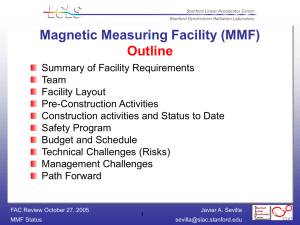

Magnetic Measuring Facility (MMF) Outline

advertisement

Magnetic Measuring Facility (MMF) Outline Organizational Chart Facility Design Criteria, User’s Requirements and Layout Previous Work Status to Date (Site preparation, Title II and Title III) Budget and Schedule Technical Challenges (Risks) ES&H Issues Management Challenges Path Forward April 5, 2005 MMF 1 Javier A. Sevilla sevilla@slac.stanford.edu Organizational Chart Magnetic Measurement Facility (MMF) Robert Ruland – Alignment Mgr Zachary Wolf – User Conventional Facilities-WBS 1.09 Project Office David Saenz – Conventional Facilities Manager Jim Welch – CF Systems Physicist Javier A. Sevilla-CF Project Engineer/CAM Jo Beth Folger-CF Engineer Richard Hislop – Construction Safety Manager Anita Malahowski –Cost/Schedule Bruce Patten – Contracts/Procurement Jesse Saldivar – CF Technical Assistance April 5, 2005 MMF 2 SAFETY Conventional Facilities Cost/ Schedule Javier A. Sevilla sevilla@slac.stanford.edu Facility RequirementsScope Facility Design Requirements Technical Note LCLS-TN-041-Z Space Requirements Environmental Stability (3 areas) Space Temperature: ± 0.1 °C short term may go up to 0.3°C if < 1Hr Relative Humidity: 45%± 5% Other areas: ±1°C and ±2.5°C Vibration <0.5 microns-MM Lab Utility Requirements Electrical (new 800A feeder MMFBldg Upgrade) Other (compressed air and small chiller for User’s equipment) April 5, 2005 MMF 3 Javier A. Sevilla sevilla@slac.stanford.edu MMF Facility Uses Undulator magnet tuning – 2 magnet measuring machine test stands Aligned with same orientation to Earth’s magnetic field as LCLS Undulator Hall. Undulator fiducialization – large coordinate measuring machine Cradle assembly area Magnet storage/temperature acclimation Work desks in lab and office space for 2 employees April 5, 2005 MMF 4 Javier A. Sevilla sevilla@slac.stanford.edu Resultant Building Criteria ~4,800 sq. ft. floor space (inc. ~3,000 laboratory space, mech Rm) + mezzanine 1,400 sf (HVAC & Electrical) Locate within an existing building to aid in temperature control Adequate ceiling height for overhead cranes Accessible for magnet delivery using trucks and forklifts Electrical service – 800A, 480v, 3Ø April 5, 2005 MMF 5 Javier A. Sevilla sevilla@slac.stanford.edu Building 081 Location Research Yard LINAC NORTH April 5, 2005 MMF LCLS Undulator Hall PEP Ring Road 6 Javier A. Sevilla sevilla@slac.stanford.edu Building 081 Site Layout Front Rear Haz Mat April 5, 2005 MMF 7 Javier A. Sevilla sevilla@slac.stanford.edu Building 081 Current Uses ~25 Ft height April 5, 2005 MMF 8 Javier A. Sevilla sevilla@slac.stanford.edu New Space Allocation for Bldg. 081 Front (N) Fire Alarm Panel (N) MCC-B081 Offices SHIPPING & RECEIVING VEHICLE SHOP EQUIPMENT REPAIR Rear April 5, 2005 MMF 9 Javier A. Sevilla sevilla@slac.stanford.edu MMF Ground Floor Plan ± 0.1°C, 45%RH ±5 Coordinate Measuring Area ~ 1,000 ft. sq. Magnet Loading and Storage ~850 ft. sq. ± 1°C, 45% RH ±5 ± 2.5°C Magnet Measuring Lab ~1,800 ft. sq. Cradle Assembly Area ~325 ft. sq. Mechanical Room ~256 ft. sq. Rear April 5, 2005 MMF 10 Javier A. Sevilla sevilla@slac.stanford.edu Mezzanine Floor Plan Equipment: 4 Air handling Units 1 Motor Control Center, X-trmr, Panels, 1 small Compressor HVAC Control Panel Mezzanine for Mechanical/Electrical Equipment in Conditioned space MCC Rear April 5, 2005 MMF 11 Javier A. Sevilla sevilla@slac.stanford.edu Rear Elevation-MMF Mezzanine Mechanical Access Staff Access Roll up door for magnets delivery April 5, 2005 MMF 12 Javier A. Sevilla sevilla@slac.stanford.edu User’s Layout (By R. Ruland, Oct, 2004) Floor plan divided into three functional areas Magnetic Measurements (± 0.1º C) Fiducialization and Assembly (± 1º C) Storage (± 2.5º C) Test stand lay-out is driven by requirement to match the Earth Magnetic Field conditions in lab to Undulator Hall, i.e. azimuth and gap orientation need to be identical April 5, 2005 MMF 13 Javier A. Sevilla sevilla@slac.stanford.edu Previous Work Title I Drawings and Specifications –completed by JE External Review October 14, 2004 Report with recommendations Internal reviews (SLAC) Facility’s User (Metrology Group) 50% and 100% drawings and Specs: ES&H, Citizen’s Committees Conventional Experimental Facilities Dept (CEF) old SEM April 5, 2005 MMF 14 Javier A. Sevilla sevilla@slac.stanford.edu Status Title II Drawings and Specifications –prepared by JE Issued for Construction-March 11, 05 In-progress: Review and “Final” approval by SLAC’ Citizens Committees and ES&H- Obtained approval for bidding Site Preparation Work (activities delayed) Resources allocation Accident related (CEF support) On-going: Design and coordination (new storage carrousel, shelving and Haz Material storage relocation, move occupants new electrical feeder to building, FA system and data network upgrade) Title III Procurement: Select only “qualified” subcontractors based on a “criteria” Develop and implement a “Commissioning” plan Beneficial Occupancy: Feb’06 April 5, 2005 MMF 15 Javier A. Sevilla sevilla@slac.stanford.edu Budget & Schedule Title III Including Site Preparation $2.04M (excludes: fire alarm building upgrade B081 and some relocation costs) Bidding and Award April – June 2005- Site visit: April 7, 2005 Bids due May 5 and Award May 27, 2005 Construction and Commissioning Execution: Mid June 05 – February 06 Beneficial Occupancy to Project Office Feb-06 April 5, 2005 MMF 16 Javier A. Sevilla sevilla@slac.stanford.edu Schedule P3 April 5, 2005 MMF 17 Javier A. Sevilla sevilla@slac.stanford.edu Cost Estimate- WBS1.09.03.02 Estimated Total Cost $2.04M Construction Subcontract: $ 1,493 K Site Preparation & Electrical LLP: $ 546K Allocated Contingency: 30% construction-not included Demolition Demolition $41,872- 2% Site Prep & LLP $545,652- 27% Mechanical-HVAC HVAC &Mechanical $566,814- 28% Structure and Foundation Interiors & Cranes $332,948- 16% Commissioning & Testing $59,451- 3% April 5, 2005 MMF Electrical Structure & Foundation, $169,583- 8% Electrical $321,835- 16% Testing & Commissioning Interiors and Cranes Site Preparation 18 Javier A. Sevilla sevilla@slac.stanford.edu Risks Internal technical: Not achieving the Temperature and Stability requirements Plan: Design reviews, constructability and commissioning plan Internal non-technical: Delays in the BO date Plan: Use good and effective Project Management approach, and select only “qualified” contractors including subs Internal non-technical: Safety accidents Plan: Pre-qualification of contractors, strict implementation and close monitoring of Safety Plans and Procedures April 5, 2005 MMF 19 Javier A. Sevilla sevilla@slac.stanford.edu ES&H Issues Demolition activities Site Preparation: Excavation Excavation Permit for Relocation of Haz Mat Storage was obtained Sampling of soil by ES&H Air quality-BAAQMD-not applicable Construction Activity Hazards Construction Safety oversight by LCLS Safety Manager, LCLS Divisional ES&H Coordinator, SLAC Safety OSHA Inspectors and by SLAC trained UTR. Subcontractors will be required to staff project with a Construction Safety Professional Includes preparation of Pre-work Hazard Analysis, Job Hazard Analysis and Mitigation (JHAM) and all applicable DOE and Federal Safety Regulations. Radiation None Hoisting/Rigging Citizens’ Committee and/or Hoisting/Rigging inspector will review and approve the Subcontractor’s Rigging Plan for the testing, commissioning and acceptance of new cranes April 5, 2005 MMF 20 Javier A. Sevilla sevilla@slac.stanford.edu Management Challenges Cost/Schedule Risks Cost estimate based on Jacobs estimate– confirmation when bids are received from subcontractors (Factors: Market conditions, qualification criteria and NEW Safety Requirements). Schedule Coordination and Support from other SLAC’s Departments (ES&H, Stores, CEF) SLAC policy changes in the wake of 10/11/04 electrical accident are still being developed. (UTR responsibilities, Authority and Oversight may change, etc.) April 5, 2005 MMF 21 Javier A. Sevilla sevilla@slac.stanford.edu Path Forward Enforce Safety Regulations to All Sub-Contractors Implement Criteria Selection for Bidding and Construction to ALL Sub-Contractors Coordinate and Complete ALL Site Preparation activities Management and Lab support Construction and Commissioning Schedule and Cost Controls Strict compliance with Drawings and Specifications Execute an integrated verification of: operational performance, testing, complete documentation and training of SLAC personnel, which will operate and maintain this Facility. April 5, 2005 MMF 22 Javier A. Sevilla sevilla@slac.stanford.edu