® bcdefg® a - Protective Coatings | International Paint

advertisement

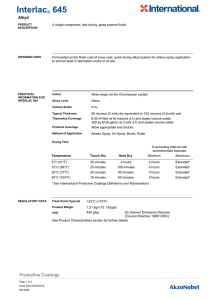

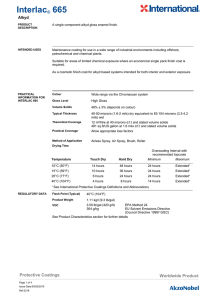

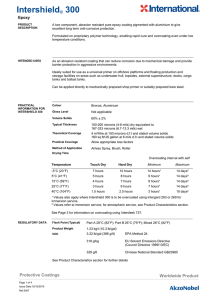

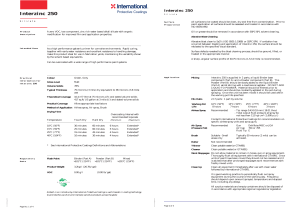

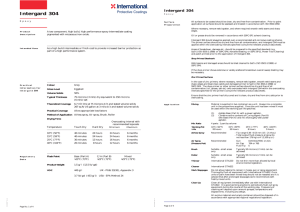

a bcdefg ® ® Interlac 688 Protective Coatings Interlac 688 A l k y d A l k y d Product Description A rapid dry general purpose gloss enamel for steel structures and equipment Dries to a hard film after a very short time Provides a brilliant gloss finish with good durability Inexpensive and easy to apply Intended Uses As a quick dry high gloss structural spraying enamel Suitable for fixed machinery, equipment, structural steel and sheet steel Practical Information for Interlac 688 Colour White and a range of AS2700 colours via the Chromascan colour matching System Gloss Level Gloss Volume Solids 33% ± 3% depending on colour. Typical Thickness 35 microns dry equivalent to 105 microns wet Theoretical Coverage 9.5m2/litre @ 35 microns d.f.t and stated volume solids Practical Coverage Allow appropriate loss factors Surface Preparation All surfaces to be coated should be clean, dry and free from contamination. Prior to paint application all surfaces should be assessed and treated in accordance with ISO 8504:1992. Primed Surfaces For best performance Interlac 688 should be applied over a recommended anticorrosive coating system. The primer surface should be dry and free from all contamination, and Interlac 688 must be applied within the overcoating intervals specified (consult the relevant product data sheet). Interlac 688 can be applied directly to steel for lower durability requirements in mild environments. Areas of breakdown, damage etc., should be prepared to the specified standard (e.g. Sa2½ (ISO 8501-1:1988), or SSPC-SP6, Abrasive Blasting, or SSPC-SP11, Hand/Power Cleaning) and patch primed prior to the application of Interlac 688. Application Mixing Mix Ratio Working Pot Life Airless Spray - Tip range 0.43-0.53 mm (17-21 thou) - Total output fluid pressure at spray tip not less than 176 kg/cm2 (2500 p.s.i.) Air Spray Recommended Gun DeVilbiss MBC or JGA (Pressure Pot) Air Cap 704 or 765 Fluid Tip E Brush Suitable for small areas Typically 100 microns wft can be achieved Roller Suitable for small areas Typically 100 microns wft can be achieved Thinner International GTA007 Do not thin more than allowed by local environmental legislation Cleaner International GTA007 Work Stoppages Thoroughly flush all equipment with International GTA007. All unused material should be stored in tightly closed containers. Partially filled containers may show surface skinning and/or a viscosity increase of the material after storage. Material should be filtered prior to use Clean Up Clean all equipment immediately after use with International GTA007. It is good working practice to periodically flush out spray equipment during the course of the working day. Frequency should depend upon amount sprayed, temperature and elapsed time, including any delays. All surplus materials and empty containers should be disposed of in accordance with appropriate regional regulations/legislation Method of Application Airless spray, Air spray, Brush and roller for small areas only Drying Time Temperature Touch Dry Hard Dry Overcoating Interval with recommended topcoats Minimum Maximum 5°C (41°F) 15°C (59°F) 25°C (77°F) 40°C (104°F) 40 minutes 20 minutes 15 minutes 10 minutes 3½ hours 2½ hours 1½ hours 45 minutes 8 hours 6 hours 2½ hours 1 hour Extended* Extended* Extended* Extended* * See International Protective Coatings Definitions & Abbreviations Regulatory Data A U S 0 9 9 9 Page No. 1 of 4 Flash Point <10°C Product Weight 0.9-1.1 kg/l VOC 457g/l This material is a one component coating and should always be mixed thoroughly with a power agitator before application. Not applicable Not applicable UK - PG6/23(92), Appendix 3 A U S 0 9 9 9 Page 2 of 4 Recommended a bcdefg ® ® Interlac 688 Protective Coatings Interlac 688 A l k y d A l k y d Product Description A rapid dry general purpose gloss enamel for steel structures and equipment Dries to a hard film after a very short time Provides a brilliant gloss finish with good durability Inexpensive and easy to apply Intended Uses As a quick dry high gloss structural spraying enamel Suitable for fixed machinery, equipment, structural steel and sheet steel Practical Information for Interlac 688 Colour White and a range of AS2700 colours via the Chromascan colour matching System Gloss Level Gloss Volume Solids 33% ± 3% depending on colour. Typical Thickness 35 microns dry equivalent to 105 microns wet Theoretical Coverage 9.5m2/litre @ 35 microns d.f.t and stated volume solids Practical Coverage Allow appropriate loss factors Surface Preparation All surfaces to be coated should be clean, dry and free from contamination. Prior to paint application all surfaces should be assessed and treated in accordance with ISO 8504:1992. Primed Surfaces For best performance Interlac 688 should be applied over a recommended anticorrosive coating system. The primer surface should be dry and free from all contamination, and Interlac 688 must be applied within the overcoating intervals specified (consult the relevant product data sheet). Interlac 688 can be applied directly to steel for lower durability requirements in mild environments. Areas of breakdown, damage etc., should be prepared to the specified standard (e.g. Sa2½ (ISO 8501-1:1988), or SSPC-SP6, Abrasive Blasting, or SSPC-SP11, Hand/Power Cleaning) and patch primed prior to the application of Interlac 688. Application Mixing Mix Ratio Working Pot Life Airless Spray - Tip range 0.43-0.53 mm (17-21 thou) - Total output fluid pressure at spray tip not less than 176 kg/cm2 (2500 p.s.i.) Air Spray Recommended Gun DeVilbiss MBC or JGA (Pressure Pot) Air Cap 704 or 765 Fluid Tip E Brush Suitable for small areas Typically 100 microns wft can be achieved Roller Suitable for small areas Typically 100 microns wft can be achieved Thinner International GTA007 Do not thin more than allowed by local environmental legislation Cleaner International GTA007 Work Stoppages Thoroughly flush all equipment with International GTA007. All unused material should be stored in tightly closed containers. Partially filled containers may show surface skinning and/or a viscosity increase of the material after storage. Material should be filtered prior to use Clean Up Clean all equipment immediately after use with International GTA007. It is good working practice to periodically flush out spray equipment during the course of the working day. Frequency should depend upon amount sprayed, temperature and elapsed time, including any delays. All surplus materials and empty containers should be disposed of in accordance with appropriate regional regulations/legislation Method of Application Airless spray, Air spray, Brush and roller for small areas only Drying Time Temperature Touch Dry Hard Dry Overcoating Interval with recommended topcoats Minimum Maximum 5°C (41°F) 15°C (59°F) 25°C (77°F) 40°C (104°F) 40 minutes 20 minutes 15 minutes 10 minutes 3½ hours 2½ hours 1½ hours 45 minutes 8 hours 6 hours 2½ hours 1 hour Extended* Extended* Extended* Extended* * See International Protective Coatings Definitions & Abbreviations Regulatory Data A U S 0 9 9 9 Page No. 1 of 4 Flash Point <10°C Product Weight 0.9-1.1 kg/l VOC 457g/l This material is a one component coating and should always be mixed thoroughly with a power agitator before application. Not applicable Not applicable UK - PG6/23(92), Appendix 3 A U S 0 9 9 9 Page 2 of 4 Recommended Interlac 688 Interlac 688 A l k y d Product Characteristics A l k y d Interlac 688 is designed primarily for workshop and site application. Airless spray application can easily lead to over-application with slow through drying and difficulty in handling. Over-application can also cause wrinkling on overcoating after ageing. Further information regarding industry standards, terms and abbreviations used in this data sheet can be found in the following sections of the International Protective Coatings data manual: Additional Information Level of sheen and surface finish is dependent on application method. Avoid using a mixture of application methods whenever possible. • Definitions & Abbreviations • Surface Preparation As with all alkyd systems, Interlac 688 has limited chemical and solvent resistance and is not suitable for use in immersion situations or in conditions of continuous condensation. • Paint Application • Theoretical & Practical Coverage Individual copies of these information sections are available upon request. Interlac 688 should not to be applied over zinc based primers or galvanised surfaces because of dangers of saponification of the alkyd resin and consequent adhesion loss. Safety Precautions For brush and roller application, and in some colours such as yellows and reds, two or more coats of Interlac 688 may be required to give uniform coverage. Available in a wide range of colours produced via the Chromascan system. This product is intended for use only by professional applicators in industrial situations in accordance with the advice given on this sheet, the Material Safety Data Sheet and the container(s), and should not be used without reference to the Material Safety Data Sheet (MSDS) which International Protective Coatings has provided to its customers. All work involving the application and use of this product should be performed in compliance with all relevant national, Health, Safety & Environmental standards and regulations. Brushing and rolling is recommended for small areas only In the event welding or flame cutting is performed on metal coated with this product, dust and fumes will be emitted which will require the use of appropriate personal protective equipment and adequate local exhaust ventilation. If in doubt regarding the suitability of use of this product, consult International Protective Coatings for further advice. 20 litre unit 4 litre unit Pack Size Systems Compatibility Interlac 688 can be applied over a range of alkyd and epoxy primers Interprime 140 Interprime 198 Interprime 371 Interprime 484 Interprime 741 20 litres in a 20 litre steel container 4 litres in a 4 litre steel container For availability of other pack sizes contact International Protective Coatings Intercure 200 Intergard 251 Interplus 356 Interseal 2020 Interlac 688 is only suitable for overcoating with itself or other mineral spirits based primers or finishes. Shipping Weight U.N. Shipping No. 1273 20 litre unit 23.6 kg 4 litre unit 4.7 kg Storage Shelf Life For other suitable primers consult International Protective Coatings. 24 months minimum at 25°C (77°F). Subject to re-inspection thereafter. Store in dry, shaded conditions away from sources of heat and ignition. Disclaimer The information given in this sheet is not intended to be exhaustive and any person using the product for any purpose other than that specifically recommended in this sheet without first obtaining written confirmation from us as to the suitability of the product for the intended purpose does so at his own risk. Any warranty, if given, or specific Terms & Conditions of Sale are contained in International’s Terms & Conditions of Sale, a copy of which can be obtained on request. Whilst we endeavour to ensure that all advice we give about the product (whether in this sheet or otherwise) is correct we have no control over either the quality or condition of the substrate or the many factors affecting the use and application of the product. Therefore, unless we specifically agree in writing to do so, we do not accept any liability whatsoever or howsoever arising for the performance of the product or for any loss or damage (other than death or personal injury resulting from our negligence) arising out of the use of the product. The information contained in this sheet is liable to modification from time to time in the light of experience and our policy of continuous product development. It is the user’s responsibility to check that this sheet is current prior to using the product. Issue date: 21/09/99 Copyright © International Paint Ltd. and International are trademarks. International Protective Coatings World Centre P.O Box 20980 Oriel House 16 Connaught Place London, W2 2ZB England Asia Region 3 Neythal Road Jurong Town Singapore 628570 Tel: (44) 171 479 6000 Tel: (65) 663 3066 Fax: (44) 171 479 6500 Fax: (65) 266 5287 Australasia Region 115 Hyde Road Yeronga Brisbane Queensland Australia Europe Region P.O Box 20980 Oriel House 16 Connaught Place London, W2 2ZB England Middle East Region PO Box 37 Dammam 31411 Saudi Arabia North America Region 6001 Antoine Drive Houston Texas 77091 Tel: (61) 7 3892 8866 Fax: (61) 7 3892 4287 H&S (61) 1800 807 001 Tel: (44) 171 479 6000 Tel: (966) 3 812 1044 Tel: (1) 713 682 1711 Fax: (44) 171 479 6500 Fax: (966) 3 812 1169 Fax: (1) 713 684 1327 South America Region Rua Gomes de Carvalho, 1356, 15° Andar, Vila Olímpia, São Paulo, S.P. CEP: 04547-005 Brazil Tel: (011) 3044 0344 Fax: (011) 3044 0322 Local Office: Tel: 0191 469 6111 Fax: 0191 495 0676 Page No. 3 of 4 A U S 0 9 9 9 Page No. 4 A U S 0 9 9 9 Interlac 688 Interlac 688 A l k y d Product Characteristics A l k y d Interlac 688 is designed primarily for workshop and site application. Airless spray application can easily lead to over-application with slow through drying and difficulty in handling. Over-application can also cause wrinkling on overcoating after ageing. Further information regarding industry standards, terms and abbreviations used in this data sheet can be found in the following sections of the International Protective Coatings data manual: Additional Information Level of sheen and surface finish is dependent on application method. Avoid using a mixture of application methods whenever possible. • Definitions & Abbreviations • Surface Preparation As with all alkyd systems, Interlac 688 has limited chemical and solvent resistance and is not suitable for use in immersion situations or in conditions of continuous condensation. • Paint Application • Theoretical & Practical Coverage Individual copies of these information sections are available upon request. Interlac 688 should not to be applied over zinc based primers or galvanised surfaces because of dangers of saponification of the alkyd resin and consequent adhesion loss. Safety Precautions For brush and roller application, and in some colours such as yellows and reds, two or more coats of Interlac 688 may be required to give uniform coverage. Available in a wide range of colours produced via the Chromascan system. This product is intended for use only by professional applicators in industrial situations in accordance with the advice given on this sheet, the Material Safety Data Sheet and the container(s), and should not be used without reference to the Material Safety Data Sheet (MSDS) which International Protective Coatings has provided to its customers. All work involving the application and use of this product should be performed in compliance with all relevant national, Health, Safety & Environmental standards and regulations. Brushing and rolling is recommended for small areas only In the event welding or flame cutting is performed on metal coated with this product, dust and fumes will be emitted which will require the use of appropriate personal protective equipment and adequate local exhaust ventilation. If in doubt regarding the suitability of use of this product, consult International Protective Coatings for further advice. 20 litre unit 4 litre unit Pack Size Systems Compatibility Interlac 688 can be applied over a range of alkyd and epoxy primers Interprime 140 Interprime 198 Interprime 371 Interprime 484 Interprime 741 20 litres in a 20 litre steel container 4 litres in a 4 litre steel container For availability of other pack sizes contact International Protective Coatings Intercure 200 Intergard 251 Interplus 356 Interseal 2020 Interlac 688 is only suitable for overcoating with itself or other mineral spirits based primers or finishes. Shipping Weight U.N. Shipping No. 1273 20 litre unit 23.6 kg 4 litre unit 4.7 kg Storage Shelf Life For other suitable primers consult International Protective Coatings. 24 months minimum at 25°C (77°F). Subject to re-inspection thereafter. Store in dry, shaded conditions away from sources of heat and ignition. Disclaimer The information given in this sheet is not intended to be exhaustive and any person using the product for any purpose other than that specifically recommended in this sheet without first obtaining written confirmation from us as to the suitability of the product for the intended purpose does so at his own risk. Any warranty, if given, or specific Terms & Conditions of Sale are contained in International’s Terms & Conditions of Sale, a copy of which can be obtained on request. Whilst we endeavour to ensure that all advice we give about the product (whether in this sheet or otherwise) is correct we have no control over either the quality or condition of the substrate or the many factors affecting the use and application of the product. Therefore, unless we specifically agree in writing to do so, we do not accept any liability whatsoever or howsoever arising for the performance of the product or for any loss or damage (other than death or personal injury resulting from our negligence) arising out of the use of the product. The information contained in this sheet is liable to modification from time to time in the light of experience and our policy of continuous product development. It is the user’s responsibility to check that this sheet is current prior to using the product. Issue date: 21/09/99 Copyright © International Paint Ltd. and International are trademarks. International Protective Coatings World Centre P.O Box 20980 Oriel House 16 Connaught Place London, W2 2ZB England Asia Region 3 Neythal Road Jurong Town Singapore 628570 Tel: (44) 171 479 6000 Tel: (65) 663 3066 Fax: (44) 171 479 6500 Fax: (65) 266 5287 Australasia Region 115 Hyde Road Yeronga Brisbane Queensland Australia Europe Region P.O Box 20980 Oriel House 16 Connaught Place London, W2 2ZB England Middle East Region PO Box 37 Dammam 31411 Saudi Arabia North America Region 6001 Antoine Drive Houston Texas 77091 Tel: (61) 7 3892 8866 Fax: (61) 7 3892 4287 H&S (61) 1800 807 001 Tel: (44) 171 479 6000 Tel: (966) 3 812 1044 Tel: (1) 713 682 1711 Fax: (44) 171 479 6500 Fax: (966) 3 812 1169 Fax: (1) 713 684 1327 South America Region Rua Gomes de Carvalho, 1356, 15° Andar, Vila Olímpia, São Paulo, S.P. CEP: 04547-005 Brazil Tel: (011) 3044 0344 Fax: (011) 3044 0322 Local Office: Tel: 0191 469 6111 Fax: 0191 495 0676 Page No. 3 of 4 A U S 0 9 9 9 Page No. 4 A U S 0 9 9 9