Customer-Focused Quality Lee Tait

advertisement

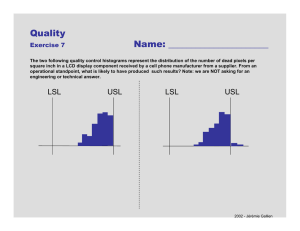

Customer-Focused Quality Lee Tait Vice President Quality & Mission Assurance Aerojet Rocketdyne Chair Elect – ASQ Aviation, Space and Defense Division When Should the Customer & Quality Engage? • Too often engagement occurs when a problem happens • This is frequently during Production & Deployment • By this time, technical requirements are set, and product yields are difficult to improve We Work Well with the Customer to Fix Problems What the Customer Needs From Us • Mission Success – Understanding the technical requirements • Predictability – Being able to forecast and meet schedule milestones • Value – Understanding what drives cost and how to control it Quality Brings Minimal Value if We Engage After Design Most Decisions Affecting Quality (Cost) Occur Early Design Assurance High ability to influence life cycle cost (70 to 75% of cost decisions made) Less ability to influence life cycle cost (85% of cost decisions made) Little ability to influence life cycle cost (90 to 95% of cost decisions made) Minimum ability to influence life cycle cost (95% of cost decisions made) Quality’s Customer Engagement Must Shift AEROSPACE REPORT NO. TOR-2009(8591)-11 Three Types of Quality Management •Inspective Quality Management (reactive) • “Sift and sort” approach • Measure after the fact • “Do Better” the next time Sample Mean • Measure during the process • Make adjustments “On-the-Fly” Xbar/R Chart for Normal 60 UCL=57.95 Mean=50.06 50 LCL=42.17 40 Subgroup 0 10 20 30 Sample Range •Corrective Quality Management (pro-active) UCL=28.91 20 R=13.67 10 0 LCL=0 • Low flexibility for product/process revisions •Process Focused Quality Management (pre-emptive) • Characterize process and product behavior • Simulate/Predict performance • Design process for desired result Quality Can Bring Value to the Customer During Design and Development LSL USL Understanding TRLs and MRLs • Engineering design requirements do not always match Manufacturing process capability • Existing Designs – Use SPC to determine the Voice of the Process – Communicate with Manufacturing and Engineering – Changes yield improved first pass yield (FPY), decreased cost and improved cycle time • New Designs – Collaboration among Engineering, Manufacturing, Quality and Programs to communicate process capabilities to customer – Engineering uses capability data during new product development – Produce product with higher FPY and lower cost Provide the Customer with Cost Trade Information Process Capability What Is Process Capability? Process capability is the baseline measurement of how a process V-22 Pylon Support is performing. Process Data USL 0.378000 Target * LSL 0.375000 Mean 0.376133 Sample N 269 StDev (Within) 0.0002097 StDev (Overall) 0.0003468 I and MR Chart for Total hours by Process Current Individual Value 700 New 600 The500 “Y” 400 300 Overall Potential (Within) Capability 5.40 8.90 LCL=150.4Z.USL Z.LSL 5.40 Cpk 1.80 1 1 0 Moving Range Within Mean=256.8 Z.Bench 100 500 USL UCL=363.3 200 Subgroup LSL 0 10 20 30 Time Current 40 50 Cpm 60 * Overall Capability Z.Bench 3.27 Z.USL 5.38 Z.LSL 3.27 Ppk 1.09 New 1 400 0.3750 0.3755 0.3760 0.3765 0.3770 The “Y” Observed Performance PPM < LSL 0.00 PPM > USL 0.00 PPM Total 0.00 Exp. "Within" Performance PPM < LSL 0.03 PPM > USL 0.00 PPM Total 0.03 Centering – Put The Process On Target 300 200 1 1 1 Spread – Reduce The Variation 100 0 UCL=130.7 R=40.01 LCL=0 A Simple Tool that can Predict Yields and Gives Customer Confidence in Performance 0.3775 0.3780 Exp. "Overall" Performance PPM < LSL 545.01 PPM > USL 0.04 PPM Total 545.04 Communication and Collaboration Critical to Customer Satisfaction Engineering, Manufacturing, Quality and Programs communication with “One Voice” to the customer on issues using data for problem solving Sustainment Design Quality Development Manufacturing Field Data Tooling Process Understanding Planning Results in improved quality and sustainable design Customer Focus Throughout Product Life Product Acquisition Requirements & Specifications Product Design & Development Assemble Test & Deliver & Support Product Build Program “A” Program “B” Block mods., CRI’s, VECP’s, provide opportunities to start the process over Program “C” Program “D” •DFMEA •Design Scorecard •SPC •MRL Assessment •Key Characteristics •Design yield •Reliability Updates •Best Design and Manufacturing Practices •Throughput yield •Supportability Data •Mistake Proofing •RCCA •DOE’s •Defect Analysis •Design to Cost •Process Capability •Lessons Learned Customer Engagement with Quality Starts During Requirements Definition Customer Needs Variation Reduction • • • • • • • Process Capability Data Key/Critical Characteristics Identified Predictive First Pass Yield TRLs/MRLs harmonized *Requirements Definition Quality Metrics: •EOs, ECNs •X drawings •Make/Buy Process • NCs (repetitive) • Scrap rate/cost Design Build/Buy Package/Process Pursuit/ Order Capture SPC in place on all Key Processes Process Variation Reduction Process Validation/Certification Design & Development •Customer Req. Capture •Product Design/Dev OK •Prod. Process Design/Dev • NCs •First Pass Yield • Scrap • ASL •VIR • Scrap • Flow/Rate • Excess / Obsolete Material VOC Enterprise Corrective Action Board (ECAB) Build Production Transition OK Parts Procurement Test • Mission Success Customer • Govt • Comm Customer Support Supplier Initiatives Root Cause Defect Analysis Needs to Transition to Production Risk Reduction and Predictive Analysis CMMi Level 1: Performed Process CMMi Level 3: Well-Defined Process CMMi Level 2: Managed Process CMMi Level 4: Measured Process Process Focused Performance Measures Less Effort on Fixing What “Went Wrong” and More on “Ensuring Success” QUALITY BY DESIGN TOOLS • International Quality Standards for Key Characteristics and Process Capability • Predicting First Pass Yield during Design Phase • Reconciliation of the maturity of Technical Requirement Levels (TRLs) with Manufacturing Readiness Levels (MRLs) • Advanced Product Quality Plan (APQP): four phase process for developing new products – Production Part Approval Process (PPAP): determines if all customer and Design specification requirements are properly understood and that processes have the potential to produce products meeting these requirements International AS&D Industry is Focusing on Early Engagement AS&D Industry Working to Provide Customers with Standard Requirements for Quality Assurance International Aerospace Quality Group IAQG Council General Assembly Forums AAQG (Americas) 19 Members EAQG (Europe) 34 Members APAQG (Asia & Pacific) 11 Members Whose mission is to: Achieve significant performance improvements in Quality, Delivery, and consequently Cost, on all products and services throughout the value stream Understanding the Customer’s “Needs” and “Wants” is Critical to Success Relationship Growth Strategy • • • • • Civil Authorities - Production Space Defense Maintenance, Repair & Overhaul Trade Associations Improvement Strategy • Requirements • People Capability • Product & Supply Chain Improvement • Performance IAQG Other Party Management Team IAQG Strategic Focus 3 Axes Aligned to Address Challenges IAQG Document Relationships Quality Standards and Best Practices IAQG Owners DataType Cert Scheme New New Publish Revision Sustain Certification Scheme QMS Standards 9101 Audit Process 9110 (Maintenance) 9120 (Distributors) 9102 FAI 9131 N/C Doc 9103 Key Char 9132 Marking 9107 DDA 9133 Sup.Qual. 9115 Software 9137 NATO Align. 9145 9134 S/C RM APQP/PPAP 9136 RCA 9114 Direct ship 9116 NoC 9138 Stat Prod Ac 9139 BoK Supply Chain Management Handbook (SCMH) Market & Sell Design & Develop Make (incl. Assemble & test) Buy Deliver Customer Support Plan & Manage People Capability documents & structure (skills matrix) 9117 DPRV 9162 Self Ver Best practices People Product & Supply Capability Chain Strategy Strategy Stream Stream Quality Management System IAQG Development and ICOP Maintenance of standards 9100 (General) Certification Scheme REQUIREMENTS Strategy Stream Oversight of Certification Scheme 9104-1 (organization) 9104-2 (surveillance/certs) 9104-3 (auditors) Stakeholders relationship and communication 14 Questions Thank you! 15