ILC R&D in the Americas Region Tor Raubenheimer (for Gerry Dugan)

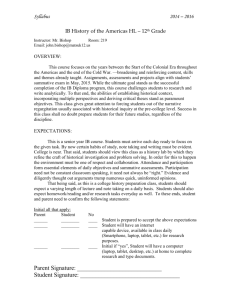

advertisement

Americas Region ILC R&D in the Americas Region Tor Raubenheimer (for Gerry Dugan) SLAC AARD Meeting Palo Alto, Dec. 21, 2005 Americas Region FALC ICFA FALC Resource Board ILCSC GDE Directorate GDE GDE Executive Committee GDE R & D Board GDE Change Control Board Global R&D Program GDE Design Cost Board RDR Design Matrix From Barry Barish, GDE Meeting, Frascati, Italy, December, 2005 Americas Region The GDE Schedule 2005 2006 2007 2008 2009 2010 Global Design Effort Project Baseline configuration Funding Reference Design Technical Design regional coord globally coordinated sample sites ICFA / ILCSC expression ofSiting interest FALC ILC R&D Program Hosting International Mgmt From Barry Barish, GDE Meeting, Frascati, Italy, December, 2005 Americas Region ILC Program • The ILC program has two portions: – Reference Design Report • A conceptual design based on sample sites with a cost estimate • Accelerator physics and engineering efforts are being developed – R&D Program • Presently administered through the different regions • ILC Global Design Effort is trying to coordinate effort more globally • ILC timeline – RDR at end of CY2006 – TDR based on supporting R&D in 2009 • ILC Americas – Effort spread between RDR and R&D programs – Some redistribution may be needed to complete the RDR – Coordinated by Gerry Dugan – MOUs between GDE and labs http://www.lns.cornell.edu/~dugan/LC/Labs/ Americas Region GDE Structure and Organization • Executive Committee for Baseline Configuration – GDE Director • Barish – Regional Directors • Dugan – Americas • Foster – Europe • Takasaki – Asia – Accelerator Leaders • Yokoya - Asia • Raubenheimer - Americas • Walker - Europe GDE Executive Committee • Responsible for decisions and documentation for the Baseline Configuration Document (BCD) Americas Region GDE Structure and Organization • GDE Groups – Design / Cost Engineers • Shidara – Asia • Bialowons – Europe • Garbincius – Americas – Siting, Civil Construction and Infrastructure • Baldy - Europe • Enomoto – Asia • Kuchler – Amercas – Physics / Detectors (WWS chairs) • Brau - Americas • Richard - Europe • Yamamoto - Asia – Accelerator Experts (44 GDE members) Americas Region GDE Organizational Evolution for RDR • Selected additions to the GDE following the BCD completion having needed skills in design, engineering, costing, etc • Change Control Board – The baseline will be put under configuration control and a Board with a single chair will be created with needed expertise. • Design / Cost Board – A GDE Board with single chair will be established to coordinate the reference design effort, including coordinating the overall model for implementing the baseline ILC, coordinating the design tasks, costing, etc. • R&D Board – A GDE Board will be created to evaluate, prioritize and coordinate the R&D program in support of the baseline and alternatives with a single chair Americas Region Reference Design Matrix Area Systems e- source e+ source Damping Rings RTML Main Linac BDS Kiriki Gao ES Kim Hayano Yamamoto Lilje Angal-Kalinin Adolphsen Seryi Guiducci Brachmann Sheppard Wolski ?? Tenenbaum Solyak Technical Systems Vacuum systems Magnet systems Cryomodule Cavity Package RF Power Instrumentation Dumps and Collimators Accelerator Physics Suetsugu Sugahara Ohuchi Saito Fukuda Urakawa Ban Kubo Michelato ?? Pagani Proch ?? Burrows ?? Schulte Noonan Thomkins Carter Padamsee Larsen Ross ?? ?? Teranuma Michizono Hosoyama Enomoto Shidara Elsen Simrock Tavian Baldy Bialwons Himel Carwardine Peterson Kuchler Garbincius Global Systems Commissioning, Operations & Reliability Control System Cryogenics CF&S Installation • Area systems leaders are responsible for design and cost • Technical systems are to provide engineering and costing • Global systems have support and design roles Americas Region ANL ILC-Americas Regional Team BNL Jefferson Lab Cornell LEPP LLNL SLAC Fermilab TRIUMF LBNL Universities FY06 resources FTE SLAC FNAL ANL Jlab LLNL LBNL BNL Cornell Universities 59.9 31.0 0.0 1.0 0.0 2.3 0.0 0.0 0.0 Labor 7,182 3,565 140 170 580 330 0 0 0 sum 94.1 11,967 M&S 3,700 4,635 14 651 230 0 0 165 0 Indirect 2,909 1,826 0 79 390 170 0 0 0 Total 13,791 10,026 154 900 1,200 500 500 165 841 9,395 5,374 28,077 University program: Wisconsin, Northwestern, Old Dominion, Yale, MIT, Tennessee, Princeton, Illinois, NCA&T, UCLA, Berkeley, Vanderbilt, Colorado State, UC Davis Additional funding for infrastructure from laboratory operating funds Americas Region Fermilab ILC R&D at Fermilab • The ILC R&D effort at Fermilab is focused on key design & technical issues in support of the RDR, cost estimate and eventually the TDR for the ILC. • Fermilab’s efforts are focused on two main areas of the ILC – Main Linac Design – Civil and Site Development • Main Linac R&D: – The goals are to demonstrate the feasibility of all Main Linac technical components, develop engineering designs, estimate costs, explore cost reduction, and engage industry in the Americas region • Civil and Site Development – Fermilab is working with the GDE and international partners to develop a matrix for comparing possible ILC sites – Fermilab is also working to develop Americas region sites at or near Fermilab for the RDR. Americas Region Fermilab Main Linac R&D at Fermilab • The main thrust of the Fermilab ILC Accelerator R&D is to establish Americas region technical capabilities in the Superconducting RF Cavity and Cryomodule technology. The main goals are – 1) Cavity technology development in the Americas region to routinely achieve > 35 MV/m and Q ~0.5-1X1010, – 2) ILC Cryomodule design, fabrication, and cost reduction – 3) Develop facilities (ILC Test Accelerator-ILCTA) to fully test the basic building blocks of the Main Linac (to evaluate performance and reliabilities issues) – 4) Explore Main Linac accelerator physics and design issues ( e.g. simulation of emittance preservation, RF control, feedback systems, etc.) – 5) RF power system development ( modulators ) – 6) LLRF, Instrumentation and Controls development Americas Region Fermilab ILC 1.3 GHz Cavities at FNAL Bead pull RF Testing @ FNAL 4 cavities received from ACCEL 4 cavities on order at AES 4 cavities expected from KEK • • • • • • • Joint ANL/FNAL BCP/EP Facility Industrial fabrication of cavities. BCP and vertical testing in collaboration with Cornell (25 MV/m) EP and vertical testing in collaboration with JLab. ( 35 MV/m) Joint BCP/EP facility being developed at ANL (late 06) High Power Horizontal test facility @ FNAL (ILCTA-MDB) Vertical test facility under development @ FNAL (ILCTA-IB1) Single/large grain Crystal cavity development in collaboration with Jlab. Americas Region Fermilab SCRF Infrastructure at FNAL PPD Machine shop (MAB) Meson Detector Building (MDB) ILCTA-MDB Cryogenics Installation 60 W @ 1.8 K TD MP9 Cryomodule Assembly Facility (CAF) First 1.3 GHz TESLA Cavity in MDB Cold and RF power in Dec AD Cryo Dept. Americas Region Fermilab Cryomodule Assembly Facility (CAF) at FNAL • Vertically tested cavities will be dressed (He vessel, coupler, etc) in CAF clean rooms prior to horizontal test at ILCTA-MDB. •Horizontally tested cavities assembled into a string at CAF • Final Cryo-module assembly takes place at CAF CAF-MP9 Class 10 and 100 clean rooms ordered, operational by March 06 Parts for new Cryomodule Assembly fixture in IB4 •CAF design intended to improve on DESY facility •Expect parts for a type III cryomodule from DESY; FNAL is building a 3.9 GHz ( 3rd harmonic) cryomodule for DESY •CAF ready to start fabrication of cryomodules by summer of 06 Americas Region Fermilab Cryomodule Design at FNAL • Industrial fabrication and cost reduction of the ILC cryomodule are both crucial issues for a realistic ILC cost estimate • In FY05 Fermilab started on converting drawings of the DESY/INFN design of the ILC cryomodule (Type-III+) to US standards for U.S. vendor fabrication and for cost reduction. • Next goal is to design an improved ILC cryomodule (Type-IV). Also working on the quadrupole design and on piezo-electric control of Lorentz detuning Americas Region Fermilab Cryomodule string test: ILCTA-NML at Fermilab New Muon Lab (NML) FNPL Photo-Injector Building a dedicated ILC cryomodule string test facility in the New Muon Lab – Building is cleaned out except for removal of CCM ( in progress) – Started to install cryogenic system – Move FNPL Photo-injector to provide electron beam (Late FY06) – Upgraded FNPL will provide beam tests of ILC cryomodules Americas Region Jefferson Lab Jefferson Lab : Develop electropolishing processes for 1.3 GHz cavities • • • FY06 Funding (MOU with FNAL) $600k Objectives: – Commission the Jefferson Lab EP and HPR processing and Vertical Test systems for 1.3 GHz TESLA cavities. – Carry out processing of cavities from a variety of sources – Develop and refine processing parameters. – Carry out detailed test program planning for individual cavities and evaluation of results. – Develop more cost effective procedures with high yield. – Develop written procedures and proposals for future improvements and toward industrial transfer. – Provide or process samples as appropriate for the SCRF materials program at FNAL – Fabricate two TESLA 9-cell cavities from large grain material Status: – DESY cavities needed to begin infrastructure development -- received by FNAL Americas Region Jefferson Lab Jefferson Lab : Fabricate, process and test cavities from large-grain/single-crystal material • FY06 Funding (direct transfer) $300k • Objectives: – Several single cell and at least one multi-cell cavity made from large grain/single crystal niobium – Improved buffered chemical polishing system for producing very smooth rf surfaces on large grain/single crystal material – Test cavity for superconducting rf joint investigations – Optimization studies of superstructure configuration based on superconducting joint – Two cavities suitable to be combined into a superstructure – Engineering package for the completion of a superstructure assembly ready for cold tests Americas Region Jefferson Lab Status: large-grain/single-crystal material cavity: fabrication and test • Superconducting joint cavity - completed, tests pending • single cell cavities from large grain material of different vendors (CBMM, Ningxia, Wah Chang and W.C.Heraeus) – fabricated, treated and tested • A 7-cell Low Loss cavity from large grain material – completed, being tuned and will be tested in next 2 weeks • fabrication of 9- cell aluminum model, 2 LL single-cells, 9-cell TESLA-shape Nb cavity, and dies and trim fixtures for the TESLA shape cavity – complete • Issue: Determining correct modification of cell shape to yield LL geometry after stiffening ring welding Americas Region Cornell Cornell LEPP ILC SCRF activities Preparations for BCP and HPR in Clean Room for 9-cell from Fermilab (ACCEL production) Vertical EP Development at Cornell Americas Region Cornell Cornell LEPP ILC SCRF activities Re-entrant Cavity Shape 47 MV/m at Cornell…Later 52 MV/m at KEK 9-cell re-entrant cavity ordered from AES Americas Region Cornell Cornell LEPP ILC accelerator physics activities • RTML design • LET emittance preservation simulation studies • Damping ring optimization: • studies of wigglers: electromagnetic design, impact on ring dynamic aperture • studies of fast kickers • Positron source •undulator design: •E166 participation • Study of the use of CESR as an ILC positron damping ring test facility (after 2007) • Supported by NSF and DOE university grants and NSF LEPP co-operative agreement Americas Region ANL ANL Plan for ILC-GDE/FY06 • SCRF Cavity Electropolishing at the ANLFNAL Joint Facility – Leverage the new (~$2M) chemistry facility and Argonne expertise to build a complete EP apparatus for ILC-type 9-cell cavities – Close collaboration with FNAL – The EP to be operational in FY 06, processing in FY07 • Positron Source Development (1.95 FTE and $10K M&S; ANL will provide $90K) – A comprehensive start-to-end simulation of conventional, polarized, and keep-alive sources, in collaboration with SLAC – Optics for positron beam separation and selection – Conventional adiabatic matching device based on Bitter magnet Americas Region ANL ANL Plan for ILC-GDE/FY06 • Damping Ring Design and Optimization(1.4 FTE and $10K M&S; ANL will provide $40K ) – Lattice optimization including practical effects (errors, injection/extraction,...) using multi-objective evolutionary algorithms; Improve simulation tools and correction schemes for vertical emittance and coupling – Particle tracking for single-bunch instabilities with 3-D wakefield – Studies of ion instability in the APS ring – Design of a hybrid wiggler satisfying the field quality tolerance • ANL can contribute significantly in other areas, for example in the control system Americas Region SLAC SLAC ILC Accelerator Design (RDR) • Strong efforts throughout the machine design – – – – – – Electron and positron sources Contributions to the damping rings and RMTL Main linac design and instrumentation Rf sources Beam Delivery System Civil construction and conventional facilities • Able to provide leadership for some RDR Area Sub-systems For more detail see: http://www-project.slac. stanford.edu/ilc/talks/SLAC_SPC_ILC_12-05.pdf Americas Region SLAC SLAC ILC R&D Program • Broad R&D Program – Availability issues (~1.3 M$) Fast (redundant) kicker for DR • Kickers, Power supplies, and control system – Beam instrumentation (~1 M$) signal from ACC1, cav 1, cplr 2 1.4 1.3 1.2 1.1 Volts 1 0.9 0.8 0.7 0.6 0.5 0 0.5 1 1.5 2 2.5 time - s 3 3.5 4 4.5 -4 x 10 TTF HOM Signal 800 monitors installed RF BPM for linac – Linac beam dynamics (~0.5 M$) • SC quad and BPM SC Quad for magnetic center tests Americas Region SLAC 12 KV Marx Cell SLAC ILC R&D Program • Broad R&D Program (cont.) – Linac rf sources (~1.5 M$) • Marx generator modulator – Electron and Positron sources (~1.2 M$) • NC structure, E-166, electron laser, and cathode – Damping rings (~ 0.3 M$) • SEY studies in PEP-II Positron capture structures SEY Test Chamber for PEP-II Americas Region SLAC ATF Extraction Kicker SLAC ILC Test Facilities • Five efforts: – ATF damping ring (~0.7 M$) (includes R&D) • Over 1 FTE in residence at KEK – ATF-2 (~1 M$) (includes R&D efforts) • Construction of magnets, PS, and instrumentation – ILCTA at FNAL (~0.2 M$) • Cryo-system design and modulator switch – ESA MDI Test Facility (~0.5 M$) – ESB L-band klystron station (~1.4 M$) ATF2 Optics ESA Energy Spectrometer Americas Region SLAC SLAC End Station B (RF Test Fac.) • Develop 5 MW and 10 MW stations – Test rf system components – Reuses extensive infrastructure Americas Region LBNL LBNL: Accelerator Design • Lattice designs for damping rings and injection/extraction lines (1.0 FTE) • Characterization of some collective effects, including space-charge, IBS and microwave instability (0.7 FTE) • Contribution to development and optimization of bunch compressor lattices (0.2 FTE) Americas Region LBNL LBNL: Test Facilities • Physics design of stripline kickers for single-bunch extraction at KEK-ATF (0.15 FTE) • Contribution to beam-dynamics studies at KEK-ATF, including CSR studies, low-emittance tuning and nonlinear dynamics (0.2 FTE) Americas Region LLNL LLNL ILC Activities in FY06 • Positron target design – $600K (1.5FTE) – Detailed engineering – Target simulations • Energy deposition, radiation damage, activation • Marx modulator – $200K (.75 FTE) – Mechanical engineering of modulator and test equipment Americas Region • Coupler Test Stand – $100K (.25FTE) – Evaluation and analysis of RF coupler designs LLNL • NanoBPM – $100K (.35 FTE) – Installation and data taking of nanometer resolution metrology frame $1M (3 FTE) program using LLNL’s engineering resources to advance the ILC design Americas Region BNL ILC Final Focus Magnet Development Brookhaven National Lab FY06 goals: •Continue to support the baseline design efforts in WG4 •Support the development of the Conceptual Design/Cost Estimate for the Beam Delivery System •Fabricate and test a short proof of principle shielded final-focus-like quadrupole coil •Fabricate and test a short proof of principle sextupole/octopole corrector-like coil Americas Region BNL Final Focus Magnet Development Brookhaven National Lab Winding tests octopole coil - how small can you go ? Shielded quadrupole proof of principle coil fabrication Beam delivery system Conceptual Design work 2 FTE’s ( 1 Sci, 0.75 Eng, 0.25 Design) $320K (labor) Coil R&D 1 FTE (0.5 Eng, 0.5 Tech) $130K (labor) $50K (materials) Total 3 FTE’s $500K Americas Region TRIUMF Potential TRIUMF Accelerator R&D Resources for ILC The specific nature of Canadian involvement is under development. Some potential collaboration areas have been identified, along with relevant LHC experience: The design of kicker magnets and the construction of associated pulse-forming networks and fast switches using power semiconductors Precision room temperature magnet systems e.g. 52 twin-aperture quadrupoles built at Alstom Canada Beam instrumentation and readout systems e.g. 2000 matched-pair 70MHz low pass filters e.g. VME64x compliant Digital Aquisition Board (DAB) Contributions to beam dynamics & lattice calculations for damping rings. Americas Region TRIUMF Building on expertise developed for TRIUMF ISAC radioactive beams accelerator, additional possible areas are: Remote handling design/consulting of target stations possible applicability to conventional positron source Peripheral aspects of superconducting r.f. such as cryogenic coolant distribution system design/consulting small quantity e-beam welding of niobium for low-beta, low-frequency UBC -Tom Mattison Vibration control systems and alignment of components for final focus system; also interest in abort kickers Americas Region Funding for the TDR (FY07-09) • TDR to be developed during the FY07-09 period – Ready for construction start around 2010 • R&D funds must grow substantially to support TDR – Need a global R&D plan without which it is difficult to estimate funding requirements – working on this • Rough funding plan listed below given to DOE – Develop of facilities for sources, DRs, BDS, etc but … – Growth mainly for main linac R&D and industrialization – Site development work must begin if US is to offer to host R&D activity FY07 FY08 FY09 Total TDR+supporting R&D at DOE labs 60 70 60 190 Industrialization 10 20 45 75 30 60 90 120 165 355 Site civil engineering (host region only) Total 70 Americas Region ILC-Americas Regional Team Summary/Conclusion FY06 resources by functional area W BS 1 2 3 4 5 Description Program direction and administration Accelerator design, including RDR Research and development Engineering, including cost estimates Infrastructure and test facilities Laboratory W P leader FTE Total 9.4 32.4 33.5 0 18.9 Labor 1,097 4,050 4,600 0 2,220 94.1 11,967 M&S 780 764 5,221 0 2,630 Indirect 453 1,553 2,298 0 1,069 Total 2,330 6,367 13,460 0 5,919 9,395 5,374 28,077 FY06 resources by machine area MACHINE AREA FTE Program direction and administration 9.4 Management 4.3 Global systems 5.5 Electron sources 3.3 Positron sources 7.5 Damping rings 7.9 Bunch compressor 1.6 Main Linacs: Optics, beam dynamics, instrumentation 7.1 Main Linacs: RF systems 18.0 Main Linacs: Cavities and Cryomodules 16.5 Beam delivery system 10.2 Conventional facilities 3.0 TOTAL 94.1 Labor 1,097 506 744 390 1,310 1,061 198 837 2,240 1,958 1,267 360 11,967 M&S 780 100 460 100 202 567 0 50 2,170 3,896 520 550 Indirect 453 188 330 151 574 446 77 295 1,019 1,115 514 212 Total 2,330 794 1,707 676 2,086 2,298 312 1,248 5,493 7,143 2,867 1,122 9,395 5,374 28,077