Temperature-Aware GPU Design Problem Statement

advertisement

Temperature-Aware GPU Design

Jeremy W. Sheaffer, Kevin Skadron, David P. Luebke

{jws9c, skadron, luebke}@cs.virginia.edu

University of Virginia, Charlottesville, VA 22904

http://gfx.cs.virginia.edu

http://qsilver.cs.virginia.edu

http://lava.cs.virginia.edu

Problem Statement

Simulator Setup and Output

Cooling for graphics processors is becoming prohibitively expensive, but cooling solutions are designed for worst-case behavior. Since power

dissipation is spatially non-uniform across the chip, localized heating occurs much faster than chip-wide heating, which leads to “hot spots”

and spatial gradients that can cause accelerated aging and timing errors. Reducing hot spots reduces cooling requirements. In fact, as true

worst-case behavior is rare, a solution designed for the worst case is overdesigned for typical operating conditions. However, a package

designed for typical behavior could be overcome by some unusual application, requiring dynamic thermal management (DTM).

GPU Simulation with Qsilver

To study thermal issues in a GPU, we have developed a simulator

called Qsilver that:

• models GPU clock-cycle-by-cycle activity and power in the

microarchitecture domain.

•uses the Chromium† system to intercept a stream of OpenGL calls,

annotating it with aggregate information about the vertices and

fragments, textures, lighting, and other relevant rendering state

Qsilver is useful for:

•analyzing performance bottlenecks

•estimating power

•exploring new graphics architectural ideas

Texture accesses

Fragments generated

Vertices transformed

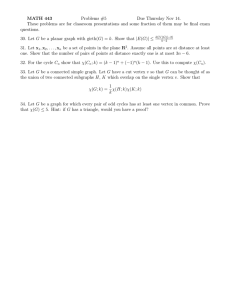

Thermal Simulation Results

Default

Floorplan →

Performance

Maximum

Technique ↓

Architecture-Level Thermal Modeling

Cost

Requirements:

and fast,

and must model

heating at the granularity of architectural objects

We

have used General,

Qsilver simple,

to analyze

a hypothetical

fixed-function

console-like

GPU

architecture.calculate

For these

results, for

weeach

augment

Must be able

to dynamically

temperatures

block in the architecture

Qsilver with an architectural thermal model called HotSpot‡ that

Must be able to simulate billions of clock cycles in a few hours

tracks temperature in each functional unit over time.

Must be general enough to use for modeling a variety of processor architectures

Must be able to reason about results at the architecture level

No DTM

† http://chromium.sourceforge.net/

‡ http://lava.cs.virginia.edu/HotSpot/

Floorplans

Solution:

an equivalent

circuit

of lumped

resistances

andbecapacitances.

In

order toDerive

add thermal

modeling

to Qsilver,

thethermal

simulator

must first

instrumented with an architectural floorplan. From the left, these

This circuitare:

must be derived at the granularity of the processor architecture.

floorplans

•Default—based on an nVIDIA marketing photo. We use this chip to drive an 800×600, console-like display in our simulations.

Key components:

•Separating

Hot Units—based on the default floorplan. The two hottest units, framebuffer operations and the vertex engine, are separated.

Floorplanning

•High Resolution—also based on the default, but modified to drive a PC display at 1280×1024. The framebuffer, fragment engine, and

Lumped-RC

circuit

derivation

texture

cache are

enlarged

to maintain reasonable power densities under higher workload.

•Partitioned High Resolution—this novel floorplan maintains the functional unit area of the high resolution design, but partitions units into

separate blocks per pipe, and separates hot blocks from cooler ones.

Vertex Engine

Rasterizer

Vertex Engine

Rasterizer

Unused

Data Compression

Framebuffer control

Unused

Host

Interface

Vertex Engine

2D Video

Framebuffer and

Framebuffer and

Data Compression

2D Video

2D Video

Framebuffer and

Data Compression

Data Compression

Fragment Engine

Fragment Engine

Fragment Engine

Rasterizer

Rasterizer

Framebuffer control

Fragment Engine

Host

Texture

Interface

Cache

2D Video

Framebuffer control

Texture Cache

Host

Texture

Interface

Cache

Host Interface

Texture Cache

Fragment Engine

Fragment Engine

Vertex Engine

Framebuffer control

Framebuffer control

Default

Separating Hot Units

High Resolution

Clock Gating

Fetch Gating

Vertex Fetch

Fetch Gating

Rasterizer

Dynamic Voltage

Scaling

Multiple Clock

Domains

Temperature

Separating Hot Units

Performance

Cost

Maximum

Temperature

Partitioned High Resolution

High Resolution

Performance

Cost

Partitioned High Resolution

Maximum

Temperature

Performance

Cost

Maximum

Temperature

0.0%

62.0%

106.4

97.0

0.0%

13.6%

105.5

97.0

0.0%

14.8%

103.7

97.0

0.0%

0.7%

100.9

97.0

25.9%

102.9

10.2%

98.7

9.2%

101.3

0.5%

98.1

90.1%

98.1

17.7%

97.8

17.4%

97.0

0.7%

97.8

13.1%

100.7

3.4%

98.2

3.4%

97.4

0.1%

97.0

16.7%

98.4

4.1%

97.0

3.7%

97.0

0.5%

97.4

From left to right, below: No architectural thermal management with the default floorplan yields a very hot vertex engine; the hot units

moved apart, combined with DVS make the chip cooler with a less profound thermal spatial gradient; fetch gating on the high resolution

system; and DVS on the redesigned high-res chip, where the affect of separating hotspots on spatial gradient is more obvious—combining

static and dynamic techniques is a double win.

Vertex Engine

Framebuffer and

Framebuffer control

For these results, our simulator is configured to model a system:

•Built on a 180nm process at 1.8V and 300MHz

•Using an aluminum cooling solution with no fan

•With a temperature sensor on each functional unit block. We assume

that the vendor specifies a 100°C maximum safe operating temperature

and enable dynamic thermal management at 97°C to account for sensor

imprecision.

We have implemented the following DTM techniques on Qsilver:

•Clock Gating—the clock is stopped until the chip drops below the

threshold temperature.

•Fetch Gating—a single stage in the pipeline is slowed down. We

implement this in both the vertex fetch and rasterization stages.

•Dynamic Voltage Scaling—DVS scales the core voltage, and with it

frequency, yielding a cubic reduction in power.

•Multiple Clock Domains—MCD also scales voltage and frequency,

but on the granularity of individual functional units. Both DVS and

MCD require a sync time ‘penalty’ when they are enabled and disabled.

Note that to better illustrate their full dynamic range, these thermal

maps are not all on the same scale.