Notes for Informal Discussion with Senior Fusion Leaders

advertisement

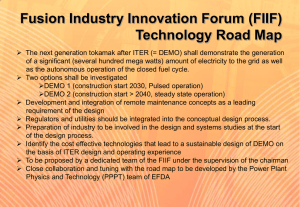

M. Abdou 3-24-03 Notes for Informal Discussion with Senior Fusion Leaders in Japan (JAERI and Japanese Universities) Outline 1. Notes on US-35Yr Plan 2. Why CTF in the US Plan 3. Political situation for fusion and budget issues 4. ITER organization in the US 5. ITER Blanket Test Module (BTM) - ITER plan for BTM and what it means - R&D timing (EU rollback R&D plan) - US-Japan Collaboration on BTM - Collaboration with JAERI - Collaboration with Japanese Universities (and Relationship to JUPITER-II) US 35-Yr Plan •To put electricity from fusion on the US Grid in 35 years •Charge from Dr. Ray Orbach, Director of the DOE Office of Science •Panel had 19 members; Started October 2002 •Final Report (81 pages) submitted to FESAC; Accepted and Endorsed Some Highlights of the Plan •DEMO must be a “real” DEMO (50% availability, tritium self-sufficiency, etc.) • Ferritic steel is the only realistic structural material for DEMO •Portfolio of both IFE&MFE with selection in 2019 •MFE Portfolio has ITER, IFMIF, and CTF •International collaboration assumed on ITER and IFMIF and other activities •Total cost of the plan is $24B - The US contribution to ITER construction was assumed to be $1B - The US contribution to IFMIF is about 25% - The US is willing to pay the full cost for CTF (MFE) [or ETF for IFE] NIF and ITER Drive the Urgency of the Plan NIF ITER A strong parallel effort in the science and technology of fusion energy is required to guide research on these experimental facilities and to take advantage of their outcome. Fiscal Year 03 05 07 09 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39 41 43 45 47 Theory, Simulation and Basic Plasma Science Configuration Configuration Optimization Optimization Concept Exploration/Proof of Principle IFE IREs Key Decisions: IFE IREs Design MFE PE Exp’ts Construction Burning Plasma Operation IFE NIF MFE PEs Indirect Drive Direct Drive ITER Phase II MFE ITER (or FIRE) IFMIF Materials Testing Materials Science/Development MFE or IFE First Run Second Run IFMIF Demo Component Testing Engineering Science/ Technology Development IFE ETF MFE CTF Demonstration Systems Analysis / Design Studies US Demo 03 05 07 09 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39 41 43 45 47 Fiscal Year 03 MFE Detail and Dependencies 05 07 09 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39 41 43 45 47 Theory, Simulation and Basic Plasma Science Configuration Optimization Concept Exploration Configuration Optimization MST & NSTX NCSX New POP’s Design Existing MFE PE Exp’ts Key Decisions: Construction 1st New MFE PE 2nd New MFE PE Operation MFE PEs Burning Plasma IFMIF MFE or IFE ITER Phase II MFE ITER (or FIRE) Materials Testing Materials Science/Development Demo First Run Second Run IFMIF Component Testing Engineering Science/ Technology Development MFE CTF Demonstration Systems Analysis / Design Studies US Demo 03 05 07 09 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39 41 43 45 47 The Administration on Fusion “This [progress in fusion science] is an enormous change that is enough to change the attitudes of nations toward the investments required to bring fusion devices into practical application and power generation.” Presidential Science Advisor John Marburger “By the time our young children reach middle age, fusion may begin to deliver energy independence … and energy abundance …to all nations rich and poor. Fusion is a promise for the future we must not ignore. But let me be clear, our decision to join ITER in no way means a lesser role for the fusion programs we undertake here at home. It is imperative that we maintain and enhance our strong domestic research program … . Critical science needs to be done in the U.S., in parallel with ITER, to strengthen our competitive position in fusion technology.” Secretary of Energy, Spencer Abraham “The results of ITER will advance the effort to produce clean, safe, renewable, and commercially-available fusion energy by the middle of this century. Commercialization of fusion has the potential to dramatically improve America’s energy security while significantly reducing air pollution and emissions of greenhouse gases.” President George W. Bush Political Support and Budget Issues for Fusion in the US • Good News - Strong statements from President Bush and Secretary of Energy • Join ITER & Develop Fusion Energy - 35-Yr Plan widely supported by the fusion community • Concerns: Budget! Budget! Budget! - The Budget reality does not match the Presidential Policy - FY03 came from Congress as $250M ($7M less than the President’s request) - FY04 President’s Budget Submission • Only $257M (no increase) • Deep and disturbing cuts in Fusion Technology (Draconian cuts) • Other Major Concerns: - Two camps in the Administration. One camp wants fusion to focus only on Plasma Science. The other camp wants fusion energy. Fusion Budget Problem is Worldwide? • The US Fusion Budget problems are not unique • Similar problems in EU, in Japan? • Problem: Political commitment is not strong enough to be reflected in budgets!! One Necessary Measure (Personal View) - We must enhance international collaborations - We must increase effectiveness of domestic programs and international collaboration The US has now joined ITER Negotiations (also China) ITER Organization in the US For Now • An ITER Project Office at PPPL Director: Ned Sauthoff (C. Baker, Deputy) • BP-PAC (Burning Plasma Program Advisory Committee) - Will provide guidance (technical and organizational) - Includes 10 people from Universities, Labs, and Industry • Mike Roberts will be OFES Manager responsible for ITER For the Long-Term • Organization will evolve and become more formal ITER Operational Plan Calls for Testing Breeding Blankets from Day 1 of Operation H-Plasma Phase D Phase First DT plasma phase Accumulated fluence = 0.09 MWa/m2 Blanket Test TBM Roll Back from ITER 1st Plasma Shows CT R&D must be accelerated now for TBM Selection in EU schedule for Helium-Cooled Pebble Bed TBM (1 of 4 TBMs Planned) 02 03 04 05 06 07 08 09 10 11 12 2005 ITER First Plasma 13 14 15 16 17 18 19 20 21 22 23 24 25 HCPB Programme PB Material Fabrication and Char. (mech., chem, etc) Out-of-pile pebble bed experiments Pebble bed Irradiation Programme Modelling on Pebble beds including irradiation effects Key issues of Blanket Structure Fabr. Tech. HCPB Programme for ITER Develop. and testing of instrumentation for TBM Develop. and testing of components of Ext. Loops TBM and Ext. Loop Mock-up Design TBM and Ext. Loops Mock-up Fabrication Operation of TBM and Ext. Loop Mock-ups a final decision on blanket test modules selection by 2005 in order to initiate design, fabrication and out-of-pile testing Final Design of TBM Fabrication and qualification of TBM and Ext. Loops Operation in the Basic Performance Phase of ITER (Reference: S. Malang, L.V. Boccaccini, ANNEX 2, "EFDA Technology Workprogramme 2002 Field: Tritium Breeding and Materials 2002 activities- Task Area: Breeding Blanket (HCPB), Sep. 2000) ITER Test Program US-Japan Collaboration (Ferritic Steel is the Reference DEMO material worldwide) Blanket Options for ITER Blanket Test Module (BTM) 1) Solid Breeder Blankets – Common Interest in EU, Japan, and US – Collaboration between US and JAERI – Some limited activity under JUPITER-II (Task 2.2) 2) Molten Salt Self-Cooled Concept – Some activity under JUPITER-II – Is it a candidate for ITER TBM? 3) Liquid Metal Blanket Concepts – Self-cooled Li/V concept – Helium-cooled Pb-17Li concept – Helium-cooled Pb-17Li concept with SiC insert Main Critical Issues Common to all concepts: - tritium self-sufficiency - ferromagnetic effects - forces and stresses caused by disruptions - reliability of blanket/First Wall/divertor Specific to helium-cooled Pb-17Li concepts: - tritium permeation and control, corrosion - SiC insert compatibility and performance integrity Specific to self-cooled Li concept: - coating development and crack tolerance - MHD effects - tritium recovery and control Specific to molten salt concept: - redox, tritium recovery and control, Be toxicity - enhancing Heat Transfer Specific to solid breeder blanket concepts: - effective thermal conductivity and interface thermal conductance - irradiation effect on beryllium, tritium inventory in Be - high burn up effect on ceramic breeder materials - tritium control ITER Test Program US-Japan Collaboration Questions 1) If each party is allowed only to test two blanket concepts: a) What are the two favored concepts in Japan? And in US? b) What are the mechanisms in the US and in Japan to arrive at these decisions? c) Should we have joint study/assessments to try to arrive at common concepts to maximize the utilization of limited resources/budgets in both countries? 2) Should the US have collaboration with JAERI separate from collaboration with Japanese Universities? a) How do we enhance US-JAERI collaboration? b) Should we orient JUPITER-II to serve collaboration between US and Japanese Universities on ITER BTM? CTF CTF Component Test Facility Chamber Technology Facility New Name for VNS • CTF is included in the US Plan as a Necessary Facility prior to DEMO • For detailed information on Why CTF Is Needed: 1) Presentation by M. Abdou (e.g. Seminar at MIT is on cd) 2) See paper-- “Results of an International Study on a HighVolume Plasma-Based Neutron Source for Fusion Blanket Development,” Fusion Technology, 29: 1-57 (1996) by M. Abdou, et.al • Note that Component Testing is NECESSARY in all Engineering Development. (It is not just material development.) What is CTF? CTF Component Test Facility (or Chamber Technology Facility) (CTF is a new name for VNS) • The idea of CTF is to build a small size, low fusion power DT plasma-based device in which Fusion Nuclear Technology experiments can be performed in the relevant fusion environment at the smallest possible scale, cost, and risk. - In MFE: small-size, low fusion power can be obtained in a low-Q plasma device. - Equivalent in IFE: reduced target yield and smaller chamber radius • This is a faster, much less expensive, lower-risk approach than testing in a large, ignited/high Q plasma device for which tritium consumption, and cost of operating to high fluence are very high (unaffordable!, not practical). Critical R&D Issues for Chamber Technology (FNT) 1. 2. 3. Remaining Engineering Feasibility Issues, e.g. • feasibility, reliability and MHD crack tolerance of electric insulators • tritium permeation barriers and tritium control • tritium extraction and inventory in the solid/liquid breeders • thermomechanics interactions of material systems • materials interactions and compatibility • synergistic effects and response to transients D-T fuel cycle tritium self-sufficiency in a practical system depends on many physics and engineering parameters/details: e.g. fractional burn-up in plasma, tritium inventories, FW thickness, penetrations, passive coils, and many more variables. A related issue is how to supply Tritium for burning plasma experiments, such as ITER. Reliability/Maintainability/Availability: failure modes, effects, and rates in blankets and PFC’s under nuclear/thermal/mechanical/electrical/ magnetic/integrated loadings with high temperature and stress gradients. Maintainability with acceptable shutdown time. 4. Lifetime of blanket, PFC, and other FNT components Stages of FNT Testing in Fusion Facilities Fusion “Break-in” Stage: Required Fluence 2 (MW-y/m ) Size of Test Article I ~ 0.3 SubModules • Initial exploration of performance in a fusion environment • Calibrate non-fusion tests • Effects of rapid changes in properties in early life • Initial check of codes and data • Develop experimental techniques and test instrumentation Design Concept & Performance Verification Component Engineering Development & Reliability Growth II III 1-3 >4-6 Modules Modules / Sectors • Tests for basic functions and phenomena (tritium release / recovery, etc.), interactions of materials, configurations • Verify performance beyond beginning of life and until changes in properties become small (changes are substantial 2 up to ~ 1-2 MW · y/m ) • Data on initial failure modes and effects • Narrow material combination and design concepts • Establish engineering feasibility of blankets (satisfy basic functions & performance, 10 to 20% of lifetime) • 10-20 test campaigns, each is 12 weeks • Select 2 or 3 concepts for further development • Identify failure modes and effects • Iterative design / test / fail / analyze / improve programs aimed at improving reliability and safety • Failure rate data: Develop a data base sufficient to predict mean-timebetween-failure with sufficient confidence • Obtain data to predict mean-time-toreplace (MTTR) for both planned outage and random failure • Develop a data base to predict overall availability of FNT components in DEMO D E M O Critical Factors in Blanket / PFC / FNT Testing that Make CTF a Necessary Facility in Fusion Energy Development Pathway Toward Demo • Tritium Consumption / Supply Issue • Reliability / Maintainability / Availability Issue • Cost • Risk • Schedule Fundamental Considerations in Blanket / PFC / FNT Fusion Testing that Make CTF Necessary • The FNT Testing Requirements are Fusion Power only 20-30 MW Over about 10m2 of surface area (with exposure to plasma) With Steady State Plasma Operation (or plasma cycle >80%) Testing Time on successive test articles equivalent to neutron fluence of 6 MW • y/m2 • Tritium Consumption / Tritium Supply issue dictates that any fusion facility that performs FNT testing must internally breed all (or most) of its own tritium - If TBR <1, Larger Power Devices require larger TBR - For a given TBR, the FW area required for breeding is much larger than for small devices • FNT Testing involves RISKS to the fusion testing device - unvalidated technology with direct exposure to plasma - frequent failures are expected - considerable amounts of tritium and activated materials - These risks are much greater for large power devices because of the much larger area for tritium breeding • Cost - Frequent failures will require frequent replacements: COST will be much higher for the larger power, larger area devices - COST of operation to higher fluence is larger for larger devices CTF MISSION is integrated testing and development of fusion power and fuel cycle technologies (FNT) in prototypical fusion power conditions Scope of Testing in CTF Information Obtained from Basic Device – Divertor Operation – Heating and Current Drive Systems PFC – Partial to full breeding, high temperature blanket (staged operation and breeding) – Neutronics and Shielding – Tritium Fuel Cycle Demonstration of Remote Maintenance Operations – through frequent changeout of various test articles – through repairs and changeout on the basic device Testing in Specialized Test Ports (and substantial FW coverage at later stages of operation) – Materials Test Module • Material Properties Specimen matrix – Blanket Test Modules • Screening Tests • Performance Verification • Reliability Growth – Divertor Test Modules • Engineering Performance • Design Improvements and Advanced Divertor Testing – Current Drive and Heating Launchers – Neutronics Test Sector – Safety Aspects of the Test Program – Tritium Processing Tritium Consumption in Large and Small Power DT Devices AND Tritium Supply Issue AND Impact on the Path to FNT Development Note: Projections of world tritium supply available to fusion for various scenarios were generated by Scott Willms, including information from Paul Rutherford’s 1998 memo on “Tritium Window”, and input from M. Abdou and D. Sze. Projected Ontario (OPG) Tritium Inventory (kg) Projections for World Tritium Supply Potentially Available to Fusion 30 25 Candu Supply 20 w/o Fusion 15 10 5 0 1995 2000 2005 2010 2015 2020 2025 2030 2035 2040 2045 Year • World Maximum Tritium Supply (mainly CANDU) available for fusion is 27 kg • Tritium Consumption in a DT facility burns tritium at a rate of 55.8 kg/yr per 1000 MW of fusion power • Tritium decays at a rate of 5.47% yr • Current Tritium cost is $30 million/kg • Once the Canadian Tritium is gone, additional tritium may be produced at a projected cost of $200 million/kg (estimate by Anderson, Wittenberg, Willms, & Sze) Conclusion A large power DT facility must breed its own tritium Separate Devices for Burning Plasma and FNT Development, i.e. ITER (FEAT) + CTF is more Cost Effective and Faster than a Single Combined Device (to change ITER design to satisfy FNT testing requirements is very expensive and not practical) NWL Fusion Power Fluence (MW·y/m2) Tritium Consumption (TBR = 0) Tritium Consumption (TBR = 0.6) 0.55 500 MW 0.1 5 kg 2 kg 2) FNT Testing (CTF) >1 < 100 MW >6 33 kg 13 kg Single Device Scenario (Combined Burning Plasma + FNT Testing), i.e. ITER with major modifications (double the capital cost) >1 910 MW >6 >305 kg >122 kg Two Device Scenario 1) Burning Plasma (ITER) FACTS - World Maximum Tritium Supply (mainly CANDU) available for Fusion is 27 kg - Tritium decays at 5.47% per year - Tritium cost now is $30M / kg. More tritium will cost $200M / kg. Conclusion: - There is no external tritium supply to do FNT testing development in a large power DT fusion device. FNT development must be in a small fusion power device. Projected Ontario (OPG) Tritium Inventory (kg) The Lack of Adequate Tritium Supply and the Need for Tritium Breeding Blanket are Already Having a Major Impact NOW on ITER Operational Plans and Fusion Energy Development Plans 30 CTF 5 yr, 100 MW, 20% Avail, TBR 0.6 5 yr, 120 MW, 30% Avail, TBR 1.15 10 yr, 150 MW, 30% Avail, TBR 1.3 25 20 Candu Supply w/o Fusion 15 1000 MW Fusion, 10% Avail, TBR 0.0 ITER-FEAT (2004 start) + CTF 10 5 0 1995 ITER-FEAT (2004 start) See calculation assumptions in Table S/Z 2000 2005 2010 2015 2020 Year 2025 2030 2035 2040 2045 • World Tritium Supply would be Exhausted by 2025 if ITER were to run at 1000 MW fusion power with 10% availability without tritium breeding capability. • Large Power DT Fusion Devices are not practical for blanket/PFC development. • Blanket/PFC must be developed prior to DEMO (and we cannot wait very long for blanket/PFC development even if we want to delay DEMO). • CTF is a critical facility for fusion energy development. Reliability / Maintainability / Availability Critical Development Issues Unavailability = U(total) = U(scheduled) + U(unscheduled) This you design for This can kill your DEMO and your future Scheduled Outage: Planned outage (e.g. scheduled maintenance of components, scheduled replacement of components, e.g. first wall at the end of life, etc.). This tends to be manageable because you can plan scheduled maintenance / replacement operations to occur simultaneously in the same time period. Unscheduled Outage: (This is a very challenging problem) Failures do occur in any engineering system. Since they are random they tend to have the most serious impact on availability. This is why “reliability/availability analysis,” reliability testing, and “reliability growth” programs are key elements in any engineering development. Availability (Due to Unscheduled Events) 1 i represents a component Availability: = 1 Outage Risk i (Outage Risk) i = (failure rate) i • (mean time to repair) i= MTTR i MTBFi MTBF = mean time between failures = 1/failure rate MTTR = mean time to repair • A Practical Engineering System must have: 1. Long MTBF: have sufficient reliability - MTBF depends on reliability of components. One can estimate what MTBF is NEEDED from “availability allocation models” for a given availability goal and for given (assumed) MTTR. But predicting what MTBF is ACHIEVEABLE requires real data from integrated tests in the fusion environment. 2. Short MTTR: be able to recover from failure in a short time - MTTR depends on the complexity and characteristics of the system (e.g. confinement configurations, component blanket design and configuration, nature of failure). Can estimate, but need to demonstrate MTTR in fusion test facility. The reliability requirements on the Blanket/FW (in current confinement concepts that have long MTTR > 1 week) are most challenging and pose critical concerns. These must be seriously addressed as an integral part of the R&D pathway to DEMO. Impact on ITER is predicted to be serious. It is a DRIVER for CTF. 800 ed (R ) 600 5 400 200 0 Expected 0 1 2 C A 0 3 MTBF per Blanket Segment(FPY) 10 N ee d MTBF per Blanket System(FPY) The Chamber Technology Program NOW is leading the way to resolving this challenge. MTTR (Months) A = Expected with extensive R&D (based on mature technology and no fusion-specific failure modes) C = Potential improvements with aggressive R&D Reliability/Availability is a challenge to fusion, particularly blanket/PFC, development • Fusion System has many major components (TFC, PFC, plasma heating, vacuum vessel, blanket, divertor, tritium system, fueling, etc.) - Each component is required to have high availability • All systems except the reactor core (blanket/PFC) will have reliability data from ITER and other facilities • There is NO data for blanket/PFC (we do not even know if any present blanket concept is feasible) • Estimates using available data from fission and aerospace for unit failure rates and using the surface area of a tokamak show: PROBABLE MTBF for Blanket ~ 0.01 to 0.2 yr compared to REQUIRED MTBF of many years Aggressive “Reliability Growth” Program We must have an aggressive “reliability growth” program for the blanket / PFC (beyond demonstrating engineering feasibility) 1) All new technologies go through a reliability growth program 2) Must be “aggressive” because extrapolation from other technologies (e.g. fission) strongly indicates we have a serious CHALLENGE “Reliability Growth” Upper statistical confidence level as a function of test time in multiples of MTBF for time terminated reliability tests (Poisson distribution). Results are given for different numbers of failures. 1.0 Number of Failures 0 Confidence Level 0.8 Example, TYPICAL TEST SCENARIO 1 To get 80% confidence in achieving a particular value for MTBF, the total test time needed is about 3 MTBF (for case with only one failure occurring during the test). 2 0.6 3 0.4 4 0.2 0.0 0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 Test Time in Multiplies of Mean-Time-Betw een-Failure (MTBF) Reference: M. Abdou et. al., "FINESSE A Study of the Issues, Experiments and Facilities for Fusion Nuclear Technology Research & Development, Chapter 15 (Figure 15.2-2.) Reliability Development Testing Impact on Fusion Reactor Availability", Interim Report, Vol. IV, PPG-821, UCLA,1984. It originated from A. Coppola, "Bayesian Reliability Tests are Practical", RADC-TR-81-106, July 1981. DEMO reactor availability obtainable with 80% confidence for different testing scenarios, MTTR = 1 month DEMO Reactor Availability 0.3 0.2 MTTR = 1 month 12 test modules 1 failure during the test Experience factor =0.8 III: ITER +VNS 0.492 This assumes that the divertor has availability similar to blanket system availability, & that combined availability of all other major Demo components = 60% II: ITER BPP +VNS 0.360 IV: ITER + delayed VNS 0.1 0.189 I: ITER only 0.0 2006 2013 2010 2014 2018 2022 2026 2017 2021 2025 2029 2033 Blanket System Availability 0.654 0.4 (Schedule back 2030 in 1995) 2037 (Schedule now in 2002) Calendar year Note: ITER in Scenarios I, III and IV assumes fluence of 1.1 MWy/m2 (ITER-FEAT 1st phase has 0.1 MWy/m2) Conclusions on Blanket and PFC Reliability Growth • Blanket and PFC tests in ITER alone cannot demonstrate DEMO availability higher than 4% (This also assumes ITER would be modified to a higher wall load and to operate with steady state plasma) • Blanket and PFC testing in VNS (CTF) allows DEMO blanket system and PFC system availability of > 50%, corresponding to DEMO availability > 30% Note that testing time required to improve reliability becomes even longer at higher availability [e.g. testing time required to increase availability from 30% to 50% is much longer than that needed to improve availability to 30%] Recommendations on Availability/Reliability Growth Strategy and Goals - Set availability goal for initial operation of DEMO of ~ 30% (i.e. defer some risk) - Operate CTF and ITER in parallel, together with other facilities, as aggressively as possible - Realize that there is a serious decision point with serious consequences based on results from ITER and CTF • If results are positive proceed with DEMO • If not, then we have to go back to the drawing board Are there Good Design Options for CTF? • A key point in the rationale behind CTF is to design a small size, small fusion power (~100 MW), yet achieve a high neutron wall load and steady state plasma operation. • This can be achieved in MFE by using highly driven plasma (low-Q plasma ~ 1-2). [Similar idea in IFE is to use low target-yield to lower the fusion power but make the chamber radius small enough to get higher wall load] • Several good options for CTF look attractive. • The fusion physics and engineering communities need to jointly explore in more detail the options for CTF: e.g. - ST, low-A, standard-A - physics and engineering details