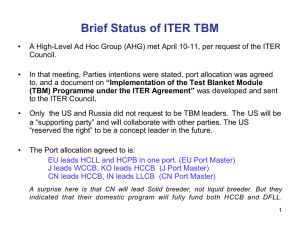

Blanket Concepts and Issues Mohamed Abdou

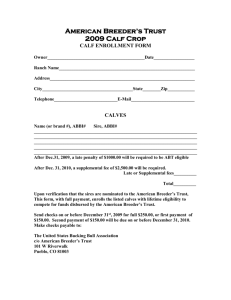

advertisement

Blanket Concepts and Issues Mohamed Abdou Distinguished Professor of Engineering and Applied Science Director, Center for Energy Science and Technology (CESTAR) Director, Fusion Science and Technology Center University of California, Los Angeles (UCLA) web: http://www.fusion.ucla.edu/abdou/ Lecture at the symposium "Towards a Mexican Fusion Programme" 21-22 June, 2007 held at Universidad Nacional Autonoma de Mexico Blanket (including first wall) Blanket Functions: A. Power Extraction – Convert kinetic energy of neutrons and secondary gamma rays into heat – Absorb plasma radiation on the first wall – Extract the heat (at high temperature, for energy conversion) B. Tritium Breeding – Tritium breeding, extraction, and control – Must have lithium in some form for tritium breeding C. Physical Boundary for the Plasma – Physical boundary surrounding the plasma, inside the vacuum vessel – Provide access for plasma heating, fueling – Must be compatible with plasma operation – Innovative blanket concepts can improve plasma stability and confinement D. Radiation Shielding of the Vacuum Vessel There are Many Blanket Concepts Proposed Worldwide They all have feasibility issues and attractive features Material or Configuration Options Structural Materials Reduced Activation Ferritic Steel Alloys (including ODS), Vanadium Alloys, SiC Composites Coolant Media Helium, Water, Liquid Metals, Molten Salts Breeder Media Lithium-Bearing: Ceramic Breeders (Li4SiO4, Li2TiO3, Li2O); Liquid Metals (Li, PbLi, SnLi); Molten Salts (FLiBe, FLiNaBe); Varying enrichments in Li-6 Neutron Multiplier Materials Beryllium, Be12Ti, Lead MHD/Thermal Insulator Materials SiC composites and foams, Al2O3, CaO, AlN, Er2O3, Y2O3 Corrosion and Permeation Barriers SiC, Al2O3, others Plasma Facing Material Beryllium, Carbon, Tungsten alloys, others HX or TX Materials Ferritic Steels, Refractory Alloys, SiC, Direct Gas Contact Blanket Configurations He or Water Cooled Ceramic Breeder/Be; Separately Cooled, Self-Cooled, DualCoolant LM or MS Ceramic Breeder Configurations Layered, Mixed, Parallel, Edge-On (referenced to FW) Liquid Breeder Configurations Radial-Poloidal Flow, Radial-Toroidal Flow, others MHD/Thermal Insulator Config. Flow Channel Inserts, Self-Healing Coatings, Multi-Layer Coatings Structure Fabrication Routes HIP; TIG, Laser and E-beam Welding; Explosive Bonding; Friction Bonding; Investment Casting; and others Blanket Concepts (many concepts proposed worldwide) A. B. Solid Breeder Concepts – Always separately cooled – Solid Breeder: Lithium Ceramic (Li2O, Li4SiO4, Li2TiO3, Li2ZrO3) – Coolant: Helium or Water Liquid Breeder Concepts Liquid breeder can be: a) Liquid metal (high conductivity, low Pr): Li, or 83Pb 17Li b) Molten salt (low conductivity, high Pr): Flibe (LiF)n · (BeF2), Flinabe (LiF-BeF2-NaF) B.1. Self-Cooled – Liquid breeder is circulated at high enough speed to also serve as coolant B.2. Separately Cooled – A separate coolant is used (e.g., helium) – The breeder is circulated only at low speed for tritium extraction B.3. Dual Coolant – FW and structure are cooled with separate coolant (He) – Breeding zone is self-cooled Solid Breeder Blanket Concepts The idea of a solid breeder blanket is to have the lithium-containing tritium breeder as non-mobile and to reduce lithium and tritium inventory as described in M.A. Abdou, L.J. Wittenberg, and C.W. Maynard, "A Fusion Design Study of Nonmobile Blankets with Low Lithium and Tritium Inventories", Nuclear Technology, 26: 400–419 (1975). – Always separately cooled – Coolant: Helium or Water – Solid Breeder: Lithium Ceramic (Li2O, Li4SiO4, Li2TiO3, Li2ZrO3) – A neutron multiplier is always required to achieve TBR > 1 (with the possible exception of Li2O) because inelastic scattering in non-lithium elements render Li-7 ineffective – Only Beryllium (or Be12Ti) is possible (lead is not practical as a separate multiplier) – Structure is typically Reduced Activation Ferritic Steel (RAFS) A Helium-Cooled Li-Ceramic Breeder Concept: Example Material Functions • Beryllium (pebble bed) for neutron multiplication • Ceramic breeder (Li4SiO4, Li2TiO3, Li2O, etc.) for tritium breeding • Helium purge (low pressure) to remove tritium through the “interconnected porosity” in ceramic breeder • High pressure Helium cooling in structure (ferritic steel) Several configurations exist (e.g. wall parallel or “head on” breeder/Be arrangements) “Temperature Window” for Solid Breeders • The operating temperature of the solid breeder is limited to an acceptable “temperature window”: Tmin– Tmax – Tmin, lower temperature limit, is based on acceptable tritium transport characteristics (typically bulk diffusion). Tritium diffusion is slow at lower temperatures and leads to unacceptable tritium inventory retained in the solid breeder – Tmax, maximum temperature limit, to avoid sintering (thermal and radiation-induced sintering) which could inhibit tritium release; also to avoid mass transfer (e.g., LiOT vaporization) • The limitations on allowable temperature window, combined with the low thermal conductivity, place limits on allowable power density and achievable TBR Liquid Breeders Many liquid breeder concepts exist, all of which have key feasibility issues. Selection can not prudently be made before additional R&D and fusion testing results become available. Type of Liquid Breeder: Two different classes of materials with markedly different issues. a) Liquid Metal: Li, 83Pb 17Li High conductivity, low Pr number Dominant issues: MHD, chemical reactivity for Li, tritium permeation for LiPb b) Molten Salt: Flibe (LiF)n · (BeF2), Flinabe (LiF-BeF2-NaF) Low conductivity, high Pr number Dominant Issues: Melting point, chemistry, tritium control Liquid Breeder Blanket Concepts 1. Self-Cooled – Liquid breeder circulated at high speed to serve as coolant – Concepts: Li/V, Flibe/advanced ferritic, flinabe/FS 2. Separately Cooled – A separate coolant, typically helium, is used. The breeder is circulated at low speed for tritium extraction. – Concepts: LiPb/He/FS, Li/He/FS 3. Dual Coolant – First Wall (highest heat flux region) and structure are cooled with a separate coolant (helium). The idea is to keep the temperature of the structure (ferritic steel) below 550ºC, and the interface temperature below 480ºC. – The liquid breeder is self-cooled; i.e., in the breeder region, the liquid serves as breeder and coolant. The temperature of the breeder can be kept higher than the structure temperature through design, leading to higher thermal efficiency. Advantages of Liquid Metal Blankets LM Blankets have the Potential for: High heat removal Adequate tritium breeding ratio appears possible without beryllium neutron multiplier in Li, PbLi (Pb serves as a multiplier in PbLi). (Note that molten slats, e.g flibe has beryllium part of the salt and generally requires additional separate Be.) Relatively simple design Low pressure, low pumping power (if MHD problems can be overcome) See BCSS for review of many possible blanket systems. Flows of electrically conducting coolants will experience complicated magnetohydrodynamic (MHD) effects What is magnetohydrodynamics (MHD)? – Motion of a conductor in a magnetic field produces an EMF that can induce current in the liquid. This must be added to Ohm’s law: j (E V B ) – Any induced current in the liquid results in an additional body force in the liquid that usually opposes the motion. This body force must be included in the Navier-Stokes equation of motion: V 1 1 (V )V p 2 V g j B t – For liquid metal coolant, this body force can have dramatic impact on the flow: e.g. enormous MHD drag, highly distorted velocity profiles, non-uniform flow distribution, modified or suppressed turbulent fluctuations Main Issue for Flowing Liquid Metal in Blankets: MHD Pressure Drop Feasibility issue – Lorentz force resulting from LM motion across the magnetic field generates MHD retarding force that is very high for electrically conducting ducts and complex geometry flow elements Thin wall MHD pressure drop formula p MHD LJB LVB p, pressure L, flow length J, current density B, magnetic induction V, velocity , conductivity (LM or wall) a,t, duct size, wall thickness 2 wt w a c A perfectly insulated “WALL” can eliminate the MHD pressure drop. But is it practical? Conducting walls Insulated walls Lines of current enter the low resistance wall – leads to very high induced current and high pressure drop 1 0.8 0.6 0.4 1 0.8 0.6 0.4 0.2 0.2 0 0 -0.2 -0.2 All current must close in the liquid near the wall – net drag from jxB force is zero -0.4 -0.6 -0.8 -1 • • -0.6 -0.8 -1 -1 -1 • -0.4 -0.8 -0.6 -0.4 -0.2 0 0.2 0.4 0.6 0.8 -0.8 -0.6 -0.4 -0.2 0 0.2 0.4 0.6 0.8 1 1 Net JxB body force p = cVB2 where c = (tw w)/(a ) For high magnetic field and high speed (self-cooled LM concepts in inboard region) the pressure drop is large The resulting stresses on the wall exceed the allowable stress for candidate structural materials • • Perfect insulators make the net MHD body force zero But insulator coating crack tolerance is very low (~10-7). – • It appears impossible to develop practical insulators under fusion environment conditions with large temperature, stress, and radiation gradients Self-healing coatings have been proposed but none has yet been found (research is on-going) Separately-cooled LM Blanket Example: PbLi Breeder/ helium Coolant with RAFM EU mainline blanket design All energy removed by separate He stream The idea is to avoid MHD issues. But, PbLi must still be circulated to extract tritium ISSUES: - Low velocity of PbLi leads to high tritium partial pressure , which leads to tritium permeation (Serious Problem) - Tout limited by PbLi compatibility with RAFM steel structure ~ 500C (and also by limit on Ferritic, ~550C) - Possible MHD Issues : A- MHD pressure drop in the inlet manifolds B- Effect of MHD buoyancy-driven flows on tritium transport EU-PPCS B Drawbacks: Tritium Permeation and limited thermal efficiency EU – The Helium-Cooled Lead Lithium (HCLL) DEMO Blanket Concept Module box (container & surface heat flux extraction) Breeder cooling unit (heat extraction from PbLi) [18-54] mm/s [0.5-1.5] mm/s Stiffening structure (resistance to accidental in-box pressurization i.e He leakage) He collector system (back) HCLL PbLi flow scheme Pathway Toward Higher Temperature Through Innovative Designs with Current Structural Material (Ferritic Steel): Dual Coolant Lead-Lithium (DCLL) FW/Blanket Concept First wall and ferritic steel structure cooled with helium Breeding zone is self-cooled Structure and Breeding zone are separated by SiCf/SiC composite flow channel inserts (FCIs) that Provide thermal insulation to decouple PbLi bulk flow temperature from ferritic steel wall Provide electrical insulation to reduce MHD pressure drop in the flowing breeding zone DCLL Typical Unit Cell Pb-17Li exit temperature can be significantly higher than the operating temperature of the steel structure High Efficiency Flow Channel Inserts are a critical element of the high outlet temperature DCLL FCIs are roughly box channel shapes made from some material with low electrical and thermal conductivity – SiC/SiC composites and SiC foams are primary candidate materials They will slip inside the He Cooled RAFS structure, but not be rigidly attached They will slip fit over each other, but not be rigidly attached or sealed FCIs may have a thin slot or holes in one wall to allow better pressure equalization between the PbLi in the main flow and in the gap region FCIs in front channels, back channels, and access pipes will be subjected to different thermal and pressure conditions; and will likely have different designs and thermal and electrical property optimization 17 DCLL should be effective in reducing MHD pressure drop to manageable levels Higher outlet temperature due to FCI thermal insulation allows large coolant delta T in breeder zone, resulting in lower mass flow rate requirements and thus lower velocity. Electrical insulation provided by insert reduces bare wall pressure drop by a factor of 10-100. 500 (dP/dx)0 / (dP/dx) Low velocity due to elimination of the need for FW cooling reduces MHD pressure drop. PEH PES 400 300 200 100 0 1 10 100 1000 Electrical conductivity, S/m Key DCLL DEMO R&D Items PbLi Thermofluid MHD Key impacts on thermal/power extraction performance, FCI load, safety SiC FCI development including irradiation effects Key impacts on DCLL lifetime, thermal and power extraction performance RAFS/PbLi/SiC compatibility & chemistry control Impacts DCLL lifetime and thermal performance Tritium extraction and control Critical element for PbLi which has low T solubility High temperature heat exchanger system Critical element for high temperature DCLL operation He distribution and heat transfer enhancement Key impacts on DCLL thermal and power extraction optimization RAFS fabrication development and materials properties Critical for any RAFS system Integrated behavior leading to Test Blanket Module testing in ITER Critical for any blanket system performance and reliability Brayton Cycle optimization for DCLL parameters Key impacts on thermal/power extraction performance Molten Salt Blanket Concepts • Lithium-containing molten salts are used as the coolant for the Molten Salt Reactor Experiment (MSRE) • Examples of molten salt are: – Flibe: (LiF)n · (BeF2) – Flinabe: (LiF-BeF2-NaF) • The melting point for flibe is high (460ºC for n = 2, 380ºC for n = 1) • Flinabe has a lower melting point (recent measurement at SNL gives about 300ºC) • Flibe has low electrical conductivity, low thermal conductivity Concepts considered by US for ITER TBM (but were not selected): – Dual coolant (He-cooled ferritic structures, self-cooled molten salt) – Self-cooled (only with low-melting-point molten salt) 20 Performing integrated breeding blanket experiments has been a principal objective of ITER since its inception “ITER should test design concepts of tritium breeding blankets relevant to a reactor. The tests foreseen in modules include the demonstration of a breeding capability that would lead to tritium self sufficiency in a reactor, the extraction of high-grade heat, and electricity generation.” SWG1, reaffirmed by ITER Council, IC-7 Records (14–15 December, 1994), and stated again in forming the Test Blanket Working Group (TBWG). The need to test breeding blankets in ITER has been recognized many times in the US planning efforts for ITER “Deliver to ITER for testing the blanket test modules needed to demonstrate the feasibility of extracting high-temperature heat from burning plasmas and for a self-sufficient fuel cycle (2013)” A Strategic Program Plan for Fusion Energy Sciences. http://www.ofes.fusion.doe.gov/News/FusionStrategicPlan.pdf “Participate in the [ITER] test blanket module program”, and “Deploy, operate and study test blanket modules”, Planning for U.S. Fusion Community Participation in the ITER Program, US BPO Energy Policy Act Task Group, 2006 TBM is an integral part of ITER Schedule, Safety, and Licensing ITER Schedule 1st 10 yrs Early H-H Phase TBM Testing is mandated by ITER IO and licensing team: 1. Optimize plasma control in the presence of Ferritic Steel TBMs 2. Qualify port integration and remote handling procedures 3. License ITER with experimental TBMs for D-T operation ITER Provides Substantial Hardware Capabilities for Testing of Blanket System TBM System (TBM + T-Extrac, Bio-shield Heat Transport/Exchange…) A PbLi loop Transporter located in the Port Cell Area 2.2 m ITER has allocated 3 ITER equatorial ports (1.75 x 2.2 m2) for TBM testing Each port can accommodate only 2 Modules (i.e. 6 TBMs max) He pipes to TCWS Equatorial Port Plug Assy. Vacuum Vessel TBM Assy Aggressive competition for space. (Note: fluence in ITER is limited. We also have to build another facility, CTF/VNS, for FNT development) Port Frame Blanket Concepts Proposed by 7 Parties for ITER Testing Concept Acronym Materials Proposing Party HCCB RAFS Structure Be multiplier Ceramic breeder (Li2TiO3, Li4SiO4, Li2O) Helium coolant and purge Water-Cooled Ceramic Breeder WCCB RAFS structure Be multiplier, Ceramic breeder (Li2TiO3, Li2O) Water coolant, He purge Helium-Cooled Lead-Lithium HCLL RAFS structure Molten Pb-17Li breeder/multiplier Helium coolant DCLL RAFS structure SiC flow channel inserts Molten Pb-17Li breeder/coolant/multiplier Helium coolant HCML RAFS structure Lithium breeder Helium coolant KO Li/V Vanadium alloy structure Insulator barrier (e.g., AlN) Lithium breeder/coolant RF LLCB RAFS structure, PbLi multiplier/breeder/coolant Dual Helium Coolant Dual Ceramic Breeder IN Helium-Cooled Ceramic Breeder Dual-Coolant Lead-Lithium Helium-Cooled Molten Lithium Self-Cooled Lithium Lead-Lithium Ceramic Breeder EU, KO, CN (JA,US, RF, IN)* *Supporting/Submodule Role JA EU, CN US, CN (EU, JA, IN)* *Supporting Role - Proposed 12 designs for TBM’s representing 7 classes of concepts - But there is much common R&D (e.g. for ferritic steel, ceramic breeder, PbLi) among the concepts HCCB Joint Partnership Preliminary discussions occurred among US, Japan, and Korea about a possible partnership on HCCB. US ITER TBM KO Submodule JA Submodule US Submodule The proposed US HCCB sub-module will occupy 1/3 of an ITER horizontal half-port The back plate coolant supply and collection manifold assembly, incorporating various penetration pipes, flexible supports, and keyways, should be collaboratively designed by partner Parties. A “Lead Party” takes responsibility for fabrication of the back plate and integration of the three sub modules. Baseline strategy proposes different levels of participation for two US TBM concepts US ITER TBM After extensive effort two blanket concepts that have substantially different feasibility issues were selected: 1. The Dual-Coolant PbLi Liquid Breeder Blanket (DCLL) concept with self-cooled PbLi breeding zone and flow channel inserts (FCIs) as MHD and thermal insulator. – Innovative concept (favored by US PC and ARIES, and EU – DEMO) that provides “pathway” to higher outlet temperature/higher thermal efficiency while using ferritic steel . – US lead role in collaboration with other parties. Plan an independent TBM that will occupy half an ITER test port. 2. The Helium-Cooled Solid Breeder Blanket (HCCB) concept with ferritic steel structure and beryllium neutron multiplier, but without an independent TBM. – ALL parties are interested. HCCB is the most likely candidate for near-term breeding blankets, e.g. in ITER extended phase. – Supporting partnership with other parties with shared ancillary equipment. With modest investment in HCCB, US will gain access to large international program, – Contribute submodule test articles that focus on particular technical issues. DCLL TBM Module (1660 x 484 x 410 mm) Poloidal flow PbLi Channel He-cooled RAFS FW SiC FCI HCCB TBM sub-module (710 389 510 mm) Ceramic breeder pebbles He-cooled RAFS FW Be Pebbles R&D, Design, Fabrication and Qualification for TBMs must proceed Similar to all ITER components Key Project Milestones Approve 1st Module Fabrication, Final TSD Key early design decisions, TSD 1st Draft Approve Prototype Fabrication, complete structural design criteria • TBMs must not affect ITER availability • TBM systems make up part of the “Safety” boundary • TBMs must be part of the ITER licensing for HH and DT operation Framework Proposed for TBM collaboration & responsibilities (proposed by TBWG DH, July 2006) Each 1/2 of a port is dedicated to testing of one TB concept design (one module or several connected sub-modules). Each Concept design is tested by a partnership of a TB concept leader + supporting partners One of the two TB leaders occupying the same port must play a role of the Port master – responsible for integration of the given port Port Master has main responsibility of integration of 2 concepts in the same port frame and preparation of the integrated testing program (replacement strategy) for the port ITER has only 3 ports Only 6 TBMs can be tested List of TBM Design Proposals for day-one Helium-cooled Lithium-Lead TBM (2 designs) Dual-coolant (He+Lithium-Lead) TBM (2 designs) He-cooled Ceramic Breeder/Beryllium multiplier TBM (4 designs) Water-cooled Ceramic Breeder/Beryllium multiplier TBM (1 design) He-cooled Liquid Lithium TBM (1 design) Self-cooled Liquid Lithium TBM (1 design) 1248 750 (DDDs completed by Parties) 524 1700 Horizontal Vertical Each Port can hold two vertically or horizontally oriented half-port size integrated TBMs ITER TBM is a Necessary First Step in Fusion Environment Role of CTF (VNS) Role of ITER TBM Component Engineering Development & Reliability Growth Fusion “Break-in” & Scientific Exploration Engineering Feasibility & Performance Verification Stage I Stage II Stage III 1 - 3 MW-y/m2 > 4 - 6 MW-y/m2 1-2 MW/m2, steady state or long pulse COT ~ 1-2 weeks 1-2 MW/m2, steady state or long burn COT ~ 1-2 weeks 0.1 – 0.3 MW-y/m2 0.5 MW/m2, burn > 200 s Sub-Modules/Modules • Initial exploration of coupled phenomena in a fusion environment • Uncover unexpected synergistic effects, Calibrate non-fusion tests • Impact of rapid property changes in early life • Integrated environmental data for model improvement and simulation benchmarking • Develop experimental techniques and test instrumentation • Screen and narrow the many material combinations, design choices, and blanket design concepts Modules • Uncover unexpected synergistic effects coupled to radiation interactions in materials, interfaces, and configurations • Verify performance beyond beginning of life and until changes in properties become small (changes are substantial 2 up to ~ 1-2 MW · y/m ) • Initial data on failure modes & effects • Establish engineering feasibility of blankets (satisfy basic functions & performance, up to 10 to 20 % of lifetime) • Select 2 or 3 concepts for further development Modules/Sectors • Identify lifetime limiting failure modes and effects based on full environment coupled interactions • Failure rate data: Develop a data base sufficient to predict mean-timebetween-failure with confidence • Iterative design / test / fail / analyze / improve programs aimed at reliability growth and safety • Obtain data to predict mean-time-toreplace (MTTR) for both planned outage and random failure • Develop a database to predict overall availability of FNT components in DEMO D E M O Many R&D tasks are highly interactive, and collectively, they provide information critical to design, procurement specifications, qualification/acceptance tests, and definition of operating conditions US ITER TBM Example: Flow Channel Insert Function Decouple PbLi & FS Thermal insulation Electric insulation 10 Electrical Conductivity (S/m) 5 0 -5 -10 -15 -20 -25 -30 0 0.0005 0.001 0.0015 0.002 0.0025 0.003 0.0035 0.004 1/T (1/K) Flow Channel Insert (FCI) in DCLL Thermofluid MHD Effectiveness of FCI as electric/thermal insulator MHD pressure drop and flow distribution MHD flow and FCI property effects on T ITER TBM Low primary stress Robust to thermal stress - T ~200C Structural Analysis FCI stresses FCI deformations FCI/SiC Devel. & Fabrication Tailoring k and k(T), (T) Irradiation effect Fabrication issues ITER DT MHD Experiments Manifolds 3D FCI features ITER DT: Max stress<45 MPa UCLA Manifold Flow distribution Experiment (~1m length) VTBM Integrated Data/multi-code multi-physics modeling activities, or Virtual TBM, is key for ITER TBM R&D activity. • The design of a complex system like the ITER TBM requires an exhaustive CAE effort encompassing multiple simulation codes supporting multi-physics modeling. US ITER TBM CAD model of structure CAD Model Input Fix CAD model Temperature in solid domain CAD to Analysis Intermediaries Neutronics Electromagnetics Thermo Fluid Mass Transfer Structural Stress and Strain in solid domain