4 Failure Analysis of Semiconductor Devices

advertisement

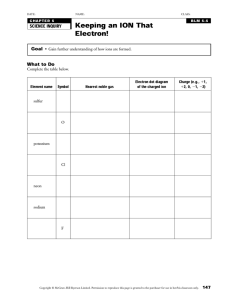

4 Failure Analysis of Semiconductor Devices Contents i 4.1 Importance of Failure Analysis 4- 1 4.2 Procedures for Failure Analysis 4- 1 4.2.1 Confirmation of information on failure 4- 4 4.2.2 External observation 4- 4 4.2.3 Confirmation of characteristic analysis/ failure mode 4- 4 4.2.4 Nondestructive analysis 4- 5 4.2.5 Unsealing 4- 7 4.2.6 Internal observation and measurement 4- 8 4.2.7 Search for failure locations 4-11 4.2.8 Processing technology for analyses 4-15 4.2.9 Surface microanalysis 4-17 4 4. Failure Analysis of Semiconductor Devices Failure Analysis of Semiconductor Devices 4.1 Importance of Failure Analysis Failure analysis is the process of investigating semiconductor devices after failure by electric measurement, and by physical and chemical analysis techniques if necessary, to confirm the reported failure and clarify the failure mode or mechanism. Progress of semiconductor devices has rapidly accelerated toward high integration, high density and high functionality. In addition, use applications are widely penetrated into various civil and industrial fields. Our company tries to consider high reliability through the design, development and manufacturing processes of semiconductor devices with the goal of “zero failures” and to provide those products to customers. However, it is impossible to eliminate all failures. So, our company analyzes failures occurring during the manufacturing process, reliability test, mounting process at the customer’s site and in the market (field), investigates the failure mechanism and cause thoroughly, and feeds them back to each department in charge to prevent a failure from recurring. 4.2 Procedures for Failure Analysis Figure 4.1 and Table 4.1 respectively show the procedures for failure analysis and an example of devices to be used. When conducting failure analysis, it is recommended to adopt unified procedures, and it is important to promote failure analysis so as to obtain information required to determine the failure mechanism. T04007BE-4 2009.4 4-1 4 Failure Analysis of Semiconductor Devices Arising failure Source origin Confirmation of failure information Product class name Manufacturing code Status of use Symptom of failure Discoloration/deformation Attachment of foreign substances Crack External observation Check according to product specifications Operation according to application circuits V-I between terminals Vibration Heating Cooling Condition change of characteristic operation Damaged circuit analysis Characteristic analysis Baking X-ray fluoroscopy Ultrasonic flaw detection analysis Nondestructive analysis Mechanical unsealing Chemical solution Plasma etching Unsealing Probe static characteristic measurement Probe dynamic characteristic measurement Confirmation of symptoms Microscopic observation Photomicrography Cross-section photograph Video monitor Liquid crystal analysis Microscopic observation SEM analysis Probe determination Secondary electron image Reflection electron image Voltage contrast image Electromotive force image EB tester Etching/lapping Detailed chemical physical analysis EPMA SIMS AES Analysis result Feedback Figure 4.1 T04007BE-4 2009.4 4-2 Reliability test Process Burn-in Market Procedures of failure analysis 4 Table 4.1 Failure Analysis of Semiconductor Devices Examples of main equipment used for failure analysis Purpose Observation Electrical characteristic measurement Elemental analysis Equipment Stereoscopic microscope Metallographic microscope Infrared microscope Ultrasonic microscope X-ray fluoroscope Ultrasonic flaw detection equipment Liquid crystal analysis equipment Emission microscopic analysis equipment Photographic projection equipment Scanning electron microscope (SEM) Transmission electron microscope (TEM) OBIC/OBIRCH equipment Curve tracer Transistor tester/IC tester LSI tester/memory tester EB tester Oscilloscope Pulse oscillator Ammeter/voltmeter Noise meter Laser tester CV meter LCR meter Manipulator SR tester Electron probe micro analyzer (EPMA) X-ray fluorescence spectrometer Auger electron spectroscopy (AES) Ion micro analyzer (IMA) Electron beam diffraction analyzer X-ray diffraction analyzer Electron spectroscopy analyzer (ESCA) Infrared absorption spectrometer Emission spectrophotometer Atomic absorption spectrometer Ion chromatography equipment Gas chromatography equipment Mass spectrometer Sample preparation Cutting machine/Grinding equipment Sample packing device Package unsealing equipment Plasma etcher Deposition equipment Draft (discharge air/wastewater) Etching liquid Clean bench Ultrasonic disc cutter Laser cutter FIB Thickness/shape measurement NanoSpec (trade name) Ellipsometer Talystep (trade name) Tunneling microscope T04007BE-4 2009.4 4-3 4 Failure Analysis of Semiconductor Devices 4.2.1 Confirmation of information on failure When obtaining the device to be analyzed and to analyze the failure, it is necessary to confirm the following items. Product class name, manufacturer name, product specification, serial number (manufacturing time) Delivery time, contents of receiving inspection, implementation time Implemented device, implementation condition, circuit, device position in the circuit Failure occurrence status (use environment, use conditions, period of use, failure occurrence time) Failure mode (any of complete failure, gradual failure and intermittent failure; electric characteristic, failure rate) Route and period from failure occurrence to obtainment of failed products By studying the above information well, the contents of failure and the failure mechanism can be estimated to some extent and concrete procedures of later failure analyses can be determined. The number of the failed devices is usually small and there are many cases with only one. Mistakes in analysis procedures may lead to not only the destruction of samples but also an unknown cause of failure. Before starting failure analyses, it is vital to gather and confirm information well. During analyses, it is important to prepare non-defective products and carry on the analysis while comparing with them. 4.2.2 External observation The failure analysis begins with observing the failed devices well and confirming the failure mode. Stereoscopic microscopes (with 5 to 100 times power) are the most suitable for the external observation. Pay attention to the appearance of encapsulation resin (discoloration, attachment of foreign substances, crack) and the appearance of leads (plating, soldering, migration, whisker, fracture). If necessary, observe with higher-power optical microscopes or scanning electron microscopes. If there is a foreign substance, identify the element using the surface micro-analyzer described later. If the existence of a crack is suspected, detect the position and the size using ultrasonic flaw detection equipment (SAT analysis). 4.2.3 Confirmation of characteristic analysis/failure mode After the external observation, confirm the failure mode. Check the operating conditions of circuits using curve tracers, oscilloscopes or LSI testers or the like, and compare them with the characteristics of product specifications and non-defective products. If the failure does not reappear, measure at high temperature or after vibration tests. If the failure is not found, it may not be caused by the device itself, so it is necessary to study the occurrence status again. T04007BE-4 2009.4 4-4 4 4.2.4 Failure Analysis of Semiconductor Devices Nondestructive analysis a) X-ray fluoroscopy This is the method to observe the internal state nondestructively without unsealing the package of the device. As the transmission rate of X-rays differs according to the quality of materials or the thickness, the internal structure is obtained as a contrast image of the X-ray. Aluminum (Al), silicon (Si) and the like with light atomic weight have a high transmission rate and are difficult to identify, but gold (Au), cupper (Cu), iron (Fe), solder (Sn, Bi, Ag, Pd) and the like have a low transmission rate, so the state can be identified easily. The state of bonding wires (wire breakage, short-circuit, wire flow), the state of die bond (spread/void), voids and the like in the encapsulation resin can be confirmed (Figure 4.2 and Figure 4.3). Recently there is equipment with small X-ray focus (1 μm to 10 μm) and it is applied to the analysis of compact packages such as CSP (chip size package) or TCP (tape carrier package). Au bump Places short-circuited by the attachment of foreign Figure 4.2 Case example of X-ray analysis of wire flow Figure 4.3 Case example of X-ray analysis of short-circuit between CSP bumps T04007BE-4 2009.4 4-5 4 Failure Analysis of Semiconductor Devices b) Ultrasonic flaw detection analysis (SAT analysis) Formerly, when analyzing the interfacial delamination between a package crack or Si chip or a die pad (lead frame) and encapsulation resin, the method of cutting the package and grinding the cross section (destructive analysis) was employed. There are some problems in this method, such as inefficiency (working hours, number of processed pieces), difficulty in positioning analysis places and the occurrence of troubles (delamination, crack). These arise from the analysis being made by destroying the package. On the other hand, SAT (scanning acoustic tomograph) is a method of analyzing using ultrasonic waves without destroying the package. The ultrasonic wave transmitting medium is partially reflected and partially transmissive if there is any interface with a different medium (Snell’s law). If ultrasonic waves are projected from the surface of the package, the ultrasonic waves transmit resin, reach the surface of Si chip and at the interface reflected waves and transparent waves are generated (Figure 4.4). Therefore, the defects and the structure inside the package can be analyzed two-dimensionally by receiving the reflected waves moving (scanning) a lens tube (transducer) discharging ultrasonic waves and by performing image processing (tone indication) of the characteristics (mainly the intensity of reflected wave) (Figure 4.5). For example, if the delamination is generated at the interface between the resin and the silicon chip, almost all the incident ultrasonic waves in the delamination (air layer) are reflected, so the reflected waves with high intensity are received and the delamination can be detected. As the delamination and cracks generated in the package are in a minute air layer, they can be also detected. However, if the package surface is uneven, a black shadow may appear in a marking part as the ultrasonic waves reflect diffusely on the uneven part. SAT analyses are positioned as an analysis technology essential for semiconductor packages which will become more and more important, including the reduction of the lead time for development, evaluation cost reduction, analysis accuracy improvement, etc. Ultrasonic pulse (Transmitting wave) (Receiving wave) Place where a black shadow appears due to marking Water Inner lead Reflected wave Chip Resin Chip Delamination places Die pad Figure 4.4 Ultrasonic exploration principle T04007BE-4 2009.4 4-6 Figure 4.5 Case example of analysis (delamination on a white part at the corner of the chip surface) 4 4.2.5 Failure Analysis of Semiconductor Devices Unsealing The purpose of unsealing is to expose the surface of the chip without damaging the surface of the silicon chip, the wire and the lead frame and to make the later observation and measurement, but it is unexpectedly difficult to unseal in a non-skilled method and firmly. During unsealing, it is important to select the method in view of the types and the materials of packages. In case of ceramic encapsulation devices, the cover is unsealed with a mechanical technique. Currently, mainstream plastic encapsulation devices are unsealed using the following: a) Encapsulation resin dissolution by chemicals b) Encapsulation resin ashing by a plasma reactor c) Mechanical unsealing In addition, recently new types of packages such as CSP (chip size package) or TCP (tape carrier package) are used, and various unsealing methods suitable for them are reported4.1). a) Encapsulation resin dissolution by chemicals Fuming nitric acid (70°C to 80°C) and sulfuric acid (200°C to 250°C) are used to dissolve epoxy group resin. The URESOLVE (trade name) and the like are used to dissolve silicon group resin. Though dissolution by chemicals can be done easily, it has the disadvantages that it requires much skill and that the foreign substances on the surface of chips might be removed at the same time. In practical application, samples useful for the later observation and measurement can be obtained if the wire and the lead are kept as they are when the resin on the chip has been partially removed with a drill and dissolved until the whole surface of the chip is exposed. Unsealing using chemicals must be conducted in a draft as it is harmful and dangerous to human bodies. Also, the waste disposal must be done in compliance with the law. b) Encapsulation resin ashing by a plasma reactor In this method, oxygen (O2) gas in a plasma state is reacted with encapsulation resin and removed. The drawback of this method is that it takes a long time to process samples as the reaction rate is slow (approx. 50 μm/h), but its use has been gradually generalized as the state of the surface of the chip is well kept. c) Mechanical unsealing In this method, unsealing is conducted by cutting the resin with a mechanical force using metal scissors, pincers, nippers, files, etc. The surface of the chip is exposed relatively easily by breaking the device when it is taken out and put into a solder bath and thermal stress is applied to it. Though this method can be conducted most easily, the drawback is the lack of certainty. T04007BE-4 2009.4 4-7 4 Failure Analysis of Semiconductor Devices 4.2.6 Internal observation and measurement The device, with the surface of the chip exposed by unsealing, is observed with a stereoscopic microscope and then with an optical microscope. With the stereoscopic microscope, the state of chips (cracks, the attachment of foreign substances), the state of die bonds, the state of wires and the state of leads are observed carefully. It is important to change the lighting conditions by tilting the device in various directions. Then the surface of the chip is observed with the optical microscope. Optical microscopes are essential to the observation of the surface of chips as they have 1500 times power. As the surfaces of the chips differ in the thickness of oxide films, etc., they are colored by interference. As the interference color depends on the film thickness, abnormalities of the film thickness can be detected by comparing with non-defective products. The abnormalities detected by internal observations are as follows: Attachment of foreign substances Pattern abnormalities Abnormalities of the film thickness Wire breakage, short-circuit Corrosion of Al wire Al migration Cracks on passivation films a) Optical microscopic observation As optical microscopes have been used for a long time and there are a variety of different types, it is important to select and use those most suitable, according to their features. Table 4.2 shows the types and the features of optical microscopes. Table 4.2 Types and features of optical microscopes often used for failure analysis Types and attached Magnifying power functions of microscope Stereoscopic microscope x0.7 to x160 Abnormalities on the surface can be detected by projecting light at a sharp angle to the surface of samples. Dark field Polarization system Infrared system T04007BE-4 2009.4 4-8 Used for macro observations such as low power, long operating distance, wide field, three-dimensional observation and packages Microscopes used for the most varied purposes in the field of microelectronics. Usually used in the bright field and incidence. The following functions are included. Metallographic microscope Differential interference Features/applications x25 to x1500 Create a color coordinating the difference between the unevenness on the surface of samples by using a prism and polarized light. Abnormalities and defects on the surface can be detected coordinately by using two rotating polarized light filters. Observe the bonding condition between the silicon ship and the die pad utilizing a high transmission property of infrared ray for silicon. 4 Failure Analysis of Semiconductor Devices Metallographic microscopes are the most widely used in the field of semiconductors for observation by projecting light on the sample and magnifying the light reflected from the surface of the sample with a lens. With dark-field microscopes, the unevenness on the surface is emphasized by projecting light diagonally on the sample. In differential interference, the unevenness of the sample appears colored for emphasis. Polarization systems are effective for observing the structure of transparent samples by using polarized light and are used for observing in liquid crystal analysis to detect the position of leaks on chips. In infrared systems, the state of die bonds under the silicon chips can be observed by using a high transmission property of infrared ray for silicon. b) SEM observation SEMs (scanning electron microscopes) as well as optical microscopes are widely used for failure analyses. With SEMs, the surface of the sample is observed by projecting electron beams on the sample and detecting the secondary electron emitted from the sample, and the sample can be magnified from a few times to 100,000 times. As SEMs have a large focus depth and it is easy to obtain the observations of stereoscopic shapes, they are used not only for failure analyses but also for acceptance inspections of materials or parts and for quality control in the manufacturing process. Figure 4.6 shows observation example of the surface of the chip by SEM. Figure 4.6 Case example of observation of SEM T04007BE-4 2009.4 4-9 4 Failure Analysis of Semiconductor Devices With SEMs, not only is the shape of the surface of the sample observed using the secondary electron, but a wide variety of information can also be obtained by adding various kinds of observation equipment. VC (voltage contrast) method In this method, voltage is applied to the sample electrode and the distribution of potentials on the surface of the chip is obtained. Though the materials of wires are the same, the contrasts differ according to potentials, so potential maps can be obtained. EBIC (electron beam induced current) method This method utilizes the phenomenon that electric current flows when the electron beam is irradiated on the p-n junction, and it is used for the determination of the position of the p-n junction or the diffusion depth. CL (cathode luminescence) method This method utilizes the phenomenon that the electron excited by electron beams and the positive hole emit light at the time of recombination, and it is used for the determination of defects inside chips, precipitation and the length of carrier diffusion. EPMA (electron probe micro analysis) method This is the method of elemental analyses using characteristic X-rays emitted from the samples. The details of this method are described in “4.2.9 Surface microanalysis”. c) TEM observation While SEMs are equipment by which electron beams are reflected on the surface of the sample, TEMs (transmission electron microscopes) to make observations by transmitting electron rays are also effective. TEMs have a resolution of approx. 0.1 nm to 0.2 nm and it is possible to magnify to the atomic level. So, they are used to observe tiny precipitate and lattice defects in chips, but it is rather difficult to prepare the samples because the sample thickness must be reduced to approx. 0.1 μm. T04007BE-4 2009.4 4-10 4 4.2.7 Failure Analysis of Semiconductor Devices Search for failure locations Recent semiconductor devices may not be able to identify failure locations only by internal observations because of the advanced miniaturization and high integration. To identify the failure locations is the most important analysis to determine the failure mechanism. EB tester analysis, liquid crystal analysis or emission microscope analysis, and wiring-part defect analysis using OBIRCH equipment are some of the methods to search the failure locations, and each of them is effective. Each method is described below. a) EB tester analysis EB tester analysis is the method for detecting the operating waveform and the potential contrast image of a device without contact by operating the semiconductor device with an LSI tester in SEM. An example of EB tester analysis is shown in Figure 4.7. Figure 4.7 Case example of EB tester analysis (wire breakage) b) CAD navigation This is a method to make identifying the region in large integrated circuits infinitely easier by linking design layout data (electronic file) and the positional information of analysis equipment such as an EB tester. T04007BE-4 2009.4 4-11 4 Failure Analysis of Semiconductor Devices c) Liquid crystal analysis method In case of leak current trouble in the device, the place of leak occurrence generates heat, so the temperature of the place rises. A certain type of liquid crystal causes phase transition at near ordinary temperatures, and becomes the transmission state of polarized light due to ups and downs of the transition point, so by using this, the places of leak occurrence can be identified. Figure 4.8 shows a case example of liquid crystal analysis methods. Figure 4.8 T04007BE-4 2009.4 4-12 Case example of liquid crystal analysis4.2) 4 Failure Analysis of Semiconductor Devices d) Emission microscopic analysis Emission microscopes are equipment for detecting luminous phenomena occurring when voltage is applied to the device. In case of leak current trouble in the device, the electric field is concentrated on the failure locations and hot carrier is generated. Then the weak light emitted during recombination is detected by highly sensitive detectors and observed as a luminescence image, and the luminous places (failure locations) are identified. Figure 4.9 shows the case example. Recently multilayer wiring structures have become the mainstream, with the high integration of semiconductor devices. So, the luminous phenomena may not be detected from the surface of chips. Then, these days, the luminous places may sometimes be identified by processing the device and using the emission microscope from the back surface of chips. Figure 4.10 shows the case example. Figure 4.9 Case example of emission microscope analysis Figure 4.10 Case example of emission microscope analysis from back surface T04007BE-4 2009.4 4-13 4 Failure Analysis of Semiconductor Devices e) Wiring-part defect analysis using OBIRCH equipment OBIRCH (optical beam induced resistance change) methods are the methods for detecting the change in the current due to the temperature rise of wiring caused by laser beam irradiation on Al wiring4.3). The temperature rise at the moment the laser is irradiated on the point with defects such as voids at the wiring part is bigger than that during irradiation on the points without defects. Consequently, the resistance increase in defective parts becomes large and the current decrease becomes large, too. This current change is detected by a highly sensitive detector and the defective parts are identified. Figure 4.11 shows the case example. Failure point (a) Failure identified by OBIRCH Figure 4.11 T04007BE-4 2009.4 4-14 (b) Cross section observation of failure part by SIM Case example of analysis in OBIRCH method4.4) 4 4.2.8 Failure Analysis of Semiconductor Devices Processing technology for analyses a) Etching In order to carry on analyses, it is necessary to remove a part of the sample device by dissolution. Table 4.3 shows the etching liquid usually used. During etching, it is necessary to select an etching liquid that does not dissolve other substances but dissolves only the intended substances. For the measurement of film thickness, there are optical methods such as ellipsometers, NanoSpec (trade name) and mechanical methods using contact needles such as Talystep (trade name). Table 4.3 Etching liquid usually used Substance Etching liquid composition SiO2 28ml : HF 170ml : H2O 113g : NH3 100 to 250nm/min PSG Same as above 550nm/min HF Si3N4 Remarks 100nm/min CVD at 800°C H3PO4 10nm/min 180°C Polysilicon 1ml : HF 26ml : HNO2 33ml : CH3COOH 150nm/min Al 1ml : HCl 2ml : H2O Au 4g : KI 1g : I2 40ml : H2O 0.5μm/min to 1μm/min T04007BE-4 2009.4 4-15 4 Failure Analysis of Semiconductor Devices b) Cross-section grinding In case of observing the cross section of the sample (cross section of chip, cross section of lead frame, cross section of encapsulation resin), observe by embedding the sample in the resin and exposing the intended cross section by grinding. In this case, it may be necessary to cut or form the sample to be suitable for embedding. In each case, process in such a way that mechanical stress is not applied, and so that there is no alteration of samples due to temperature rise. When selecting embedding resin, resin with the best adhesion to samples must be selected. When grinding, change sanding sheets successively from those with large particle size to those with small particle size, but be careful not to leave scars due to grinding on the sample. Figure 4.12 shows a photograph of the cross section of the chip. Figure 4.12 Cross section of chips by cross-section grinding c) FIB processing In order to observe the cross section of arbitrary places of miniaturized semiconductor devices, FIB (focused ion beam) equipment with alternative etching functions and SIM functions exercise its power these days. In FIB equipment, micro alternative etching can be realized by narrowing down a gallium ion (Ga+) beam to approx. 0.1 μmm and irradiating it to the sample. The usage of this equipment enables cross-sectional observation to advance dramatically. Figure 4.13 shows a photograph of the cross section processed by FIB equipment. Cu Low- k N iS i 55nm S TI Figure 4.13 T04007BE-4 2009.4 4-16 Cross-section view of chip by FIB processing4.5) 4 4.2.9 Failure Analysis of Semiconductor Devices Surface microanalysis In analyzing failures, there may be some cases that require elemental analyses of trace substances. Recently, surface microanalysis of solid substances has been developed significantly and samples of 1 μm3 can be analyzed at a sensitivity of 100 ppm. The principle of surface analysis is to identify elements by projecting electrons, ions, light, X-rays, etc. on the sample and detecting electrons, ions, light, X-rays, etc. emitted from the sample. Table 4.4 shows a synopsis of surface microanalysis technology. a) EPMA (XMA) (electron probe micro analysis) EPMAs are in the most widespread use for analysis, usually equipped with SEMs. Making observation with SEM, the identification of elements on the spot and the measurements of the element distribution on the surface of the sample can be made. In EPMAs, as specific characteristic X-rays are generated in the sample elements in case of the incidence of electron rays on the sample, the elements are identified by dispersing characteristic X-rays. Also, the abundance can be determined from X-ray intensity. There are WDX (wavelength dispersion method) and EDX (energy dispersion method) detection methods of X-rays. Each method has its positive features and both are widely used. Figure 4.14 shows measurement examples of the element distribution of foreign substances by EPMA. (a) SEM image in the wiring part Figure 4.14 (b) Measurement example of Al element in EPMA Example of EPMA analysis of foreign substance in chip T04007BE-4 2009.4 4-17 4 Failure Analysis of Semiconductor Devices b) SIMS (secondary ion mass spectrometry) In SIMS, argon (Ar), oxygen (O), etc. are irradiated on the sample and the elements are identified by mass analysis of ions emitted from the sample by sputtering. There are many types of SIMS, using various irradiation systems and detection systems, but the method that analyzes surfaces using fine ion beams is called I(M)MA. I(M)MA can analyze all the elements. As its detection limit is approx. 1 ppm and it is highly sensitive, it is used for the identification of foreign substances, the measurement of diffusion profile, etc. c) AES (Auger electron spectroscopy) In AES, elements are analyzed by incidence of low accelerated electrons and by dispersing Auger electrons generated from the sample. As the depth resolution of this method is as shallow as 1 to 2 nm, it is very effective for measuring the composition of 2 or 3 atomic layers on the surface of the sample. This method can analyze all the elements except hydrogen (H) and helium (He). The sensitivity differs according to the element, but it is approximately 0.1% of the atomic layer. It can measure the profiles of the depth directions of foreign substances and thin films in conjunction with sputtering devices. d) ESCA (XPS) (electron spectroscopy for chemical analysis) ESCAs disperse photoectrons emitted from the sample by incidence of X-rays or ultraviolet rays to the sample. As not only the identification of elements but also the chemical-bonding state can be seen, this method can analyze the interface between semiconductors and insulating films. e) XRFS (X-ray fluorescence spectroscopy) XRFSs identify elements by incidence of X-rays to the sample and by dispersing X-rays emitted from the sample. XRFSs are used for analyzing foreign substances, and for quantitative analyses of phosphorous (P) of passivation films, etc. These surface microanalysis technologies serve as very powerful tools for failure analyses because they can make elemental analyses of micro regions of μm order at the sensitivity of approx. ppm. The handling of the equipment and the interpretation of the results require high technology and experience. T04007BE-4 2009.4 4-18 Electron Paramagnetic Resonance Electron Spectroscopy for Chemical Analysis Electron Spin Resonance ESCA ESR Electromagnetic wave (to 10 MHz) Electromagnetic wave (to 10 MHz) Characteristic X-ray Electron (Some to 50 keV) Electron Probe Micro Analysis EPMA EPR Light Current Electroluminescence EL (Radius) >0.5 μm (Thickness) 0.3 μm to some μm (Energy, substance dependence) Composition analysis on wafer and device (ultrathin film, not applicable), contamination, detection of attachment Elemental composition analysis (above Na with EDX, above boron (B) with WDX) Dispersion by EDX or WDX of characteristic X-rays generated by electron beam irradiation Measurement of resonant absorption spectrum by transition Electromagnetic between Zeeman levels generated wave placing electron spin in the magnetic external field Generic designation of XPS and UPS Identification of impurity ion, defective structure, electron spin relaxation, electron spin interaction PL law is used in case of special analysis. Degradation analysis of lightemitting device, defects in process introduction, impurity evaluation Energy level and relative concentration centering band gap, emission recombination Spectroanalysis of the light emitted during recombination of a few carriers forward bias is applied to and injected to Identification of defects by hydrogen (H), etc. in α-Si Utilization of SOR (synchrotron orbital radiation) is expected. Position of impurity in semiconductor bulk crystal, defective structure (Radius) >10 nm (in case of using STEM) (Thickness) 0.3 μm to some μm (Energy, substance dependence) Utilization as a means of EPMA Elemental composition analysis through the energy distribution of X-ray intensity (sensitivity of 0.1% and more) Pulse-height analysis of irradiated X-ray energy (pulseheight) by semiconductor detectors (SSD) such as Si (Li) (Radius) 1 μm to some μm (Thickness) Some μm Existence of dislocation penetrating p-n junction, analysis of degradation of light-emitting device, measurement of diffusion length Distribution of electromotive force Existence centering carrier effects of metal-semiconductor by recombination such as crystal electron-hole of electron beam defects near junctions excitation, or both ends of p-n junction (Radius) >0.5 μm (Thickness) to 1μm Defects in semiconductors, precipitates, impurity segregation, measurement of carrier diffusion length Light emission by recombination Nonradiative state in the of electron-hole of electron beam unexcited part or the quick recombination part excitation ESR in case of paramagnetic Electromagnetic samples wave Electron X-ray (Some to 30 keV) Energy Dispersive X-ray Spectroscopy EDX Current Photon Electron (Some to some dozens of keV) Electron (10 keV to 40 keV) Cathodeluminescence CL (Radius) 0. some nm Micro region TED (to 20 nm) Micro region EDX (to 10 nm) Micro region SACP (to 3 nm) Able to collect complementary data with various attachments as well as STEM functions STEM+EDX(+ELS) (+DLTS) (+SACP selection field channeling pattern) Electron (transmission/ diffraction) Electron (100 keV to 200 keV) (Radius) 0.1 mm to 1 mm (Thickness) 1 nm to 2 nm Surface oxidation, contamination, impurity analysis, depth direction elemental analysis, composition analysis of layer such as intermediate reaction Able to analyze the surface element (above Li) and depth in conjunction with ion guns Energy dispersion of Auger electron (by CMA, etc.), record Auger electron of differential curves. Resolution Application Principle or Method Source: OYO BUTURI, Vol. 51, p. 827 (1982) Summary of surface microanalysis technologies Obtainable Information Detection Electron Beam Induced Current Analytical Electron Microscopy AEM Electron (0.1 keV to 5 keV) Input EBIC Auger Electron Spectroscopy Name AES Abbreviation Table 4.4 4 Failure Analysis of Semiconductor Devices T04007BE-4 2009.4 4-19 T04007BE-4 2009.4 4-20 Ionized atom Electrical field (to some dozens of keV) Electron (diffraction) Electron Electron (15 keV to 500 keV) Electron (≤ some hundreds of eV) Electromagnetic wave Low Energy Electron Diffraction Low Energy Electron Loss Spectroscopy Nuclear Magnetic Resonance LEED LEELS NMR Surface crystal structure, absorption state, surface atom rearrangement, etc. (superperiodic lattice structure) Nuclear internal field, identification of nuclide from nuclear spin relaxation, atomic arrangement of substances Incidence of low-speed electron Surface electronic state of single beam on the surface of the sample, crystal (band structure) measurement of energy distribution of reflection electron by applying AC to electron gun accelerating voltage Vertical incidence of low-speed electron beam on the surface of the sample, image formation of reflective diffraction pattern on hemisphere fluorescent screen Analysis of hydrogen (H) and fluorine (F) in α-silicon Electronic structure of semiconductor clean surface, impurity absorption surface structure Thin film crystal structure, semiconductor surface absorption layer Identification of substances from Measurement of concentration of oxygen (O) and carbon (C) absorption band peculiar to molecule or analysis of molecule in silicon structure Change the number of frequency (wavelength) of infrared rays and irradiate, measure the absorption spectrum by molecular vibration. Composition analysis of multilayer epitaxial layer, impurity diffusion, residual impurity analysis One-dimensional elemental composition analysis, depth direction composition analysis (composition sensitivity ppb to ppm, larger dependence on elements) Sputter-ionize surface substances with primary ion, analyze with mass analyzer, micro beam scanning method and image conversion method. Same as RBS TEM image of thick sample High voltage TEM Dynamic observation of dislocation Si atomic structure (superlattice (Radius) 0. some nm to some nm structure, etc.), atomic structure (Thickness) Monoatomic layer of compound semiconductor Record of ionization energy distribution on the surface of high electrical field as a figure Field evaporation ion at the end of needle-like metal or surface field distribution is converted to ionization rate such as rare gas. (Thickness) Some atomic layer (Wave number) > 0.1 cm-1 (Radius) 1 μm to 2 μm, surface ionization type ion: 0.1 μm (Thickness) Some nm to 10 nm (Radius) Some nm (Radius) Some nm (Thickness) Monoatomic layer Semiconductor structure, surface diffusion, analysis of depth of field penetration Record of emission probability on the surface of high electrical field as a figure, surface atomic structure, atom motion Resolution High electrical field is formed at the end of needle-like metal, energy more than work function is obtained and atom is radiated to outside of vacuum. Application Obtainable Information Principle or Method Measurement of resonant absorption spectrum by transition Electromagnetic between Zeeman levels generated wave by placing nuclear spin in the magnetic external field Photon (transmission) Photon (Infrared rays 2.5 μm to 16 μm) Infrared Absorption Spectroscopy Secondary ion Ion Microprobe (Mass) Ion (Ar, O, Cs, etc.) (Some keV to Analysis 30 keV) Ion Back Scattering IR IMMA IBS Neutral atom Electrical field (to some dozens of keV) Electron (transmission/ diffraction) Detection Input Electron High Voltage Electron (0.5 MeV and more) Microscopy Field Ion Microscopy FIM HVEM Field Emission Microscopy Name FEM Abbreviation 4 Failure Analysis of Semiconductor Devices SIMS Electron (Some dozens to 200 keV) Secondary Ion Mass Spectrometry Scanning Transmission Electron Microscopy Ion (Ar, O) (Some hundreds of eV to 10 keV) Scanning Ion Microscopy SIM STEM Ga+ ion (5 keV to 30 keV) Scanning Electron Microscopy SEM Voltage Secondary electron Electron (5 keV to 50 keV) Scanning Auger Electron Spectroscopy SAES Spreading Resistance Secondary electron Reflection electron Electron (3 keV to 20 keV) Scanning Auger Microscopy SAM SR Scattered ion H+, He+ ion (Some hundreds of eV to some MeV) Rutherford Back Scattering RBS Electron TEM including the mechanism (transmission/ able to scan primary irradiation diffraction) beam Secondary electron Current SEM mode image by secondary electron applicable, most able to add EELS, etc. Usable as AEM Resistivity measurement of bulk, epitaxial wafer Composition analysis of surface (Radius) 100 μm to 500 μm (Thickness) Monoatomic monoatomic layer, surface layer to some atomic layer absorption, contaminated impurity analysis, impurity analysis of ion-implanted layer (Radius) to 1 nm (Thickness) Some nm (Width-Thickness) Some μm (Radius) >10 nm Elemental composition analysis of surface substances (secondary distribution not applicable), but higher sensitivity than I(M)MA Detect the flowing current when Specific resistance forward voltage is applied to metal probe contacted with the surface of semiconductor, and obtain specific resistance. Two-probe method Sputter-ionize surface substances with primary ion and Secondary ion analyze with mass analyzer. Primary ion is not scanned. Scan micro ion beam and record the intensity of secondary electron (SE) in synchronization with primary beam scanning. Scan micro electron beam and record the intensity of secondary electron (SE) and reflection electron (BE) in synchronization with primary beam scanning. Same as SAM Surface thin layer shape of various materials and device (Depth to 40 nm), grain status. Local composition analysis of the (Radius) ≥ 50 nm surface of wafer, device, analysis (Thickness) 0. some nm to 2 nm of various contamination, oxidation, reaction layer Three-dimensional elemental composition analysis of surface thin films, rather difficult analysis of chemical shift Uneven surface shape, material difference, grain size or direction difference. (Radius) 5 nm to 20 nm (The heavier element, the smaller) Wafer surface rearrangement, atomic site of impurity diffusion, structural analysis of thin films (SiO2/Si, etc.) Rearrangement of surface construction atoms, interstitial site of impurity atom using channeling phenomena, existence of defects Backward anelasticity (Rutherford), estimation of energy dispersion and quantity of scattered ion (Radius) > 3 nm Various materials, surface shapes of devices, length measurement standards, etc. can be recorded simultaneously. (Radius) Some μm The depth depends on optical-absorption length. Evaluation of crystal growth, analysis of defects in process introduction such as ion implantation, identification of impurities Energy level and relative concentration centering band gap and emission recombination Spectroanalysis of the light emitted during recombination of electrons excited by irradiation of light such as laser Uneven surface shape, qualitative composition analysis Resolution Application Obtainable Information Principle or Method AES scanning micro electron Auger electron beam (SEM type: ≤ 20 nm, CMA type: to 100 nm) Light Light Photoluminescence Detection PL Input Name Abbreviation 4 Failure Analysis of Semiconductor Devices T04007BE-4 2009.4 4-21 Detection Secondary electron Input Electron (Some keV to 30 keV) T04007BE-4 2009.4 4-22 X-ray Microprobe Analysis X-ray Photo-emission Spectroscopy X-ray Fluorescence Spectroscopy X-ray Topography XPS XRFS XRT XD XMA X-ray Diffractometry WDX Photoelectron X-ray (Some keV to 30 keV) X-ray (diffraction) X-ray, RI Characteristic radiation source X-ray (10 keV to 100 keV) (fluorescence) X-ray (Some keV to 10 keV) X-ray (diffraction) X-ray (diffraction) X-ray (Some to some dozens of keV) Wavelength Dispersive X-ray Spectroscopy UPS X-ray Photoelectron Photon (Ultraviolet ray, 4 eV to 40 eV) Ultraviolet Photo-emission Spectroscopy Electron Electron Transmission Electron (transmission/ (30 keV to 200 keV) Microscopy diffraction) Stroboscopic SEM StroboSEM TEM Name Abbreviation Obtainable Information Application Crystal structure analysis, detection Crystallinity, defect (twin of directions, photographic crystal, etc.) evaluation method, chart method (single crystal, powder, etc.) Record diffraction X-ray pattern or intensity by Bragg reflection on crystal lattice surface. (Radius) to 5 μm (Thickness) to 10 μm (Section topograph) Defect distribution in wafers (bulk, device process, distorted distribution, etc.) Parallel scanning of dispersion X-ray beam together with the sample, record of diffraction image corresponding to single crystal Crystal defect (dislocation), precipitates, imaging of impurity concentration stripe on photograph or TV screen (Thickness) 0.1 μm to some μm Analysis of surface attached substances Elemental composition, band (Thickness) 1 nm to some nm structure of crystal, measurement of bonding state, analysis of interface between semiconductor and insulating film (Thickness) 0.1 to some dozens of μm Spectroanalysis by EDX or WDX Elemental composition analysis of secondary (fluorescent) X-ray (above N), difficult for below Ni in two-crystal method Energy dispersion of X-ray (usually AlK ray, Mgk ray, etc.) excited photoelectron (core electron) With the shift of atomic orbital energy in chemical-bonding state, detect chemical shift especially in light elements. Used as a means of EPMA Elemental composition analysis through wavelength distribution of X-ray intensity (sensitivity: 0.01% and more) Disperse wavelength of irradiation X-ray by Bragg reflection by dispersive crystal and measure the intensity by photoelectric conversion. Same as EPMA (Thickness) Monoatomic layer Surface treatment state, interaction of transition metal and absorbed electron, interfacial reaction layer structure Elemental composition analysis of surface substances, electronic surface level, estimation of dissociation or non-dissociation, chemical-bonding state Energy dispersion of photoelectron (valence electron, conduction electron) of ultraviolet excited wavelength, measurement of electronic energy of shallow levels (Radius) Some μm (Thickness) 0.3 μm to some μm (Energy, substance dependence) (Radius) to 0. some nm (Thickness) to 5 nm (Stereographic image) Crystal defects in semiconductor materials (dislocation, precipitates, etc.), crystal structure analysis Crystal cross-section shape, crystal structure analysis by diffraction, existence of defects, etc. (Radius) > 3 nm Resolution Diffraction by primary thermal electron or field-emission electron, or record of transmission magnified image, also called CEM Using the dependence of emitted Carrier flow in electronic circuit, Potential change in the unit of etc., potential change, signal ps in IC circuit, operating secondary electron dose on propagation rate, etc. analysis surface potential of substances, measure potential distribution by phase synchronization with pulsed irradiation beam. Principle or Method 4 Failure Analysis of Semiconductor Devices 4 Failure Analysis of Semiconductor Devices Reference documents: 4.1) Matsushita, Matsushima, and Wada, “Basic Reliability of CSP and Consideration of Failure Analysis Technique”, The 26th Union of Japanese Scientists and Engineers, pp. 99-104 (1996). 4.2) Kataoka and Wada, “Higher Accuracy of Liquid Crystal Analysis Technique”, The 26th Union of Japanese Scientists and Engineers, pp. 113-118 (1995). 4.3) Nikawa and Inoue, “Failure Analysis Technique of LSI Using Laser Beam Radiation”, The 25th Union of Japanese Scientists and Engineers, pp. 29-36 (1995). 4.4) Nakano and Wada, “Al Void Growth in W Via Hole by Stress Migration”, The 44th Japan Society of Applied Physics, 29a-pc-20 p. 758 (1997). 4.5) Fujii et al., “65 nm Process Technology”, Matsushita Technical Journal Vol. 52, No. 1, p. 13 (2006). T04007BE-4 2009.4 4-23