ITER Test Blanket Module (TBM) and ITER Nuclear Science and Engineering Mohamed Abdou

advertisement

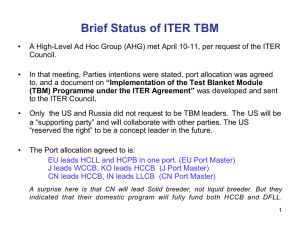

ITER Test Blanket Module (TBM) and ITER Nuclear Science and Engineering Mohamed Abdou VLT/USIPO Meeting, October 20-21, 2004 1 Outline Introduction Recent Progress in ITER TBM Program Issues and Recommended Approach FY05 and FY06 Plans Recommended Approach for Increased Effectiveness 2 Introduction 3 What is the ITER TBM Program? Integrated testing of breeding blanket and first wall components and materials in a Fusion Environment Breeding Blankets/FWs will be tested in ITER, starting on Day One, by inserting Test Blanket Modules (TBMs) in specially designed ports. Each TBM will have its own dedicated systems for tritium recovery and processing, heat extraction, etc. Each TBM will also need new diagnostics for the nuclear-electromagnetic environment. Each ITER Party is allocated limited space for testing two TBMs. (Number of Ports reduced to 3. Number of Parties increased to 6). ITER’s construction plan includes specifications for TBMs because of impacts on space, vacuum vessel, remote maintenance, ancillary equipment, safety, availability, etc. The ITER Test Program is managed by the ITER Test Blanket Working Group (TBWG) with participants from the ITER International Team and representatives of the Parties. 4 Blanket Testing in ITER is one of ITER’s Key Objectives Strong international collaboration among the ITER Parties is underway to provide the science basis and engineering capabilities for ITER TBMs Bio-Shield Plug TBM Frame & Shield Plug Cryostat Plug Breeder Concentric Pipe Transporter EU HCLL Test Module FW Cryostat Extension US Solid breeder submodule Drain Pipe 5 Conceptual Liquid Breeder Port Layout and Ancillary equipment ITER’s Principal Objectives Have Always Included Testing Tritium Breeding Blankets “The ITER should serve as a test facility for neutronics, blanket modules, tritium production and advanced plasma technologies. The important objectives will be the extraction of high-grade heat from reactor relevant blanket modules appropriate for generation of electricity.” —The ITER Quadripartite Initiative Committee (QIC), IEA Vienna 18–19 October 1987 “ITER should test design concepts of tritium breeding blankets relevant to a reactor. The tests foreseen in modules include the demonstration of a breeding capability that would lead to tritium self sufficiency in a reactor, the extraction of high-grade heat and electricity generation.” —SWG1, reaffirmed by ITER Council, IC-7 Records (14–15 December 1994), and stated again in forming the Test Blanket Working Group (TBWG) 6 ITER Blanket Testing is Essential to: Achieve a key element of the “ITER Mission” Establish the conditions governing the scientific feasibility of the D-T cycle, i.e., determine the “phase-space” window of plasma, nuclear, material, and technological conditions in which tritium self-sufficiency can be attained - The D-T cycle is the basis of the current world plasma physics and technology program. There is only a “window” of physics and technology parameters in which the D-T cycle is feasible. (If the D-T cycle is not feasible the plasma physics and technology research would be very different.) - Examples of questions to be answered: – Will tritium self-sufficiency allow low plasma-edge recycling? – Are advanced physics modes acceptable? – Is the “temperature window” for tritium release from solid breeders sufficient for adequate TBR? – Can circulated liquid metal breeders and coolants be used? – Is there a blanket/material system that can exist in this phase-space? – Are nuclear predictive capabilities (codes, data) adequate to predict accurate 7 TBR in realistic system ITER Blanket Testing is Essential to (cont’d): Achieve the most critical milestone in blanket and material research: testing in the integrated fusion environment (ITER construction and operation is for the next 30 years. Without such fusion testing, material and blanket research loses “focus”, relevance: Why are we doing any research in these areas then?) Develop the technology necessary to install breeding capabilities to supply ITER with tritium for its extended phase of operation Resolve the critical “tritium supply” issue for fusion development - and at a fraction of the cost to buy tritium for large D-T burning plasma 8 Nuclear Science and Engineering is Critical to ITER and to the US Fusion Program ITER will produce neutrons at a rate higher than any nuclear facility ever constructed (including operating fission reactors). It will have energetic neutrons, gamma rays, activated components, tritium, etc. Challenges in predicting the radiation field: • Complex geometry, large system • “Deep radiation penetration” problem in predicting dose to external components and radiation exposure to personnel ITER base design changes, TBMs, port-based diagnostic packages, licensing, etc. will need more accurate nuclear simulation to ensure robust design, safe operation, and correct interpretation of experimental results. US has been a leader in Nuclear Science and Engineering for fusion. Work on ITER base device and TBMs helps build US knowledge, experience and competence needed to develop practical and safe D-T fusion devices. (Building competence takes decades.) 9 Recent Progress in ITER TBM Program 10 US Plasma Chamber Systems/Blanket Effort has been redirected to support ITER With the US rejoining ITER, the Blanket/Chamber community concluded that it is very important for the US to participate in the ITER Test Blanket Module (TBM) Program (March 2003). Extensive deliberations have occurred in the US since March 2003 among the community, DOE and VLT. Reached consensus on a general framework for the direction of activities in the US Chamber/Blanket Program: Provide fusion nuclear technology (FNT) support for the basic ITER device as needed Participate in ITER TBM program and redirect good part of resources toward R&D for TBM Encourage partners in international collaborations, such as IEA and JUPITER-II, to focus more on ITER TBM Important work has been carried out to implement the strategy. • A study of ITER TBM issues and US options was initiated • Some R&D was initiated • Rejoined TBWG, strong participation • The US interacted with all the other 5 parties to identify areas of collaboration 11 What should the US Blanket Options be for ITER TBM? This has been a central question for the US community during FY 2004. A study was initiated to select the two blanket options for the US ITER TBM in light of new R&D results from the US and world programs over the past decade. Key conclusions reached early in the study: Selection between solid and liquid breeders can not be made prior to fusion testing in ITER. All Liquid Breeder Options have serious feasibility (“Go/No-Go”) issues, but potential for higher performance. More assessment needed. Solid breeders are accepted by all parties. For the past year, the study has focused mostly on assessment of the critical feasibility issues for liquid breeder concepts. Examples of issues are MHD insulators, MHD effects on heat transfer, tritium permeation, corrosion, SiC insert viability, and compatibility. The study has been led by the Plasma Chamber community with strong participation of the Materials, Safety and PFC Programs. Many international “Experts” in key areas participated in several meetings 12 and provided important input. US Selected Options for ITER TBM Select a helium-cooled solid breeder concept with ferritic steel structure and neutron multiplier, but without an independent TBM. Support EU and Japan using their designs and their TBM structure and ancillary equipment. Contribute only unit cell and sub-module test articles that focus on particular technical issues of unique US expertise and of interest to all parties. (All ITER Parties have this concept as one of their options.) Focus on testing Dual-Coolant liquid breeder blanket concepts with potential for self-cooling. Develop and design TBM with flexibility to test one or both of these two options: a helium-cooled ferritic structure with self-cooled LiPb breeder zone that uses SiC insert as MHD and thermal insulator (insulator requirements in dual-coolant concepts are less demanding than those for self-cooled concepts); a helium-cooled ferritic structure with low melting-point molten salt. Because of the low electrical and thermal conductivity of molten salts, no insulators are needed. (The key issues for MS are being addressed under JUPITER-II and no additional work is planned under ITER-TBM.) 13 Helium-Cooled Pebble Breeder Concept for EU Helium-cooled stiffening grid Breeder unit FW channel - The US can provide small breeder units “inside” the EU SB structure. - US Issues: Tritium Release and Thermomechanical Interactions 14 ITER Test Blanket Module Activities Active participation in ITER test blanket working group (TBWG) for test and infrastructure planning WSG participation Ancillary equipment and machine interface definition Evaluate blanket options for DEMO and evaluate R&D results for key issues to select primary US blanket concepts Perform concurrently R&D on the most critical issues required MHD flow with insulators and inserts Tritium recovery and control SiC inserts compatibility and failure modes Solid breeder / multiplier / structure / coolant interactions Develop engineering scaling and design, in collaboration with ITER partners, for TBMs. 15 Test Blanket Working Group (TBWG) TBWG was proposed by SWG-1 and established by the ITER Council (IC-7 RECORDS, 14-15 December 1994) A formal and detailed charter of TBWG was developed During EDA, the US made major contributions to testing strategy, engineering scaling, test port, frame design, and machine interface TBWG Main Objectives: Develop a Coordinated Blanket Test Program and address the Interface between machine and the blanket modules The TBWG was re-established in new conditions (6 partners) in late 2003 and has had 3 meetings in FY04 TBWG Scope of Activities: A. Provide the design documentation for the assessment of TBMs prepared by the Parties, integration of TBMs into the ITER machine B. Promote cooperation among the ITER Parties’ TBMs C. Verify integration of the TBMs in the safety and environmental evaluations of each ITER candidate site D. Further develop the coordinated blanket test program 16 Two types of Solid Breeder TBMs have been studied in FY04 1. Unit cells (3) 192.5 mm x 211 mm x 650 mm 2. Quarter-port Submodules 730 mm x 910 mm x 600 mm • The proposal calls to share the port space to test contemporaneously independent unit 17 cells/submodules Various analyses have been performed for TBM designs to preserve key prototype parameters Unit cell temperature profile (edge-on design) Be Stress analysis shows smax = 268.4 MPa located at the corner of the front inner wall SB He In He out The displacement profile shows a non-uniform distribution with a maximum displacement of 3.51 mm 18 He in He out Sophisticated 2-D neutronics analysis shows testing objective can be achieved for a proposed NT TBM 5 10 -5 Right Configuration Left Configuration 4 10 Layer# -5 Layer# 1 3 10 1 2 3 -5 2 3 2 10 -5 5 6 3 4 7 4 1 10 -5 8 5 6 0 0 10 12 Left TBM Wall Be Layer-Left Config. Left VCP-Left Config. Br1 Right TBM Wall Be Layer- Middle Be-Rt. Submdule Be Layer-Rt. Config. Rt. VCP- Left Config. Left VCP-Rt. Config. Rt. VCP-Rt. Config. 10 JA TBM Finding: Flat nuclear heating and tritium production profiles allow two designs to be evaluated in a ¼ port submodule 8 Breeder (Lft. Config.) 6 4 Be (Rt. Config.) 2 0 10 20 30 40 30 40 50 60 70 Distance from Frame, cm Depth = 42 mm behind FW Proposed NT TBM 20 9 50 60 70 Toroidal Distance from Frame, cm 80 Tritium production profiles are nearly flat over a reasonable distance in the toroidal direction allowing accurate measurements be 19 performed FS/He/PbLi Dual Coolant Blanket Concept: Higher Performance Potential with current generation ferritic structure The reason fusion pursued high temperature structural materials is for high coolant temperature. MHD effects in high-velocity channel flows leads to very high primary stresses. IDEA of the Dual Coolant Concept* – Cool structure with He so that FS can be used. “Decouple” surface from bulk heating. Self-Cooled – Flow PbLi for self-cooling at low velocity – Use a SiC insert to electrically and thermally insulate the LM from the wall, so LM bulk temperature can be higher than the wall temperature (use the poor thermal and electrical conductivity of SiC as an advantage). – Result: potential for high bulk temperature with lower MHD pressure drop using Ferritic Steel. *Dual Coolant concepts proposed by ARIES and EU Breeder Zone ARIES-ST DCLL Breeder Unit 20 Structure, Insert, and Breeder Temperatures FS grid Temperature drop across the FCI is 175 C 21 Complex geometry MHD codes already being applied to DCLL blanket with SiC Flow Channel Inserts 2D and 3D codes (developed for Liquid walls) have been modified for DCLL Initial results show strong sidelayer jets at sSiC = 500 S/m with current DCLL design 2D and 3D codes give conflicting results concerning flow in the “stagnant” gap region. Code improvements and debugging, and continued simulations planned for FY05. Strong negative flow jet near pressure equalization slot not seen in 3D simulation Velocity profile from 2D Simulation Slice from 3D Simulation Gap corner jets not seen in 2D simulation 22 Study of DCLL system and SiC FCI feasibility has shown: SiC flow channel inserts in DCLL systems have an interesting combination of effects that reduce pressure drop as compared to selfcooled LM systems Sensitivity to flaws and flow in complex geometry flow elements will dominate pressure drop and must be carefully examined Flow balancing technique must be analyzed and tested in more detail. SiC FCI properties and fabrication must be established more definitively Compatibility of FCI in a PbLi/RAFM steel system is a critical development issue Compatibility and corrosion are linked issues with DCLL design and MHD behavior More definitive first and second level compatibility experiments and modeling are necessary – definition of needed experiments could be an IEA Liquid Breeder Topic Tritium control is a key issue which will also be affected by the baseline MHD and subsequent FCI compatibility and corrosion Effective DCLL testing in ITER is possible and desirable MHD testing building towards integrated FCI performance Synergism with EU PbLi and RAFM program, Scaling and test program planning in the US underway 23 Technical Details from the US ITER-TBM efforts this year were presented at ANS TOFE Meeting in Madison e.g. Abdou, "US Plans and Strategy for ITER Blanket Testing" Morley, “Thermofluid Magnetohydrodynamic Issues for Liquid Breeders” Ying, “Engineering Scaling Requirements for Solid Breeder Blanket Testing” Smolentsev, “MHD Effects on Heat Transfer in a Molten Salt Blanket Youssef, “Activation Analysis for Two Molten Salt Dual-Coolant Blanket Concepts for the US Demo Reactor” Wong, “Assessment of Liquid Breeder First Wall and Blanket Options for the Demo Design” Sawan, “Neutronics Assessment of Molten Salt Breeding Blanket Design Options” Youssef, "On the Strategy and Requirements for Neutronics Testing in ITER“ … 24 J2 thermofluid experiments establish reference database for molten salt turbulence and heat transfer Umean(DNS) Umean(PIV) 20 Umean(DNS) Umean(PIV) 20 Ave Velocity u+ u+ Ave Velocity 10 10 0 100 1 101 y+ Re=5300 Re=5300 2 101 102 y+ 1 uv(DNS) uv(PIV) 0.8 Re=11300 0 100 10 uv/u uv(DNS) uv(PIV) 0.8 0.6 0.6 uv Careful turbulence measurements using PIV technique show excellent agreement with Direct Numerical Simulation in near wall and in channel core (see figs right ) Heat transfer reference cases also showing good agreement with standard correlations. Special 2T gap magnet with unobstructed viewing access for laser diagnostics designed and nearing completion. To be installed at UCLA in Dec. 2004. 0.4 0.4 0.2 0 0 0.2 Re stress 50 100 y+ Re = 5286 150 0 0 Re stress Re=11300 100 y+ 200 Re = 11,300 300 25 Two types of Solid Breeder TBMs have been studied in FY04 1. Unit cells (3) 192.5 mm x 211 mm x 650 mm 2. Quarter-port Submodules 730 mm x 910 mm x 600 mm • The proposal calls to share the port space to test contemporaneously independent unit 26 cells/submodules Simulation and experimental measurement of CERAMIC BREEDER PEBBLE BEDs plate Capacitance displacement sensor Li4SiO4/Li2O pebble beds 0.3 Experimental Data (700 oC) Experimental Data (750 oC) Experimental Data (800 oC) Creep Compaction strain (%) 0.25 FEM (700 oC) FEM (750 oC) FEM (800 oC) 0.2 0.15 0.1 0.05 0 2 4 Time (hour) 6 8 Due to the high stress at the local contact area, especially at the high temperature, creep deformation occurs. Discrete Element Method (DEM) is able to capture thermal deformation characteristics and can provide the detail stress distribution inside the pebble beds at both steady and transient states. Force distribution in the pebble bed simulated by DEM – line width gives a measure of contact force 27 Lithium Ceramic (Solid Breeders) Pebble Bed thermal conductivity data collected from all world fusion program experiments effective conductivity of Li-ceramic pebble bed for temp. (400 to 850C) interface conductance for temp. up to 550C. 20.47" 20 Vacuum Vacuum 21 Helium Ø 6.00" 6 2 1.26" 9.38" 3 4 1.97" 1 16 Thermal conductivity (W/m.K) Published studies show a wide spread in data, little error analysis, and conflicting temperature dependence Significant work this 1.9 1.8 year at UCLA to Li4SiO4, PF=62.5% [1] 1.7 design an Li4SiO4, 0.5mm [13] 1.6 experimental apparatus Li2TiO3, 60% [26] 1.5 Li2TiO3, 80% [26] to measure 1.4 1.3 1.2 1.1 1.0 0.9 0.8 0.7 0.6 0.5 Li2TiO3, 59% [1] Li2ZrO3, 53.4% [1] Li2ZrO3, 63% [28] Li2ZrO3, 60% [30] Li2ZrO3, 63-65% [3] Li2O, 62.1% [1] Li2O, 48% [5] Li4SiO4, PF=65% [27] Li4SiO4, PF=64.4% [29] 17 18" 0.97" 0.97" 0.5" 5 1" 7 1" 8 1" 9 0.88" 18 19 0.75" 13 0.5" 200 400 600 800 1000 1200 Temperature (C) 11 12 0.75" 0 10 14 15 2" 28 Ø 9.97" 4.00 1 Pebble Bed 6 Insulation (Particles Bed) 11 Vacuum CF-Flange 16 Vacuum Envelope 2 Heater 7 Heat Flux Meter (SS316) 12 VHT Glass-Mica Disc 17 Flexible Coupling 3 Thermocouple 8 Macor Disc 13 VHT Glass-Mica Disc 18 TC Feedthrough 4 Macor Ring 9 Macor Disc 14 HT Glass-Mica Disc 19 Vacuum Port 5 Heat Flux Sensors Disc 10 Vacuum CF-Flange 15 Water-Cooled Heat Sink 20 Vacuum Chamber 21 Helium Chamber Issues and Recommended Approaches 29 Tritium Self-Sufficiency Tritium self-sufficiency condition: Λa > Λr Λr = Required tritium breeding ratio Λr is 1 + G, where G is the margin required to account for tritium losses, radioactive decay, tritium inventory in plant components, and supplying inventory for start-up of other plants. Λr is dependent on many system physics and technology parameters: plasma edge recycling, tritium fractional burn-up in the plasma tritium inventories (release/retention) in components efficiency/capacity/reliability of the tritium processing system, etc. Λa = Achievable tritium breeding ratio Λa is a function of technology, material and physics. FW thickness, amount of structure in the blanket, blanket concept (ITER detailed engineering is showing FW may have to be much thicker than we want for T self sufficiency) Presence of stabilizing/conducting shell materials/coils for plasma control and attaining advanced plasma physics modes Plasma heating/fueling/exhaust, PFC coating/materials/geometry Plasma configuration (tokamak, stellerator, etc.) Uncertainties in nuclear data required for accurate determination of TBR For a few million dollars’ expenditure on test blanket modules, we will acquire vital data and develop critical technologies – an additional excellent return on the billions of dollars invested in ITER. 30 Tritium Consumption and Production Tritium Consumption in Fusion is HUGE! 55.8 kg per 1000MW fusion power per year Production & Cost • CANDU Reactors: 27 kg from over 40 years, $30M/kg (current) • Fission reactors: 2-3 kg per year. It takes tens of fission reactors to supply one fusion reactor. $84M-$130M per kg, per DOE Inspector General* Conclusions • The cost of blanket development and ITER TBM is a fraction of the cost to “purchase” tritium for a burning plasma facility such as ITER. • “Availability” of external tritium supply for continued fusion development is an issue. • Large power DT facilities must breed their own tritium. (This is why ITER’s extended phase was planned to install a tritium breeding blanket.) *DOE Inspector General’s Audit Report, “Modernization of Tritium Requirements Systems”, Report DOE/IG-0632, December 2003, available at www.ig.doe.gov/pdf/ig-0632.pdf 31 World Tritium Supply Would be Exhausted by 2025 if ITER Were to Run at 1000MW at 10% Availability (OR at 500 MW at 20% availability) Projected Ontario (OPG) Tritium Inventory (kg) 30 25 CANDU Supply 20 w/o Fusion 15 1000 MW Fusion, 10% Avail, TBR 0.0 10 ITER-FEAT (2004 start) 5 0 1995 2000 2005 2010 2015 2020 2025 2030 2035 2040 2045 Year 32 ITER Provides the First Integrated Experimental Conditions for Fusion Technology Testing • Simulation of all Environmental Conditions Neutrons Plasma Particles Electromagnetics Tritium Vacuum Synergistic Effects • Correct Neutron Spectrum (heating profile) • Large Volume of Test Vehicle • Large Total Volume, Surface Area of Test Matrix 33 Highlights of US Strategy for ITER TBM (Evolved over the past year by the community, DOE and VLT) The US will seek to maximize international collaboration. There is a need for all parties to collaborate, and to possibly consider a more integrated plan among the ITER parties for carrying out the R&D and construction of the test modules. ITER TBM should be viewed as a collaborative activity among the VLT program elements. While the Blanket/Chamber Program provides the lead role for ITER TBM, major contributions from other programs (e.g., Materials, Safety, PFC) are essential. The US community has now reached consensus on preferred options for ITER TBM (see separate slide), following assessment of new technical results obtained over the past few years 34 Strategy for Testing Solid Breeder (He/SB/Be/FS) Concepts The US plans on unit cells and submodule tests to address specific technical issues such as temperature window and temperature control (not a fully independent TBM, uses other Parties ancillary equipment) The world program (particularly EU and Japan) in this area is strong There are very good reasons why the US program should contribute to this area 1. the only universally accepted concept, 2. exciting issues with a lot of science, 3. Nearest term breeding capability for extended phase in ITER 35 Present U.S. Solid Breeder R&D Effort Carried out mostly in collaboration with other countries (IEA, JUPITER-II) Solid Breeder Blanket Specifics: Focus on niche areas of solid breeder blanket material system thermomechanics interactions (Primary organizations: UCLA, Support: ORNL, PNL) • design database on effective thermo-physical and mechanical properties for breeder and beryllium pebble beds • experiments and modeling development on evaluation of thermomechanical states of blanket element pebble beds under different loading conditions Material/Blanket Experiments Interface: Development of Web based INTEGRATED FUSION MATERIALS DATABASE (UCLA, UCBS, ANL, ORNL) Construction of VISTA (VIRTUAL INTERNATIONAL STRUCTURAL TESTING ASSEMBLY) modelling tool, to evaluate a range of potential interactions and failure paths (perform “Virtual Experiments”). (UCLA, UCBS, FZK, ANL, ORNL) 36 DCLL Test Phases in ITER H and D Specific electromagnetic structure and MHD TBM: Structural TBMs reaction to field environment and various transient plasma events – for instance “water hammer” effect during rapid plasma current quench Scaled pressure drop tests, flow balance test and critical velocity profiles affecting heat transfer in increasing field strength SiC FCI integrity under MHD loading Low Duty DT Thermofluid TBMs: High Duty DT Partially-integrated Thermafluid TBMs: Scaled stress response of thermally loaded SiC inserts and the effects of failures on pressure drop and thermal field Tritium production and permeation Corrosion and compatibility in nuclear field Radiation damage ~1 dpa in the inserts Tritium control 37 DCLL Concepts Issues: SiC FCI Properties A) Electrical and thermal conductivity of the SiC/SiC perpendicular to the wall should be as low as possible to avoid velocity profiles with sidelayer jets and excess heat transfer to the He-cooled structure. B) The inserts have to be compatible with Pb-17Li at temperatures up to 700-800°C. C) Liquid metal must not “soak” into pores of the composite in order to avoid increased electrical conductivity and high tritium retention. In general “sealing layers” are required on all surfaces of the inserts. - Even if the change in conductivity results in modest increase in pressure drop, it could seriously affect flow balance. D) There are minimum primary stresses in the inserts. However, secondary stresses caused by temperature gradients must not endanger the integrity under high neutron fluence. E) The insert shapes must be fabricable and affordable. 38 DCLL Concept Issues: MHD effects in self-cooled liquid metal breeding regions Primary issue for blanket application and ITER testing is the MHD pressure and flow distribution for complex geometry flow elements: SiC FCI overlap regions (stovepiping) Defects in FCIs Flow balancing sections Turns, Field entrance/exit regions, Manifolds, Expansions/Contractions Coaxial Pb-Li supply/return lines MHD velocities profiles can exhibit strong jets next to regions of stagnation and even reversed flow Large temperature gradients can drive natural convection flows that MHD effects do not damp – can swamp forced flow velocity in slow moving breeder zone regions All of these MHD issues, through effects on temperature, velocity shear and convection, and determination of LM-facing material, will have effects on the corrosion and tritium permeation of the concept 39 Tritium Permeation • Tritium Permeation is emerging as a persistently serious issue for most (some believe for ALL) concepts • Developing acceptable solutions requires integrated efforts among many programs: Materials, Tritium, PFC, Safety, Plasma Chamber 40 FY05 and FY06 plans 41 ITER TBWG Participation, Planning and Documentation Requirements ITER TBWG ~quarterly meetings and contribute to the final TBWG report on test strategy For both Solid Breeder and Dual Coolant Pb-17Li Concepts, prepare and deliver to TBWG, a complete preliminary Design Description Document containing TBMs design Fabrication Qualification program plans Optimization of TBM system Provide initial TBM delivery date 42 Solid Breeder and Multiplier tasks Participate in the collaborative tasks that have been defined in the IEA solid breeder (and liquid breeder subgroups), in which R&D results improve/impact TBM designs • design database on effective thermo-physical and mechanical properties for breeder and beryllium pebble beds • experiments and modeling development on evaluation of thermomechanical states of blanket element pebble beds under different loading conditions 43 IEA collaboration on solid breeder pebble bed time dependent thermomechanics interactions/deformation Primary Variables • Materials • Packing • Loadings • Modes of operation Partially integrated out-of-pile and fission reactor tests (NRG,ENEA) Single/multiple effect experiments (NRG, UCLA) Finite Element Code (ABQUS, MARC) (NRG, FZK, UCLA) Design Guideline and Evaluation (out-of-pile & in-pile tests, ITER TBMs) Primary & Secondary Reactants: • Temperature magnitude/ gradient • Differential thermal stress/contact pressure • Plastic/creep deformation • Particle breakage • gap formation Discrete Element Model (UCLA) Thermo-physical and Mechanical Properties Consecutive equations Database Experimental Program (FZK, JAERI, CEA,UCLA) Goal: Performance/Integrity prediction & evaluation Irradiation Effect (NRG) 44 Pb-17Li dual coolant blanket concept TBM Main R&D Tasks, Multi-year: Strong effort on development of simulation capability (see slice of 3D simulation, right) and experimental test plan, facility construction for LMMHD effects in closed channels with complex geometry and heterogenous wall conductivity Example simulation: MHD boundary layer jets formed in a channel with SiC flow channel insert Assessment, compatibility and property experiments on the feasibility of the SiC insert DCLL Reference and scaled TBM design for dual-coolant PbLi concepts in collaboration among US Plasma chamber community 45 What experiments needed to determine Pb-Li SiC compatibility? FY05 - More definitive capsule experiments required to show first level of compatibility More prototypic SiC composite should be used Long exposure time to overcome any incubation period for wetting Pressurization, impurities typical of RAFM steel Careful post-examination of both SiC crucible for evidence of attack and PbLi melt for accurate concentration of dissolved SiC As an intermediate step suitable models should be developed and the basic material properties (most important diffusivity and saturation concentration as functions of temperature) should be obtained from the literature when available, and from dedicated experiments as necessary. FY06 and beyond – Quantification of the allowable interface temperature in a corrosion flow loop with relevant temperature gradients, typical materials, and realistic flow conditions (Provided SiC/PbLi passes first level of assessment ) 46 JUPITER-II collaboration for Plasma Chamber Systems All experiments are directed to solve key feasibility issues for the molten salt, Li/V and solid breeder ITER test modules. 1. Flibe REDOX control Completed flibe purification process. Completed flibe mobilization experiment. Started hydrogen isotopes (D) permeation, diffusion and solubility measurements. Preparation for the REDOX experiments. Presented two papers at ICFRM and Be workshop. 2. Flibe heat transfer and flow mechanics Measured straight pipe velocity profile and turbulent statistics. Constructed 304SS heat transfer test section, with some initial data available. New acrylic PIV attachment section constructed and tested. Prepared for the MHD experiment with a US supplied magnet. 3. MHD coating development Coatings of AlN, Y2O3 and Er2O3 have been tested in Li up to 800C. Vacuum distillation system developed and tested to remove residue lithium from test coupons. Resistivity experiments conducted for Er2O3, Y2O3 and (Y,Sc)O3 to confirm sufficient resistivity for MHD coating. 4. SiC/pebble bed thermomechanics experiments Two configurations were developed. 47 ITER Nuclear Analysis Needed in Three Areas Nuclear analysis for ITER TBM • This effort is ongoing and funded as part of the US ITER TBM activities Nuclear support for basic ITER Device • Nuclear support is needed particularly for US preferred procurement packages (diagnostics, plasma heating and CD, module 18 (baffle), CS coils) • This support will ensure that the US delivers components with great confidence in its successful performance in ITER nuclear environment • ~$200K (~1 FTE) a year needed. Small burden to the US ITER construction budget to support the other programs • The US neutronics community (primarily Universities) has strong interest in providing this support. This allows training students and young scientists Development of CAD/Neutronics coupling • Needed to facilitate the 3-D neutronics analysis of ITER components effectively • Allows using geometric models directly from the actual design system, resulting in more accurate results and reduce time between CAD-based design changes and analysis • ITER International Team requested that support • Resources needed ~$100K (~0.5 FTE) per year for two years 48 Nuclear Analysis for TBM TBM designs will be developed and modeled for 3-D neutronics calculations with all design details The TBM 3-D model will be integrated in the complete basic ITER machine 3-D model Perform 3-D neutronics calculations using the integrated model Neutronics calculations will provide important nuclear environment parameters (e.g., radiation damage, tritium production, transmutations, radioactivity, decay heat, and nuclear heating profiles in the TBM) that help in analyzing TBM testing results 49 Nuclear Analysis for ITER Basic Machine As ITER proceeds to construction, individual component designs become more clearly defined and more accurate nuclear analyses are needed. Accurate evaluation of the nuclear radiation level at these components is essential to assess their survivability and performance capability Special attention should be devoted to components that are sensitive to radiation and have penetrations with radiation streaming concern Detailed 3-D nuclear analyses needed in support of US procurement packages Radiation leakage through holes and other penetrations must be fully assessed to establish activation levels for personnel access Module 18 50 CAD-Based MCNP Development Use Sandia’s CGM interface to evaluate CAD directly from MCNP » CGM provides common interface to multiple CAD engines, including voxel-based models MCNP MCNP Native Geometry CGM Pro/E Voxels Benefits: » Dramatically reduce turnaround time from Clothespin, w/helical ARIES-CS Plasma CAD-based design changes spring surface – Identified as key element of ITER Neutronics analysis strategy » No translation to MCNP geometry commands – Removes limitation on surface types – Robustness improved by using same engine for CAD and MCNP » Can handle 3D models not supported in MCNP Status: prototype using direct CAD query from MCNP Issues/plans: ACIS Benchmarking the current prototype version of MCNP/CGM for ITER analyses. Explore various approaches to transferring geometry from the ITER CAD design system (possibly CATIA) to the ACIS-based MCNP/CGM The most immediate limitation is that it is slower than MCNP alone. The focus will be to speed up the ray-tracing portion of the code (lots of acceleration techniques possible) 51 Goal: speed comparable to MCNP, but using direct CAD evaluation Recommended approaches to increased effectiveness 52 Programmatic Issues Requiring DOE, VLT, and US ITER Management Attention Include ITER-TBM and Nuclear Science and Engineering in US ITER Organization a “box/area” for TBM in the Organizational Chart – this is essential to keep ITER link for TBMs that will influence basic machine design and building space – budget from DOE can remain separate from ITER construction funds a “box/area” for Nuclear Science and Engineering – Small budget should come from ITER funds to support US procurement packages in diagnostics, module 18, etc. Recognize ITER-TBM as a US Program and organize it as a community effort Led by Plasma Chamber but with major contributions from Materials Program and significant contributions from PFC, Safety, and Tritium Programs Form Steering Committee with members from TBWG , 53 Plasma Chamber, Materials, PFC, Safety, etc. Programmatic Issues Requiring DOE, VLT, and US ITER Management Attention (Cont.) Resources Needed Technical expertise is available Required financial resources will be estimated over the next few months, but preliminary estimates show they are modest, not much beyond present budgets (mostly “refocus” and “rebalance” with modest increases) Resources consist of: a) annual R&D: starting now; already started under Plasma Chamber with some support from Materials, Safety , and PFC. Need to do more under other programs. • Need a lot more from the Material Program in particular (discussions to refocus parts of Materials to serve ITER-TBM needs is underway) b) cost of constructing Test Articles (to be inserted in ITER): needed 7 years from now . It is modest and can be adjusted based on the role US wants to play. 54