Secondary Unit Substations —Secondary Below

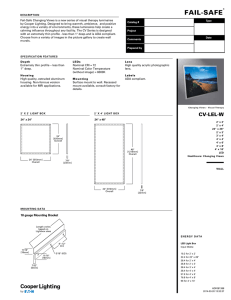

advertisement