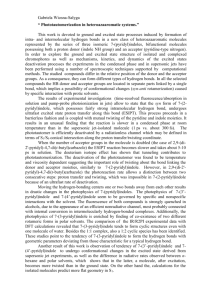

Electrosprayed poly(butylene succinate) microspheres loaded with indole derivatives: system with anticancer activity

advertisement

Electrosprayed poly(butylene succinate) microspheres loaded with indole derivatives: a system with anticancer activity Sara K. Murase1, Mireia Aymat1, Aureli Calvet1, Luis J. del Valle1,2,*, Jordi Puiggalí1,2,* 1 Departament d’Enginyeria Química, Universitat Politècnica de Catalunya, Av. Diagonal 647, Barcelona E-08028, Spain 2 Center for Research in Nano-Engineering (CrNE), Universitat Politècnica de Catalunya, Edifici C, C/Pasqual i Vila s/n, Barcelona E-08028, Spain *Corresponding author: L.J. del Valle (E-mail: luis.javier.del.valle@upc.edu) and J.Puiggalí (Email: Jordi.Puiggali@upc.edu) 1 ABSTRACT Electrospraying of poly(butylene succinate) and its mixture with different indole derivatives was successfully performed using chloroform as solvent and relatively low flow rates and concentrations. Morphology of particles (size, diameter distribution and surface texture) and encapsulation efficiency were dependent on the loaded drug and specifically on the type of substituent (methyl or phenyl) and its position in the indole core. In general, particles showed a raisin-like morphology caused by the shell collapsing of the resulting structurally weak microspheres. Accumulation of electrosprayed particles gave rise to consistent mats and they had a more hydrophobic surface than that determined for smooth films. The increase of hydrophobicity was mainly dependent on the porosity and the hydrophobic nature of the incorporated drugs. Indole derivatives were hardly delivered in a standard phosphate saline buffer due to their scarce solubility in aqueous media but the addition of ethanol caused a drastic change in the release behavior. This was generally characterized by a fast burst effect and followed by establishment of an equilibrium condition that was dependent on the indole derivative. However, a clearly different behavior was found when the indole was unable to form hydrogen bonds (e.g. 1-methylindole) since in this case a slow and sustained release was characteristic. Microspheres loaded with indole derivative showed a high antiproliferative activity that was dependent on encapsulation efficiency and the type of loaded drug. The best results were specifically attained for the indole with an aromatic substituent. Interestingly significant differences were found between cancer and immortalized cells, a feature that points out the potential use of such systems for cancer prevention and treatment. Keywords: Electrospraying, poly(butylene succinate), indole derivatives, drug release, anticancer activity. 2 1. Introduction Electrospinning and electrospraying are electrohydrodynamic atomization techniques that are widely employed in nanotechnology. These top-down physical methods can lead to materials at the nano- or microscale level through the interaction between electrical energy and processed fluids [1,2] without involving a previous energy-transfer process (e.g. ultrasounds or microwaves) [3]. Electrical energy from electrospinning allows the removal of organic solvents and the production of polymer nanofibers or even nanoparticles suitable for drug delivery applications [4-6]. Electrospinning techniques are based on the application of a high voltage between the tip of a polymeric solution container and a counter electrode located at a collector. The solution drop at the tip is deformed by the electrical field, and when the electrostatic forces of repulsion overcome the droplet surface tension, a charged jet ejects and deforms uniaxially through the electric field towards the collector. The microfluid jet is quickly dried (often in the order of 10 -2 seconds) producing continuous nanosized fibers [7,8]. Loading of active substances such as drugs can also be easily achieved (e.g. by simple inclusion of the drug into the electrospinning polymeric solution) and furthermore the loaded nanofibers may exhibit excellent performance in enhancing the dissolution rates of poorly-water soluble drugs. Therefore, electrospinning becomes a useful tool for generating solid dispersions of poorly water-soluble drugs [9]. The electrospray technique is derived from electrospinning. Electrosprayed particles are produced when the formed liquid jet undulates and breaks up into small electrically charged droplets which repel each other and form a dispersed shower downwards to the collector. A progressive decrease in droplet diameter can be derived from the continuous evaporation of the solvent. Nowadays, electrospraying has grown in popularity because of its simplicity and ability 3 to produce particles with a mean diameter that can be varied between hundreds of micrometers to tens of nanometers [10]. Therefore, electrospraying has been utilized to produce materials with a wide range of applications in areas as diverse as pharmaceutical, ceramics, cosmetics and food industries but, especially, it appears useful for biomedical applications such as drug delivery [11]. A great number of synthetic and natural polymers have been successfully formulated into microspheres by means of electrospraying [12-14]. Despite the simplicity of the process, operational parameters must be experimentally found for each polymer in order to attain the desired particle size, morphology and size distribution. Biodegradable and biocompatible polymers have received particular attention as drug delivery systems, being in this case highly interesting to obtain particles with homogeneous sizes for a good control of the drug release rate. Physicochemical properties of the selected polymer determine the interactions with the active compound and influence the drug encapsulation/entrapment process as well as the drug release kinetics. Polylactides have been widely employed for encapsulation of therapeutic molecules due to their biodegradability and biocompatibility. Those requisites can also be found with poly(alkylen dicarboxylate)s, being probably poly(butylene succinate) (PBS, Figure 1) the most significant polymer of this family due to its unusual combination of good properties (e.g. thermal and mechanical) as well as the relatively high molecular weight that could be obtained through the polycondensation reaction [15]. Indole derivatives occur widely in natural products, existing in different kinds of plants, animals and marine organisms [16]. The indole core is a near-ubiquitous component of biologically 4 active natural products. For example, among the microorganisms in some bacteria, indole is used as a cell-signaling molecule in both intra- and inter-species communication (process termed quorum sensing) [17,18]. The indole core is also well known as one of the most important “scaffolds” for drug discovery, a term first introduced by Evans and co-workers to define scaffolds which are capable of serving as the ligand for a diverse array of receptors [19-21]. The indole core has been deemed as an important moiety found in many pharmacologically active compounds (Table 1). These possess certain biological features such as anticancer effectiveness [34-41] and antiviral activity [42]. Furthermore, indole derivatives have the unique property of mimicking the structure of peptides and reversibly bind enzymes [43,44]. There is an amazing number of approved indole containing drugs in the market as well as compounds currently going through different clinical phases or registration states. In fact, seven indole-containing commercial drugs can be found between the Top-200 Best Selling Drugs by US Retail Sales in 2012 [45]. The most relevant is Cialis, an approved drug for the treatment of men's erectile dysfunction and the signs and symptoms of benign prostatic hyperplasia [46,47]. In summary, the broad spectrum and the important physiological activities of indole-derivatives make highly desirable the fabrication of loaded micro/nanoparticles with them for their use in several biomedical applications. Herein, we report an efficient and simple strategy to prepare polybutylene succinate (PBS) microspheres loaded with indole and indole-derivatives by means of the electrospraying technique. For this purpose, the effect of relevant processing parameters (e.g. solvent, polymer concentration, applied voltage, tip-collector distance and flow rate) on the size and shape of the resulting microsphere structures was studied. In addition, encapsulation and release of five indole compounds (Figure 1) having methyl and phenyl substituents at different positions of the ring (i.e. indole, 1-methylindole, 2-methylindole, 3-methylindole and 2- 5 phenylindole) were evaluated. The comparison of these five delivery systems was also performed, in terms of morphology, physicochemical properties, and biological activity, since it may provide an archetype model to understand encapsulation, release and stability from harsh environmental conditions for others compounds based on the indole ring. [Table 1] [Fig. 1. ] 2. Experimental section 2.1. Materials Polybutylene succinate (PBS) is a commercial product (Bionolle® 1001) supplied by Showa Denko K.K. (Germany). The polymer has a melt flow index of 1.6 g/10 min (measured at 190 ºC under a load of 2.16 Kg according to ASTM-D1238). Indoles were purchased from SigmaAldrich Chemical Co. Ltd. (St. Louis, MO, USA). Indole (≥99%, 1H-Benzo[b]pyrrole), 1Methylindole (≥97%), 2-Methylindole (98%), 3-Methylindole (98, Skatole), 2-Phenylindole (technical grade, 95%).All solvents were of analytical grade and used without further purification. 2.2. Preparation of microspheres 0.25 g PBS and 0.028 g of the selected indole were dissolved in up to 10 g of chloroform placed into a glass vial. The solution was quickly homogenized by stirring at 150 rpm for 1 h until PBS was completely dissolved. Thus, weight percentages of PBS and the selected indole in the electrospray solutions were 2.5 wt% and 0.28 wt%, respectively. Finally, 1 µL of formic acid per 6 1 mL of solution was added in order to increase ionic conductivity and improve the formation of droplets during electrospray process. Electrosprayed microspheres were collected on a target placed at different distances (8-17 cm) from the needle tip (18G, inside diameter 0.84 mm). The voltage was varied between 8 and 30 kV and applied to the target using a high-voltage supply (Gamma High Voltage Research, ES305W). Polymer solutions were delivered via a KDS100 infusion syringe pumps (KD Scientific, USA) to control the flow rate (from 0.5 to 5 mL/h). All electrospraying experiments were carried out at room temperature. Unloaded (blank sample) and indole loaded microspheres were prepared using optimized parameters as shown later in the results. Thus, the theoretical content of indoles in the electrosprayed microspheres was 10 wt%. Electrosprayed microspheres will be denoted by PBS-I, PBS-1MI, PBS-2MI, PBS-3MI and PBS-2PI, which indicate the polymer (PBS) loaded with indole (I), methylindole (MI) and phenylindole (PI). The number preceding indole abbreviation indicates the position of the substituent group in the indole core. 2.3. Morphology and particle size The initial evaluation for size and morphology of the microspheres was carried out by optical microscopy using a Zeiss Axioskop 40 microscope. Micrographs were taken with a Zeiss AxiosCam MRC5 digital camera. Detailed inspection of texture and morphology of microspheres was conducted by scanning electron microscopy using a Focus Ion Beam Zeiss Neon 40 instrument (Carl Zeiss, Germany). Carbon coating was accomplished by using a Mitec K950 Sputter Coater fitted with a film thickness monitor k150x. Samples were visualized at an accelerating voltage of 5 kV. Diameter 7 of microspheres was measured with the SmartTiff software from Carl Zeiss SMT Ltd. For the latter, the diameters of 100 microspheres were measured, and values were analyzed using a frequency distribution adjusted to Gaussian model using the OriginPro v10 software (Origin Microcal, USA). 2.4. Solid state characterization Infrared absorption spectra were recorded in the 3600 - 600 cm-1 range employing a Jasco FTIR 4100 Fourier Transform infrared spectrometer. A Specac MKII Golden Gate attenuated total reflection (ATR) accessory was employed. Contact angles (CA) were measured at room temperature with sessile drops using an OCA-15 plus Contact Angle Microscope (Dataphysics, USA) and SCA20 software. Contact angle values of the right and left sides of distilled water drops were measured and averaged. Measurements were performed 10 s after the drop (0.5 µL) was deposited on the sample surface. All CA data were an average of at least six measurements on different surface locations. 2.5. Release experiments Controlled release measurements were carried out with square pieces (weighing approximately 20 mg) of mats constituted by the electrosprayed microspheres. These were incubated in tubes of 50 mL for 1 week at 37 ºC and using an orbital shaker at 150 rpm. 20 mL of phosphate buffered saline (SS) and alternatively its mixture with ethanol (i.e. SS/ethanol, 3:7 v/v) as a more hydrophobic component were employed as release media. Drug concentration was evaluated by UV-Vis spectroscopy. To this end, aliquots (i.e. 1 mL) were withdrawn from the release medium 8 at predetermined time intervals. The volume of the release medium was kept constant by subsequent addition of fresh medium. Analytical curves were obtained by plotting the absorbance measured at 271 nm (for I and 2MI), 281 nm (for 1MI and 3MI) and 311 nm (for 2PI) versus drug concentrations. These ranged from 0.0009 to 0.05 mg/mL and from 0.001 to 0.2 mg/mL using SS/ethanol and SS as solvent, respectively. The linear correlation coefficient (r) value was higher than 0.99. All drug release tests were carried out using three replicates and the results were averaged. 2.6. Determination of indoles content Typically, 1 mg of the microsphere mat was weighed into an Eppendorf microtube and then 0.1 mL of chloroform was added to dissolve the microspheres under constant agitation (150 rpm) at 25ºC for 30 min. Then, the indoles were extracted by adding 0.9 mL of SS/ethanol (3:7 v/v). Afterwards, samples were centrifuged at 10,000 rpm for 15 min. Finally, 0.5 mL of the supernatants were recovered for quantification of indoles using a UV-Vis spectrometer as above indicated. The experiments were carried out in triplicate. The encapsulation efficiency (EE) was calculated using the following equation: (1) where I0 is the initial amount of indoles and Is is the amount of indoles remaining in the supernatant. 2.7. Water uptake of scaffolds 9 The water uptake of mats of electrosprayed microspheres was estimated by the liquid intrusion method. Vacuum dried samples were weighed prior to immersion in 2 mL of water for 24 h using a shaker table to allow diffusion of water into the void volume. The samples were taken out and reweighed. In this procedure a value for the porosity was calculated according to equation (2): (2) where mw and md, are the weights of the wet and dry mat, respectively and w and p refer to the densities of water (1.0 g/mL) and semicrystalline PBS (1.26 g/mL), respectively. 2.8. Cell adhesion and proliferation assays Human osteosarcoma (Saos-2 cells), human fetal lung fibroblast (MRC-5 cells), African green monkey (Cercopithecus aethiops) kidney epithelial (Vero cells) and kidney fibroblast (COS-7 cells) were purchased from ATCC (USA). The in-vitro antiproliferative activities of indoles were determined by MTT assay. To this end, cells were cultured in Dulbecco’s Modified Eagle Medium (DMEM) supplemented with 10% fetal calf serum, 2mM L-glutamine, 100 U/mL penicillin, and 100 µg/mL streptomycin. Briefly, cells were seeded into 96-well plates at a density of 1x104 cells/well. 24 h later, triplicate wells were treated with media containing the different drugs. After 72 h of incubation at 37 ºC in 5% CO2, the drug containing medium was removed and replaced by 100 µL of fresh medium with 5 mg/mL MTT solution. After 3 h of incubation, the medium with MTT was removed, and 100 µL of dimethyl sulfoxide (DMSO) were added to each well. The plates were gently agitated until the 10 purple formazan crystals were dissolved, and the A570 value was determined using a microplate reader (Biochrom, UK). The data were calculated and plotted as the percent viability compared to the control. The 50% inhibitory concentration (IC50) was defined as the concentration of the drug that inhibited cell viability by 50%. The antiproliferative activities of the microspheres matrices were determined using the following protocol. Square pieces (0.5×0.5×0.1 mm3) of the microspheres matrices were placed into the wells of a 48-well culture plate. Samples were fixed with a small drop of silicone (Silbione® MED ADH 4300 RTV, Bluestar Silicones France SAS, Lyon, France) and then sterilized by UVradiation in a laminar flux cabinet for 30 min. For the assay, aliquots of 50-100 µL containing 5x104 cells were seeded onto the matrices samples in each well and incubated for 30 min. Then, 1 mL of fresh medium was added to each well, and the cells were allowed to proliferate for 72 h. Finally, the cell viability was assessed by MTT assay [48]. The cell growth onto the well without matrix was used as control. Samples were evaluated using six replicates and the results were averaged. 2.9. Statistical analysis Data are expressed as mean ± SD. The difference of parameters was statistically tested for significance with one-way ANOVA followed by Tukey test using OriginPro v10 software (Origin Microcal, USA). p < 0.05 was considered statistically significant. 3. Results and discussion 3.1. Optimization of operational conditions for electrospraying of PBS 11 The success of an electrospraying process requires a strict control of operational parameters (i.e., strength of the applied electrical field, tip-collector distance, flow rate) and solution properties (i.e., viscosity, surface-tension, electrical conductivity, volatility, concentration), which allows controlling the breakup of liquid jet and consequently determining both size and shape of resulting micro/nanoparticles [49]. In general, high voltages increase the charge density on the droplets and promote the breakup of the liquid jet when the polymer dissolution had low concentration. Nevertheless, high voltages should also be avoided since they may cause undesirable and irregular multi-jets that lead to the formation of a broad distribution of small and large microspheres [50]. Large particle sizes are characteristic of high electrode spaces that lead to an insufficient breakup. High flow rates are associated to a reduction of charge density, a limited breakup, an increased size and a bad sphericity [51]. Selection of an appropriate solvent system probably becomes one of the most crucial points, especially when compounds of highly different characteristics (i.e. PBS and selected indole derivatives) must be processed. Table S1 shows the solubility characteristics of the indicated compounds that point out the use of dichloromethane and chloroform as ideal solvents for all possible combinations. In reference to solution properties, it has been established that fission of droplets is logically hindered when surface tension is increased. Specifically, it has been reported that a liquid can hardly be atomized when its surface tension is higher than 50 mN/m [52]. On the other hand, an increase on the solution conductivity favors the fission process (i.e. reduction of particle size) since sprayed drops can accumulate a higher surface charge [51]. Solution viscosity (determined 12 by solvent, temperature, polymer concentration and molecular weight) is however, the key factor to control both size and shape of particles since breakup and deformation is hindered when viscous force is high (i.e. fibers or particles are obtained from high or low viscosity solutions, respectively). Figure S1 shows typical morphologies attained during the optimization process of PBS electrospraying from chloroform solutions. Thus, Fig. S1a demonstrated the high influence of polymer concentration since continuous microfibers are exclusively produced at high concentrations (i.e. 10 wt-%) whereas the ratio of microparticles increased as concentration decreased until 2.5 wt-% as well as the applied voltage increased (i.e. from 20 to 30 kV). Figure S1b mainly points out the increase of the particle size when the flow rate was increased. Optimized conditions for chloroform and dichloromethane solutions are indicated in Table 2. Detailed morphology of nanoparticles obtained from the chloroform solution is shown in the SEM micrograph of Fig. 2a. Diameter distribution ranged between 8 and 21 m with an average value close to 15 m. Microspheres were very irregular and displayed a wrinkled surface. In fact, it has been indicated that particles tend to collapse giving rise to a raisin-like morphology when low solute concentration are employed [53]. A solid PBS shell is expected to be formed as a consequence of the rapid evaporation of the solvent. Nevertheless, this shell should easily collapse since the core of the particle is structurally weak due to the low polymer concentration [54]. [Table 2] Electrospraying parameters were modified when a solution of dichloromethane was employed. Basically, a very low polymer concentration was required to avoid a great particle size. As 13 shown in Fig. 2b, this condition was problematic since the solvent was not completely evaporated despite its high volatility when particles reached the collector. Note that most of them became flattened as consequence of the impact. It should also be considered that dichloromethane has a slightly better affinity with PBS than chloroform and consequently a higher solvent retention could occur. Specifically, Hildebrand parameters are 18.7 MPa1/2 and 20.2 MPa1/2 for chloroform and dichloromethane [55,56], respectively. The estimated parameter for PBS, considering a density of 1.26 g/mL and the Small attractive constants [57], is 20.36 MPa1.26 (i.e. closer to the parameter of dichloromethane). [Fig. 2.] 3.2. Electrosprayed PBS microparticles loaded with indole derivatives: Morphology and encapsulation efficiency Figure 3 shows representative SEM images of electrosprayed PBS microparticles loaded with the different indole derivatives, whereas Fig. 4 displays the corresponding diameter distributions. Processing was always performed under the optimized conditions of the single polymer and consequently differences on size, distribution and morphology should only be attributed to the effect that the incorporation of a low percentage of the selected drug caused to the solution. It is interesting to point out that the type of substituent and even its position on the indole core had a significant influence on the final characteristics. Note that 1-methylindole and 2-phenylindole are probably the more distinctive derivatives since in the first case the compound is unable to form hydrogen bonds and in the second case the compound has a remarkable aromatic content. [Fig. 3.] In general, the average diameter decreased when the electrospraying solution contained the indole derivatives (i.e. from 14.8 m to 6.4 m). Indole and its derivatives with a methyl group 14 in positions 2 and 3 gave rise to rather similar mean sizes (i.e. 9.3, 9.1 and 7.9 m for indole, 2methylindole and 3-methyindole), whereas a greater value (10.9 m) was determined for the derivative without capacity to establish hydrogen bonding interactions with the carboxylic groups of PBS (1-methylindole). For this sample, the diameter was closer to that observed for unloaded PBS particles. Hydrogen bonds could also be established with the aromatic derivative (2-phenylindole), which caused the largest decrease on the size (i.e. 6.4 m). Diameter distributions were also different and specifically, narrower distributions were observed for microparticles loaded with indole, 3-methylindole and 2-phenylindole. Regular multi-jets seem to be ejected from the tip when the electrospraying solution incorporated drugs with capacity to establish hydrogen bonds. [Fig. 4.] The texture of microparticles changed also by the incorporation of 3-methylindole and, especially 2-phenylindole. Thus, the raisin-like morphology typical of PBS and the other studied indoles changed giving rise to spheres with more compact surfaces and presence of pores (Fig. 3e and 3f). Collapsing of spheres seems less pronounced probably as consequence of the lower particle size (e.g. diameter of 6.4 m for the aromatic derivative with respect to 14.8 m for unloaded PBS). It may be also indicated that the presence of pores on the surface has been typically explained as a consequence of a thermally induced phase separation that could occur when highly volatile solvents are employed [58]. Surface temperature of the solution droplet could significantly decrease because of the quick evaporation of solvent, giving rise to some polymer poor regions that could subsequently be transformed into pores. 15 Encapsulation efficiency considerably varied in function of the loaded drug (i.e. from 20.4% to 97.6%). The efficiency clearly increased as the particle size diminished, being consequently the lowest and highest values determined for samples loaded with 1-methylindole and 2phenylindole, respectively. Intermediate values of 36.0%, 40.2% and 53.6% were determined for indole, 2-methylindole and 3-methylindole, respectively. Note also that the lowest efficiency could also be related to the incapacity of the drug 1-methylindole to establish strong interactions with the polymer matrix. 3.3. Properties of mats constituted by electrosprayed particles. FTIR analysis, porosity and contact angles of mats formed by indole-loaded microspheres Prolonged electrospraying over a surface gives rise to a consistent mat that allows obtaining information concerning their hydrophobicity and porosity, and performing the spectral characterization of microparticles. FTIR spectra (Fig. 5) obviously showed the typical signals of the polyester matrix (e.g. 2940, 1714, 1155 and 1048 cm-1 that are associated to CH2, C=O, asymmetric C-O and symmetric C-O absorption modes, respectively). Characteristic bands of the indole groups can also be detected even for the samples with low encapsulation efficiency (i.e. 1-methylindole). In all cases, the CH out of plane deformation band at 745 cm-1 was the most relevant signal. The NH stretching band was observed (except for 1-methylindole) at a wavenumber close to 3400 cm-1 that suggests a difficulty to form intermolecular hydrogen bonds with PBS in the solid state and probably, a phase separation. Only the mat loaded with the aromatic substituted indole showed a complex 16 NH band that could suggest the existence of different molecular arrangements. In any case, a clear shift of infrared bands respect to those found in the pure components was not detected. Electrospraying is a simple technique to produce a polymer particle coating on a given surface and, specifically, to enhance its hydrophobicity through the greater roughness caused by the spherical protrusions and the air pockets derived from the increased porosity [59]. In fact, the surface architecture plays a pivotal role in the final wettability. Note that reported contact angles (CA) on flat surfaces are always lower than 120º, being necessary to increase roughness or porosity to render highly hydrophobic surfaces. The effect of air pocket formation is given by the Cassie-Baxter equation [60]. cos w = f1 cos 1 + f2 cos 2 (3) where fi represents the fraction of each component (polymer and air) and i the corresponding contact angles. When f2 represents the area fraction of trapped air, equation 3 can be modified according to simple equation 4: cos w = f cos Y + (1-f ) cos 180º = f cos Y + f – 1 (4) where f is an area fraction of the solid-liquid interface and (1-f ) is that of the air-liquid interface. [Fig. 5.] Contact angle measurements obtained by the sessile drop method for the studied samples are shown in Fig. 6. An angle of 104.2º ± 2.9º was determined for the mat of PBS electrosprayed microspheres, indicating as expected a higher hydrophobicity with respect to a PBS film (85° ± 3.5º). The value was significantly lower that determined from scaffolds of electrospun fibers (131.5º ± 1.8°) and evidenced the importance of controlling the morphology of the samples and, 17 in particular, the dependence with porosity (film < microspheres < fibers). Contact angle of electrosprayed samples loaded with indoles increased significantly (up to 114.8º-124º) with respect to non-loaded particles as a consequence of the hydrophobic character of the incorporated drug. Differences were not highly significant between loaded samples, being values grouped in a narrow range (i.e. 116.7º ± 2.5º for PBS-I, 114.8º ± 5.3º for PBS-1MI, 119.2º ± 1.3º for PBS-3MI and 116º ± 2.1º for PBS-2PI) with the only exception of PBS-2MI (124º ± 1º). In fact multiple factors should be taken into account to discuss the induced changes on hydrophobicity, playing in some cases opposite effects. Therefore, particle size and texture, encapsulation efficiency and intrinsic hydrophobicity of the drug, which depends on the type of substituent and its position in the indole core, should be considered. [Fig. 6.] Porosity of matrices could be estimated by determining the void volume through water-uptake measurements (i.e. the amount of water that was filling the interstitial space formed by neighboring microspheres). Interstitial spaces of the matrix were interconnected to form channels and galleries that allowed the fluid movement while a swelling effect, indicative of absorption and accumulation of water inside particles, was not produced as it was expected from their hydrophobic nature. In general, porosities significantly varied depending on the sample (Fig. 7) and specifically tended to increase with the size of the electrosprayed particles since a lower compactness could be achieved. Thus, the lowest (87.9% ± 4.5%,) and highest (98.3% ± 0.6%) porosities were observed for mats constituted by unloaded and 2-phenylindole loaded particles, which had the highest (14.8 m) and lowest (6.4 m) average diameters, respectively. Intermediate values of 95.2% ± 2.5%, 92.8% ± 2.2% and 90.8% ± 2.2% and 87.9% ± 3.5% were determined for mats 18 of particles loaded with 1MI, 2MI, 3MI and I, respectively. Note that for loaded particles those incorporating 1MI had the highest diameter (10.9 m) and exhibited the highest porosity. [Fig. 7.] 3.4. Release of indole derivatives from PBS electrosprayed microparticles Although indole-based compounds present interesting activity against some types of tumors, they also have some limitations: a) Slight solubility in water that logically limits their administration and cause low bioavailability or poor absorption; b) Rapid oxidation, metabolization and elimination, which decreases considerably the levels of indoles in serum and their bioavailability. These disadvantages limit clinical applications, being considered the use of chemically modified products (e.g. alkaloids) or their encapsulation into a polymeric matrix. This system could act as an appropriate device for controlling drug release and enhance significantly the drug bioavailability. The simple encapsulation is governed by weak attractive intermolecular forces between polymer molecules and the indoles trapped between them. This feature contrasts with the establishment of covalent bounds that could led to a meaningful pharmacological activity loss. The cumulative percentage of indoles released in the hydrophilic SS medium is shown in Fig. 8. In general, the release of indoles can be related to their scarce solubility in aqueous media. Thus, the non-substituted indole was progressively released from the microspheres up to a maximum value (close to 80%) after only 4 h of exposure and then the release was completely stopped (Fig. 8a) since the solubility limit was achieved (2.8 g/L was the reported solubility of indole in water at 25 ºC). No release (Fig. 8b and 8e) was observed when the drug was unable to form hydrogen bonds with the solvent (i.e. 1MI) or was highly hydrophobic due to its aromatic substituent (i.e. 2PI). Intermediate releases where found for 2MI (30%, Fig. 8c) and 3MI (20%, Fig. 8d). 19 Differences with the non-substituted indole can be justified considering their lower solubility (e.g. 0.45 g/L at 20 ºC for 3MI) and even the greater amount of encapsulated drug (e.g. 53.6% and 36.0% for 3MI and I, respectively). It should also be indicated that a slightly slower release rate was determined for 3MI since 6-8 h were necessary to reach the maximum release percentage. Drug delivery behavior changed drastically when ethanol was added to the release medium as a consequence of an increased solubility when the hydrophobicity of the medium was increased and also as consequence of a possible swelling of the microparticles caused by ethanol, facilitating drug diffusion to the medium. Cumulative release plots in SS/EtOH for PBS microspheres loaded with I, 2MI, 3MI and 2PI showed a massive initial burst release up to a maximum percentage and a subsequent decrease of the released percentage until a constant value. The observed plateau evidences the achievement of equilibrium at a percentage that varies according to the indole derivative. It seems that a slight percentage of the initially delivered drug was able to enter again inside the microparticle to meet the equilibrium condition. For indole (Fig. 8a), this equilibrium corresponded to a release of 70% and was reached after only 4 h while for 2MI and 3MI, 6 h and 8 h were necessary with release values close to 30% and 40%, respectively (Fig. 8c and 8d). For the more voluminous compound, 2PI, the equilibrium (50%) was logically reached more slowly (Fig. 8e). These results point out to the existence of weak interactions between the drug and the polymer matrix that allowed the free movement of drug molecules through a diffusion mechanism. A clearly differentiated release behaviour was found for 1MI (Fig. 8b) since both burst effect and equilibrium condition were not detected, being characteristic a slow and gradual release (i.e. 75 h 20 were required for a delivery of 40%). In fact, this is precisely the only studied indole that has not a NH donor group able to establish bond interactions with either the PBS matrix or the solvent. [Fig. 8.] SEM micrographs of microparticles recovered after the release experiments are shown in Fig. S2. Morphologies are similar to those observed before exposure, indicating that possible changes caused by degradation or swelling were in all cases negligible. 3.5. Antiproliferative activity assays In order to analyse anticancer activities of the studied indoles, cytotoxicity assays were carried out using four cell lines, Saos-2 and Vero (both epithelial cells) and MRC-5 and COS-7 (both fibroblast cells). Figure 9 shows the cytotoxicity of drugs in a concentration-dependent manner for all lines. Results allow determining the respective IC50 for indole, methylated indoles and 2phenylindole (Table 3). Specifically, 1MI and 2PI had the highest and lowest IC50 concentration, respectively. These preliminary results just implied that all assayed compounds could be good candidates as antiproliferative drugs for cancer cells, but 1MI excelled among them, followed in order by indole, 2MI and 3MI. However, different levels of cytotoxicity were obtained when fibroblast-like and epithelial-like cells were seeded onto mats constituted by PBS microspheres loaded with the considered indoles and subjected to an MTT assay (Figure 12). It was clearly observed that the unloaded PBS mat with a 3D structure supports a higher cell growth than the control (2D surface of the tissue culture plate). This point is meaningful since it suggests that the mat has a structure of pores and channels similar to other scaffolds developed for tissue growth, and also that PBS has good 21 biocompatibility [61]. On the other hand, mats loaded with indole and indole-derivatives showed inhibitory effects on proliferation of cell lines. The lower antiproliferative effect was observed for mats loaded with indole, 1MI and 2MI; while the greatest effect was observed for samples loaded with 3MI and 2PI. Apparently, this result is contradictory to the IC50 values found for pure drugs (see Table 3). However, it is obvious that the antiproliferative effect not only depends on the IC50 value of the drug but also on the amount of drug loaded. Therefore, the higher antiproliferative activity against cell lines was precisely found for samples where the drug was more efficiently encapsulated (i.e. PBS-2PI and PBS-3MI). [Fig. 9.] [Table 3.] A remarkable aspect is the greater antiproliferative effect observed on Saos-2 and COS-7 cell lines compared to MRC-5 and Vero cell lines. Saos-2 corresponds to cancer cells that were obtained from a human osteosarcoma, COS-7 are cells transformed with SV-40 viral DNA sequence, whereas MRC-5 and Vero are normal immortalized cells (from human lung and kidney of the African green monkey, respectively). Thus, a differential effect against cancer cells and immortalized cells is deduced. This observation is in full agreement with other reported studies that justified the differential sensitivity of cancer cells in base on the expression of a gene pool [34]. Specifically, a new indole retinoid derivative had a high antiproliferative effect against 11 breast cancer cell lines, whereas a similar effect on immortalized normal breast cell line (MCF-12A) required a fourfold higher concentration than its IC50 value. Compounds with this behavior are highly interesting because they can be used for cancer prevention or treatment and simultaneously be less toxic for normal tissues. [Fig. 10.] 22 4. Conclusions Microparticles of poly(butylene succinate) loaded with indole, several methylindoles or 2phenylindole were obtained by the electrospraying technique using chloroform as a common solvent, a low polymer concentration and a low flow rate. In general, particles showed a raisinlike morphology as a consequence of the shell collapse since a structurally weak core was formed under the given processing conditions. Nevertheless, the loaded drug had a slight influence on the texture and a great impact on both particle size and diameter distribution. Prolonged electrospraying gave rise to consistent mats, in which hydrophobicity and porosity depended on the loaded drug (i.e. on the kind of substituent and its position in the indole core). Encapsulation efficiency varied from 20.4% to 97.6% depending also on the selected drug (i.e. the indole unable to form hydrogen bonds (1MI) had the lowest EE, whereas the indole with the aromatic substituent (2PI) had the highest EE) and particularly on the particle size (i.e. EE increased as the diameter of the microparticle decreased). All indoles were hardly released using a saline buffer solution due to their scarce solubility but on the contrary high release percentages were observed when the medium was supplemented with ethanol. In this case, a significant burst effect was usually observed as well as the establishment of an equilibrium condition that led to a partial reabsorption of the released drug. Interestingly, it has been found that the release behavior depended on the type of substituent and its position in the indole molecule. These features have a great influence on the capability to establish interactions with polymer and water molecules. Particularly, it can be considered the inability to form hydrogen bonds by direct substitution in the nitrogen atom and the steric hindrances caused by the aromatic groups. Therefore, the release of anticancerigen drugs can be tuned taking into account small changes on the chemical structure. In this way, 1-methylindole 23 showed a well-differentiated behavior since a slow and sustained release was characteristic, probably as a consequence of its incapacity to establish hydrogen bonding interactions with the solvent and its greater affinity with the polymer matrix. In a similar manner, the substitution with a bulky phenyl group in position 2 gave rise to a lower release rate than the related methylated compound. Another highlight of this study was the well differentiated behavior between cancer and immortalized cells. All systems had an antiproliferative effect that increased with the encapsulation efficiency and that interestingly was more pronounced when cancer cells were employed instead of usual immortalized cells. Results point out the potential benefit of indole loaded PBS microparticles for cancer prevention and treatment, being probably PBS-2PI the most efficient system. Acknowledgments. Authors are in debt to supports from MINECO and FEDER (MAT2012-36205) from MICINN and the Generalitat de Catalunya (2009SGR1208). 24 References [1] S. Chakraborty, I.C. Liao, A. Adler, K.W. Leong, Electrohydrodynamics: a facile technique to fabricate drug delivery systems, Adv. Drug Del. Rev. 61 (2009) 1043–1054. [2] L. Ding, T. Lee, C.H. Wang, Fabrication of monodispersed taxol-loaded particles using electrohydrodynamic atomization, J. Control Release 102 (2005) 395–413. [3] D.G. Yu, G.R. Williams, X. Wang, X.K. Liu, H.L. Li, S.W. Bligh, Dual drug release nanocomposites prepared using a combination of electrospraying and electrospinning, RSC Adv. 3 (2013) 4652–4658. [4] M. Zamani, M.P. Prabhakaran, S. Ramakrishna, Advances in drug delivery via electrospun and electrosprayed nanomaterials, Int. J. Nanomedicine 8 (2013) 2997–3017. [5] H. Duan, B. Feng, X. Guo, J. Wang, L. Zhao, G. Zhou, W. Liu, Y. Cao, W.J. Zhang, Engineering of epidermis skin grafts using electrospun nanofibrous gelatin/ polycaprolactone membranes, Int. J. Nanomedicine 8 (2013) 2077–2084. [6] O.V. Salata, Tools of nanotechnology: electrospraying, Curr. Nanosci. 1 (2005) 25–33. [7] D. Li, Y. Xia, Electrospinning of nanofibers: reinventing the wheel?, Adv. Mater. 16 (2004) 1151–1170. [8] J.T. Seil, T.J. Webster, Spray deposition of live cells throughout the electrospinning process produces nanofibrous three-dimensional tissue scaffolds, Int. J. Nanomedicine 6 (2011) 1095–1099. [9] D.G. Yu, L.M. Zhu, C.J. Branford-White, J-H. Yang, X. Wang, Y. Li, W. Qian, Solid dispersions in the form of electrospun core-sheath nanofibers, Int. J. Nanomedicine 6 (2011) 3271–3280. [10] S.D. Nath, S. Son, A. Sadiasa, Y.K. Min, B.T. Lee, Preparation and characterization of PLGA microspheres by the electrospraying method for delivering simvastatin for bone regeneration, Int. J. Pharm. 443 (2013) 87–94. [11] M. Enayati, Z. Ahmad, E. Stride, M. Edirisinghe, One step electrohydrodynamic production of drug-loaded micro- and nanoparticles, J. R. Soc. Interface 7 (2010) 667–675. [12] D.G. Yu, G.R. Williams, J.H. Yang, X. Wang, J.M. Yang, X.Y. Li, Solid lipid nanoparticles self-assembled from electrosprayed polymer based macro particles, J. Mater. Chem. 21 (2011) 15957. 25 [13] L.Y. Huang, D.G. Yu, C. Branford-White, L.M. Zhu, Sustained release of ethyl cellulose micro-particulate drug delivery systems prepared using electrospraying, J. Mater. Sci. 47 (2012) 1372-1377. [14] W. Li, D.G. Yu, K. Chen, G. Wang, G.R. Williams, Smooth preparation of ibuprofen/zein microcomposites using an epoxy-coated electrospraying head, Mater. Lett. 93 (2013) 125128. [15] Y. Ichikawa, T. Mizukoshi, Bionolle (polybutylenesuccinate), Adv. Polym. Sci. 245 (2012) 285–314. [16] C. Imperatore, A. Aiello, F. D’Aniello, M. Senese, M. Menna, Alkaloids from marine invertebrates as important leads for anticancer drugs, discovery and development, Molecules 19 (2014) 20391-20423. [17] D. Wang, X. Ding, P.N. Rather, Indole can act as an extracellular signal in Escherichia coli, J. Bacteriol. 183 (2001) 4210-4216. [18] E. Nikaido, E. Giraud, S. Baucheron, S. Yamasaki, A. Wiedemann, K. Okamoto, T. Takagi, A. Yamaguchi, A. Cloeckaert, K. Nishino, Effects of indole on drug resistance and virulence of Salmonella enterica serovar Typhimurium revealed by genome-wide analyses, Gut Pathogens 4 (2012) 13p. [19] F.R. de Sá Alves, E.J. Barreiro, C.A. Fraga, From nature to drug discovery: the indole scaffold as a ‘privileged structure’, Mini Rev. Med. Chem. 9 (2009) 782-793. [20] B.E. Evans, K.E. Rittle, M.G. Bock, R.M. DiPardo, R.M. Freidinger, W.L. Whitter, G.F. Lundell, D.F. Veber, P.S. Anderson, R.S. Chang, V.J. Lotti, D.J. Cerino, T.B. Chen, P.J. Kling, K.A. Kunkel, J.P. Springer, J. Hirshfield, Methods for drug discovery: development of potent, selective, orally effective cholecystokinin antagonists, J. Med. Chem. 31 (1988) 2235-2246. [21] M.E. Welsch, S.A. Snyder, B.R. Stockwell, Privileged scaffolds for library design and drug discovery, Curr. Opin. Chem. Biol. 14 (2010) 347-361. [22] C. Won, X. Shen, K. Mashiguchi, Z. Zheng, X. Dai, Y. Cheng, H. Kasahara, Y. Kamiya, J. Chory, Y. Zhao, Conversion of tryptophan to indole-3-acetic acid by tryptophan aminotransferases of arabidopsis and yuccas in Arabidopsis, Proc. Natl. Acad. Sci. USA 108 (2011) 18518-18523. [23] M.Z. Zhang, N. Mulholland, D. Beattie, D. Irwin, Y.C. Gu, Q. Chen, G.F. Yang, J. Clough, Synthesis and antifungal activity of 3-(1,3,4-oxadiazol-5-yl)-indoles and 3-(1,3,4oxadiazol-5-yl)methyl-indoles, Eur. J. Med. Chem. 63 (2013) 22-32. [24] S.N. Young, How to increase serotonin in the human brain without drugs, J. Psychiatry Neurosci. 32 (2007) 394-399. 26 [25] L.B. Diss, S.D. Robinson, Y. Wu, S. Fidalgo, M.S. Yeoman, B.A. Patel, Age related changes in melatonin release in the murine distal colon, ACS Chem. Neurosci. 4 (2013) 879-887. [26] J.V. Higdon, B. Delage, D.E. Williams, R.H. Dashwood, Cruciferous vegetables and human cancer risk: epidemiologic evidence and mechanistic basis, Pharmacol. Res. 55 (2007) 224-236. [27] E.G. Rogan, The natural chemopreventive compound indole-3-carbinol: state of the science, In Vivo 20 (2006) 221-228. [28] Y.S. Kim, J.A. Milner, Targets for indole-3-carbinol in cancer prevention, J. Nutr. Biochem. 16 (2005) 65-73. [29] B. Biersack, R. Schobert, Indole compounds against breast cancer: recent developments, Curr. Drug Targets 13 (2012) 1705-1719. [30] W.G. Kurz, K.B. Chatson, F. Constabel, J.P. Kutney, L.S. Choi, P. Kolodziejczyk, S.K. Sleigh, K.L. Stuart, B.R. Worth, Alkaloid production in Catharanthus roseus cell cultures VIII, Planta Med. 42 (1981) 22-31. [31] F. Leon, E. Habib, J.E. Adkins, E.B. Furr, C.R. McCurdy, S.J. Cutler, Phytochemical characterization of the leaves of Mitragyna speciosa grown in USA, Nat. Prod. Commun. 4 (2009) 907-910. [32] F.E. Chen, J. Huang, Reserpine: a Challenge for total synthesis of natural products, Chem. Rev. 105 (2005) 4671-4706. [33] H. Ishikawa, D.A. Colby, D.L. Boger, Direct coupling of catharanthine and vindoline to provide vinblastine: total synthesis of (+)- and ent-(-)-vinblastine, J. Am. Chem. Soc. 130 (2008) 420-421. [34] A.S. Gurkan-Alp, M. Mumcuoglu, C.A. Andac, E. Dayanc, R. Cetin-Atalay, E. Buyukbingol, Synthesis, anticancer activities and molecular modeling studies of novel indole retinoid derivatives. Eur. J. Med. Chem. 58 (2012) 346-354. [35] X.Y. Ji, S.T. Xue, Y.C. Zhan, J.J. Shen, L.T. Wu, J. Jin, Z. Wang, Z.R. Li, Design, synthesis and antiproliferative activity of a novel class of indole-2-carboxylate derivatives. Eur. J. Med. Chem. 83 (2014) 409-418. [36] M.J.R.P. Queiroz, A.S. Abreu, M.S.D. Carvalho, P.M.T. Ferreira, N. Nazareth, M.S.J. Nascimento, Synthesis of new heteroaryl and heteroannulated indoles from dehydrophenylalanines: antitumor evaluation, Bioorgan. Med. Chem. 16 (2008) 5584– 5589. 27 [37] L.Y. Bai, J.R Weng, C.F. Chiu, C.Y. Wu, S.P. Yeh, A.M. Sargeant, P.H. Lin, Y.M. Liao, OSU-A9, an indole-3-carbinol derivative, induces cytotoxicity in acute myeloid leukemia through reactive oxygen species-mediated apoptosis, Biochem. Pharmacol. 86 (2013) 1430–1440. [38] Q. Guan, C. Han, D. Zuo, M. Zhai, Z. Li, Q. Zhang, Y. Zhai, X. Jiang, K. Bao, Y. Wu, W. Zhang, Synthesis and evaluation of benzimidazole carbamates bearing indole moieties for antiproliferative and antitubulin activities, Eur. J. Med. Chem. 87 (2014) 306-315. [39] A.E. Shchekotikhin, V.A. Glazunova, L.G. Dezhenkova, Y.N. Luzikov, V.N. Buyanov, H.M. Treshalina, N.A. Lesnaya, V.I. Romanenko, D.N. Kaluzhny, J. Balzarini, K. Agama, Y. Pommier, A.A. Shtil, M.N. Preobrazhenskaya, Synthesis and evaluation of new antitumor 3-aminomethyl-4,11-dihydroxynaphtho[2,3-f]indole-5,10-diones, Eur. J. Med. Chem. 86 (2014) 797-805. [40] A. Andreani, S. Burnelli, M. Granaiola, A. Leoni, A. Locatelli, R. Morigi, M. Rambaldi, L. Varoli, L. Landi, C. Prata, F.V. Dalla Sega, C. Caliceti, R.H. Shoemaker. Antitumor activity and COMPARE analysis of bis-indole derivatives, Bioorgan. Med. Chem. 18 (2010) 3004–3011. [41] K.V. Sashidhara, R.P. Dodda, R. Sonkar, G.R. Palnati, G. Bhatia, Design and synthesis of novel indole-chalcone fibrates as lipid lowering agents, Eur. J. Med. Chem. 81 (2014) 499509. [42] M.Z. Zhang, Q. Chen, G.F. Yang, A review on recent developments of indole-containing antiviral agents, Eur. J. Med. Chem. 89 (2015) 421-441. [43] N.K. Kaushik, N. Kaushik, P. Attri, N. Kumar, C.H. Kim, A.K. Verma, E.H. Choi, Biomedical importance of indoles, Molecules 18 (2013) 6620-6662. [44] K.K.W. Lo, K.H.K. Tsang, K.S. Sze, C.K. Chung, T.K.M. Lee, K.Y. Zhang, W.K. Hui, C.K. Li, J.S.Y. Lau, D.C.M. Ng, N. Zhu, Non-covalent binding of luminescent transition metal polypyridine complexes to avidin, indole-binding proteins and estrogen receptors, Coordin. Chem. Rev. 251 (2007) 2292–2310. [45] E.A.I.E. Vitaku, J.T. Njarðarson, Compiled and produced by the Njardarson Group (The University of Arizona), 2013. http://cbc.arizona.edu/njardarson/group/top-pharmaceuticalsposter. [46] A. Daugan, P. Grondin, C. Ruault, A.C. Le Monnier de Gouville, H. Coste, J.M. Linget, J. Kirilovsky, F. Hyafil, R. Labaudiniere, The discovery of tadalafil: a novel and highly selective PDE5 inhibitor. 2: 2,3,6,7,12,12a-hexahydropyrazino[1’,2’:1,6]pyrido[3,4b]indole-1,4-dione analogues, J. Med. Chem. 46 (2003) 4533-4542. [47] A. Daugan, P. Grondin, C. Ruault, A.C. Le Monnier de Gouville, H. Coste, J. Kirilovsky, F. Hyafil, R. Labaudiniere, The discovery of tadalafil: a novel and highly selective PDE5 28 inhibitor. 1: 5,6,11,11a-tetrahydro-1H-imidazo[1’,5’:1,6]pyrido[3,4-b]indole-1,3(2H)dione analogues, J. Med. Chem. 46 (2003) 4525-4532. [48] T. Mosmann, Rapid colorimetric assay for cellular growth and survival: Application to proliferation and cytotoxicity assays, J. Immunol. Methods 65 (1983) 55-63. [49] G.I. Loscertales, A, Barrero, I, Guerrero, R. Cortijo, M. Marquez, A.M. Gañán-Calvo, Micro/nano encapsulation via electrified coaxial liquid jets, Science 295 (2002) 16951698. [50] A. Jaworek, A.T. Sobczyk, Electrospraying route to nanotechnology: An overview, J. Electrostat 66 (2008) 197-219. [51] D.P.H. Smith, The electrohydrodynamic atomization of liquids, IEEE Trans. Ind. Appl. 22 (1986) 527-535. [52] W. Wu, J. Gu, G. Zhou, L. Zhang, M. Gong, H. Dai, Fabrication of natural cellulose microspheres via electrospraying from NaOH/urea aqueous system. J. Appl. Polym. Sci. 131 (2014) 131, 40656-40663. [53] L.W. Xue, L.X. Mao, Q. Cai, X.P. Yang, R.G. Jin, Preparation of amino acid ester substituted polyphosphazene microparticles via electrohydrodynamic atomization, Polym. Adv. Technol. 22 (2011) 2009-2016. [54] J. Gao, W. Li, J.S-P. Wong, M. Hu, R.K.Y. Li, Controllable morphology and wettability of polymer microspheres prepared by nonsolvent assisted electrospraying. Polymer 55 (2014) 2913-2920. [55] J. Brandrup, E.H. Immergut, E.A. Grulke, A. Abe, D.R. Bloch, Polymer Handbook, 4th ed., Wiley, New York, 2003. [56] D.R. Lide (Ed), CRC Handbook of Chemistry and Physics, 41th ed., CRC Press, Boca Raton, FL, 2003. [57] P.A. Small, Some factors affecting the solubility of polymers, J. Appl. Chem. 3 (1953) 7180. [58] S. Megelski, J.S. Stephens, D. Bruce Chase, J.F. Rabolt, Micro- and nanostructured surface morphology on electrospun polymer fibers, Macromolecules 35 (2002) 8456-8466. [59] I. Sas, R.E. Gorga, J.A. Joines, K.A. Thoney, Literature review on superhydrophobic selfcleaning surfaces produced by electrospinning, J. Polym. Sci. Part B: Polym. Phys. 50 (2012) 824-845. [60] A.B.D. Cassie, S. Baxter, Wettability of porous surfaces, Trans. Faraday Soc. 40 (1944) 546-551. 29 [61] E. Llorens, H. Ibañez, L.J. del Valle, J. Puiggalí, Biocompatibility and drug reléase behaviour of scaffolds prepared by coaxial electrospinning of poly(butylene succinate) and polyethylene glycol, Mater. Sci. Eng. C 49 (2015) 472-484. 30 Table 1 Biological activities of main compounds based on indole units Compound Biological activity Indole-3-acetic acid (IAA) One of the most common naturally occurring compounds. It is a plant hormone of the auxin class [22]. Tryptophan An essential amino acid that participates in many essential biological processes [23]. Serotonin or 5-hydroxyl It is a compound biochemically derived from tryptophan. It is a tryptamine (5-HT) neurotransmitter that can be found in all bilateral animals [24]. Melatonin It is a hormone that can be found in animals, plants, and microbes. Animals use the each day variation of melatonin production as a seasonal clock [25]. Indole-3-carbinol (I3C), and I3C is a natural product that can be found at relatively high 3,3’-diindolylmethane levels in cruciferous vegetables such as broccoli, Brussels (DIM) sprouts, cabbage and kale product. DIM is derived from the digestion of I3C. These compounds have been the subjects of on-going research due to their interesting anticarcinogenic, antioxidant, and antiatherogenic effects [26-29]. Ajmalicine (d-yohimbine or It is a natural alkaloid indole that is found in various plants and raubasine) that can use as an antihypertensive drug for the treatment of high blood pressure. It acts as a α1-adrenergic receptor antagonist with preferential actions over α2-adrenergic receptors, underlying its hypotensive rather than hypertensive effects [30,31]. Reserpine It is an alkaloid indole that is used to treat high blood pressure and severe agitation in patients with mental disorders [32]. Vinblastine It is used to treat several types of cancer, including Hodgkin's disease, Kaposi's sarcoma, non-Hodgkin's lymphoma, and cancer of the breast or testicles [33]. 31 Table 2 Optimized operational conditions for the preparation of PBS particles by electrospraying. Solvent Chloroform PBS (%-w) 2.5 Dichloromethane 2.5 a Voltage Flow Rate (kv) (mL·h-1) 30 2 Distancea (cm) 16 20 17 0.5 Needle-collector distance 32 Table 3. Antiproliferative activities of the pure indole compounds. Compound MRC-5 Vero I 1MI 2MI 3MI 2PI 2.94 3.28 2.06 1.80 1.10 3.07 3.69 1.55 1.39 0.88 IC50 (µM) COS-7 2.07 2.69 1.04 0.76 0.51 Saos-2 1.72 2.15 1.30 0.75 0.44 33 FIGURE CAPTIONS Fig. 1. Chemical structures of poly(butylene succinate) (PBS) and the selected indole derivatives. Fig. 2. SEM micrographs showing the morphology of electrosprayed particles obtained from chloroform (a) and dichloromethane (b) solutions under the optimized processing conditions summarized in Table 2. The magnification of the inset shows a typical raisin-like morphology. Fig. 3. SEM images showing the morphology of electrosprayed microparticles obtained from chloroform: PBS (a), PBS loaded with indole (b), PBS loaded with 1-methyl indole (c), PBS loaded with 2-methyl indole (d), PBS loaded with 3-methyl indole (e) and PBS loaded with 2phenyl indole (f). Insets show SEM high magnification images of microparticles with smooth surfaces. Fig. 4. Diameter distribution of electrosprayed microparticles obtained from chloroform: PBS (a), PBS loaded with indole (b), PBS loaded with 1-methyl indole (c), PBS loaded with 2-methyl indole (d), PBS loaded with 3-methyl indole (e) and PBS loaded with 2-phenyl indole (f). Insets show SEM images of representative particles. Fig. 5. Representative FTIR spectra for mats microspheres: a) PBS, b) Indole, PBS loaded with 1methylindole (c), PBS loaded with 2-methyl indole (d), PBS loaded with 2-phenyl indole (e). Insets show a magnification of the region corresponding to the NH stretching band. Fig. 6. Contact angles for PBS in the form of film, electrospun scaffold and mats of electrosprayed particles and drug loaded microspheres. Representative images of a water drop deposited onto each sample are shown within each bar. *p<0.05 vs PBS particles. 34 Fig. 7. Void volume determined by the water-uptake method for the different mats of electrosprayed particles. *p<0.05 vs PBS particles loaded with indole. Fig. 8. Release curves in SS (black) and SS/EtOH (red) media of: PBS-I (a), PBS-1MI (b), PBS-2MI (c), PBS-3MI (d) and PBS-2PI (e). Fig. 9. Dose-response effect of pure compounds for the in-vitro cell growth inhibition: a) COS-7, b) MRC-5, c) Saos-2 and d) Vero cell lines. Fig. 10. Antiproliferative activity of mats constituted by PBS microspheres and PBS microspheres loaded with indole (PBS-I), 1MI (PBS-1MI), 2MI (PBS-2MI), 3MI (PBS-3MI) and 2PI (PBS-2PI). Control: surface of tissue culture plate. * p<0.05 vs control; ** p<0.05 vs cell lines 35 Fig. 1. 36 Fig. 2. 37 Fig. 3. 38 Fig. 4. b) 40 30 20 10 0 0 4 8 12 16 20 50 40 30 20 10 0 24 0 4 Diameter (m) e) 40 30 20 10 0 4 8 12 16 Diameter (m) 12 16 20 30 20 10 0 24 0 4 20 24 50 30 20 10 0 4 8 12 16 Diameter (m) 12 16 20 24 20 24 50 f) 40 0 8 Diameter (m) Distribution (%) 50 0 8 40 Diameter (m) Distribution (%) Distribution (%) d) 50 c) Distribution (%) 50 Distribution (%) Distribution (%) a) 20 24 40 30 20 10 0 0 4 8 12 16 Diameter (m) 39 Fig.5. (a) Transmittance (a.u.) (b) (c) (d) (e) 3400 NH 2940 CH2 1048 C-Os 1155 745 C-Oa C-H 1714 C=O 3700 3100 2500 1900 1300 700 Wavenumber (cm-1) 40 Fig. 6. o Contact angle ( ) 150 135 120 * * 105 90 10 0 s le le le le le m rs Fil Fibe rticle Indo indo indo indo indo l l l l Pa thy ethy ethy heny e 1-M 2-M 3-M 2-P 41 Fig. 7. Water-uptake (%) 100 * * 90 80 20 0 S le le le le le PB Indo lindo lindo lindo lindo y y y y eth Meth meth Phen M 1232- 42 Fig. 8. b) 100 80 Cumulative release (%) Cumulative release (%) a) 60 40 Indole released: SS SS/EtOH 20 0 0 120 240 360 480 3000 3500 4000 100 1-Methylindole released: SS SS/EtOH 80 60 40 20 0 4500 0 120 240 360 480 Time (min) d) 100 2-Methylindole released: SS SS/EtOH Cumulative release (%) 80 60 40 20 0 0 120 240 360 480 3000 e) 3500 4000 4500 3500 4000 4500 100 3-Methylindole released: SS SS/EtOH 80 60 40 20 0 0 120 240 360 480 Time (min) Cumulative release (%) Cumulative release (%) c) 3000 Time (min) 3000 3500 4000 4500 Time (min) 100 80 2-Phenylindole released: SS SS/EtOH 60 40 20 0 0 120 240 360 480 3000 3500 4000 4500 Time (min) 43 Fig. 9. 120 b) 120 100 100 Indole 1-Methylindole 2-Methylindole 3-Methylindole 2-Phenylindole 80 60 40 20 Relative Viability (%) Relative Viability (%) a) 0.01563 0.03125 0.0625 0.125 0.25 0.5 40 20 0.01563 0.03125 1 Concentration (mg/mL) d) 120 100 Relative Viability (%) Relative Viability (%) 120 60 0 0 c) Indole 1-Methylindole 2-Methylindole 3-Methylindole 2-Phenylindole 80 Indole 1-Methylindole 2-Methylindole 3-Methylindole 2-Phenylindole 80 60 40 20 0.0625 0.125 0.25 0.5 1 Concentration (mg/mL) 100 Indole 1-Methylindole 2-Methylindole 3-Methylindole 2-Phenylindole 80 60 40 20 0 0 0.01563 0.03125 0.0625 0.125 0.25 Concentration (mg/mL) 0.5 1 0.01563 0.03125 0.0625 0.125 0.25 0.5 1 Concentration (mg/mL) 44 Fig. 10. * Relative Viability (%) 140 MRC-5 Vero COS-7 Saos-2 120 * 100 ** 80 60 ** 40 20 0 l tro n Co I I I -I S PI PB PBS S-1M S-2M S-3M S-2 PB PB PB PB 45