badger - Morningstar

advertisement

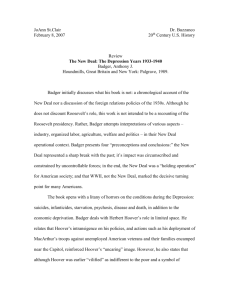

U N E A R T H I N G S O L U T I O N S F O R I N D U S T R Y technology BADGER DAYLIGHTING INC. 1 9 9 7 A NNUA L R E P O RT opportunity g r ow t h CORPORATE PROFILE BADGER DAYLIGHTING INC. IS A VERTICALLY INTEGRATED SERVICE COMPANY COMMITTED TO UNEARTHING SOLUTIONS FOR THE PETROLEUM AND UTILITIES INDUSTRIES. IN ORDER TO DO THIS, THE COMPANY HAS DEVELOPED THE BADGER DAYLIGHTING SYSTEM, A PROPRIETARY HYDROVAC SYSTEM DESIGNED TO MINIMIZE THE DIFFICULTIES ASSOCIATED WITH EXPOSING UNDERGROUND PIPELINES, UTILITIES AND OTHER BURIED INFRASTRUCTURE. BADGER ALSO OFFERS RELATED SERVICES THROUGH SEVERAL OTHER DIVISIONS. THE DELTA OILFIELD CONSTRUCTION DIVISION PROVIDES SMALL INCH PIPELINE CONSTRUCTION SERVICES; THE NEWLY FORMED BADGER SUBSURFACE TECHNOLOGY DIVISION DEALS WITH PIPELINE INTEGRITY AND REPAIR; THE HEWLETT SHORING SYSTEMS DIVISION DESIGNS, MANUFACTURES AND RENTS EXCAVATION SHORING SYSTEMS AND BOMEGA MANUFACTURING DIVISION PRODUCES AND MARKETS A WIDE VARIETY OF LIGHT AND HEAVY INDUSTRIAL EQUIPMENT FOR THE OIL AND GAS, UTILITIES AND CONSTRUCTION INDUSTRIES WITHIN NORTH AMERICA AND INTERNATIONALLY. IN KEEPING WITH ITS NAMESAKE, BADGER HAS ALSO COMMITTED TO HELP PRESERVE THE BADGER’S HABITAT BY MAKING A DONATION TO THE CANADIAN PARKS AND WILDERNESS SOCIETY. CONTENTS 1 Highlights 2 President’s Message 5 Review of Operations 7 Management’s Discussion and Analysis 10 Financial Statements 17 Corporate Information • January 7, 1997: 3.6 million special warrants were issued at $2.10 per special warrant. These special warrants were exchanged for common shares effective March 31, 1997. Gross proceeds from the offering were $7.6 million ($7.0 million net). • January 15, 1997: Hewlett Shoring Systems Ltd. was acquired for $1.0 million. Consideration for this transaction comprised of $800,000 cash and 80,000 special warrants. The special warrants have been converted into common shares. h i g h l i g h t s 1997 HIGHLIGHTS • June 5, 1997: The Company began trading on the Toronto Stock Exchange under the symbol “BAD.” • November 1, 1997: The Company acquired the assets of Delta Oilfield Construction for $20 million. Consideration for this transaction was comprised of $10 million cash and 2 million shares, issued at $5.00 per share. • November 30, 1997: 22 Badger hydrovac units were constructed, bringing the total number of units in operation to 42. • The Company’s earnings per share have grown consistently over time. Earnings per share were as follows: $0.05/share in 1995, $0.10/share in 1996 and $0.17/share in 1997. • The acquisition of the assets of Delta Oilfield Construction, combined with the licensing of Baseline Technologies Pipeline Information Control (PIC) system, positions the Company to enter the pipeline construction, integrity and repair business. • Badger entered into a commercial lending facility with the Company’s bank on December 17th, 1997.Total credit available from the bank is $26.8 million. • Badger consolidated its operations under one Company-owned facility, located at 6740 – 65 Avenue, Red Deer, Alberta. FINANCIAL RESULTS Years ended November 30, ($ thousands, except per share information) Revenue Net Income Earnings per share basic fully diluted Cash flow per share basic fully diluted Cash flow from Operations Long term debt Shareholders equity 1997 26,067 2,155 1996 5,249 558 1995 2,803 173 1994 1,896 (130) $0.17 $0.10 $0.05 ($0.04) $0.17 $0.10 $0.05 ($0.04) $0.42 $0.39 5,368 12,907 25,541 $0.20 $0.18 1,158 795 5,871 – – 491 1,042 521 – – 145 1,177 248 FINANCIAL SUMMARY Shares Outstanding: 13,428,233 Fully Diluted Shares: Fiscal Year End: 52-week High/Low: EPS Fiscal 1996: Fiscal 1997: 16,155,065 November 30 $7.00/ $2.70 $0.10 $0.17 1 m e s s a g e p r e s i d e n t ’ s PRESIDENT’S MESSAGE In 1997 Badger moved to the Toronto Stock Exchange. It recent years. As new infrastructure is put in place and exist- was a big step for the Company and I take the account- ing infrastructure ages, Badger will be there to “unearth ability that goes along with being a public company seri- solutions for industry”. ously. The financial picture for Badger was very much on track for 1997. Return on average equity (pre-Delta) was 20% for the year. Gross margin and net margins for this The following are key indicators for Badger’s continued success: past year were 27% and 8% respectively. Net income grew by 286% in 1997 resulting in $.17 basic earnings per 1. Record activity levels in the oil and gas industry have share compared to $.10 the prior year. Badger continues to resulted in a demand for construction of new infrastruc- grow and grow very profitably. ture and the repair and upgrade of existing facilities. Badger benefits from these activities in two ways. In last year’s annual report, our direction for 1997 i. When new infrastructure is put in place, opportu- was clearly articulated.The goals and plans were very aggres- nities exist for the Daylighting, Delta, Hewlett and sive, but were the catalyst for another exceptional year. In Bomega divisions. many cases we surpassed these goals and in one we elected to ii. As infrastructure ages and requires maintenance, take time to re-evaluate our target. In last years message the upgrade or replacement, the Daylighting, stated goal was production of 20 additional Badger hydrovac Subsurface Technologies and Delta divisions are units. Badger produced 22 units in 1997. These additional positioned to provide the required service. units have been put to work in existing operating areas as well 2. Expansion into the large Ontario market has diversified as four new geographical areas in Western Canada (as Badger both geographically and into the utilities and planned) and in Ontario. The intended expansion into the construction industries. United States has been deferred until 1998.The decision was made to expand the Western Canadian market and carefully 3. Planned expansion into the United States will further diversify Badger geographically. grow into the Ontario market, which now has four units. The lessons learned in the expansion into the utility based Ontario Badger’s services continue to gain acceptance in the oil and market will serve as a model as we expand into the United gas and utilities industries.To meet increasing demands from States and other international markets. existing and new customers, the Daylighting Division will add 24 hydrovac units in 1998. Badger Subsurface Technology Integration of the two acquisitions made in 1996, Hewlett plans to move from start-up and development into the Shoring Systems and Bomega Manufacturing, has been com- growth phase. Delta Oilfield will continue its historic growth pleted. Badger’s newly constructed head office and manufac- rate and will assist in the Company’s move into pipeline turing facility in Red Deer, Alberta now houses Badger integrity and repair work. Bomega Manufacturing will meet Daylighting, Badger Subsurface Technology, and Bomega the fabrication needs of the Daylighting Division as well as Manufacturing (Sales & Service) divisions. All accounting servicing our retail equipment customers. and administration is run from the Red Deer office. 1997 has been a great year for the Company. It is the efforts Delta Oilfield Construction was acquired effective of our people that have led to this success and I would like November 1, 1997, and will continue to be based in Sylvan to thank all involved for their efforts. Please join Badger’s Lake, Alberta. Hewlett Shoring Systems Ltd. continues to Board of Directors and Officers for the Annual Shareholders be headquartered in Surrey, British Columbia. Meeting, April 16, 1998 in Red Deer. LOOKING AHEAD 2 Badger is extremely well positioned to take advantage of the Kenneth C. Rose, record activity levels in the oil & gas industry experienced in President & Chief Executive Officer “BADGER IS EXTREMELY WELL POSITIONED TO TAKE ADVANTAGE OF THE RECORD ACTIVITY LEVELS IN THE OIL AND GAS INDUSTRY EXPERIENCED IN RECENT YEARS.” GARY LAYDEN, V.P. MANUFACTURING, BRIAN ANDERSON, V.P. CORPORATE DEVELOPMENT, MERVIN FALKENBERG, V.P. FINANCE AND C.F.O., KEN ROSE, PRESIDENT AND C.E.O 1997 has been a year of expansion and integration. Badger This permits accurate identification of the depth and orien- has grown both internally and through acquisition. tation of the infrastructure so that repairs or modifications achieved and will continue to be operations and the sharing of resources. The Company has been positioned to take advantage of and grow with the construction associated with the anticipated additions to oil and gas production in the coming years. Badger will THE COMPANY HAS BEEN POSITIONED TO TAKE ADVANTAGE OF units are mobile hydrovac excavating systems that use either hot or cold water under high AND GROW WITH THE CONSTRUC- pressure to agitate the soil cover. TION ASSOCIATED WITH THE THE The resulting slurry is then ANTICIPATED ADDITIONS TO THE OIL AND GAS INDUSTRY IN THE COMING YEARS. sucked up by a powerful vacuum system leaving a clean hole and a clear view of the buried structure. For 1997 the Daylighting also be well positioned to provide division achieved an equipment ongoing repair and maintenance utilization rate of 73% while to the existing and aging pipeline infrastructure. o p e r a t i o n s realized through the combining of can be completed. The “Badger” o f Economies of scale have been r e v i e w REVIEW OF OPERATIONS performing general trenching, daylighting and specialized excavation services. Badger Daylighting Inc.’s operations have been organized within three operating divisions: The operations of the Manufacturing Divisions of Bomega and Badger were consolidated into one 55,000 square foot 1. Daylighting will include the operations of the Badger Daylighting Division and Badger Line Locating. facility in Red Deer, Alberta. Badger’s goal of manufacturing 20 hydrovac units was surpassed with 22 units being produced, an increase of 12 units over 1996. Bomega’s 2. Manufacturing will include the operations of Bomega for equipment sales, parts and service. total number of custom designed and manufactured units fabricated in 1997 was 115, up from 104 in 1996. This increased production resulted from the consolidation of the 3. Construction will include the operations of Delta manufacturing operations. The economies of scale realized Oilfield Construction, Hewlett Shoring and Badger were clearly demonstrated with the man-hours to construct Subsurface Technologies. a Badger unit reduced by half. The Badger Daylighting Division provides services to the utility The Construction Division has been formed as a result of the and petroleum sectors. “Daylighting” refers to the process of acquisition of Delta Oilfield Construction, Hewlett Shoring exposing pipelines, utility lines or other buried infrastructures. Systems and the licensing of Baseline Technologies Inc.’s DELTA OILFIELD CONSTRUCTION DIVISION 5 o p e r a t i o n s o f r e v i e w PIC system. This Division will service the pipeline industry accuracy on a buried pipeline through utilization of the PIC by providing construction of new pipelines, as well as integri- system. The excavation in preparation for the repair of the ty repairs and upgrades of existing pipelines.The services of pipeline will be completed by a Badger unit and shoring will shoring and the application of the PIC System will be offered through Badger Subsurface Technologies. be installed to secure the walls of BADGER SUBSURFACE TECHNOLOGIES IS OUR NEWEST the excavated site. This combination results in a safe, cost effective access to the pipeline with minimal Delta was acquired effective DIVISION WHICH BEST EXEM- environmental impact. Inspection November 1, 1997 thus one PLIFIES THE INTEGRATION OF of the pipeline will be provided by month of operations was included for fiscal 1997. Delta constructs OUR OPERATIONS TO PROVIDE a third party and repair or replacement of the damaged piece pipelines and related facilities A FULL SUITE OF SERVICES TO of the pipeline will be performed throughout western Canada. OUR CUSTOMERS. utilizing equipment and personnel from Delta. Badger Subsurface Technologies will be providing turnkey services for pipeline integrity Badger Subsurface Technologies is our newest division and and repair work. The suite of services offered by BST exemplifies the integration of our operations to provide a full begins with the pinpointing of an anomaly to sub meter suite of services to our customers. BADGER’S NEW 55,000 SQ. FT. MANUFACTURING FACILITY IN RED DEER, ALBERTA 6 Discussion and analysis of Badger Daylighting Inc. includes million in 1996 to $7.5 million in 1997. The remaining the assets and operations purchased from Bomega Metals increase is due to the acquisitions made during 1997. Ltd., Delta Energy Ltd. and Hewlett Shoring Services Ltd. Effective December 1, 1998, Hewlett will be amalgamated Direct Costs by Division: into Badger Daylighting Inc., and the Company will report financial results under three Divisions as follows: 1996 Daylighting $7,508,418 $3,370,802 Manufacturing $8,097,232 - Construction $3,526,435 - Total Directs Costs $19,132,085 $3,370,802 2. Manufacturing—includes the Bomega division’s operations Operating Margin increased to $7.0 million from $1.9 million 3. Construction—includes the Delta division’s operations and those of Hewlett Shoring Services Ltd. in 1996 due to the increased activity and acquisitions. The d i s c u s s i o n 1. Daylighting—includes the Daylighting division’s operations 1997 m a n a g e m e n t ’ s MANAGEMENT’S DISCUSSION & ANALYSIS operating margin percentage has decreased slightly due to the Revenues increased to $26.1 million in 1997 from $5.2 Operating Margin by Division: million in 1996, a five fold increase.The increase is a result 1997 1996 of increased activity in Badger’s business of Daylighting to Daylighting $5,173,925 40.8% $1,877,962 35.8% $12.7 million in 1997 from $5.2 million in 1996. The Manufacturing $1,164,410 12.6% - - remaining increase is attributable to acquisitions made dur- Construction - - ing 1997. Total Operating Margin $6,934,739 26.6% $1,877,962 35.8% $596,404 14.5% a n a l y s i s REVENUES & lower percentage margins on the expanded business activity. Revenues by Division: Daylighting Manufacturing Construction EXPENSES 1997 1996 $12,682,343 $5,248,764 $9,261,642 - due to the Daylighting units at the end of 1996 now attract- $4,122,839 - ing a full year’s depreciation and the additional units added $26,066,824 $5,248,764 during 1997 being depreciated from the month they were The Company’s depreciation has increased by $1.2 million put into service. The Manufacturing and Construction Total Revenue assets were depreciated from the month of acquisition. Daylighting operated for the full 12 month period and reflects the activity of the 20 units operating at the start of a) Depreciation the year and the addition of 22 units through the year. Daylighting Manufacturing includes Bomega for the full 12-month period. Construction included Hewlett for 11 months and Delta for 1997 1996 $1,026,945 $457,214 Manufacturing $386,704 - Construction $268,094 - Total Depreciation $1,681,743 $457,214 one month. b) Interest DIRECT COSTS AND OPERATING MARGIN The Company’s interest expense decreased by 4% due to Direct costs increased from $3.4 million in 1996 to $19.1 mil- debt being restructured and decreased during the year. lion in 1997, a five fold increase. This is due to the increased activity in Badger’s base business of Daylighting from $3.4 7 a n a l y s i s & d i s c u s s i o n m a n a g e m e n t ’ s c) General & Administrative assist in the financing of the construction of 13 Badger The Company’s general and administrative expense Hydrovac units is also in place. increased from $0.6 million in 1996 to $1.4 million in 1997. This increase is a result of the Company’s expansion Subsequent to November 30, 1997, the Company has and acquisitions. Selling efforts were expanded into Ontario arranged a credit facility in the form of a Canadian bank and British Columbia during 1997. General and adminis- revolving operating loan of up to $10 million subject to mar- trative expense increased as a result of additional staff and gin requirements. This credit facility replaced the Canadian expenses related to the growth of the Company. As a per- bank revolving operating loan of $2.5 million in place at centage of revenue these expenses are 5.4% in 1997 com- November 30, 1997. The Company also has arranged a pared to 11.8% in 1996. credit facility in the form of a Canadian bank non-revolving term loan in the amount of $10 million to finance the acqui- d) Income Taxes sition of the assets of Delta Oilfield Construction. The Company had an effective tax rate of 20.3% for the year 1996. Interest on the Company’s bank debt ranges from the bank’s prime rate plus 0.5 percent to the prime rate plus For the year 1997, this increased to 42.7%. This increase 1.0 percent. At November 30, 1997, the interest rate range is due to a large corporation tax expense of $75,000 was 4.5% to 5.0%. (2.0%) and increased income from operations not eligible for the manufacturing processing deduction. BUSINESS RISKS & UNCERTAINTY The Company’s revenues continue to be sourced from cus- NET INCOME AND CASH FLOW FROM OPERATIONS tomers in the oil and gas, utilities, and construction indus- Net income and operating cash flow increased substantial- tries for new infrastructure projects and repair and main- ly during 1997 due to the increased business activity and tenance of existing infrastructure. The oil and gas industry the profitability of our acquisitions. Net income increased is subject to seasonal and industry cycles and fluctuations. to $2.2 million in 1997 from $0.6 million in 1996 while It is the Company’s intentions to continue to develop the operating cash flow increased to $5.4 million in 1997 from utilities and construction industry customer base to mini- $1.2 million in 1996. mize the impact of the oil and gas industry cycles. In order to do this, the Company’s services have been extended to LIQUIDITY AND CAPITAL RESOURCES Vancouver and Toronto during 1997. Plans are in place to At November 30, 1997, the credit facility available to the expand these operations in 1998 and to extend the Company and its subsidiaries included a Canadian bank Company’s services to other urban centres. revolving operating loan of up to $2.5 million, subject to 8 margin requirements. A non-revolving demand loan facility SUBSEQUENT EVENTS was also in place for up to $1.75 million to assist in the In the month of December 1997, the Company entered into financing of the construction costs associated with a new an exclusive licensing agreement with Baseline Technologies shop and office addition, all located at the Company’s Inc. to use Baseline’s Pipeline Information Control System premises at Red Deer, Alberta. At November 30, 1997, the (PIC System) for Canada, with an option on North America Company had drawn on $621,464 of this facility. It is the and a further option on the World. These options are exer- Company’s intention to replace this loan with a commercial cisable during 1998 and 1999 respectively. This license will mortgage upon completion of the construction. A non- enable the Company to provide a fully integrated service to revolving demand loan facility of up to $3.0 million to the pipeline and utility industries. REVENUE GROWTH Revenue $30,000,000 $25,000,000 $20,000,000 $15,000,000 $10,000,000 $5,000,000 $0.00 1995 1996 1997 NET INCOME GROWTH $2,500,000 Net Income $2,000,000 $1,500,000 $1,000,000 $500,000 $0.00 1995 1996 1997 G&A AS % OF REVENUE 20% % Revenue 15% 10% 5% 0% 1995 1996 1997 EARNINGS/SHARE GROWTH Basic $0.20 Fully Diluted $0.15 $0.10 $0.05 $0.00 1995 1996 1997 s t a t e m e n t s f i n a n c i a l MANAGEMENT’S STATEMENT OF RESPONSIBILITY The accompanying financial statements of Badger reporting and is ultimately responsible for reviewing and Daylighting Inc. have been prepared by management in approving the financial statements. The Board carries out accordance this responsibility principally through its Audit Committee. with generally accepted accounting principles.The financial information contained elsewhere in this report has been reviewed to ensure consistency with the financial statements. The Audit Committee of the Board of Directors and the President of the Company have reviewed the financial statements with management and the external auditors. Management maintains systems of internal accounting Ernst & Young, an independent firm of chartered control designed to provide reasonable assurance that the accountants, appointed as external auditors by the assets are safeguarded, all transactions are authorized shareholders, have audited the financial statements and and duly recorded and financial records are properly their report is included herein. maintained to facilitate statements in a timely manner. The Board of Directors is responsible for ensuring that Kenneth C. Rose, management fulfills its responsibilities for financial President and Chief Executive Officer AUDITORS’ REPORT November 30, 1997 and 1996 To the Shareholders of Badger Daylighting Inc. assessing the accounting principles used and significant estimates made by management, as well as evaluating We have audited the consolidated balance sheets of the overall financial statement presentation. Badger Daylighting Inc. as at November 30, 1997 and 1996 and the consolidated statements of income and In our opinion, these financial statements present fairly, retained earnings and changes in financial position for in all material respects, the financial position of the the years then ended. These financial statements are the Company as at November 30, 1997 and 1996 and the responsibility of the Company’s management. Our results of its operations and the changes in its financial responsibility is to express an opinion on these financial position for the years then ended in accordance with gen- statements based on our audits. erally accepted accounting principles. We conducted our audits in accordance with generally Calgary, Canada accepted auditing standards. Those standards require January 16, 1998 that we plan and perform an audit to obtain reasonable assurance whether the financial statements are free of material misstatement. An audit includes examining, on a test basis, evidence supporting the amounts and disclosures in the financial statements. An audit also includes 10 Chartered Accountants As at November 30 1997 $ Capital assets [note 6] Goodwill [note 3] LIABILITIES AND SHAREHOLDERS’ EQUITY Current Bank indebtedness [note 7] Accounts payable and accrued liabilities [note 13] Large corporations tax payable Payable on acquisition [note 4] Current portion of long term debt [note 8] Current portion of deferred revenue Long term debt [note 8] Payable on acquisition [note 4] Deferred income taxes Deferred revenue Commitments [note 12] Shareholders’ equity Shares issued and outstanding [note 9] Shares to be issued [note 4] Retained earnings 320,557 9,078,865 2,080,799 53,142 11,533,363 32,010,655 8,165,405 51,709,423 278,163 2,411,876 658,175 6,759 3,354,973 6,408,157 4,988,049 14,751,179 2,591,547 7,873,619 75,000 — 1,156,263 100,563 11,796,992 2,906,607 10,000,000 1,394,393 70,518 214,024 1,730,644 — 5,630,338 381,089 227,496 8,183,591 414,136 — 74,289 208,069 12,817,726 10,000,000 2,723,187 25,540,913 51,709,423 2,802,630 2,500,000 568,464 5,871,094 14,751,179 s t a t e m e n t s ASSETS [notes 7 and 8] Current Cash Accounts receivable Inventories [note 5] Prepaid expenses 1996 $ f i n a n c i a l CONSOLIDATED BALANCE SHEETS See accompanying notes On Behalf of the board: Ken Rose Martin Margolis CONSOLIDATED STATEMENTS OF INCOME AND RETAINED EARNINGS For the years ended November 30 1997 $ Revenues [note 13] Daylighting Manufacturing Construction Direct costs Daylighting Manufacturing Construction Expenses Depreciation and amortization Interest on long-term debt General and administrative [note 13] Income before income taxes Income taxes [note 11] Large corporation tax Deferred Net income for the year Retained earnings, beginning of year Retained earnings, end of year Net income per share [note 10] Basic Fully diluted 1996 $ 12,682,343 9,261,642 4,122,839 26,066,824 5,248,764 — — 5,248,764 7,508,418 8,097,232 3,526,435 19,132,085 6,934,739 3,370,802 — — 3,370,802 1,877,962 1,681,743 95,083 1,397,190 3,174,016 3,760,723 457,214 98,603 621,668 1,177,485 700,477 75,000 1,531,000 1,606,000 2,154,723 568,464 2,723,187 — 142,289 142,289 558,188 10,276 568,464 0.17 0.17 0.10 0.10 See accompanying notes 11 s t a t e m e n t s f i n a n c i a l CONSOLIDATED STATEMENTS OF CHANGES IN FINANCIAL POSITION For the years ended November 30 1997 $ OPERATING ACTIVITIES Operations Net income for the year Add items not affecting cash: Depreciation and amortization Deferred income taxes Loss on disposal of capital assets Funds flow from operations Net change in non-cash working capital related to operating activities FINANCING ACTIVITIES Shares issued, net of share issue costs Common shares to be issued [note 4] Repayment of long term debt Proceeds from long term debt Payable on acquisition [note 4] Deferred revenue INVESTING ACTIVITIES Purchase of capital assets Proceeds on disposal of capital assets Acquisitions [note 4] Net change in non-cash working capital related to investing activities (Decrease) increase in cash and cash equivalents during the year Cash and cash equivalents, beginning of year Cash and cash equivalents, end of year Cash and cash equivalents is comprised of Cash Bank indebtedness Funds flow from operations per share [note 10] Basic Fully diluted 1996 $ 2,154,723 558,188 1,681,743 1,531,000 1,158 5,368,624 (1,619,800) 3,748,824 457,214 142,289 — 1,157,691 (987,844) 169,847 7,247,096 10,000,000 (395,290) 3,654,616 4,369,662 (264,484) 24,611,600 2,223,210 2,500,000 (246,287) — 5,630,338 212,345 10,319,606 (9,636,730) 187,355 (21,020,335) (225,843) (30,695,553) (2,335,129) 64,139 (2,270,990) (2,833,316) 70,375 (8,130,338) 506,851 (10,386,428) 103,025 (38,886) 64,139 320,557 (2,591,547) (2,270,990) 278,163 (214,024) 64,139 0.42 0.39 0.20 0.18 See accompanying notes NOTES TO CONSOLIDATED FINANCIAL STATEMENTS November 30, 1997 and 1996 1. NATURE OF BUSINESS The Company is a public company incorporated under the laws of the province of Alberta, which operates as a service company in the petroleum and utility industries. The Company manufactures hydo-vacuum trucks (the “Badger”) which have been designed to reduce the inherent difficulties and dangers involved with exposing underground pipelines and utilities. The capabilities of the Badger include daylighting, which is the exposing of live utility and pipelines by digging and excavating around them. The Company also provides construction shoring and pipeline construction services. 2. SUMMARY OF SIGNIFICANT ACCOUNTING POLICIES These consolidated financial statements have been prepared in accordance with generally accepted accounting principles. Because a precise determination of many assets and liabilities is dependent upon future events, the preparation of financial statements necessarily involves the use of estimates and approximations which have been made using careful judgment. The consolidated financial statements have, in management’s opinion, been properly prepared within reasonable limits of materiality and within the framework of the accounting policies summarized below: Consolidation The consolidated financial statements include the accounts of the Company and its wholly-owned subsidiary, Hewlett Shoring Systems Ltd. Inventories Materials are valued at the lower of cost (weighted average) and net realizable value. Work-in-progress is valued at the lower of cost and replacement cost. Capital Assets Capital assets are recorded at cost. Depreciation is provided on a straight line basis over the estimated useful life of the assets.The annual rates of depreciation are as follows: 12 f i n a n c i a l NOTES TO CONSOLIDATED FINANCIAL STATEMENTS (CONT.) 10% 5% 10% 10% 10% 15% 20% 15% 25% Depreciation of equipment under construction is not recorded until such time as the construction is completed and the assets have been put to use. Marketing Agreements Revenue Recognition The Company has entered into revenue sharing contracts with operators of the hydro-vacuum trucks. The terms of the contract require an initial payment by the operators to the Company. The Company has the right to terminate the contract during the first three years. If that right is exercised, a prorata share of the payment must be repaid to the operator. The initial payments are recorded as deferred revenue and are recognized as contract revenue over the first three years of the contracts. s t a t e m e n t s Land improvements Buildings Shoring equipment Small tools Shop and office equipment Trucks and trailers Leasehold improvements Automotive equipment Computers Construction Revenue Recognition Profits from construction contracts are recognized using the percentage of completion method. The percentage of completion is determined by relating the actual cost of work performed to date to the current estimated total cost of respective contracts. When the current estimated costs to complete indicate a loss, such a loss is recognized immediately. Revisions in costs and earnings or loss estimates during the course of the work are reflected during the accounting period in which the facts which cause the revision become known. The profits recorded for construction contracts are based on estimates. By their nature, these estimates are subject to measurement uncertainty and the effect on the financial statements of changes in such estimates in future years could be significant. Manufacturing Revenue Recognition The Company recognizes revenue for manufacturing using the completed contract method, whereby income is recognized when the contracts are completed or virtually completed. Goodwill Goodwill arising from the business acquisitions is being amortized on a straight line basis over twenty years commencing at the time of the acquisition. The evaluation for impairment of goodwill is based on a comparison of the carrying values of goodwill and associated operating assets to the future net cash flows. No writedown was required at November 30, 1997 and 1996. Financial Instruments Financial instruments of the Company consist mainly of accounts receivable, bank indebtedness, accounts payable and accrued liabilities, payable on acquisition and long term debt. Except where disclosed otherwise, as at November 30, 1997 and 1996, there are no significant differences between the carrying values of these amounts and their estimated market values. 3. GOODWILL 1997 $ 8,423,000 (257,595) 8,165,405 Cost Accumulated amortization 1996 $ 4,988,049 — 4,988,049 4. ACQUISITIONS a) Bomega Metals Ltd. Effective November 30, 1996, the Company purchased substantially all of the assets of Bomega Metals Ltd. ("Bomega"). Bomega’s principal business activities included the manufacturing and sale of hydro-vac, tank, vacuum and lubrication systems, asphalt silos and feed bins. The purchase was accounted for using the purchase method. The purchase price was allocated as follows: Working capital Capital assets Goodwill $ 852,289 2,290,000 4,988,049 8,130,338 Consideration consists of the following: Cash 1,515,000 common shares $ 5,630,338 2,500,000 8,130,338 b) Hewlett Shoring Systems Ltd. Effective January 15, 1997 the Company acquired 100% of the shares of Hewlett Shoring Systems Ltd. (“Hewlett”). Hewlett’s principal business activity is the rental of shoring equipment.The purchase was accounted for using the purchase method.The purchase price was allocated as follows: 13 s t a t e m e n t s f i n a n c i a l NOTES TO CONSOLIDATED FINANCIAL STATEMENTS (CONT.) Working capital deficiency Capital assets Deferred income taxes Long term debt $ (79,229) 1,164,987 (57,104) (8,319) 1,020,335 Consideration consists of the following: Cash 80,000 common shares $ 820,335 200,000 1,020,335 c) Delta Energy Ltd. Effective November 1, 1997, the Company purchased substantially all of the assets of Delta Oilfield Construction (“Delta”), a division of Delta Energy Ltd. Delta’s principal business activity is the construction of small diameter oil and gas pipelines. The purchase was accounted for using the purchase method. The purchase price was allocated as follows: Working capital Capital assets Goodwill $ 151,607 16,413,442 3,434,951 20,000,000 Consideration consists of the following: Payable on acquisition 2,000,000 common shares to be issued $ 10,000,000 10,000,000 20,000,000 The amount payable on acquisition was settled with a Bank of Montreal non-revolving term loan payable, repayable in monthly principal payments of $150,000, commencing October 1, 1998 until November 30, 2002, with the balance of principal outstanding retired on maturity of the term in the amount of $2,350,000. The loan bears interest at bank prime plus .625% [see note 8 for collateral]. 5. INVENTORIES 1997 $ 1,306,775 774,024 2,080,799 Materials Work-in-progress 1996 $ 541,349 116,826 658,175 6. CAPITAL ASSETS Land Land improvements Buildings Equipment under construction Shoring equipment Small tools Shop equipment Office equipment Trucks and trailers [see notes 7 and 8] Leasehold improvements Automotive equipment Computers Land Buildings Equipment under construction Small tools Shop equipment Office equipment Trucks and trailers [see notes 7 and 8] Leasehold improvements Automotive equipment Computers 14 Cost $ 1,200,836 366,643 4,275,890 395,196 1,511,224 502,186 1,349,370 308,139 24,018,786 44,182 100,975 152,211 34,225,638 1997 Accumulated Depreciation $ — 1,217 76,019 — 81,250 11,515 73,721 18,684 1,913,724 15,540 5,079 18,234 2,214,983 Net Book Value $ 1,200,836 365,426 4,199,871 395,196 1,429,974 490,671 1,275,649 289,455 22,105,062 28,642 95,896 133,977 32,010,655 Cost $ 600,000 1,200,000 389,646 17,530 405,567 117,211 4,358,473 42,685 40,000 75,000 7,246,112 1996 Accumulated Depreciation $ — — — 5,254 20,489 3,495 802,687 6,030 — — 837,955 Net Book Value $ 600,000 1,200,000 389,646 12,276 385,078 113,716 3,555,786 36,655 40,000 75,000 6,408,157 7. BANK INDEBTEDNESS A general assignment of accounts receivable and capital assets are pledged as collateral for the operating demand bank loans which bear interest at bank prime plus 1% (November 30, 1997 - 5%; November 30, 1996 - 4 3/4%) per annum. 8. LONG TERM DEBT 1997 $ 1996 $ 287,825 451,027 GE Capital Canada equipment loan payable, repayable in monthly principal and interest payments of $15,566 until July 26, 1998, bearing interest at bank prime plus 1 1/2% and collateralized by chattel mortgages on Badger units. 120,429 288,098 Bank of Nova Scotia small business loan payable, repayable in monthly principal payments of $2,125 plus interest until November 21, 1997, bearing interest at bank prime plus 1% and collateralized by a chattel mortgage on a Badger unit. — 25,500 Bank of Nova Scotia small business loan payable, repayable in monthly principal payments of $2,125 plus interest until July 21, 1997, bearing interest at bank prime plus 1% and collateralized by a chattel mortgage on a Badger unit. — 17,000 Bank of Nova Scotia small business loan payable, repayable in monthly principal payments of $1,700 plus interest until July 21, 1997, bearing interest at bank prime and collateralized by a chattel mortgage on a Badger unit. — 13,600 33,152 — 621,464 — 3,000,000 4,062,870 1,156,263 2,906,607 — 795,225 381,089 414,136 GMAC of Canada Limited truck loan payable, repayable in monthly principal and interest payments of $906 until February 10, 2001, bearing interest at 3.9% and collateralized by a truck. Bank of Montreal commercial mortgage on the land and building, repayable in monthly principal payments of $8,783 plus interest until November 30, 2003, bearing interest at bank prime plus 1% (November 30, 1997 - 5%). Bank of Montreal non-revolving demand loan payable, repayable in monthly principal payments of $62,500 until November 30, 2001, bearing interest at bank prime plus 1/2% (November 30, 1997 - 4 1/2%). Current portion of long term debt s t a t e m e n t s GE Capital Canada equipment loan payable, repayable in monthly principal and interest payments of $15,802 until August 24, 1999 bearing interest at 8.5% and collaterialized by chattel mortgages on Badger units. f i n a n c i a l NOTES TO CONSOLIDATED FINANCIAL STATEMENTS (CONT.) Principal repayments on the above loans in each of the next five years is as follows: 1998 1999 2000 2001 2002 Remainder $ 1,156,263 987,473 865,397 857,553 104,850 91,334 4,062,870 The Bank of Montreal mortgage and loans payable are collateralized by a general security interest over the Company’s assets, property and undertaking, present and future, which includes a fixed and floating charge debenture on all assets and undertaking of the Company and its subsidiaries in the amount of $30,000,000. 9. SHARE CAPITAL Authorized Unlimited number of common shares Unlimited number of preferred shares Number of Shares Amount $ Balance November 30, 1995 Initial public offering Private placement Exercise of options Share issue costs (net of deferred income taxes of $68,000) 4,000,733 2,000,000 1,733,333 227,500 — 511,420 1,000,000 1,300,000 113,750 (122,540) Balance November 30, 1996 Exercise of warrants Public offering Shares issued for acquisitions [note 4] Exercise of options Share issue costs (net of deferred income taxes of $268,000) 7,961,566 26,667 3,600,000 1,595,000 245,000 — 2,802,630 29,334 7,560,000 2,700,000 136,225 (410,463) Issued: Balance November 30, 1997 13,428,233 12,817,726 15 s t a t e m e n t s f i n a n c i a l NOTES TO CONSOLIDATED FINANCIAL STATEMENTS (CONT.) Pursuant to an offering memorandum dated September 18, 1996, the Company offered for sale 1,733,333 units at $0.75 per unit. Each unit consists of one common share and one common share purchase warrant. Each common share purchase warrant entitles the holder thereof to acquire one additional common share at a price of $1.10 per share prior to September 18, 1998. As of November 30, 1997, 1,706,666 common share purchase warrants are still outstanding. The Company has a adopted a stock option plan for directors, officers, employees and consultants. There were 1,020,166 options outstanding at November 30, 1997 at exercise prices from $0.50 to $3.25 and expiry dates from August 1, 2000 to May 5, 2002. The Company has reserved 2,828,155 shares for issuance under the stock option plan and for the warrants outstanding. 10. NET INCOME AND FUNDS FLOW FROM OPERATIONS PER SHARE Basic net income and funds flow from operations per share was calculated on the basis of the weighted average number of shares outstanding for the year of 12,775,241 (1996 - 5,864,555). Fully diluted net income and funds flow from operations per share reflect the dilutive effect of the exercise of the stock options and share purchase warrants outstanding as at November 30, 1997. The number of shares for the fully diluted calculation was 15,042,740 (1996 - 6,825,943). 11. INCOME TAXES The provision for income taxes recorded on the consolidated financial statements differs from the amount which would be obtained by applying the statutory income tax rate to income before income taxes as follows: 1997 $ 3,760,723 44.62% 1,678,035 (192,035) 75,000 45,000 — 1,606,000 Income before income taxes Statutory Canadian corporate tax rate Calculated expected income tax expense Benefit of manufacturing processing deduction Large corporations tax Non deductible expenses Application of loss carryforward 1996 $ 700,477 44.62% 312,553 (56,038) — 7,231 (121,457) 142,289 The Company has non-capital losses for income tax purposes of approximately $399,000 which are available for application against future taxable income and which expire as follows: $ 1999 21,000 2000 111,000 2001 176,000 2003 61,000 2004 30,000 12. COMMITMENTS The Company has the following annual commitments under operating leases for office equipment, office and shop rent and vehicles. $ 1,015,711 53,447 1,069,158 1998 1999 13. RELATED PARTY TRANSACTIONS The Company had business transactions with a number of entities subject to common management control as follows: Daylighting Direct Costs $ Professional Fees $ Amounts in Accounts Payable and Accrued Liabilities $ Year ended November 30, 1997 A Company owned 50% by a director of the Company A partner of a partnership who is a director of the Company 856,689 — — 134,206 106,752 12,377 Year ended November 30, 1996 A Company owned 50% by a director of the Company A Company owned 100% by a director of the Company A partner of a partnership who is a director of the Company 760,245 — — — 5,076 19,777 114,965 — — These transactions have been recorded at their fair market value amounts in the normal course of operations. 14. COMPARATIVE FIGURES Certain of the comparative figures have been reclassified to conform with the current year’s financial statement presentation. 16 CORPORATE INFORMATION DIRECTORS David Calnan, LL.B Partner, Shea Nerland Calnan Martin Margolis, CA Chartered Accountant William R. McMahan B.A., MSc. President & C.E.O Oxbow Capital Corporation Ken Rose , P.Eng. President & C.E.O Badger Daylighting Inc. Gary Layden Vice President, Manufacturing Badger Daylighting Inc. AUDITORS Ernst & Young Chartered Accountants Calgary AB SOLICITORS Shea Nerland Calnan Calgary AB STOCK EXCHANGE LISTING Toronto Stock Exchange Trading Symbol “BAD” OFFICERS AND MANAGEMENT Ken Rose P.Eng. President & C.E.O. Brian Anderson, CA Vice President, Corporate Development Gary Layden Vice President, Manufacturing Mervin H. Falkenberg, CMA Vice President Finance & C.F.O. BANKERS Bank of Montreal Red Deer AB REGISTER AND TRANSFER AGENT Montreal Trust Company Calgary AB NOTICE OF ANNUAL GENERAL MEETING The Annual General Meeting of the Shareholders of Badger Daylighting Inc. will be held at 3:00 p.m. on Thursday April 16, 1998 at the Capri Hotel, Red Deer, Alberta. Shareholders unable to attend are encouraged to complete and return the accompanying proxy. HEAD OFFICE 6740 - 65 Ave. Red Deer, Alberta, Canada T4P 1A5 Tel: (403) 343-0303 Fax (403) 343-0401