Plasma Chamber

advertisement

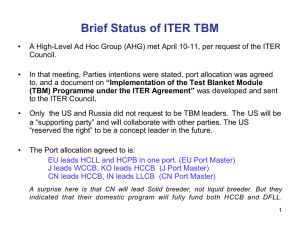

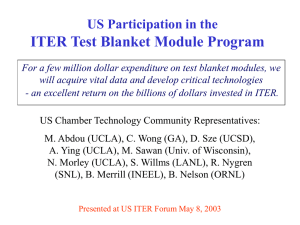

Plasma Chamber Prepared by M. Abdou, A. Ying, N. Morley, C. Wong, D. Sze, M. Sawan, P. Calderoni, S. Malang, M. Dagher, S. Smolentsev, B. Merrill (on behalf of the Plasma Chamber Community) VLT Meeting, Washington DC, August 25, 2005 Key R&D Thrusts over the next 5 years for the VLT Area 1. 2. 3. 4. 5. MHD Thermofluid Modeling and Experiments Solid Breeder Thermomechanics and Tritium Recovery Tritium Control and Predictive Capability VTBM: Virtual TBM (Integrated Modeling) Design and Analysis of TBM Test Articles and Ancillary Equipment 6. Sub-Component Verification Tests 7. Mockup Facilities Design, Construction and Operation 8. Diagnostics / Instrumentation / Control 9. “TBWG” International Testing Program and ITER/ Parties Interface 10. Tritium Supply and Self-Sufficiency 2 Descriptions of R&D thrusts 1. 2. 3. MHD Thermofluids Modeling and Experiments Experiments and modeling in 3-D complex geometry and multicomponent magnetic fields and gradients. Explore fluid flow behavior, heat, and mass transfer of flow channel inserts (as thermal and electrical insulators) in liquid metal flows, and effects of LM exposure and temperature gradients on long-term FCI performance. Characterize flow behavior in external elements such as feed pipes and manifolds, and investigate natural convection in volumetrically heated channels. Solid Breeder Thermomechanics and Tritium Recovery Experiments and modeling on the effect of stress-induced timedependent strain deformation on blanket thermal and tritium release performance. Investigate limits (“temperature window”) of tritium release. Tritium Control and Predictive Capability Explore methods, conduct experiments and develop models to predict and control tritium transport in fusion systems, accounting for convective, isotope swamping, and geometric effects under relevant pressure and temperature regimes. 3 Descriptions of R&D thrusts (cont’d) 4. 5. 6. 7. VTBM: Virtual TBM (Integrated Modeling) Develop numerical simulation tools and common data structure for overall system simulation of TBM performance and operation, coupling various advanced simulation tools for nuclear heating, thermofluid MHD, structural mechanics, corrosion and solute transport, etc. Will be used to predict steady-state and transient TBM behavior in ITER. The VTBM will be used to guide designs of TBM and mockups, as well as predict and interpret results from sub-component and mockup tests. Results from testing in ITER will be used to validate the VTBM for use in design and analysis of blankets for future systems, DEMO, and power plants. Design and Analysis of TBM Test Articles and Ancillary Equipment Complete conceptual design, carry out preliminary and final design and analysis of TBM test articles and associated ancillary equipment (piping, heat exchangers, tritium processing, pumps, etc.). Sub-Component Verification Tests Tests for specific elements of TBM article design to verify computational predictions (or obtain direct experimental data) and performance projections of sub-components, particularly in areas where there are large uncertainties in data or methods (e.g., flow distribution in complex manifolds, co-axial piping performance) Mockup Facilities Design, Construction and Operation Investigate facilities required for scaled mockup (e.g., ¼, ½ size) tests of TBM (use or upgrade existing facilities or design and construct new ones) with key environmental conditions to simulate the ITER environment. Design and test mockups for validation and qualification of performance, fabrication methods, etc. 4 Descriptions of R&D thrusts (cont’d) 8. Diagnostics / Instrumentation / Control Identify suitable diagnostic and measurement systems that can operate in the nuclear/electromagnetic environment of ITER, taking into consideration the chemical systems of the TBM, including PbLi compatibility, high-pressure helium, activated materials, etc. Corresponding operational control systems will also be considered. 9. “TBWG” International Testing Program and ITER/Parties Interface Perform tasks as required by the ITER International Testing Program responsible for the interface with the ITER basic device, developing qualification requirements and acceptance criteria, and coordination of tests among the ITER Parties. Also, Bi-lateral and multi-lateral international collaborative R&D for TBM. 10. Tritium Supply and Self-Sufficiency Dynamic simulation of world tritium supply and consumption and assessment of the tritium supply issue. Evaluate the need for and practicality of outboard breeding blanket in ITER second phase. Develop comprehensive fuel cycle dynamics model to predict tritium behavior, transport, and inventories in all system components such as plasma exhaust, PFC, blankets, and tritium processing. Determine “phase space” of plasma, nuclear, material and technological conditions in which self-sufficiency can be attained. 5 Current Spending on Plasma Chamber Thrusts • • Thrusts 1, 2, 3, 5, 9, 10: $1225 K Thrusts 4, 6, 7, 8: $0 K Notes: • There is $731 K from PFC for MHD thermofluid modeling and experiments that are “dual use” for PFC and Plasma Chamber • There is $560 K from JUPITER-II that are “dual use” with Plasma Chamber • The cost of operating facilities is shared among various programs and activities 6 Characterization of R&D thrusts to VLT missions Support US Contribution to ITER (Dual Use Technology) Additional R&D to support ITER ITER utilization as test bed (TBM, etc.) Next generation technology (current, future machines) X Longer-term R&D (for machines beyond ITER) MHD Thermofluids X X SB Thermomechanics & T Recovery * X X T Control & Predictive Capability X X X * * X X X * * X X X X X X X TBWG & ITER Interface * X T Supply & Self-Sufficiency X X Virtual TBM TBM Design and Analysis Verification Tests Mockup Facilities & Tests Diagnostics X X X X X X * Supports providing T-breeding capabilities in ITER second phase (years 11-20) 7