LCLS Control System Personnel Linac & BC2 Controls progress LTU, Dump Controls

advertisement

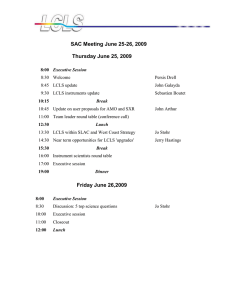

LCLS Control System Personnel Linac & BC2 Controls progress LTU, Dump Controls Undulator Control System Summary June 17, 2008 LCLS FAC Controls Review 1 Hamid Shoaee hamid@SLAC.Stanford.edu New responsibilities in Controls Enzo Carrone, the new deputy in Controls Department, is now responsible for the LCLS control system June 17, 2008 LCLS FAC Controls Review 2 Hamid Shoaee hamid@SLAC.Stanford.edu Questions from Tom Himel H1: Any new problems which have come up or items where you would like our advice The immediate question of delivering of long term high level applications VS resource allocation to the linac upgrade … See Patrick Krejcik’s presentation H2: MPS progress and schedule [S. Norum’s talk] H3: A general overview of the schedule for hardware installation and software with emphasis on any problems [E. Carrone’s talk] H4: How is the integration of the old controls group into LCLS going? How have the layoffs and shutdown of PEP effected things? June 17, 2008 LCLS FAC Controls Review 3 Hamid Shoaee hamid@SLAC.Stanford.edu Questions from Tom Himel H5: What is your situation and policy as regards hardware spares? We have started the process of converting the old CAMAC maintenance shops to support VME and other LCLS type hardware. We are also reviewing our spares needs and developing a plan for long term inventory and maintenance. H6: How is the high level applications infrastructure coming? What were the results of the review we suggested? [see P. Krejcik’s presentation] H7: When do you need to move away from MATLAB based feedbacks, and how is the new feedback development coming? The plan is to test 120 Hz operation in July of 2010. We are looking at list of issues to address, including time slot feedback, etc. BC2 Commissioning June 17, 2008 LCLS FAC Controls Review 4 Hamid Shoaee hamid@SLAC.Stanford.edu LCLS MPS… [S. Norum’s talk] Great progress has been made developing the hardware and software Completed hardware Completed software MPS Link Processor MPS Link Node GbE Switches Beam Loss Monitor QADC and transition boards prototypes complete EPICS PVs for fault status, bypass status and value Machine state buffer Machine protection logic (algorithm) handling Machine rate buffer Mitigation processing In progress QADC currently being tested June 17, 2008 LCLS FAC Controls Review 5 Hamid Shoaee hamid@SLAC.Stanford.edu Undulator Magnet PS - PH4 Installation Program 54 MCORs - UND 18 QUAD 36 X/YCOR B913 B921 45 MCORs – UND 15 QUAD 30 X/YCOR 03 Intermediate PS – DUMP 06 MCORs – DUMP June 17, 2008 LCLS FAC Controls Review 6 Hamid Shoaee hamid@SLAC.Stanford.edu First Light in FEE CD-4 (7/31/2010) FEE/NEH Install LTU/Und/Dump Controls Install PPS Cert. LTU/Dump Controls Installation for LTU, Undulator, Dump PPS J F MA M J J A S ON D J F MAM J J A S OND J F MAM J J Down 2008 2009 2010 Linac/BC2 Commissioning Re-commission Inj/BC2 to SL2 LTU/Und Comm. FEE Comm. April 18, 2008 Remaining Controls installation benefits greatly from the injector, linac & BC2 experience LTU Controls is similar in scope to Linac & BC2 We are past the engineering learning curve with very little development remaining Almost all procurement is complete including 100% of cable plant All IOCs and VME crates are on hand The order for over 95% of all required control modules (PLC, ADC, motion control, etc.) has been placed Some I&C rack delivery is being delayed, no impact on installation Racks are currently being loaded & tested in high bay area June 17, 2008 LCLS FAC Controls Review 8 Hamid Shoaee hamid@SLAC.Stanford.edu Rack Assembly Area (B024 ) B913 & B921 PS racks B911 & B912 PS racks June 17, 2008 LCLS FAC Controls Review 9 Hamid Shoaee hamid@SLAC.Stanford.edu INSTALLATION SCHEDULE June 17, 2008 LCLS FAC Controls Review 10 Hamid Shoaee hamid@SLAC.Stanford.edu PPS cable plant installation is in progress Equipment Status / Rack Readiness – B921 B921-10 B921-11 49 GROUND BUS 209-958-00 48 47 NEUTRAL BUS 209-959-00 46 45 AC DISTRIBUTION BOX 44 LCLS 4-30 CIRCUIT BREAKERS ACBOX 43 LCLS 4-30 CIRCUIT BREAKERS 42 41 40 CIR-BREAKR 39 CIR-BREAKR 38 37 LCLS MCOR BULK PS PLC CHASSIS 36 LCLS MCOR BULK PS PLC CHASSIS 35 34 33 (UND1 ) 384-801 32 CABLE FEEDTHRU (DUMP ) 384-801 C-FEEDTHRU 31 CABLE FEEDTHRU C-FEEDTHRU 30 MCOR-12 DRIVER CHASSIS 16CH 29 MCOR-12 DRIVER CHASSIS 16CH 28 27 26 25 (UND1 ) 236-251-00 24 BLOWER (DUMP ) 236-251-00 23 BLOWER BLOWER-2 22 MCOR-12 DRIVER CHASSIS 16CH BLOWER-2 21 MCOR-12 DRIVER CHASSIS 16CH 20 19 18 17 (UND1 ) 236-251-00 16 BLOWER (UND1 ) 236-251-00 15 BLOWER BLOWER-2 14 MCOR-12 DRIVER CHASSIS 16CH BLOWER-2 13 12 11 10 ESS POWER SUPPLY 60V/165A 9 (UND1 ) 236-251-00 8 BLOWER 7 BLOWER-2 6 ESS POWER SUPPLY 60V/165A 5 (MCOR BULK PS 3 ) ESS60V165A ESS POWER SUPPLY 60V/165A 4 3 2 (MCOR BULK PS 1 ) ESS60V165A June 17, 2008 LCLS FAC Controls Review 1 (MCOR BULK PS 2 ) ESS60V165A 12 Hamid Shoaee hamid@SLAC.Stanford.edu Schedule – B913 June 17, 2008 LCLS FAC Controls Review 13 Hamid Shoaee hamid@SLAC.Stanford.edu Safety Systems BCS Mature design Project is on schedule MPS Concurrently developing new LCLS MPS Response time of less than one pulse at 120 Hz New hardware extended 1.2 km past current MPS Non-CAMAC Ready for photon section PPS The system design is based on the extension of the injector PLCbased architecture Need to now address the BSY area June 17, 2008 LCLS FAC Controls Review 14 Hamid Shoaee hamid@SLAC.Stanford.edu Undulator Motion Control Software delivered by ANL and is being checked out June 17, 2008 LCLS FAC Controls Review 15 Hamid Shoaee hamid@SLAC.Stanford.edu Undulator Control System is on schedule for field installation Magnets power supply and controls in very good shape Loaded racks are being tested in B024/B15 There is a detailed schedule covering bench testing, through field installation Software design is mature, requires little if any changes RF BPMs – production proceeding well Receivers will be shipped to SLAC June-July Timing, Vacuum, Networks are all on schedule Wire position monitor & hydrostatic leveling system will be interfaced to the control system June 17, 2008 LCLS FAC Controls Review 16 Hamid Shoaee hamid@SLAC.Stanford.edu Top Level CD Org Chart CONTROLS DEPARTMENT April 28, 2008 BOYSEN, Tanya $#CORVIN, Clay de SALVO, Michael LILLY, Deborah KREJCIK, Patrick CONTROLS DEPARTMENT HEAD: SHOAEE, Hamid Department Office DEPUTY CARRONE, Enzo DEPUTY CHESTNUT, Ron SAFETY SYSTEMS BENNETT, Brian BONG, Patrick $BROWN, Jeffrey FICKLIN, David HARMS, Michael G. HILL, Alan McDONALD, Devon MURPHY, James SALESKI, Michael SIMMONS, Bob STARNER, Suanne TURNER, Kristina ITALICS % $ # Contract Employee Casual Employee or < 50% Safety Committee On Loan June 17, 2008 Department total = 71 LCLS FAC Controls Review SOFTWARE ENGINEERING WILLIAMS, Ernest LAHEY, Terri (Deputy) ALARCON, Arturo BOYES, Matt BROBECK, Ken BURGESS, Richard CHEVTSOV, Sergei CHU, Paul DECONTRERAS, Ginger FAIRLEY, Diane #GRANIERI, Charles GRUNHAUS, Elie HALL, Robert HOOBLER, Sonya $KNOPF, Jim KOTTURI, Dayle LUCHINI, Kristi MILLER, Ed PENG, Sheng ROCK, Judy ROGIND, Debbie SANDBOTHE, Bob SCHUH, Stephen SPENCER, Nancy WHITE, Greg #WOODLEY, Mark ZELAZNY, Mike ZHOU, Jingchen ENGINEERING SUPPORT TILGHMAN, Anthony JACOB, Ralph (Deputy) ANDERSON, David AVELAR, Alonzo BONG, James BRECHIN, Vernon BROWN, R. (Vergne) CORDOVA-GRIMALDI HARMS, Michael J. HOANG, Frank NGUYEN, Sony O’NEAL, John SMITH, Vernon TRALLER, Robert %TRUEBENBACH, John 17 ELECTRONICS & INSTRUMENTATION ENGINEERING BROWNE, Mike New Head – TBD JOHNSON, Ron (Deputy) BROWN, David G DUSATKO, John GIOUMOUSIS, Andrew MEDVEDKO, Evgeny NORUM, Stephen OLSEN, Jeff ROSS, William SMITH, Stephen YEE, Chuck YOUNG, Andrew Hamid Shoaee hamid@SLAC.Stanford.edu Software Engineering Section CONTROLS DEPARTMENT Software Section Task Assignments April 28, 2008 ZHOU, Jingchen Systems BROBECK, Ken HALL, Robert ROCK, Judy ITALICS % $ # KREJCIK, Patrick (acting) High Level Apps WILLIAMS, Ernest EPICS CHEVTSOV, Sergei CHU, Paul FAIRLEY, Diane ROGIND, Debbie WHITE, Greg #WOODLEY, Mark ZELAZNY, Mike ALARCON, Arturo BOYES, Matt HOOBLER, Sonya KOTTURI, Dayle LUCHINI, Kristi PENG, Sheng SCHUH, Stephen Contract Employee Casual Employee or < 50% Safety Committee On Loan June 17, 2008 LCLS FAC Controls Review 18 LAHEY, Terri Networking BURGESS, Richard DeCONTRERAS, Ginger #GRANIERI, Charly GRUNHAUS, Eli $KNOPF, Jim SANDBOTHE, Bob MILLER, Ed SPENCER, Nancy Hamid Shoaee hamid@SLAC.Stanford.edu CD-PCD Project Work Flow CD - PCD Project Execution Installation PCD Commissioning CD Production Test CD-PCD Engineering Services PCD Engineering Design CD Subsystem Design ● ● ● ● ● ● ● ● ● Receive Requirements Detail Specifications Conceptual Design Prototype Design Detail Circuit Design Material List Circuit Board Layout Sketches to PCD Functional Design Doc ● Detail Standard Panel Layout ● Detail E-M drawings ● Begin System Drawings Prototype Unit Production ● Develop Firmware ● Develop Test & Calibration Software ● Develop Test & Calibration Hdwe ● Document Test & Calibration Procedure ● Develop Rack, Cable System Sketches ● Receive Prototype ● Debug & Test ● Train Technician(s) ● Rework, approve prototype for manufacture ● ● Receive Pckg Layout, Board Layout, Parts List ● Procure materials ● Prepare kit, PCB bids ● Procure PCB (2) ● Load Prototype ● Machine, Label Panels ● Final Assembly Proto I ● Final Quality Check ● Receive Prototype for Manufacture ● Order parts, prepare kits, prepare bid packages ● Place vendor orders ● QC Incoming Inspect ● Deliver to Production Test ● Develop overall Product test system ● Develop QC plan ● Setup Product Test areas ● Procure, build test equipment ● Train personnel ● Receive production units ● Perform tests, stress tests, rework cycles ● Maintain database ● Deliver final QC product to Installation ● Develop Field Installation Plans ● Develop Field Installation Drawings, Instructions ● Develop Resource plans, cost estimates, schedules ● Develop Bid Packages. Contracts Rack Production Installation Commissioning ● Develop Rack, layouts, Cable system sketches Review, approve Rack, Cable, System drawings ● Review, approve Bid Packages ● Receive Rack, Cable, Crate System Sketches ● Document Racks, cables, crates, intra-rack cabling, long-haul cabling ● Develop Rack, Cable, Crate Bid Packages ● Order Racks, Cables, Crates ● Receive & Inspect Racks, Cables, Crates ● Install Rack AC power, Crates, DC Power Supplies ● Install tested units in Crates ● Install internal Rack power, signal wiring ● Test assembled Racks ● Complete all factory testing of loaded racks ● Deliver Loaded Racks ● Bid, award installation contracts ● Assemble internal resources ● Train resources, UTR’s Receive all loaded Racks, Cables, Trays FIELD INSTALLATION ● Install AC power, cooling water, Cable Trays ● Install Loaded Racks, Earthquake bracing ● Install Long haul signal cable plant, networks ● Install Rack safety systems, monitoring COMMISSIONING ● Safety Systems ● AC Power systems ● Top Level control system ● Timing System ● Networks, Sector Nodes ● Instrumentation Subsystems ● Test all Systems with Beam DRAWN BY RAY LARSEN 01-30-2008 LCLS PROJECT DIRECTOR J. Galayda LCLS CONTROLS PROJECT May 7, 2008 R11 DATA ACQUISITION & CONTROL System Manager WILLIAMS, Ernest MAGNET POWER & CONTROL LUCHINI, Kristi -SE/ BELLMO, Paul -EE DeLIRA, Antonio -EE MacNAIR, David -EE ROGIND, Debbie -SE MOVER SYSTEMS SAFETY ENGINEER SALESKI, Michael PROJECT MANAGEMENT LIAISON BOYSEN, Tanya CABLE PLANT SYSTEMS System Manager RODRIGUEZ, Ponciano SAFETY SYSTEMS System Manager SALESKI, Michael (Acting) CABLE PLANT CONTRACTS RODRIGUEZ, PoncianoEE ORTEGA, Mario-AE DiSALVO, Michael-AE BALTAZAR, Dak-AE AGUAS, Bernardo-AE BUHAIN, Juanito-AE RACKS, DC PWR & SIGNAL DIST. ORTEGA, M. -AE PERSONNEL/LASER PROTECTION PPS/ LSS BONG, Patrick -EE MURPHY, J – EE McDONALD, D – ET FICKLIN, D - D ENGINEER BEAM CONTAINMENT BCS TILGHMAN, Anthony – AE LCLS CONTROL SYSTEM HEAD: CARRONE, Enzo BEAM INSTRUMENTS & DIAGNOSTICS System Manager JOHNSON, Ronald TOROIDS BROWN, David-EE MONTAGNE, M.-ME BPMS JOHNSON, R.-EP SMITH, S. -EP STRAUMANN,T.-EP MEDVEDKO, E. -EE MONTAGNE, T.-ME SMITH, V. - AE BUNCH LENGTH BLM, OTR, YAG SCREENS PENG, Sheng -EE FRISCH, Josef -EP BROWN, V -AE ZDARKO, Richard -C MONTAGNE, Tim-ME BENNETT, Brian -AE TRUNKS & PATCH PANELS TILGHMAN, Anthony-AE LASER CONTROLS WHITE, William PENG, Sheng-EE ROSTER, Bill-AE MONTAGNE, Tim -ME NGUYEN, Sony -C MONTAGNE, Tim -ME DC 24V PWR DiSALVO, Michael -AE RAGO, Carl -ME LOW LEVEL RF AKRE, Ron -EE KOTTURI, Dale-SE HILL, Alan -AE TEMP MONITORS SCHUH, Stephen -EP ALARCON, Arturo -EP SIMMONS, Robert -AE MACHINE PROTECTION INTERMED. IMPS TILGHMAN, Anthony -AE TUNE-UP DUMP PENG, Sheng-EE ENGINEER BROWN, V. -AE RAGO, C. -ME VACUUM SYSTEMS SCHUH, Steve -EP LCLS FAC Controls Review NGUYEN, Sony -C O’NEAL, John -AE TIMING KREJCIK, Patrick BROWNE, Michael DUSATKO, John-EE ALLISON, Stephanie-SE BROWN, David - EE ZELAZNY, Michael -SE MONTAGNE, Timothy -ME ROGIND, Debbie, SE 20 APPLICATIONS SOFTWARE System Manager FAIRLEY, Diane/ ZELAZNY, Michael ENGINEERING SERVICES System Managers J. Olszewski-AE T. Montagne-ME R. Chestnut-EP HIGH LEVEL APPLICATIONS FAIRLEY, Diane-SE ZELAZNY, Michael - SE DESIGNER DRAFTER COORDINATOR TECHNICIAN Contract Support Captar CHEVTSOV, Sergei -SE CHU, Paul -SE LARRIEU, Chris – SE ROGIND, Debbie – SE WHITE, Greg - SE ENGINEER PROGRAMMER Contract Support MCC APPLICATIONS Electrical Electronic DOOLITTLE, L. -EE ENGINEER Mechanical Electromechanical PROFILE MONITORS PENG, Sheng-EE BROWN, V. -AE RAGO, C. -ME TILGHMAN, Anthony-AE RAGO, Carl -ME June 17, 2008 FARADAY CUPS SERVERS/NETWORKS LAHEY, Terri -SE NORUM, Stephen- EE NGUYEN, Sony -AE MACHINE PROTECTION NEW NORUM, Stephen - EE GLOBAL SYSTEMS System Manager KREJCIK, Patrick PRECISION TIMING LBNL BYRD, J. -EP CAVITY BPMS ANL LILL, Robert – EE WALTER, Dean - ME NORUM, Eric - SE CONTROLS SYSTEM PHYSICIST KREJCIK, Patrick -EP FEEDBACK SYSTEMS ENGINEER Wire Pos. Mon. Hydrostatic Leveler BROBECK, Kenneth -SE ZHOU, Jingchen -SE MURRAY, Douglas -AE DiSALVO, Michael -AE MONTAGNE, Tim -ME KNOPF, Jim - AE Controls Engineering & Software LEGEND EE-ElecEngr ME-MechEngr SE-Software Engr EP- EngPhys AE-AssocEngr C- Coordinator D-Designer ET- Elect Tech MT- Mech Tech Hamid Shoaee hamid@SLAC.Stanford.edu Controls Status since the last review The Linac/BC2 Controls installation went very well The system was delivered in December 2007, within a week of the scheduled date (12/03/07) Summary of Controls Sub-Systems installed for Linac and BC2 Commissioning Cable Plant Networking Magnet power supply Vacuum Controls LLRF Timing system Laser control upgrade OTR/YAG imaging BPM Wire Scanners June 17, 2008 LCLS FAC Controls Review Faraday Cup Cerenkov monitor Moveable collimator BC2 beamline control Bunch length monitor MPS BCS Configuration software MATLAB feedback system Bunch length measurement 22 Hamid Shoaee hamid@SLAC.Stanford.edu Linac & BC2 Controls in use by physicists & Operations New Feedback framework & bunch length measurement applications are in operation Injector laser Controls has been upgraded for BC2 operation June 17, 2008 LCLS FAC Controls Review 25 Hamid Shoaee hamid@SLAC.Stanford.edu Conclusions The linac & BC2 control system is online & operational We are on schedule for the installation and completion of the electron control system The major risk for the above items is schedule rather than technical complexity detailed plans are in place for the undulator control in collaboration with ANL June 17, 2008 LCLS FAC Controls Review 26 Hamid Shoaee hamid@SLAC.Stanford.edu