Lab #4: Pull and Perfection

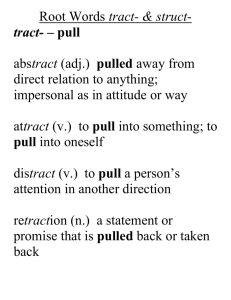

advertisement

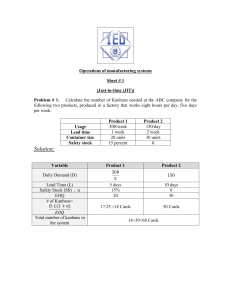

Lab #4: Pull and Perfection MG/IE 3400 – Production System Design The New Scenario … Products: Blue sapphire Black diamond Grey pearl 2/minute 2/minute 1/minute Customers want clocks delivered in less than 1 minute Pull Production Information Flow OUT OUT OUT Work Center Work Center Work Center A B C IN IN Material Flow Warehouse IN Number of Kanbans k = # kanbans/signals (here, c=1) d = demand per unit time L = lead time a = safety factor k= dL(1+a) Little’s Law L=lW Process ‘law’: WIP = production rate x lead time ‘steady-state’ performance TimeWise What determines the production rate? Session Morning Afternoon 1 2 3 1 2 3 WIP Actual Lead Time (min) 20 88 82 60 84 32 9 >15 >15 >15 >15 11, 14 Little's Law Back/Hand Assembly Blue Blue Black Black Visual Layout How to Accomplish Lean 7. Improve Product Design: Standard product configuration Standardize and reduce number of parts Process design with product design Quality expectations 1. Design Flow Process Link operations Balance workstations capacity Redesign layout for flow Emphasize preventive maintenance Reduce lot sizes Reduce setup/changeover time 2. Total Quality Control: Concurrently Solve Problems: Root cause Solve permanently 6. Reduce Inventory More: Look for other areas Stores Transit Carousels Conveyors Team approach Worker responsibility Measure: SQC Enforce compliance Fail-safe methods Automatic inspection Line and specialist responsibility Continual education 3. Stabilize Schedule: Measure Performance: Level schedule Emphasize Improvement Underutilize capacity Track trends Establish freeze windows 5. Work with Vendors: Reduce lead times Frequent deliveries Project usage requirements Quality expectations 4. Kanban Pull: Demand pull Backflush Reduce lot sizes