Description of the LCLS Undulator System Argonne National Laboratory Stephen Milton

advertisement

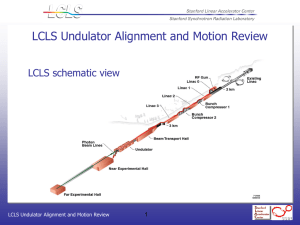

Description of the LCLS Undulator System Stephen Milton Argonne National Laboratory Office of Science U.S. Department of Energy A U.S. Department of Energy Office of Science Laboratory Operated by The University of Chicago Overview Pioneering Science and Technology Office of Science U.S. Department of Energy Undulator Systems WBS 1.2.3 Undulator Systems WBS 1.4 Pioneering Science and Technology Office of Science U.S. Department of Energy Cell structure of the LCLS Undulator Line 3420 657 421 UNDULATOR 11528 mm Horizontal Steering Coil Vertical Steering Coil Beam Position Monitor X-Ray Diagnostics 33 Undulators ~ 130-m Overall Length Quadrupoles Pioneering Science and Technology Office of Science U.S. Department of Energy List of the Undulator Line Systems • Undulator module – Magnets – Poles – Strongback – Other • Mechanical support - movers • Quadrupole Lens • Coils - correctors • E-beam position monitors • X-ray diagnostics • Undulator vacuum chamber and diagnostics station • Controls and data acquisition • Support laboratory - magnet measurement facility – Technical Definition and Oversight Only Pioneering Science and Technology Office of Science U.S. Department of Energy LCLS Project Engineering Design Organization Pioneering Science and Technology UCLA Office of Science U.S. Department of Energy PED Organization LCLS Undulator Management Project Leader Fabrication Management Project and Contract Assistant S. Milton J. Noonan F. Coose Diagnostics And Vacuum Controls Magnet Systems D. Walters J. Stein J. Noonan Low Power X-ray Diag. Magnet Systems 2nd Prototype High-Power X-Ray Diag. X-ray Diagnostics Undulator Magnets End of Und. X-ray Diag. Electron Beam Diagnostics Quadrupole Magnets Electron Beam Diag. Vacuum System Supports Vacuum System Machine Protection System Pioneering Science and Technology Office of Science U.S. Department of Energy Prototypes Pioneering Science and Technology Office of Science U.S. Department of Energy Undulator Design Issue • Field Variations – Must Maintain DB/B < 1 x 10-4 • Implies gap changes of < 1 mm • And to maintain temperature to within 0.4 C • Partial Compensation – Accomplished by Differential expansion of the titanium strong back and the aluminum magnet array comb. – This helped, but did not fully compensate the device – A Clever Field Control Scheme will be used Pioneering Science and Technology Office of Science U.S. Department of Energy Full Length Prototype [] V ert. TrajectoryH or. Trajectorymm Performance Measured to be within the Design Specification 4.5 4.0 3.5 3.0 2.5 2.0 1.5 1.0 0.5 0.0 -0.5 2.0 -2000 1.5 1.0 0.5 0.0 -0.5 -1.0 -1.5 -2.0 -2000 A s A ssem bled A fter Final Tuning -1000 0 2000 z [m m ] A s A ssem bled A fter F inal T uning -1000 0 z [m m ] Pioneering Science and Technology 1000 1000 2000 Device completed over a year and ½ ago. Office of Science U.S. Department of Energy 2nd Prototype Pioneering Science and Technology Office of Science U.S. Department of Energy Undulator System Schedule F03 F04 F05 F06 F07 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Critical Decisions CD-2a Long-Lead Procurement Budget Approval CD-2b Performance Baseline Approval CD-3a Long-Lead Procurement Approval and Authorize Long-Lead Procurement Funds CD-3b Start of Construction Approval and Authorize Construction Funds CD-4 Start of Operation Approval Phases PED Period Construction Period Key Milestones/Events Begin Conctrols Specifications 1st Vacuum Pipe Prototype Prepare Und. Bid and Procurement Packages Complete 2nd Undulator Prototype 1st Diagnostics Prototype Begin Long Lead Purchases Complete 1st Production Diagnostics Complete 1st Production Undulator Assemble 1st Full Module Begin Purchase of All Other Components Assemble and Measure Undulators Assemble Diagnostics Install Undulator System Pioneering Science and Technology • • • • • • • • • • • • • • • • • • • • • • • • • • • Office of Science U.S. Department of Energy Milestone Summary of Schedule Milestone Design of 2nd undulator prototype complete Assembly and Testing of 2nd prototype undulator complete Bid package for undulator assembly complete First production undulator complete 33rd production undulator complete Installation of undulator system complete Date 2/04 9/04 7/1/05 7/1/05 6/1/07 7/1/07 See J. Noonan’s presentation for a more thorough summary and explanation Pioneering Science and Technology Office of Science U.S. Department of Energy Where We Stand • In the Project Engineering Design Phase • Need to ramp up in staffing…quickly! • 10 to 15 people working full time within 6 months to 1 year • People will be drawn from APS and ANL when possible • Contract work out as necessary • Project will be Baselined in April 2004 • Long-lead procurements begin in FY05 • “Real” Construction begins in FY06 • Undulator installed and ready to go in Summer 2007 • First Operations in Winter 2008 Pioneering Science and Technology Office of Science U.S. Department of Energy Charge for the LCLS Undulator Magnet Review Committee: Nov. 14th, 2003 1. Review the overall design and design/engineering decisions/solutions used for the 1st prototype undulator magnet and comment on the appropriateness of these decisions with respect to minimizing risk in meeting LCLS performance specifications. In particular, is this a robust design capable of being mass produced. 2. Assess the overall quality and appropriateness of the measurements and tuning methods. In particular, has a suitable set of measurements been carried out on the 1st prototype to prove that it has achieved the required specifications without undue difficulty in manufacturing, and has this design been proven to be sufficiently stable over time? 3. Based on the knowledge gained from the 1st prototype have the appropriate design modifications been made and, in your opinion, will they be successful in a mass produced device? 4. The 2nd prototype will be constructed in a manner similar to the acquisition plan for the production run. I would like your comments on the acquisition plan and schedule for the 2nd prototype and the production magnets. Pioneering Science and Technology Office of Science U.S. Department of Energy