using the CCS. The normalized additive compensation error (NEadd ) of equation (11) can be expressed with the normalized eccentricity x (= α/δ) as a 1 eq NEadd = −1 −1 . (12) √ x 1 − x2 Here, 0 x xe 1, xe is the normalized maximum eccentricity, and aeq = 4a sin ζ /π. The optimal gain aeq is the end point xe so that the normalized additive compensation errors at two end points are the same. The maximum normalized error can be calculated by substituting the critical point at which the derivative of equation (12) becomes zero. The proposed compensation method of equation (11) is too complex to be implemented with an analogue circuit. Moreover, if the rotor is maintained to be near the centre of the CCS, the compensation error is very small. Hence, we can further simplify the compensation method as follows: CZ = Ci − am (|XCCS | + |YCCS |) − Coffset . (13) i The compensation gain a is modified as am and the compensation error obviously increases. The eccentricity is √ approximated as the sum of absolute displacements: 2 2 XCCS + YCCS ≈ (|XCCS | + |YCCS |). The modified compensation gain can be calculated by minimizing a modified normalized additive compensation error such as am 1 min −1 −1 am xe 1 − (xe )2 √ 2am 1 (14) − max −1 . −1 √ 0xxe x 1 − x2 The calculated compensation gains and relative compensation errors are shown in figure 4. Two compensation gains are same when the normalized eccentricity is less than 0.5 and the optimal modified compensation gain has discontinuity as the normalized eccentricity is larger than 0.9. In addition, although the normalized compensation error using the modified compensation method of equation (13) becomes large as the rotor eccentricity increases, the compensation error is not too severe where the normalized rotor eccentricity is less than 0.8. 3.4. Finite element analysis The proposed CCS is modelled under the assumption that there is no coupling between radial and axial capacitances. However, this assumption is not valid at the edge of the CCS. Therefore, an electrostatic analysis using the finite element 2029 H-J Ahn 0.8 0.8 a =xe Modi. gain a Normalized additive error Optimal compensation gain 1 m 0.6 0.4 0.2 0.7 0.6 a =x e Modi. gain am 0.5 0.4 0.3 0.2 0.1 0 0 0.2 0.4 0.6 Normalized eccentricity 0.8 1 0 0 0.2 0.4 0.6 Normalized eccentricity (a) 0.8 1 (b) Figure 4. Compensation method: (a) compensation gain and (b) normalized errors. Cr Sensor Sensor Car Ca Target -50 (a) (b) Figure 5. FEM analysis: (a) electric field and (b) capacitance variation. method (FEM) is performed to investigate the radial and axial capacitance coupling. Figure 5(a) shows the results of the FEM analysis in a case where the radial gap is 0.5 mm and the axial gap is 0.9 mm. The axial electric field is bent at the edge of the CCS. To investigate the edge effect of the CCS, capacitance variations from the reference axial gap (0.1 mm) to various gaps (up to 0.9 mm) are calculated and shown in figure 5(b). The ideal case of neglecting axial and radial capacitance coupling the capacitance variation is calculated using equation (5), while the real case considering axial and radial capacitance coupling is calculated using the FEM. The capacitance between the axial area and the target radial area, Car in figure 5(b), contributes to the increase of the axial measurement sensitivity. The edge effect is good for the axial motion measurement and it is not significant, so we neglect the effect in this paper. shown in equation (15) since the linearized gain at the centre α linear = 4 εbw sin ζ cos β, is XCCS δ δ 1 2 − 1 − 1. (15) RDr = 2 √ x 1 − x2 4. Error analysis and design rule 4.2. Error analysis in the axial measurement 4.1. Error analysis in the radial measurement There are harmonic errors of the radial displacements measured with the proposed CCS due to its intrinsic nonlinearity, as shown in equation A.5 [12]. The harmonic errors of the measured radial displacements are transmitted into the axial measurement during the compensations of the total radial capacitance. However, the nonlinear compensation The nonlinear characteristic of the radial motion measurement is expressed as equation (9) and its linearized normalized gain near the CCS centre is 1. The relative deviation of the nonlinear gain from the linearized gain at the centre (RDr ) is 2030 Here, x is α/δ. The CCS gain has severe nonlinearity as the normalized eccentricity increases. Thus, the CCS is generally calibrated using a regression within a given operating range. The relative deviation and regressed relative error are shown in figure 6(a), and their ratio is shown in figure 6(b). The ratio is nearly constant (≈2.5) if the normalized rotor eccentricity varies from 0.1 to 0.8. Therefore, the relative error of the radial measurement (REr ) can be approximated as 1 1 2 REr (x) − 1 − 1 . (16) √ 2.5 x 2 1 − x2 A CCS for both radial and axial motion measurements 10 3.5 2 0.6 10 10 Width ratio (t/w) 10 1 Ratio of two errors Normalized additive error (%) 3 0 −1 2.5 2 1.5 10 10 −2 0.5 Normalized eccentricity 0.3 0.2 0 0 0.5 −3 0 0.4 0.1 1 Deviation Regres. error 0.5 1 0.2 0.4 0.6 0 0 1 0.5 Figure 7. Desired width ratios (t/w). 1 Normalized eccentricity (a) width ratio t/w. That is, the width ratio should satisfy NEadd |max (x) δδa max + REr (x) δδa max − δδa |min t δ = . − δ w REr (x) δ (b) Figure 6. Relative error of radial measurement: (a) relative deviation and error and (b) their ratio. δa min δa max error is much bigger than the harmonic errors and the nonlinear harmonic error is ignored in this analysis. If NEadd |max is the maximum normalized additive compensation error, the axial sensor output can be simplified by 2πεt (b + t/2) 2πεbw NEadd |max − δa δ t 2πεbw t δ − NEadd |max . 1+ = δ w δa 2b CZ = ZCCS = 1/CZ − 1/CZ0 , δa min (20) The desired width ratio t/w of equation (20) is calculated with increasing radial measurement range in the case when the axial measurement range is given by 0.5 δ/δa 2 and the result is shown in figure 7. 5. Simulation and experiment (17) The sum of the total capacitance should be inverted in order to obtain the axial displacement from the CCS output, (18) and the relative error of the axial motion measurement, REax , can be represented by the ratio of the measurement error to the ideal sensor output. The axial measurement error of the developed CCS depends on its geometry, as shown in equation (17): radial thickness, axial width and axial and radial air gaps. Since t/2b is very small (1), the linearity error depends on the ratio of the radial thickness to the axial width (width ratio), t/w, and the axial and radial gaps ratio, δ/δa . As a result, the relative measured error of the developed CCS is calculated by REax = 0.8 Normalized eccentricity (α/δ) ideal ZCCS − ZCCS ideal ZCCS NEadd |max · δδa max t δ . (19) = δ − δ − NEadd |max δa max δa min w δa min 4.3. Design rule Obviously, the relative errors of both radial and axial measurements should be equalized in a given measurement range in order to balance the accuracies of both radial and axial measurements. The relative errors of both radial and axial measurements (equations (16) and (19)) are equalized. Then, we can determine an important sensor geometry or the 5.1. Experimental set-up To verify the performance of the proposed CCS, an experimental set-up was built as shown in figure 8(a). The experimental set-up consists of the proposed CCS, a motorized XY stage (Newport M-VP-25XA), a manual Z stage (Sigma Koki TSD-603), a target and a sensor supporter. Figures 8(b) and (c) show the proposed CCS and the target assembly that consists of the motorized XY stage, the manual Z stage and the target. The CCS specifications are as follows: the diameter is 54 mm, the radial air gap is 0.5 mm, the sensor axial length is 6 mm and the sensor thickness is 2.5 mm. The proposed CCS uses the same circuit as an existing CCS for the radial measurement. An axial measurement circuit is composed of a sum of all capacitances and an offset adjustment. The schematic diagram of the experimental set-up is shown in figure 9. First, offsets of the proposed CCS are set electrically through setting the X and Y sensor outputs to zero without the target and the Z offset is adjusted through setting the Z sensor output zero only with the radial target. Then, X, Y motions are actuated using a GPIB communication with PC and Z motion is adjusted manually (±0.3 mm by 0.05 mm steps in the X and Y directions and from 0.3 to 0.95 mm by 0.05 mm steps in the Z direction), and the X, Y and Z sensor outputs were measured synchronously with the stage motion. The maximum normalized eccentricity is 0.6 and the gap ratio (δ/δa ) varies from 0.5 to 1.67. 5.2. Results Experimental and simulation results are shown in figure 10. Simulations were performed under the assumption 2031 10 0 5 5 −1 −5 −10 0.2 −4 0.2 Y Target ) Y −0.2 m ) m 0 −0.2 di −0.2 0.2 0 Y di sp − 0.2 .(m 0 sp .(m m ) 0 ) mm p.( dis − 0.2 X − 0.2 0.2 ) mm p.( dis ) mm p.( dis 0 0.2 X X 0.2 0 (a) Experimental setup −3 .(m −10 −2 sp −5 0 di 0 Z sensor output (V) 10 Y sensor output (V) X sensor output (V) H-J Ahn (a) (b) Sensor (c) Target assembly Figure 8. Experimental set-up. 10 − 0.8 Z sensor output (V) Motorized XY stage Complex sensor output (V) Manual Z stage 5 0 −5 −1 − 1.2 − 1.4 − 1.6 − 1.8 − 10 −2 0.2 0 − 0.2 − 0.2 ) ) m m Y .( p dis 0.2 0 .(m .(m − 0.2 ) mm sp sp 0 di di 0.2 0 − 0.2 X X 0.2 Y m .( isp m ) d (b) Figure 10. Sensor outputs at Z = 0.65 mm: (a) experiment and (b) simulation. Figure 9. Schematic of experiment. 2032 5 Y sensor output (V) 5 X sensor output (V) that radial and axial capacitances are independent of each other. Experiments were performed in Cartesian coordinates while the simulations were performed in cylindrical coordinates. The Z sensor output before the compensation is highly dependent on the rotor position. At the centre of the CCS, the X, Y sensor outputs due to the axial motions are shown in figure 11. The X, Y sensor outputs did not change and the gain near the centre decreases about 2%, which is caused by the coupling effect of the axial and radial capacitances. Compensations are performed using both equations (11) and (13) and the results are shown in figure 12. The radial position dependence of the axial measurement is reduced significantly (about five times), compared with figure 10. The normalized additive errors due to the radial motion are shown in figure 13(a). Axial measurement errors due to radial motions are normalized using the theoretical sensor gain as in equation (12), and the compensations 1 and 2 in figure 12 denote methods of equations (11) and (13), respectively. In addition, the normalized additive errors from experiments, simulations and theory are compared in table 1. The results 0 −5 0 −5 0.3 −0.2 0.5 Xd isp. 0 0.2 (mm ) 0.7 0.9 is Zd p.( ) mm 0.3 −0.2 0.5 Yd isp. 0 0.2 (mm ) m p.(m 0.7 0.9 ) is Zd Figure 11. Radial sensor variation due to axial motion. of experiment, simulation and theory agree well. After the conditioning of equation (18), the measured axial sensor outputs and their variations are shown in figure 13. The width ratio t/w of the designed CCS is 0.417. The relative error in the radial measurement is about 15% and the measured error of the axial measurement is about 25%, as expected. The A CCS for both radial and axial motion measurements − 0.6 − 0.8 −1 − 1.2 − 0.4 − 0.6 − 0.8 −1 − 1.2 − 0.3 Compensated Z output (V) − 0.4 − 0.3 Compensated Z output (V) − 0.2 Compensated Z output (V) Compensated Z output (V) − 0.2 − 0.4 − 0.5 − 0.6 − 0.7 − 0.8 − 0.9 X 0.2 dis 0 p.( − 0.2 mm ) − 0.2 0 0.2 0.2 X d isp 0− 0.2 ) − 0.2 .(m m) m isp.(m Yd 0.2 0 X (mm) p. Y dis − 0.4 − 0.5 − 0.6 − 0.7 − 0.8 − 0.9 dis 0.2 0 p.( mm − 0.2 ) − 0.2 0.2 0 X (mm) p. Y dis (a) 0.2 dis p.( 0 − 0.2 mm − 0.2 0.2 0 p.(mm Y dis ) ) (b) Figure 12. Compensation results: (a) experiment: equations (11) and (13), (b) simulation: equations (11) and (13). Normalized sensor output (1/Z) Normalized additive error 0 0.25 w/o compen. (Exp.) w/o compen. (Theory) Compen. 1 (Exp.) Compen. 1 (Theory) Compen. 2 (Exp.) Compen. 2 (Theory) 0.2 0.15 0.1 0.05 0 0.3 0.4 0.5 0.6 0.7 0.8 0.9 Z displacement (mm) − 0.2 − 0.4 − 0.6 − 0.8 −1 Ideal Compen. 1 Compen. 2 w/o compen. − 1.2 − 1.4 − 1.6 0.3 0.4 0.5 0.6 0.7 0.8 Z displacement (mm) (a) 0.9 (b) Figure 13. Axial motion measurement: (a) normalized additive error due to the radial motion and (b) conditioned axial sensor output. Table 1. Comparison of the normalized addition errors. w/o Compensation 1: Compensation 2: compensation equation (11) equation (13) Theory 0.250 Simulation 0.2395 Experiment 0.2438 0.0486 0.050 0.0513 0.1075 0.1033 0.0946 measurements. Finally, a test rig for the proposed CCS was built, and the performances of the proposed CCS were verified with simulations and experiments. The developed CCS is expected not only to reduce the system complexity but also to afford a good balance between the radial and axial motion measurement accuracies. Acknowledgments sensor gain increases about 10% due to the radial and axial capacitance coupling. 6. Conclusion This paper proposed a cylindrical capacitive sensor (CCS) for both radial and axial motion measurements. Although the developed CCS has the same geometric configuration as a conventional CCS, an unused axial area of the CCS is utilized to measure the axial motion of a rotor. First, a theoretical model of the proposed CCS was derived. Based on the derived theoretical model, compensation methods to decouple the radial and axial motion measurements were proposed. In addition, an error analysis of the CCS was performed and a design rule was developed to guarantee the same accuracy in measuring both radial and axial motion This work was supported by the Brain Korea 21 Project in 2005 and by the Soongsil University Research Fund. Appendix. Nonlinear analysis of the radial motion measurement [12] The measured X displacement using a CCS of angular size 2ζ can be expressed as follows: ζ π +ζ XCCS = C − C. (A.1) −ζ π −ζ The small capacitance, equation (7), can be expressed using a power series as follows: ∞ n εbw α cos(θ − β) θ. (A.2) C δ n=0 δ 2033 H-J Ahn If equation (A.2) is substituted into equation (A.1), the measured X displacement can be calculated as follows: ∞ 2εbw ζ α 2l+1 cos2l+1 (θ − β)θ. (A.3) XCCS = δ δ −ζ l=0 Using the trigonometric functional relation of equation (A.4), the measured displacement of the rotor can be simplified as equation (A.5): 2l+1 cos XCCS l 1 2l + 1 ϑ= l cos (2l + 1 − 2k)ϑ k 4 k=0 (A.4) l ∞ εbw α 2l+1 2l + 1 =8 δ l=0 2δ k k=0 × sin (2l + 1 − 2k)ζ cos (2l + 1 − 2k)β. 2l + 1 − 2k (A.5) There appear harmonic errors in the radial motion measurement of the CCS and the biggest nonlinear harmonic error is the third harmonic one that can be removed if ζ is 60◦ . In addition, the nonlinear mean gain of the CCS can be calculated through summing the first harmonic terms: ∞ εbw α 2l+1 2l + 1 1 XCCS =8 sin ζ cos β. (A.6) l δ l=0 2δ Equation (A.6) can be simplified with the power series of equation (A.7), 1·3 2 1·3·5 3 1 1 x + x + ··· =1+ x+ √ 2 2·4 2·4·6 1−x ∞ ∞ 2k x k 2k + 1 1 k+1 = =1+ x . 2k+1 k k 4 2 k=0 k=0 (A.7) That is, the nonlinear mean gain can be expressed by 1 XCCS ∞ εbw δ α 2l+2 1 2l + 1 =8 sin ζ cos β δ α l=0 δ 22l+1 l (A.8) 2034 and the simplified nonlinear mean gain is given by (A.9), which is a function of the normalized rotor eccentricity, α/δ. ∞ εbw δ α 2l+2 1 2l + 1 1 =8 sin ζ cos β XCCS l δ α l=0 δ 22l+1 1 εbw δ (A.9) =8 2 − 1 sin ζ cos β. δ α 1 − αδ References [1] Kim O S, Lee S H and Han D C 2003 Positioning performance and straightness error compensation of the magnetic levitation stage supported by the linear magnetic bearing IEEE Trans. Ind. Electron. 50 374–8 [2] Schweitzer G, Bleuler H and Traxler A 1994 Active Magnetic Bearings (Switzerland: Hochschulverlag AG de ETH Zurich) [3] Whitehouse D J 1976 Some theoretical aspects of error separation techniques in surface metrology J. Phys. E: Sci. Instrum. 9 531–6 [4] Mitsui K 1982 Development of a new measuring method for spindle rotation accuracy by three-points methods Proc. 23rd Int. MTDR pp 115–21 [5] Chapman P D 1985 A capacitive based ultraprecision spindle error analyser J. Precis. Eng. 7 129–37 [6] Ahn H J, Jeon S and Han D C 2000 Error analysis of the cylindrical capacitive sensor for active magnetic bearing spindles Trans. ASME, J. Dyn. Syst. Meas. Control 122 102–7 [7] Jeon S, Ahn H J, Chang I B and Han D C 2001 A new design of cylindrical capacitive sensor for on-line precision control of AMB spindle IEEE Trans. Instrum. Meas. 50 757–63 [8] Ahn H J and Han D C 2003 Optimal multi-segment cylindrical capacitive sensor Meas. Sci. Technol. 14 531–42 [9] Ahn H J, Han D C and Hwang I S 2003 A built-in bearing sensor to measure the shaft motion of a small rotary compressor for air conditioning Tribol. Int. 36 561–72 [10] Gradshteyn I S and Ryzhik I M 1982 Tables of Integrals, Series, and Products (New York: Academic) [11] Choi J K, Hur K and Han D C 1992 Oil film thickness in engine main bearings: comparison between calculation and experiment by total capacitance method SAE Paper 922345 [12] Ahn H J, Kim I H and Han D C 2005 Nonlinear analysis of cylindrical capacitive sensor Meas. Sci. Technol. 16 699–706