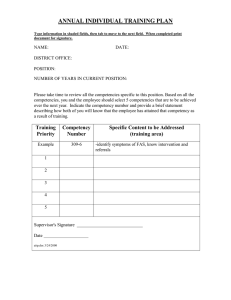

4 Assessment

advertisement