Information Engineering Enhancing Information Quality for Effective Decision-Making in Textiles

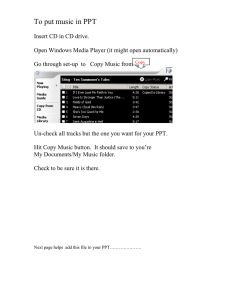

advertisement

Information Engineering Enhancing Information Quality for Effective Decision-Making in Textiles for The 2000 Massachusetts Institute of Technology Conference on Information Quality October 21, 2000 Cambridge, Massachusetts Presented By Mr. Neil Cahill Vice President Institute of Textile Technology Charlottesville, Virginia with Dr. George Hodge North Carolina State University Dr. William Oxenham North Carolina State University Mr. Yatin Karpe North Carolina State University i:\share\sandys\conferences\informationengineering-mit2.ppt . . . plant having Performance Capability a traditional plant does not have, and, therefore, cannot match performance, no matter how modern or well managed. i:\share\sandys\conferences\informationengineering-mit2.ppt ONE NEW CAPABILITY NEEDED . . . High proportion of current manufacturing performance losses are due to slow response to production problems. i:\share\sandys\conferences\informationengineering-mit2.ppt PERFORMANCE DEGRADATION CURVE Point of Degradation Normal X Point of Malfunction Process Performance X Point of Failure Poor X Response Delay Time i:\share\sandys\conferences\informationengineering-mit2.ppt SLOW RESPONSE CONTROL Good X Performance Loss X Performance Measures Reaction Point X Poor Short Response Delay Time Long i:\share\sandys\conferences\informationengineering-mit2.ppt FAST RESPONSE CONTROL Good X Reaction Point Performance Loss X Measures X Poor Short Response Delay Time Long i:\share\sandys\conferences\informationengineering-mit2.ppt TIME VALUE OF INFORMATION i:\share\sandys\conferences\informationengineering-mit2.ppt . . . Value of Information decays rapidly with elapse time after need to know. i:\share\sandys\conferences\informationengineering-mit2.ppt TIME VALUE OF INFORMATION Use Value of Information Need to Know TIME Info Available i:\share\sandys\conferences\informationengineering-mit2.ppt . . . Finding and Diagnosing information takes 80% of total time needed to complete a decision! i:\share\sandys\conferences\informationengineering-mit2.ppt DECISION RESPONSE TIME Decision Action Find Slow Reaction & Diagnose 10% 10% 80% 100% Fast Reaction Fd Diag Dec Act 5% 10% 10% 10% 35% i:\share\sandys\conferences\informationengineering-mit2.ppt Measuring Decision Effectiveness (Manufacturing Problem Solving) i:\share\sandys\conferences\informationengineering-mit2.ppt BASIC DETERMINANTS OF MANUFACTURING DECISION EFFECTIVENESS 1. Number of process malfunctions. 2. Delay in responding to problems. 3. Effectiveness of corrective action taken. i:\share\sandys\conferences\informationengineering-mit2.ppt DECISION EFFECTIVENESS EQUATION Decision Effectiveness = Malfunction Frequency Failure Rate ( )( Defects/ Hr )+ ( )( ) ( ) Response Delay Reaction Delay R.E. = % Response Effectiveness Defects/ Hr Elapse Time 1.0-R.E. Action Effectiveness TWO CONCEPTS OF AN INFORMATION SYSTEM i:\share\sandys\conferences\informationengineering-mit2.ppt INFORMATION DELIVERY SYSTEMS 1. Information Distribution System. 2. Decision Message System. i:\share\sandys\conferences\informationengineering-mit2.ppt Users Information Generator O O Information Flow Pipe O O General Report Traditional Information System i:\share\sandys\conferences\informationengineering-mit2.ppt WHAT DO USERS REALLY WANT? Information in Reports? OR Meaning in Information? i:\share\sandys\conferences\informationengineering-mit2.ppt . . . it is Meaning which allows people to understand situations and make appropriate decisions i:\share\sandys\conferences\informationengineering-mit2.ppt MESSAGES . . . Intended meaning to be conveyed by the information to the user. i:\share\sandys\conferences\informationengineering-mit2.ppt . . . I told him 10 times (Information), but he still doesn’t understand what’s happening (Message)! i:\share\sandys\conferences\informationengineering-mit2.ppt Users O O O Customized Report Expected Decision Message Interface Information Generator Information Flow Pipe Decision Message System i:\share\sandys\conferences\informationengineering-mit2.ppt Technician O O Manager Customer Message Interface Ta p Ta p Information Flow Customized Message Interface For User i:\share\sandys\conferences\informationengineering-mit2.ppt INFORMATION ENGINEERING . . . method to extract the Meaning Content from information before sending to user. i:\share\sandys\conferences\informationengineering-mit2.ppt . . . information needs are Decision-Driven i:\share\sandys\conferences\informationengineering-mit2.ppt DATA TO DECISION CYCLE Detection Data Information . . . sense an event . . . identify and quantify event . . . relationship of different events Diagnosis . . . meaning of relationships Message . . . understanding relationship Decision . . . choice of response Action . . . implement change i:\share\sandys\conferences\informationengineering-mit2.ppt DATA TO DECISION CYCLE Detection Data Information Information Reporting Diagnosis Message Decision Action i:\share\sandys\conferences\informationengineering-mit2.ppt DATA/INFORMATION REPORT Weaving Computer Monitoring Report MCH % EFF STY WVR S/RLH WS 0049 0052 0051 0053 0054 0055 0037 0038 0039 0040 0561 0562 0563 0564 0565 0001 0002 0003 0004 0005 0572 0573 Avg. 091.0 080.4 083.1 074.1 091.6 091.6 105.2 094.1 094.5 086.0 094.6 096.6 098.0 094.0 094.1 072.1 086.8 089.5 079.5 094.1 094.8 095.0 090.0. 056 056 056 056 056 056 056 056 053 056 056 053 056 056 053 056 056 053 056 053 056 053 032 033 033 033 033 032 032 032 033 033 033 032 032 033 032 033 033 032 033 032 032 032 1.09 1.24 0.90 2.02 0.27 1.22 0.00 0.13 0.13 0.72 0.26 0.65 0.38 0.13 0.53 2.08 0.72 1.68 0.94 0.53 1.18 0.92 0.80 5 6 5 11 2 8 0 1 1 3 2 3 3 1 3 4 1 3 2 1 2 5 FS 2 2 0 1 0 1 0 0 0 2 0 2 0 0 1 8 3 7 4 3 1 2 OS 1 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 1 2 0 0 6 0 i:\share\sandys\conferences\informationengineering-mit2.ppt DATA TO DECISION CYCLE Detection Data Information Diagnosis Message Meaningful Messages Decision Action i:\share\sandys\conferences\informationengineering-mit2.ppt MEANING/MESSAGE REPORT 100 o o o Machine Efficiency (%) o oo 95 o 90 o o o Weaver 032 o 85 80 Weaver 033 75 0 2 4 6 8 10 12 14 Stops Rate Efficiency Delay Curve i:\share\sandys\conferences\informationengineering-mit2.ppt Users O O O Customized Report Expected Decision Message Interface Information Generator Information Flow Pipe Decision Message System i:\share\sandys\conferences\informationengineering-mit2.ppt Walk-through Visit of 21st Century Textile Plant i:\share\sandys\conferences\informationengineering-mit2.ppt CIM Computer-Integrated Manufacturing i:\share\sandys\conferences\informationengineering-mit2.ppt Figure 1. Automated and computerized plant with full-factory communications network (Murata CIM Mill). i:\share\sandys\conferences\informationengineering-mit2.ppt . . . Future textile plants will be highly automated! i:\share\sandys\conferences\informationengineering-mit2.ppt Automated Piece Up and Cone Doffing Academic\No5Class899.ppt i:\share\sandys\conferences\informationengineering-mit2.ppt 38 i:\share\sandys\conferences\informationengineering-mit2.ppt 45 PLANT COMMUNICATIONS NETWORK . . . Local Area Network (LAN) providing real-time bi-directional communication between individual machines and plant computer. i:\share\sandys\conferences\informationengineering-mit2.ppt COMMUNICATIONS CENTER Assess Plant Performance Status and Broadcast Action Messages i:\share\sandys\conferences\informationengineering-mit2.ppt i:\share\sandys\conferences\informationengineering-mit2.ppt Broadcast Messages To Selected Personnel O Computer Control Center Broadcast O Message O Factory Network Machine-to-Man messaging i:\share\sandys\conferences\informationengineering-mit2.ppt SIGNAL DISPATCHED OPERATORS . . . Computerized monitoring system detects Machine Service Needs and automatically Calls appropriate personnel. i:\share\sandys\conferences\informationengineering-mit2.ppt O O Technician Operator O Handler Spinning Machine Change-Over Swat Team O Cleaner i:\share\sandys\conferences\informationengineering-mit2.ppt So now must . . . Put intelligence into the machine system! i:\share\sandys\conferences\informationengineering-mit2.ppt i:\share\sandys\conferences\informationengineering-mit2.ppt AUTOMATED DECISION OF FABRIC GRADE IF: More than (3) Stops/50 yards OR: Technician Repair Required THEN: Send AGV to Human Inspector IF NOT: Send AGV to Loading Dock i:\share\sandys\conferences\informationengineering-mit2.ppt ENGINEERING INFORMATION FOR MANUFACTURING DECISION MAKERS i:\share\sandys\conferences\informationengineering-mit2.ppt INSTANTANEOUS FACT-FINDING . . . provide a decision-maker with needed facts in the logical order to readily understand performance problem as soon as detected. DECISION MAKER DRAWS THE CONCLUSIONS i:\share\sandys\conferences\informationengineering-mit2.ppt TYPES OF DECISIONS MADE IN MANUFACTURING i:\share\sandys\conferences\informationengineering-mit2.ppt CLASSIFY DECISION TYPES 1. PROGRAMMABLE DECISION . . . repetitive situations with predictable response. 2. DISCRETIONARY DECISION . . . Situation requiring a judgment call. 3. KNOWLEDGE INTENSIVE DECISION . . . Unique situations requiring special knowledge for response. i:\share\sandys\conferences\informationengineering-mit2.ppt TYPE DECISIONS MADE IN MANUFACTURING 100 80 % Manufacturing Decisions 60 40 20 0 Programmable i:\share\sandys\conferences\informationengineering-mit2.ppt Discretionary Knowledge Intensive . . . concentrates on Programmable Decisions avoiding Discretionary or Knowledge-Intensive Decisions, which are highly complex and uncertain. i:\share\sandys\conferences\informationengineering-mit2.ppt DESIGNING THE MESSAGE INTERFACE i:\share\sandys\conferences\informationengineering-mit2.ppt MESSAGE INTERFACE . . . Part of communications system that converts information into Meaningful Message so user can make quicker and more effective decisions. i:\share\sandys\conferences\informationengineering-mit2.ppt Technician O O Manager Customer Message Interface Ta p Ta p Information Flow Customized Message Interface For User i:\share\sandys\conferences\informationengineering-mit2.ppt DATA TO DECISION CYCLE Detection Data Information Diagnosis Message Message Interface to User Decision Action i:\share\sandys\conferences\informationengineering-mit2.ppt DESIGNING THE MESSAGE INTERFACE 1. 2. 3. 4. 5. 6. 7. 8. Identify Machinery Layout. Identify Information Sources Identify Information User Determine Expected Decision. Determine Need-to-Know Information. Develop Diagnostic Logic. Design Actionable Message Format. Assess Action Effectiveness. i:\share\sandys\conferences\informationengineering-mit2.ppt STEP 1. MACHINERY LAYOUT . . . specific type and arrangement of production machinery to be controlled. i:\share\sandys\conferences\informationengineering-mit2.ppt PROCESS NAME MACHINE LAYOUT TYPE MONITOR Barco Sycotex Stretch Breaker Rebreaker Barco Sycotex Blender Servo Sliverdance Roving Barco Sycotex FA.NI Monitor Ring Spinning Savio Elios Linked Winding i:\share\sandys\conferences\informationengineering-mit2.ppt Loepfe Clearers PACKING Barco Sycotex STEP 2. IDENTIFY INFORMATION SOURCES . . . Determine what computer accessible sources of information are available. i:\share\sandys\conferences\informationengineering-mit2.ppt INFORMATION SOURCE DIAGRAM . . . Identifies types of information and monitoring source at each manufacturing process. i:\share\sandys\conferences\informationengineering-mit2.ppt INFORMATION SOURCE DIAGRAM Process Stretch Breaker Information Type Production Output Pounds Pounds/Hour Efficiency Stops Declaration (Long Stops) Maintenance Service Stop Cause Rebreaker Production Output Pounds Pounds/Hour Efficiency Stops Declaration (Long Stops) Maintenance Service Stop Cause i:\share\sandys\conferences\informationengineering-mit2.ppt STEP 3. IDENTIFY INFORMATION USER . . . Specific individuals, technicians, operators, managers, etc., who make decisions in response to problem situations. i:\share\sandys\conferences\informationengineering-mit2.ppt . . . Target User is maintenance technician. i:\share\sandys\conferences\informationengineering-mit2.ppt STEP 4. DETERMINE EXPECTED DECISIONS . . . decisions routinely made by Individual responsible for responding to a particular problem. i:\share\sandys\conferences\informationengineering-mit2.ppt MAINTENANCE TECHNICIAN EXPECTED DECISION PROBLEM SITUATION EXPECTED DECISION 1. High Flag Machines Quickly identify High Flag Machines and take corrective action with high First Time Success rate. 2. High Off-Quality Machines Identify quality defects while On-Machine and correct immediately. 3. Meet Maintenance Schedule Meet all maintenance schedules and assure adequate parts inventory. i:\share\sandys\conferences\informationengineering-mit2.ppt STEP 5. DETERMINE NEED-TO-KNOW INFORMATION . . . Specific information in logical order needed by decision-maker to understand situation and make right choice. i:\share\sandys\conferences\informationengineering-mit2.ppt MAINTENANCE TECHNICIAN Need-To-Know High Flag Machines 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. Which Machine? What Style? How Long? Type of Flags? Flag History. Maintenance Record. Parts Replacement Records Assigned Technicians. Assigned Weaver. Any Special Events i:\share\sandys\conferences\informationengineering-mit2.ppt STEP 6. DEVELOP DIAGNOSTIC LOGIC . . . Arrange need-to-know information into the logical order of inquiry that a decision-maker would follow to understand what happened and how to respond. i:\share\sandys\conferences\informationengineering-mit2.ppt TWO TYPES OF INQUIRY MADE BY COMPUTER QUESTIONS (Q’s) . . . information in database; go get it! MESSAGES (M’s) . . . information not available in database; ask people to find it! i:\share\sandys\conferences\informationengineering-mit2.ppt COMPUTING DIAGNOSTIC LOGIC High Flag Machine Diagnostic Stage I. Problem Focus . . . What problem to diagnose? II. Localize Problem . . . Where is problem located? Order of Inquiry Q1 Who is the User? Q2 What Malfunction triggered alarm? Q3 Which Machine triggered alarm? Q4 What Product being run? Q5 How long has problem been happening? Q6 All or some Machines? Q7 All or some positions on machine? Any other alarms on this machine? Q8 M1 i:\share\sandys\conferences\informationengineering-mit2.ppt Question/Message Statement Message to Maintenance: Check settings on alarm machines STEP 7. DESIGN ACTIONABLE MEASURE FORMAT . . . Did report to user (1) provide needed information, (2) explain what happened, and (3) allow an effective decision? i:\share\sandys\conferences\informationengineering-mit2.ppt ALERT/ADVISORY MESSAGE TO: Bob Roberts, Maintenance Technician ALERT: Machine 18 classified as Malfunctioning with Chronic High Flags. ADVISORY: Over past 5 days (1/1-1/5), 65% of checks out-of-limit, including stops, efficiency, flags, and quality points. ACTION: Flags which average 2/day relative to expected 0.25/day are the major source of losses. EFFECTIVENESS LOOP . . . System continuously assesses State of Control in manufacturing and Effectiveness of control action taken. i:\share\sandys\conferences\informationengineering-mit2.ppt DATA TO DECISION CYCLE DATA INFORMATION EFFECTIVENESS . . . did it work MEANING MESSAGES DECISION ACTION i:\share\sandys\conferences\informationengineering-mit2.ppt . . . Value of Information is its Meaning Content! i:\share\sandys\conferences\informationengineering-mit2.ppt