Fusion Science and Technology Mohamed Abdou, Neil Morley, Alice Ying

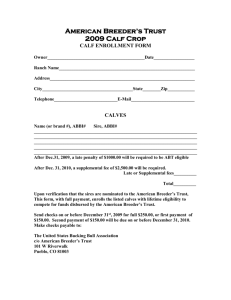

advertisement

Fusion Science and Technology Mohamed Abdou, Neil Morley, Alice Ying Mechanical and Aerospace Engineering Dept. CESTAR: Center for Energy Science and Technology Advanced Research WEB SITE: http://www.fusion.ucla.edu/ Presentation at KAIST/UCLA Joint Workshop, January 13-14, 2005 Fusion Science and Technology at UCLA • Fusion Research is exciting and active worldwide • UCLA has strong research programs in plasma physics, fusion science and technology • The largest part of the Fusion Science and Technology Research at UCLA is in the Mechanical and Aerospace Engineering Department • UCLA leads the US program in Fusion Nuclear Technology • We already have strong international collaborative programs with Europe, Japanese Universities, JAERI, Korea (KAIST and KAERI), China, and Russia • Our research involves many technical disciplines: fluid mechanics, heat transfer, MHD, tritium transport, neutronics, materials, structural mechanics • We have constructed world-class experimental facilities. Many students do their Ph.D. research in these facilities. The facilities also attract important international collaborations Introduction Incentives for Developing Fusion • Fusion powers the Sun and the stars – It is now within reach for use on Earth • In the fusion process lighter elements are “fused” together, making heavier elements and producing prodigious amounts of energy • Fusion offers very attractive features: – Sustainable energy source (for DT cycle; provided that Breeding Blankets are successfully developed) – No emission of Greenhouse or other polluting gases – No risk of a severe accident – No long-lived radioactive waste • Fusion energy can be used to produce electricity and hydrogen, and for desalination The Deuterium-Tritium (D-T) Cycle • World Program is focused on the D-T cycle (easiest to ignite): D + T → n + α + 17.58 MeV • The fusion energy (17.58 MeV per reaction) appears as Kinetic Energy of neutrons (14.06 MeV) and alphas (3.52 MeV) • Tritium does not exist in nature! Decay half-life is 12.3 years (Tritium must be generated inside the fusion system to have a sustainable fuel cycle) • The only possibility to adequately breed tritium is through neutron interactions with lithium – Lithium, in some form, must be used in the fusion system Fusion Nuclear Technology (FNT) Fusion Power & Fuel Cycle Technology FNT Components from the edge of the Plasma to TF Coils (Reactor “Core”) 1. Blanket Components 2. Plasma Interactive and High Heat Flux Components a. divertor, limiter b. rf antennas, launchers, wave guides, etc. 3. Vacuum Vessel & Shield Components Other Components affected by the Nuclear Environment 4. Tritium Processing Systems 5. Instrumentation and Control Systems 6. Remote Maintenance Components 7. Heat Transport and Power Conversion Systems Shield Blanket Vacuum vessel Radiation Plasma Neutrons First Wall Tritium breeding zone Coolant for energy conversion Magnets Blanket Concepts (many concepts proposed worldwide) A. B. Solid Breeder Concepts – Always separately cooled – Solid Breeder: Lithium Ceramic (Li2O, Li4SiO4, Li2TiO3, Li2ZrO3) – Coolant: Helium or Water Liquid Breeder Concepts Liquid breeder can be: a) Liquid metal (high conductivity, low Pr): Li, or 83Pb 17Li b) Molten salt (low conductivity, high Pr): Flibe (LiF)n · (BeF2), Flinabe (LiF-BeF2-NaF) B.1. Self-Cooled – Liquid breeder is circulated at high enough speed to also serve as coolant B.2. Separately Cooled – A separate coolant is used (e.g., helium) – The breeder is circulated only at low speed for tritium extraction B.3. Dual Coolant – FW and structure are cooled with separate coolant (He) – Breeding zone is self-cooled A Helium-Cooled Li-Ceramic Breeder Concept: Example Material Functions • Beryllium (pebble bed) for neutron multiplication • Ceramic breeder (Li4SiO4, Li2TiO3, Li2O, etc.) for tritium breeding • Helium purge (low pressure) to remove tritium through the “interconnected porosity” in ceramic breeder • High pressure Helium cooling in structure (ferritic steel) Several configurations exist (e.g. wall parallel or “head on” breeder/Be arrangements) Liquid Breeder Blanket Concepts 1. Self-Cooled – Liquid breeder circulated at high speed to serve as coolant – Concepts: Li/V, Flibe/advanced ferritic, flinabe/FS 2. Separately Cooled – A separate coolant, typically helium, is used. The breeder is circulated at low speed for tritium extraction. – Concepts: LiPb/He/FS, Li/He/FS 3. Dual Coolant – First Wall (highest heat flux region) and structure are cooled with a separate coolant (helium). The idea is to keep the temperature of the structure (ferritic steel) below 550ºC, and the interface temperature below 480ºC. – The liquid breeder is self-cooled; i.e., in the breeder region, the liquid serves as breeder and coolant. The temperature of the breeder can be kept higher than the structure temperature through design, leading to higher thermal efficiency. Flows of electrically conducting coolants will experience complicated magnetohydrodynamic (MHD) effects What is magnetohydrodynamics (MHD)? – Motion of a conductor in a magnetic field produces an EMF that can induce current in the liquid. This must be added to Ohm’s law: j (E V B ) – Any induced current in the liquid results in an additional body force in the liquid that usually opposes the motion. This body force must be included in the Navier-Stokes equation of motion: V 1 1 (V )V p 2 V g j B t – For liquid metal coolant, this body force can have dramatic impact on the flow: e.g. enormous MHD drag, highly distorted velocity profiles, non-uniform flow distribution, modified or suppressed turbulent fluctuations Large MHD drag results in large MHD pressure drop Conducting walls Insulated wall Lines of current enter the low resistance wall – leads to very high induced current and high pressure drop 1 0.8 0.6 0.4 1 0.8 0.6 0.4 0.2 0.2 0 0 -0.2 -0.2 All current must close in the liquid near the wall – net drag from jxB force is zero -0.4 -0.6 -0.8 -1 • • -0.6 -0.8 -1 -1 -1 • -0.4 -0.8 -0.6 -0.4 -0.2 0 0.2 0.4 0.6 0.8 -0.8 -0.6 -0.4 -0.2 0 0.2 0.4 0.6 0.8 1 1 Net JxB body force p = cVB2 where c = (tw w)/(a ) For high magnetic field and high speed (self-cooled LM concepts in inboard region) the pressure drop is large The resulting stresses on the wall exceed the allowable stress for candidate structural materials • • Perfect insulators make the net MHD body force zero But insulator coating crack tolerance is very low (~10-7). – • It appears impossible to develop practical insulators under fusion environment conditions with large temperature, stress, and radiation gradients Self-healing coatings have been proposed but none has yet been found (research is on-going) ITER U.S. In-kind Contributions to ITER 4 of 7 Central Solenoid modules Steady-state power supplies 15% of port-based diagnostic packages 44% of ICRH Antenna, plus all transmission lines, RF-sources, power supplies Start-up gyrotrons, all transmission lines, and power supplies Test Blanket Module Tokamak exhaust processing system Pellet Injector Baffle Cooling for Divertor and Vacuum Vessel Roughing pumps, standard components ITER Provides the First Integrated Experimental Conditions for Fusion Technology Testing • Simulation of all Environmental Conditions Neutrons Plasma Particles Electromagnetics Tritium Vacuum Synergistic Effects • Correct Neutron Spectrum (heating profile) • Large Volume of Test Vehicle • Large Total Volume, Surface Area of Test Matrix Blanket Concepts for ITER-TBM Selected by the Various Parties • Solid Breeders – He/SB/Be/FS: All parties are strongly interested – H2O/SB/Be/FS: Only Japan (some interest from China) • Liquid Breeders – He/LiPb/FS (Separately cooled): EU lead (one of two main concepts for EU, interest from other parties) – Dual Coolant (He/LiPb/FS with SiC): US lead, strong interest from EU and other parties – Li/V (Self-cooled): Russia is main advocate (but no significant resources on R&D!) – Molten Salts: US and Japanese Universities want the option to decide later whether to test – He/Li/FS: Korea’s proposal Blanket Testing in ITER is one of ITER’s Key Objectives Strong international collaboration among the ITER Parties is underway to provide the science basis and engineering capabilities for ITER TBMs Bio-Shield Plug TBM Frame & Shield Plug Cryostat Plug Breeder Concentric Pipe Transporter EU HCLL Test Module FW Cryostat Extension US Solid breeder submodule Drain Pipe Conceptual Liquid Breeder Port Layout and Ancillary equipment UCLA Activities UCLA Program in Fusion Engineering Research Current UCLA Research Activities – – – – – ITER Test Blanket Module R&D Molten Salt Thermofluid MHD (Jupiter-II) Solid Breeder / SiC Thermomechanics (Jupiter-II) Solid Breeder / Steel Thermomechanics (IEA) ITER Basic Machine and Procurement Package Support – Free Surface MHD Flows for Plasma Facing Components – IFE Chamber Clearing Study Experiments, Microscopic and Macroscopic Modeling efforts simultaneously underway to Understand and Predict Solid Breeder Blanket Pebble Bed Thermomechanics Interactions Force distribution inside Average stress exerted on the particles at the particles with 1% compressive strain initial time and at time 2000 minutes Stress exerted on the wall at different bed temperatures 0.5 0.25 -0.25 Normal Stress (MPa) DEM calculations Temp = 450 oC Temp = 650 oC Temp = 822 oC 0 -0.5 -0.75 -1 -1.25 -1.5 -1.75 -2 MARC calculations -2.25 -2.5 0 10 20 30 40 50 Radial distance (mm) Stress relaxed as creep initiated Stress magnitude profiles at different times 1 Time = 0 hr Time = 2 hr Time = 24 hr Time = 48 hr Normal Stress (MPa) 0.5 0 Solid breeder pebbles after the tests -0.5 -1 -1.5 MARC calculations -2 0 10 20 30 Radial distance (mm) 40 50 Test Article for Deformation Study IEA collaboration on solid breeder pebble bed time dependent thermomechanics interactions/deformation research Primary Variables • Materials • Packing • Loadings • Modes of operation Partially integrated out-of-pile and fission reactor tests (NRG,ENEA) Single/multiple effect experiments (NRG, UCLA) Finite Element Code (ABQUS, MARC) (NRG, FZK, UCLA) Design Guideline and Evaluation (out-of-pile & in-pile tests, ITER TBMs) Primary & Secondary Reactants: • Temperature magnitude/ gradient • Differential thermal stress/contact pressure • Plastic/creep deformation • Particle breakage • gap formation Discrete Element Model (UCLA) Thermo-physical and Mechanical Properties Consecutive equations Database Experimental Program (FZK, JAERI, CEA,UCLA) Goal: Performance/Integrity prediction & evaluation Irradiation Effect (NRG) UCLA is collaborating on HIMAG 3D - a complex geometry simulation code for free surface MHD flows Simulations are crucial to both understanding phenomena and exploring possible flow option for NSTX Li module Problem is challenging from a number of physics and computational aspects requiring clever formulation and numerical implementation Complex geometry: Free surface flow around cylindrical penetration Unstable MHD velocity profiles in gradient magnetic fields breakdown into instability Complex geometry MHD codes already being applied to DCLL blanket with SiC Flow Channel Inserts • 2D and 3D codes (developed for Liquid walls) have been modified for DCLL • Initial results show strong sidelayer jets at SiC = 500 S/m with current DCLL design • 2D and 3D codes give conflicting results concerning flow in the “stagnant” gap region. • Code improvements and debugging, and continued simulations planned for FY05. Strong negative flow jet near pressure equalization slot not seen in 3D simulation Velocity profile from 2D Simulation Slice from 3D Simulation Gap corner jets not seen in 2D simulation UCLA MTOR can be for basic flow physics, free surface and TBM module simulation experiments Large magnetic volume for complex geometry modules Higher field smaller volume regions for higher MHD interaction experiments 30 liter gallium alloy flowloop FC#1 FC#2 MTOR LM-MHD Facility Experiments on film flows show formation of 2D turbulence structures B Turbulent fluctuations organize into 2D structures with U vorticity along the magnetic field Corner vortices and small surface disturbances suppressed Flow can Pinch-IN in field gradients and separate from the wall Drag can be severe, slowing film down by 2x or 3x B Sophisticated 2-D neutronics analysis shows testing objective can be achieved for a proposed NT TBM 5 10 -5 Right Configuration Left Configuration 4 10 Layer# -5 Layer# 1 3 10 1 2 3 -5 2 3 2 10 -5 5 6 3 4 7 4 1 10 -5 8 5 6 0 0 10 12 Left TBM Wall Be Layer-Left Config. Left VCP-Left Config. Br1 Right TBM Wall Be Layer- Middle Be-Rt. Submdule Be Layer-Rt. Config. Rt. VCP- Left Config. Left VCP-Rt. Config. Rt. VCP-Rt. Config. 10 JA TBM Finding: Flat nuclear heating and tritium production profiles allow two designs to be evaluated in a ¼ port submodule 8 Breeder (Lft. Config.) 6 4 Be (Rt. Config.) 2 0 10 20 30 40 30 40 50 60 70 Distance from Frame, cm Depth = 42 mm behind FW Proposed NT TBM 20 9 50 60 70 Toroidal Distance from Frame, cm 80 Tritium production profiles are nearly flat over a reasonable distance in the toroidal direction allowing accurate measurements be performed Pulsed electro-thermal plasma gun facility provides extreme high heat flux capability for IFE super-heated vapor condensation study Goal: Time 0 assessing chamber clearing issues in Inertial Fusion Energy systems 820 ms 1640 ms Frame sequences recorded with high Electrical network system provides a pulsed speed camera - 10,000 frames per second energy source simulating the pellet explosion for and shutter speed of 100 ms rapid vapor generation Vapor pressure decay curve Droplet size ~ 1 to 2 mm Condensed steel droplets on top of deposited film Vapor density decays exponentially Condensation characterization from super-heated vapor (for Z-pinch) with a time constant of 6.58 ms in the Expansion chamber and diagnostics for super17 -3 range between 5x10 cm and heated vapor consideration studies 2x1015 cm-3 Possibilities for Collaboration Excellent opportunities exist for collaboration between US and Korea on fusion engineering • US has extensive experience in fusion blanket systems developed over 30 years • US has focused blanket R&D on key areas of blanket feasibility • Korea has strong background in fission and now fusion technology systems • Korea has strong industrial and manufacturing capabilities • Collaboration possibilities are numerous, especially on development and deployment of ITER TBMs of joint interest. Possibilities for US-Korea Collaboration on Helium-Cooled Ceramic Breeder Blankets • Development and characterisation of ceramic breeder and beryllium pebbles • Thermo-mechanics of pebble beds • Tritium release characteristics of ceramic breeders and beryllium • Beryllium behaviour under irradiation • Helium cooling technology • Prototypical mock-up testing in out-of-pile facility • In-pile testing of sub-modules • Development of instrumentation Possibilities for US-Korea Collaboration on Liquid Metal* Breeder Blankets • Fabrication techniques for SiC Inserts • MHD and thermalhydraulic experiments on SiC flow channel inserts with Pb-Li alloy • Pb-Li and Helium loop technology and out-ofpile test facilities • MHD-Computational Fluid Dynamics simulation • Tritium permeation barriers • Corrosion experiments • Test modules design, fabrication with RAFS, preliminary testing • Instrumentation for nuclear environment *Similar possibilities exist also for molten-salt blankets