Technical Cable Guide

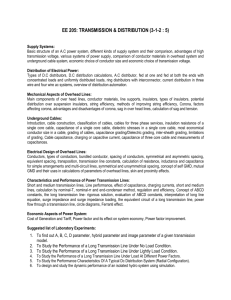

advertisement