UNIVERSITY OF GLASGOW ASBESTOS GUIDANCE FOR CONTRACTORS WORKING ON

advertisement

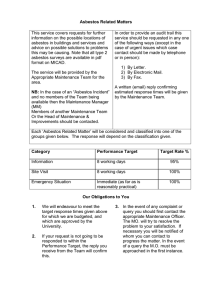

UNIVERSITY OF GLASGOW ASBESTOS GUIDANCE FOR CONTRACTORS WORKING ON UNIVERSITY PREMISES ESTATES AND BUILDINGS & SAFETY AND ENVIRONMENTAL PROTECTION SERVICES Date of Issue: October 2005 Asbestos Guidance for Contractors Working on University Premises 1. Introduction In the past a variety of asbestos containing materials (ACMs) have been used in one form or another in the construction and fitments of some University buildings. ACMs can also be found in plant, equipment and appliances. As such, this Guidance Note has been produced to give advice to contractors working on University premises whose work activities may bring them into contact with existing ACMs. Following the advice given in this Guidance Note should help to eliminate/reduce the risk of contact with ACMs and all contractors are requested to co-operate in this endeavour. It should be noted however, that this Guidance Note does not apply to Licensed Asbestos Removal Contractors who are subject to separate arrangements. 2. Those at Risk It is University policy that only specialist contractors who are licensed by the Health and Safety Executive (HSE) may carry out work on ACMs on University premises. However, it is recognised that the work of some contractors may bring them into contact with existing ACMs on University premises. Therefore, they must be aware of possible presence of ACMs, be able to recognise them when they encounter them and know what to do to prevent or minimise exposure to asbestos fibres. Examples of trades that might encounter asbestos during their normal duties include: Joiners, Gas fitters, Plumbers, Flooring contractors, Electricians, Cabling installers/layers, Heating/ventilation engineers, Demolition workers, Painters/decorators, Fire/security alarm installers, Plasterers, Telecommunications engineers, Roofing workers, General maintenance workers etc. Main or Principal Contractors must ensure that any sub-contractors they engage are made aware of the contents of this Guidance Note. 3. Competence It is a requirement that all contractors engaged by the University whose normal work activities may bring them into contact with existing ACMs within the University, will employ a competent workforce at all times. Amongst other things, this will mean that their employees have been provided with suitable and sufficient information, instruction and training in asbestos awareness in construction work appropriate to their position/authority within the organisation and will be competent to recognise the possibility of asbestos being present and how to deal with it. Such awareness should include knowledge of the following topics: The common uses and typical locations of asbestos products (See Appendix A), Legislation relating to work with asbestos (See Appendix B), The properties of asbestos, The health hazards posed by exposure to asbestos fibres and the risks that different types of asbestos pose to health, How to prevent or minimise exposure to asbestos fibres, How to recognise typical asbestos containing materials, What to do if suspected asbestos materials are encountered, The emergency procedures that should be followed if an area becomes contaminated. 4. Asbestos Register Estates and Buildings maintain an Asbestos Register of all known locations of ACMs within the fabric of the University buildings. This Register is based on a Type 2 Asbestos Survey carried out by specialist surveyors. Unless there is no risk of disturbing ACMs, the Asbestos Register must be consulted before any work, however minor, is undertaken. Where the work planned involves disturbance of the structure beyond what is visible by surface inspection, it may be necessary to arrange an additional asbestos survey such as a Type 3 to determine what lies deeper within the structure. Such a survey would require to be carried out by a specialist asbestos surveyor. This will be determined by the nature of the work planned and the existing information available. In the first instance, advice should be sought from the relevant Project Officer or Maintenance Officer. Note: It should not be assumed that there are no ACMs present in an area just because there is no mention in the Register. It only identifies the areas that have been subject to survey and some ACMs may still be concealed within the structure where only the most rigorous and destructive of surveys would reveal it. 5. Types of Buildings Likely to Contain Asbestos Many of the University's buildings date from an era when the use of asbestos was common and it may still be found in many locations within them. Asbestos is most likely to be found in the following categories of buildings: Those built or refurbished between 1950 and 1980; Those with a steel framed construction; Those fitted with elderly boilers or pipework with thermal insulation. 6. Work on the Building Fabric Although refurbishment, repair and maintenance work create the most obvious risks of damage, any task that involves work on the fabric of the building can potentially lead to disturbance of ACMs. In particular, whenever any drilling, sawing, cutting, sanding, scraping, hammering, or breaking-up of unknown materials is to be carried out steps must be taken to ensure that these do not contain asbestos. Other activities that can cause disturbance of ACMs include installation of cables, fire alarms, blinds, shelving, maintenance and repair of certain older types of electrical equipment etc. Careless movement of goods and equipment can also cause physical damage to asbestos containing building materials. Whenever any work likely to involve disturbance to the fabric of buildings is to be carried out, the risk of disturbing ACMs must always be actively managed and controlled. The presumption must always be that a material contains asbestos unless there is strong evidence that it does not. Provided that the material is in good condition, and is unlikely to be disturbed, damaged or worked on it does not present a risk to health. The Health and Safety Executive advise that, under these conditions, is safest to leave it in position. If any material is found which is suspected of containing asbestos, or if damaged ACMs (or suspected ACMs) are discovered, or work activity has resulted in damage to ACMs, work must be stopped immediately and the area sealed off. Estates and Buildings must then be informed. Appendix A Typical Locations of ACMs and their Usage The following table identifies some materials containing asbestos and indicates possible usage and locations where they might be found. The asbestos products are listed in approximate order of potential for fibre release. Asbestos Product Typical Usage/Location Loose asbestos insulation or packing Fire breaks in ceiling voids and fire stopping around cables. Also used as sound insulation between floors Sprayed coatings. Wet or dry applied. Usually un-bonded fibres. Usually known as “limpet” or “flock” asbestos. (Sometimes treated to provide a decorative finish) Generally fire protection in ducts, firebreaks, ceiling panels, partitions, soffit boards, around structural steel work and reinforced concrete beams/columns. Also used as anticondensation insulation on underside of roofs etc and acoustic insulation Thermal insulation. Hand-applied lagging or mass produced moulded or preformed products e.g. pipe sections Generally used in thermal insulation of heating systems where high levels of heat retention were required e.g. pipes, boilers, calorifiers, pressure vessels etc. Insulating boards (including blocks, composite products and “Millboard”) Usually known as AIB General fire protection, thermal and acoustic insulation in partitioning, firebreaks, infill panels, ceilings (including tiles) wall and stair linings, roof underlay and ducts. Used as heat-resisting panels screwed to, or in the centre of fire doors. Also used where moisture could be a problem and as a general building board. Also used for insulation of electrical equipment, boiler casings, oven linings, storage heaters and other heating appliances. Often used as heat resistant panels for ironing boards and Bunsen burner stands Woven asbestos products such as ropes, yarns, cloths and fabric joints Thermal insulation of boilers, pipes calorifiers etc. Also used for packing, jointing and sealing in boilers, incubators and ovens (particularly in door seals), gaiters between ductwork flanges and caulking of pipe ducts in brickwork. Cloths used as thermal insulation in the form of fire-resisting blankets (e.g. some very old types of fire blanket), protective curtains, gloves, aprons etc. Insulation between copper pipes and steel pipe clips. Insulation in electrical switchgear, particularly fuse boxes Paper, felt and cardboard products Insulation of electrical equipment and wiring, fire proofing of wood boarding, lining to flooring (backing to floor tiles) and DPC products. Also used to line surfaces of other boards, ceiling tiles and sheet materials. Corrugated cardboard sometimes used as pipe and duct insulation Gaskets, washers and strings Seals in boilers, calorifiers and other heating appliances, pipes and valve joints. Strings used for sealing various screw thread joints such as seals in hot water radiators Friction products Brakes and clutches in vehicles, machinery and lifts. Sometimes used in some drive belts Asbestos cement products A variety of applications such as roofing, partitioning, wall cladding products, soffits, rainwater goods, cold-water storage systems, pipes and flues, ventilation ducts, fume cupboards, portable buildings, propagation beds, general weather boarding, cooling towers, laboratory worktops, windowsills and boxes, draining boards, shuttering, dampproofing etc. Often used as heat resistant panels for ironing boards and Bunsen burner stands. Unlike AIB does not have a high resistance to fire but does have a high resistance to weathering Textured coatings and paints containing asbestos fibres Decorative/flexible coatings on walls and ceilings. Some types of “Artex”, “Pebblecoat” or “Wondertex” products Bitumen products, mastics, sealants, putties, tapes and adhesives Roofing felts, gutter linings, flashings, DPC, jointing tapes and floor/wall adhesives. Also used as anti-resonance pads under kitchen sinks Flooring products Thermoplastic and PVC tiles Reinforced PVC, plastic and resin composite products Panels, cladding, toilet seats and cisterns, banisters, window seals, lab bench tops, brake and clutch linings Note: Whilst this list is not exhaustive, it gives an indication of the type of materials and their typical locations, which commonly contained asbestos. Appendix B List of Key Legislation and References Introduction Many organisations have produced publications dealing with asbestos but the Health and Safety Executive (HSE) in particular have produced a wide range of publications that show how to reduce the risks from asbestos. Much of the advice focuses on construction and building maintenance, the area which carries the greatest risk of exposure. The publications also cover other areas including plumbing, joinery, electrical work and computer cable and fire alarm installation etc. This list has been produced as a guidance to enable contractors to be aware of HSE publications that are available. 1. Regulations (Statutory Instruments): SI 2002/2675: Control of Asbestos at Work Regulations 2002 (CAWR). SI 1983/1649: Asbestos (Licensing) Regulations 1983 (as amended). (ASLIC). SI 1992/3067: Asbestos (Prohibitions) Regulations 1992 (as amended). 2. HSC/HSE Approved Codes of Practice (ACoP’S): L127 The Management of Asbestos in Non-domestic Premises. Regulation 4 of The Control of Asbestos at Work Regulations 2002. Approved Code of Practice and Guidance. L28 Work with Asbestos Insulation, Asbestos Coating and Asbestos Insulation Board. Control of Asbestos at Work Regulations 2002. Approved Code of Practice. (Fourth edition) 2002. L27 Work with Asbestos which does not Normally Require a Licence. Control of Asbestos at Work Regulations 2002. Approved Code of Practice. (Fourth edition) 2002. 3. HSE Guidance Books: HSG227 A Comprehensive Guide to Managing Asbestos in Premises. 2002. HSG189/1 Controlled Asbestos Stripping Techniques for Work Requiring a Licence. 1999. HSG189/2 Working with Asbestos Cement. 1999. HSG210 Asbestos Essentials: Task Manual. Task Guidance Sheets for the Building Maintenance and Allied Trades. 2001. HSG213 Introduction to Asbestos Essentials - Comprehensive Guidance on Working with Asbestos in the Building Maintenance and Allied trades. 2001. L11 A Guide to the Asbestos (Licensing) Regulations 1983 as amended. (Second edition.) 1999. MDHS 100 Surveying, Sampling and Assessment of Asbestos-Containing Materials. 2001. (Methods for the Determination of Hazardous Substances) HSG248 Asbestos: The Analysts Guide for Sampling, Analysis and Clearance Procedures. 2005. HSG247 Asbestos: The Licensed Contractor’ Guide (Due for publication 2005). 4. HSE Leaflets: INDG223 A Short Guide to Managing Asbestos in Premises. 2002. INDG289 Working with Asbestos in Buildings. Asbestos: The Hidden Killer. Are You at Risk? 1999. INDG288 Selection of Suitable Respiratory Protective Equipment for Work with Asbestos. 1999. INDG255 Asbestos Dust Kills. Keep Your Mask On. Guidance for Employees. 1999. 5. HSE Pocket Cards: INDG188 Asbestos Alert: Workers Card for Building Maintenance, Repair and Refurbishment Workers. 1999. 6. HSE Posters: C50 Asbestos Building: Typical locations for ACMs. 7. HSE Environmental/Medical Guidance Notes: EH 47 The Provision, Use and Maintenance of Hygiene Facilities for Work with Asbestos Insulation, Asbestos Coating and Asbestos Insulating Board. EH 51 Enclosures Provided for Work with Asbestos Insulation, Coatings and Insulating Board. 2001. EH 50 Training Operatives and Supervisors for Work with Asbestos Insulation and Coatings. 1988. EH 57 The Problems of Asbestos Removal at High Temperatures 1993. MS 13 Asbestos: Medical Guidance Notes. 2005. 8. DETR (Environment) Guidance: Asbestos and Man-made Mineral Fibres in Buildings. (HMSO). Practical Guidance. 1999. 9. Videos: “How Are You Today?” “How Are You Managing?” Available from HSE Videos, PO Box 35, Wetherby, West Yorkshire LS23 7EX, Tel: 0845 741 9411, Fax: 01937 541083. 10. Other references: Asbestos Products (Safety) Regulations 1985. BS 4624: 1981 Methods of Test for Asbestos-cement Building Products. BS 5415: 1985 Spec. for Type “H” Vacuum Cleaners for Dusts Hazardous to Health. Carriage of Dangerous Goods by Road Regulations 1996. Carriage of Dangerous Goods by Road (Driver Training) Regulations 1996. Carriage of Dangerous Goods (Classification, Packaging and Labelling) Regs. 1996. Chemicals (Hazard Information and Packaging for Supply) Regulations 2002. Civic Government (Scotland) Act 1982. Control of Asbestos in the Air Regulations 1990. Construction (Design and Management) Regulations 1994 (as amended). Construction (Health, Safety and Welfare) Regulations 1996. Controlled Waste (Registration of Carriers and Seizure of Vehicles) Regulations 1991. Department of Health: SIB(85)16: Asbestos in Electric Storage Heaters. Environmental Protection Act 1990. Environmental Protection (Duty of Care) Regulations 1991 (as amended). Environmental Protection (Prescribed Process and Substances) Regulations 1991. Environment Act 1995. Health and Safety at Work etc. Act 1974. Health and Safety (Consultation with Employees) Regulations 1996. Health and Safety (Safety Signs and Signals) Regulations 1996. HSE 282/28(rev2002). Information Document: Fit Testing of RPE Facepieces. HSG173: Monitoring Strategies for Toxic Substances. 1997. HSG53: The Selection, Use and Maintenance of RPE 1998. INDG368: Use of Contractors: A Joint Responsibility. ISO/IEC 17025: 1999 General Requirements for the Competence of Testing and Calibration Laboratories Application of ISO/IEC 17025 for Asbestos Sampling and Testing – LAB 30 UKAS ISO 17020 International Standards published as BS EN 45004: 1995 General Criteria for the Operation of Various Types of Bodies Performing Inspection. BS EN ISO/IEC 17024: 2003 Conformity Assessment. General Requirements for Bodies Operating Certification of Persons. LAC No. 5/3: Asbestos Removal: Alternatives to Dry Stripping. LAC No. 5/13: Solvent Vapour Exposure Arising from the Use of Aerosol Glues During the Erection of Asbestos Stripping Enclosures and Selection of Suitable RPE. LAC No. 5/17: Asbestos (Prohibitions) (Amendment) Regulations 1999. LAC No. 5/18: Fit Testing of RPE Used for Controlling Exposure to Asbestos Fibres. LAC No. 5/19: Health Effects of Inadvertent Exposure to Asbestos – Guidance for HSE Field Operations Staff when Responding to Enquiries. LAC No. 5/20: Changes to Asbestos Licence Conditions. Management of Health and Safety at Work Regulations 1999. MDHS 39/4: Asbestos Fibres in Air: Sampling and Evaluation. (Fourth edition) (Soon to be fully replaced by HSG248) MDHS77: Asbestos in Bulk Materials: Sampling and Identification by Polarised Light Microscopy (PLM). (Soon to be fully replaced by HSG248) MDHS97: Methods for Sampling for Surface Contamination. MISC155: Substitutes for Chrysotile (white) Asbestos. *PAS 60 BS Codes of Practice: Equipment used in the controlled removal of ACMs: 1:2004 Controlled wetting of asbestos-containing materials. Specification. 2:2004 Negative pressure units. Specification. 3:2004 Operation, cleaning and maintenance of class H vacuum cleaners. Pollution Prevention and Control Act 1999. Personal Protective Equipment at Work Regulations 1992. Reporting of Injuries, Diseases and Dangerous Occurrences Regulations 1995. Safety Representatives and Safety Committees Regulations 1977. SHE9 Asbestos Use in Buildings. Loss Prevention Council. Special Waste Regulations 1996. (as amended) Waste Management Licensing Regulations 1994. Workplace (Health, Safety and Welfare) Regulations 1992. *Publicly Available Specification - produced by BSI in collaboration with HSE as a fully recognised specification for the asbestos removal industry. NOTE: This list is current at the date of issue. (See front cover)