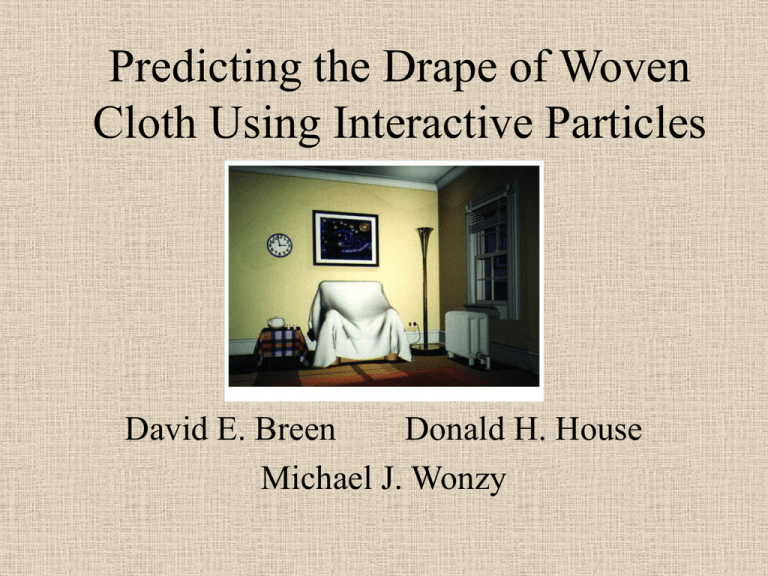

Predicting the Drape of Woven Cloth Using Interactive Particles Michael J. Wonzy

advertisement

Predicting the Drape of Woven Cloth Using Interactive Particles David E. Breen Donald H. House Michael J. Wonzy Cloth Simulation • Cloth can be represented as spatially couple particles • Particles represent the crossing points of the warp and weft threads • Energy equations are then used to simulate interactions between the particles Energy Equations • Four basic mechanical interactions occur at the crossing points: thread collisions, thread stretching, bending, and trellising. Urepel - artificial force of repulsion helping prevent thread collision Ustrech - energy of tensile strain between particle and four neighbors Ubend - energy due to threads bending out of local plane of cloth Utrellis - energy due to bending around a thread crossing in the plane Ugrav - potential energy due to gravity as a function of height Repelling and Stretching The stretching and repelling functions are both functions of the distance to other particles in the cloth. The repelling function is a sum of S for all particles in the cloth while the stretching functions is a sum of R for its four connected neighbors. Bending and Trellising The B energy is a function of the angle between three particles along a weft or warp thread. The bending energy is a summation of the B for the eight nearest neighbors. The T energy is a function of the angle formed between a particle and its two neighbors as it moves away from equilibrium. The trellis energy is a summation of T for the particles four nearest neighbors. Energy Equations Three Phase Process First Phase: Calculate the dynamics of each particle as if it were falling freely under gravity in a viscous medium. Second Phase: Perform energy minimization to enforce interparticle constraints. Third Phase: Corrects the velocity of the particles to account for the second phase. Different Cloth Problem: Different types of cloth behave differently due to the different materials and weaves. Kawabata Evaluation System • Standard set of fabric measuring equipment to measure the bending, shearing, tensile, compressibility, and surface roughness of a specific fabric. • Generates plots of force as a function of measured geometric deformation. • Energy equations for the type of cloth are derived from the empirical data. KES Tensile Compression Shearing Bending Surface Properties Kawabata Plots Results Results Other Cloth Simulations Maria Huang, Bradley D. Nelson http://graphics.stanford.edu/courses/cs348b-competition/cs348b-99/ Other Cloth Simulations http://www.cg.tuwien.ac.at/research/vr/studierstube/naehstube/ Other Cloth Simulations http://www.cg.tuwien.ac.at/research/vr/studierstube/naehstube/ Other Cloth Simulations http://www.cg.tuwien.ac.at/research/vr/studierstube/naehstube/