Comparison of the microbial dynamics and grape, apple and yogurt

advertisement

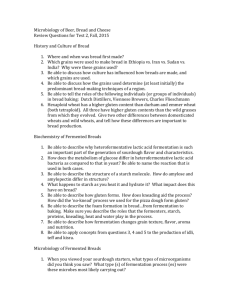

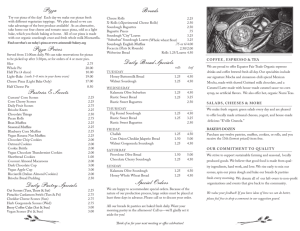

Comparison of the microbial dynamics and biochemistry of laboratory sourdoughs prepared with grape, apple and yogurt Abstract The microbiological culture-dependent characterization and physicochemical characteristics of laboratory sourdough prepared with grape (GS) were evaluated and compared with apple (AS) and yogurt (YS), which are the usual Spanish sourdough ingredients. Ripe GS took longer than AS and YS to reach the appropriate acidity and achieved lower values of lactic acid. In all sourdoughs, the lactic acid bacteria (LAB) increased during processing and were the dominant microorganisms (>1E+8 CFU/g). GS, as well as AS, had high diversity of LAB species. In ripe YS Pediococcus pentosaceus was the only species identified; in GS and AS, several Lactobacillus were also found, Lb. plantarum, Lb. brevis, and Lb. sakei; in addition, in GS Weisella cibaria also appeared. Regarding the yeast population, non-Saccharomyces yeasts from GS and AS showed a very high specific population (> 1E+7 CFU/g), but this was reduced in ripe sourdough (<1E+4 CFU/g). Finally, the Saccharomyces group dominated in all sourdoughs. Starting ingredients or raw material provided microbiological specificity to sourdoughs, and grape could be considered one of them. Keywords Sourdough, grape, yeast, lactic acid bacteria, ingredients 1 Introduction Sourdough was introduced in middle of the 19th Century and has been used in bread production since ancient times, because it was necessary for dough leavening (Hansen and Schieberle, 2005). The tradition of making wheat bread with the addition of sourdough is still widely used in some European countries. Spanish artisan bakeries, especially in Catalonia (northeast Spain), are interested in promoting and encouraging the consumption of these types of longfermentation breads again. Their preparation is more labour-intensive but it allows these bakeries to be different and to respond to the demand of the consumers for these types of breads, as well as enabling them to fend off competition from industrial bread manufacturers. In Spain, sourdough is called ‘mother-dough’ and sometimes the name of the distinguishing ingredient is added (apple sourdough, lactic sourdough). The basic ingredients are wheat flour (if necessary, supplemented with malted barley flour), whole wheat or rye flour, and water. In order to increase the microbiological diversity of sourdough, fermented apple juice or a little milk derivative such as yogurt are frequently added during preparation. The use of lightly fermented grape must could provide, as in wine, greater diversity of the non-Saccharomyces yeasts group and may contribute to give specificity to the sensory characteristics of sourdough. Specific ingredients can also be added to part of the ripe sourdough in the final stages of propagation, in order to transform it and impart a special aroma and flavour to the bread (Bellsolà, 2010). The development of the sourdough is performed as a multi-stage process which controls factors like the incubation temperature, pH and aroma. The bakeries have propagated the same spontaneous sourdough for many years, as in earlier generations (Barriga, 2003), and they don’t add commercial starters at any time during the spontaneous sourdough process. The impact of endogenous factors such as the chemical composition and microbiology of the dough during the continuous propagation of the sourdough produces a dynamic balance among the microorganisms present such as LAB and yeasts (De Vuyst and Neysens, 2005). Between these microorganisms, there are specific and stable associations, and their metabolic activity can contribute to the production of aroma and flavour compounds. LAB contributes specifically to the process of acidification of the sourdough since they are the main microbial group responsible for the production of lactic and acetic acids. Yeast is considered to be the main factor responsible for CO2 production and the increase in dough volume, especially if baker’s yeast is not used for bread making. In general, in ripe sourdough, the LAB counts are already 1E+9 CFU/g of dough, and 1E+6-1E+7 CFU/g of dough to yeasts (Arendt et al., 2007). The level and intensity of the factors that simultaneously affect the lactic and alcoholic fermentation of the sourdough will influence acid formation, volatile compound production, and carbon and nitrogen degradation, ultimately determining the overall quality of the bread. 2 The aim of this study is to evaluate the behaviour of white grape must (variety Xarel·lo) lightly fermented, for 48 h at 20ºC, as a new starting ingredient in sourdough preparation. The microbial dynamics of LAB and yeasts, as well as changes in biochemical parameters (pH, acidity, and other organic compounds), will be evaluated during sourdough preparation. These characteristics, together with the results of molecular identification of LAB species, will be compared with the sourdoughs elaborated with yogurt and apple juice fermented which are usually used in artisan bread-making. Materials and methods Sourdough process preparation using apple, yogurt, and grape in laboratory conditions Three types of sourdough were prepared using a multiphase protocol provided by an artisan bakery (‘Fleca Parés’, Vilafranca del Penedès, Catalonia, Spain) (Table 1). This method, with some variations, is one recommended by the Association of Bakers of Barcelona (Spain). The sourdoughs were prepared by starting each of them with different ingredients such as organic apple (AS), plain yogurt (YS) and organic grape (GS).The grape sourdough studied was prepared using white Xarel.lo variety from the Valldolina vineyard. The sourdoughs elaborations were duplicated, and Table 1 shows the process scheme for the three sourdoughs. The dough was prepared in a spiral dough mixer (Kenwood KM 336) at 200 rpm for 5 min, conditions which allowed good mixing of the ingredients so as to obtain the correct consistency. The sourdough process comprises three phases: the first phase is the preparation of the liquid starter (apple juice fermented and grape must lightly fermented). The fermentation of small pieces of apple mixed in water and honey for 5 days at 40ºC, and stirred twice a day, was performed. The grapes were pressed and the must was fermented 2 days at 20ºC. For the yogurt sourdough, a plain commercial product was used, and according to the guidelines concentrations of Lactobacillus delbrueckii subsp. bulgaricus and Streptococcus thermophillus (≥ 1.0E+06 CFU/g of each species) were expected. A second phase is the pre-sourdough preparation, and in this the growth microorganisms, fermentation and microbial stabilization would take place. This phase lasts 5 days at two different temperatures; for the first three days, the pre-sourdough is kept at 22°C, facilitating the growth of LAB and yeast; the remaining two days storage is at 5°C to select and stabilize the existing microbiota. In this phase, samples to be analysed were taken every 24 or 48 h before the next mixing (samples named P1, P2, P3, P4). Later on, the third phase is the propagation and maintenance of the ripe solid sourdough. The liquid sourdough becomes solid modifying the dough/flour/water relationship. Daily process, known as refreshment, is performed three times a day, at 9:00 a.m., 1:00 p.m., and 5:00 p.m. 3 Before each refreshment step at 9:00 h (every 24 h) samples were taken from sourdough to be analyzed (samples named R1, R2, R3, R4, R5). Microbiological analysis Control of yeast (total and non-Saccharomyces) and LAB. Every 24 or 48 h, a microbiological analysis was performed depending on preparation phase. For the analysis, 10 g of sourdough was homogenized with 90 mL of saline solution ringer ¼ (Scharlab, Spain) using a Stomacher apparatus (BagMixer® 400P, Interscience, Paris) for 2 min. Decimal dilutions were made using the same solution, and microbiological seeding was performed in duplicate on agar plates: i) total yeasts count on WL agar supplemented by 0.5 g/L chloranphenicol (Scharlab, Spain), ii) non-Saccharomyces yeasts on lysine agar (Scharlab, Spain), and iii) lactic acid bacteria on MRS agar (Scharlab, Spain) supplemented by 15% tomato juice, 15% grape juice, and 75 mg/L cycloheximide (pH 5.5). The yeasts were incubated for 3 to 5 days at 27°C, and lactic bacteria were incubated for 5 days at 30°C. The countable plates (between 30 and 300 colonies in MRS agar and 15 and 150 colonies in WL or Lysine agar) were used to quantify the microbial population. Yeast colonies were classified depending on their morphology, colour and colony size. Based on these differences, the percentage of different types of yeast colonies that appeared throughout the study was determined. Isolation and identification of LAB by PCR-sequence of the 16S rDNA gene. Three strains LAB were isolated per sample in order to pick colonies of different appearance. The isolates were characterized by Gram staining, and catalase testing. Homofermentative and heterofermentative tests were performed to determine CO2 production from glucose in paraffinsealed test-tubes. For LAB identification 10 mL Elliker broth (Scharlab, Spain) was inoculated with isolated bacteria for testing. Cells were grown for 3-4 days at 30°C, until sufficient population was achieved for the purification of the DNA. Cells from the culture were harvested by centrifugation at 5000 g for 15-30 min at 4°C, and washed with 10 mL of PBS. The bacteria pellet was then suspended in 1.5 mL of PBS and recovered in a microtube by centrifugation at 5000 g for 5 min at 4°C. The pellet was suspended in 100 L of buffer P1 (0.05 mol/L TrisBase, pH 8.0, 4 g/L EDTA, and 100 mg/L RNAase); this suspension was stored at 4°C for 5 min. Subsequently, 150 L of lysis buffer P2 (8 g/L NaOH, and 10 g/L SDS) and 60 L of 10 mg/mL Lysozyme (prepared in 10 mM Tris, pH 8) were added, and the mixture was kept at 37°C for 1 h. The reaction was then neutralized using 200 L buffer P3 (294.5 g/L potassium acetate, pH 5.5), and the suspension was centrifuged at 10000 g for 5 min. The supernatant was obtained using absolute ethanol to precipitate the DNA. The DNA quality was determined by the ratio A260/A280. 4 The 16S ribosomal gene was amplified by PCR and sequenced to the molecular identification of the lactic acid bacteria (De Vuyst et al., 2002; De Vuyst and Vancanneyt, 2007; Scheirlinck et al., 2008). To this end, universal primers 8F (5’-AgAgTTTgATCCTggCTCAg-3’) and 1510R (5’-ggTTACCTTgTTACgACTT-3’) were used in the PCR to amplify a product of 1.5 Kb approximately. The PCR was performed at 40 cycles, applying the following steps: DNA denaturation for 1 min at 94°C, annealing for 30 s at 55°C, and DNA polymerization for 2 min at 72°C. The PCR was finished with an extension for 5 min at 70°C. Finally, amplification products were analysed on 1.5% agarose gels. These amplicons were then used as templates for the sequencing reaction (BigDye, Quiagen, Germany), and the DNA fragments were commercially sequenced (Macrogen, Korea). Sequences were analysed by performing a BLAST (Basic Local Alignment Search Tool) search of the National Center for Biotechnology Information nonredundant DNA sequence database (National Center for Biotechnology Information, U.S. National Library of Medicine, Bethesda, MD). Physical and chemical analysis The changes in biochemical characteristics during the multistage sourdough process were determined from an analysis of the pH, the total titratable acidity (TTA), the sugars (maltose, sucrose), the organic acids (lactic and acetic acid), and ethanol. 60 g samples were taken from the different sourdough stages and kept frozen at -20°C in 10 g aliquots prior to analysis. All determinations were performed with two replicates and results were expressed as mean values jointly with their standard errors. Determination of pH and total titratable acidity (TTA). The pH values were determined in 10 g samples blended with 90 mL distilled water. The measurements were taken using a pH-meter (Crison Instruments, S.A., Spain). Then the same suspensions were titrated to an end point of pH 8.5 using 0.1 mol/L NaOH (Lefebvre et al, 2002). TTA was expressed as the spent NaOH volume. Determination of sugars, organic acids, and ethanol. The organic component extraction method was adapted from Meignen et al. (2001). The 10 g dough samples were blended with 90 mL of distilled water. The sample was kept in an ultrasonic bath for 15 min, and then agitated at room temperature for a further 45 min. The dough extracts were centrifuged at 4000 g at 15°C for 15 min. The concentrations of maltose, sucrose, lactic acid, acetic acid, and ethanol were analysed by HPLC (McFeeters et al., 1984). HPLC separation was performed at room temperature using a reversed phase C18 column (250 mm x 4.6 mm) eluted with 0.05 M phosphoric acid (pH 2.5, adjusted with concentrated NH4OH) and at a flow rate of 1.2 mL/min. Before injection, 40 µL of the sample was mixed with an equal volume of elution buffer (2X), and filtered using a nylon syringe filter (0.45 µm). The samples were automatically injected into 5 a chromatograph (110B Model, Beckman) with a refractive index detector (RID 156 Model, Beckman). Statistical analysis With the physical and chemical determinations of laboratory sourdough, taking into account the last values when the stabilization of the three sourdoughs was achieved, the one-way analysis of variance and multiple comparisons tests (Tukey's method) were used in order to compare the different groups of data (Minitab, 2007). The probability level of significance was set at 0.05. Results and discussion Microbiological results Microbiological count and population dynamics in laboratory prepared sourdough. The timecourse of mean values and corresponding standard errors of the populations of microorganisms in sourdoughs prepared (GS, AS, YS) are shown in Figure 1(a) to (c). In the three sourdoughs, the viable LAB increased throughout the process, while the total yeasts and non-Saccharomyces yeasts decreased in different percentages according to the sourdough. The ripe sourdough microorganisms were largely dominated by LAB (> 1E+08 CFU/g), and yeasts were found in a lower proportion. The ratio LAB/yeasts was close to 10000/1 in GS sourdough while in AS and YS this ratio was 1000/1. The LAB/yeast ratio obtained across the three sourdoughs was greater than others described in the literature (Wlodarczyk, 1985; Vera et al., 2009). It is known that several factors influence the results of development and control of LAB sourdough and the ratio of values could change (Van der Meulen et al., 2007), for example, sourdough preparation conditions (such as ingredients, temperature, time backslopping) and LAB control methodology (such as media, incubation conditions -aerobic, anaerobic, microaerophilic-, culture-independent methods). In our study the culture-dependent method and aerobic conditions were selected, as done by many other authors (Van der Meulen et al., 2007; Vranckren et al., 2011; Zhang et al.,2011; Lattanzi et al., 2013). The methodology used means that some LAB strains could be lost, and the same could happen in other conditions. It was estimated that the colony numbers isolated from aerobically and anaerobically incubated agar plates were generally 10 times higher than on anaerobically grown plates (Viiard et al., 2013). The main differences in viable LAB counts among the three sourdoughs prepared were detected throughout the pre-sourdough phase. The initial LAB count in GS was 1.5E+03 CFU/g, which was 2 and 3 exponential units lower than those found in YS and AS counts, respectively. LAB concentration in GS increased at the beginning of the ripe sourdough phase when the count was 1E+08 CFU/g, a value which was maintained in a stable manner throughout the rest of the process. In contrast, the initial LAB counts in the AS and YS pre-sourdough phase were higher, 6 reaching 1E+08 CFU/g at the end of this phase. During the ripe sourdough phase, LAB increased slightly in a similar manner to AS and YS, reaching a population of 1E+09 CFU/g. The total yeast counts at the beginning of the preparation for the three pre-sourdoughs were also different. For this microbial group, GS behaved more like AS. GS had an initial yeast count of 3.65E+07 CFU/g (i.e. P1, Figure 1(a)), one order of magnitude higher than AS and nearly 6 units higher than YS. High initial total yeast counts in GS and AS are the result of both sourdoughs, being prepared using grape must lightly fermented and apple juice fermented, and consequently containing a population of proliferative yeast. By contrast, YS showed a low total yeast count due to dilution of the yeast found in wholemeal flour when mixed with the yogurt. According to the literature, the total yeast counts in flour were around 1E+02 – 1E+04 CFU/g (Berghofer et al., 2003; Eglezos, 2010). Nevertheless, the total yeast population in the yogurt pre-sourdough after 72 h (i.e. P3) was similar to that for the apple pre-sourdough. In the three sourdoughs, the maximum total yeast population was achieved at some point during the presourdough stage. The controls performed at the ripe sourdough stage showed that the total yeast population in GS and YS decreased, stabilizing at the end of the study. In AS, the total yeast population increased and stabilized at the end of the ripe sourdough phase, but without reaching the high counts found in the pre-sourdough phase. The non-Saccharomyces counts at the initial preparation of the sourdough (i.e., P1,) were higher in GS (1E+07 CFU/g), followed by AS (1E+06 CFU/g), and lower concentrations were observed in YS (1E+01 CFU/g). Yeast non-Saccharomyces counts carried out during the ripe sourdough phase showed a large decrease in all three sourdoughs. In the GS and AS presourdoughs, the non-Saccharomyces yeast count coincided with the total yeast count. Thus, in GS and AS, the majority of the yeasts were different from the Saccharomyces genera. In the YS sourdough there is a difference of about 3 or 4 exponential units between total yeast and nonSaccharomyces yeast count. It seems that in the YS sourdough there was less diversity of yeasts, with most belonging to the Saccharomyces group. The lowest concentration of nonSaccharomyces yeasts may be related to the yogurt used as the starting ingredient. Yogurt does not contain yeast, unlike grape must lightly fermented and apple juice fermented. During the preparation of GS and AS it was introduced and multiplied the yeasts found in their own starter sourdough, as well as those present in the flour itself. A wide variety of yeast species of Saccharomyces and non-Saccharomyces yeasts have been described in connection with apple fruit (Pelliccia et al., 2011; Vadkertiová et al., 2012) and in the cider-making process; where the frequency of non-Saccharomyces in the first phase of fermentation varied with the harvest (Pando et al., 2010). As in cider apple, non-Saccharomyces yeasts are also found predominantly in grapes and in freshly processed must. Even though S. cerevisiae is the most important yeast for wine production, the role of non-Saccharomyces yeasts in wine fermentation is receiving increasing attention by wine microbiologists (Jolly et al., 2006). Finally, the results in GS and 7 AS of the non-Saccharomyces yeasts highlight the importance of the initial ingredient used in the preparation of sourdoughs. Changes in procedure such as starting a new sourdough more often or incorporating the differential ingredient at the last refreshment could ensure the activity of non-Saccharomyces yeasts. Figure 2 shows the frequency of different types of yeasts isolated in the preparation of sourdough. As described in the Materials and methods section, the yeasts were also characterized according to colour colonies and morphology on WL and Lysine agar. They were differentiated by two types of non-Saccharomyces yeast (Type 1.1 and Type 1.2 differentiated by morphology on Lysine) and two types of Saccharomyces yeast (Type 2.1 and Type 2.2, only differentiated by colour on WL). The GS pre-sourdough and the first days of ripe sourdough were dominated by a type of non-Sacchararomyces yeast different from that of AS. Lysine agar was shown to be useful to differentiate and quantify the non-Saccharomyces yeast group. Thus, Lysine agar is currently employed by yeast producers to detect contamination and to carry out quality controls on wines (Gordún et al, 1991; Hansen et al., 2001; Tofalo et al., 2011) and the brewing industry (Kühle and Jespersen, 1998). It is known that the environment of propagation has an influence on the microbiota composition, but in contrast to other studies (Vrancken et al., 2010; Minervini et al., 2012), Saccharomyces yeast was dominant in all ripe sourdough propagated in laboratory. It is necessary to identify the isolated yeasts involved in the successive populations during the development of the sourdough. In any case, the ingredients included in the raw materials influence the type of yeast present. Identification of LAB. Table 2 presents the results of the identification of LAB. A total of 35 strains were identified from laboratory sourdoughs. Some strains of LAB were non-culturable after their initial isolation, or growth was very low, and so the extraction of DNA was deficient. The medium used for strain maintenance was the same as for isolation (MRS agar enriched with vitamins from grape juice and tomato). Various authors have proposed modifying the MRS agar according to the genera to be isolated (Vera et al., 2009). MRS supplemented with maltose and fructose as well as amino acids and vitamins with lowered pH are successful for the isolation of sourdough LAB (De Vuyst and Vancanneyt, 2007). Nevertheless, the medium does not seem to be the best suited for the maintenance of some acid lactic strains. Also, for this reason it is necessary to continue the search for new LAB species, focusing the investigation on improving the formulation of the growth medium and the growth parameters (De Vuyst and Vancanneyt, 2007). The identification of LAB allowed differentiation between AS and YS. The AS presented greater bacterial diversity than YS. YS showed the presence and the domain of Pediococcus pentosaceus from the beginning of the pre-sourdough until the end. In YS there was no detected characteristic LAB from plain yogurt (as Lb. delbrueckii subsp. bulgaricus and S. thermophillus) and this may be due to the temperature of the sourdoughs process in which the 8 maximum microbiological growth occurred as in the first part of the second phase. It was performed at 22ºC according to the recipe. Yogurt bacteria needs higher growth temperature and this may have caused the loss of these species. In AS, the same specie dominated throughout the process, together with other Lactobacillus species like Lb. plantarum, Lb. brevis and Lb. sakei. The GS was similar to AS in terms of diversity. The novelty was that Weisella cibaria appeared, which had not been encountered in AS or YS. Unlike grape must lightly fermented, apple juice fermented is an important source of LAB because the malolactic and alcoholic fermentations start at the same time. In the traditional cider process, a great diversity of LAB has been described, fundamentally heterofermentative bacteria; being Lactobacillus species the most abundant and in low proportion Pediococcus (Dueñas et al., 1994; Sánchez et al., 2010); other dominant LAB as Leuconostoc (Salih and Drilleau, 1988) and Oenococcus (Sanchez et al., 2012) have been mentioned. In cereal sourdough, in general, microbiota is also clearly dominated by lactobacilli, and more than 55 Lactobacillus species have been identified. Other LAB species may also be found, including members of the genera Weissella, Pediococcus, Leuconostoc, Lactococcus, Enterococcus and Streptococcus (Huys et al., 2013). Some species like Lb. sanfranciscensis seem to be specific to the sourdough environment, but others, such as Lb. brevis and Lb. plantarum, have also been found in many other food ecosystems (De Vuyst et al., 2009). The use of different ingredients with their own microflora may have influenced the diversity of LAB, single species in YS and more complex communities in GS and AS. It is not frequent to find a sole LAB specie, but occasionally it has been described for Lb. sanfranciscensis (Zapparoli et al., 1996, 1998 and Foschino et al., 1999) and other species. In these sourdoughs processed for 10 days, Pediococcus pentosaceus was present in all phases, and in other sourdough studies the microarray data also revealed the dominance of Pediococcus pentosaceus in most of the fermentations during the whole period (Weckx et al., 2010). Physical and chemical determinations of laboratory sourdough The results of pH and TTA are shown in Figure 3(a) and (b), respectively. In the measuring of pH at the mature phase (R4-R5), statistically significant differences between GS and AS-YS were detected (p-value<0.001), but not in the TTA (p-value=0.769). GS takes four days to reach a pH of 4, following the recipe, which is the ripe sourdough phase. However, some days before finishing the preparation or during the pre-sourdough stage, both AS and YS already had pH values of around 4. In all three types of sourdough, the pH value stabilized at pH 4. Final pH, which ranges from 3.5 to 4.3, is considered as an index of a well-developed sourdough fermentation (Collar et al., 1994). TTA of the three ripe sourdoughs stabilized at values close to 6 mL, but GS took several days longer than AS and YS to reach this acidity. Monitoring of both pH and TTA parameters indicates that GS matures more slowly than AS and YS, although 9 ultimately similar pH and TTA values are reached. The evaluation of the change of pH and TTA during the preparation of the sourdough allows the establishment of the time when the sourdough ripens; something which does not always coincide with expectations from the recipe, especially when new ingredients are included, as in this study. In P3 and P4 stages, according to the recipe, flour and water were added and kept for 2 h at 22°C and 22 h at 5°C. The latter condition affected the decrease of the enzymatic activity of microorganisms present. Therefore, there was a dilution of the pH and TTA accumulated and there was not enough fermentation time to recover these two parameter values, especially in GS, and less in AS and YS. The lower LAB counts in the GS pre-sourdough phase (around 1E+05 CFU/mL while in AS and YS was close to 1E+8 CFU/mL) was the main difference that may have influenced the delay in reaching the optimum pH and TTA. Several studies have revealed the substantial influence of the LAB evolution (counts and composition) on acidification behaviour (Collar et al., 1994, Gatto and Torriani, 2004; Corsetti et al., 2007; Bartkiene et al., 2013). Equally high concentrations (≥ 1E+08 CFU/mL) were reached by LAB in the ripe phase of the three sourdoughs. Other parameters quantified during the processing of the sourdough were lactic acid and acetic acid; the results are shown in Figure 3(c) and Table 3 respectively. In the measurement of lactic acid at the mature phase (R4-R5), significant differences between GS and AS-YS were detected (p-value=0.001). The acetic acid, in some cases, was not quantified due to the lack of precision of the analytical method. It was not possible to establish a correlation between acetic acid concentration and the number of heterolactic strains despite the heterofermentative LAB being the main producer. The concentration of lactic acid in the GS was considerably lower than in the AS and YS sourdoughs, both in the pre-sourdough and ripe sourdough phases (Figure 3(c)). The average concentration of lactic acid in the final phase of ripe sourdough (last 5 days) was 0.4 g/100 g for GS and 1.0 g/100 g for AS and YS. The production of acetic acid in GS was lower than in AS (Table 3); the ripe AS (last 5 days) produced 0.27 g/100 g. As expected, acetic acid production was lower than lactic acid and the fermentation ratio between lactic and acetic acids (molar ratio between these acids) to AS was 2.5. The results relating to maltose and ethanol in the sourdough are shown in Table 3. There were no statistically significant differences in the amount of maltose in the three ripe sourdoughs (pvalue=0.494). In the sourdough prepared during the pre-sourdough and ripe sourdough phases, maltose was available for the different microorganisms, which indicates that the amount of maltose produced from hydrolysed starch by the amylase enzymes was greater than the maltose metabolized by different microorganisms. In the final phase of the ripe sourdough (last 2 days), the concentration of maltose was lower and stabilized for all the sourdough with values close to 0.4 g/100 g. Ethanol production by the microorganisms was detected during the processing of the sourdough, and there were significant differences between GS and AS-YS in the mature phase (p-value<0.001); maximum values were reached in this final phase of the ripe sourdough 10 (1.03 g/100 g, 1.89 g/100 g and 2.46 g/100 g for GS, AS, and YS respectively), showing a Saccharomyces group population close to 1E+05 for GS, and close to or higher than 1E+06 for AS and YS. Ethanol is the main metabolite produced by yeasts of the Saccharomyces group and, in a smaller quantity, by heterofermentative LAB, nevertheless in some sourdoughs ethanol concentration could be attributed to heterofermentative LAB (Van der Meulen et al, 2007). During the sourdough preparation the ethanol concentration showed some variations with an increase at the end of the study, coinciding with the dominance of the Saccharomyces group over the non-Saccharomyces group, and with an increase of their metabolic activity due to the fermentation temperature, 29ºC (higher than the previous phase, 22ºC), and the use of nutrients from the three refreshments per day. In YS (pre-sourdough and ripe sourdough) ethanol concentrations were higher than in GS sourdough, coinciding with a reduced presence of nonSaccharomyces group yeasts and higher concentrations of the Saccharomyces group, which are more resistant to this metabolite. The rate of alcoholic fermentation of S. cerevisiae was dependent on the temperature used (Gobetti et al., 1995), especially at 22ºC yeast activity decreased compared to 25, 28 or 31ºC (Häggman and Salovaara, 2008), and the inoculum yeast size (Akdogan and Ozilgen, 1992). Other factors may have favoured the ethanol production, such as the interaction between yeast and LAB (Guerzoni et al., 2007). Conclusions When comparing sourdoughs made with the three different ingredients, it can be stated that grape must lightly fermented and apple juice fermented offer microbiological specificities that are different from yogurt. They provide their own microbiota, which does not always remain in ripe sourdough, and they obstruct or retard the development of the indigenous microorganisms in the flour, with an effect that could modify the organoleptic properties. In this study, a new sourdough prepared from grape must lightly fermented was evaluated and it proved to be a good alternative to the traditional ingredients used in artisan bread-making. The grapes correspond to local indigenous variety, specifically the Xarel.lo, which was processed by fermentation over a 48 h period at 20°C. From a physicochemical standpoint, and following this recipe, GS requires more time than AS and YS to attain a suitable pH. And microbiologically, GS shows a population and a diversity of microorganisms similar to AS. It would be interesting in future studies to optimize the preparation of the grape sourdough process and determine the influence of the grape must on the fermentation time, the sourdough microbiota, and the longterm stability of the microbiota, especially the group of non-Saccharomyces, as well as the overall flavour produced. Acknowledgements 11 Thanks to Marc and Gabriel Parés of the centennial artisan bakery Fleca Parés, for providing us with the recipes and sourdough ingredients, and motivating us to carry out this research. References Akdogan H and Ozilgen M. (1992). Kinetics of microbial growth, gas production, and dough volume increase during leavening. Enzyme and Microbial Technology 14 (2): 141-143. Arendt E, Ryan Liam A M and Dal Bello F. (2007). Impact of sourdough on the texture of bread. Food Microbiology 24(2): 165-174. Bartkiene E, Schleining G, Rekstyte T, Krungleviciute V, Juodeikiene G, Vaiciulyte-Funk L and Maknickiene Z. (2013) Influence of the addition of lupin sourdough with different lactobacilli on dough properties and bread quality. International Journal of Food Science and Technology 48, 2613–2620. Berghofer L K, Hocking A D, Miskelly D and Jansson E. (2003). Microbiology of wheat and flour milling in Australia. International Journal of Food Microbiology 85(1-2): 137-149. Barriga X. (2003). Panadería Artesana, Tecnología y producción. Montagud Editores, Barcelona, Spain. Bellsolà A. (2010). Pan en casa. Editorial Océano, Barcelona, Spain. Catzeddu P, Mura E, Parente E, Sanna M and Farris G A. (2006). Molecular characterization of lactic acid bacteria from sourdough breads produced in Sardinia (Italy) and multivariate statistical analyses of results. Systematic and Applied Microbiology 29(2): 138-144. Collar C, Benedito de Barber C and Martínez-Anaya M A. (1994). Microbial sourdoughs influence acidification properties and bread-making potential of wheat dough. Journal of Food Science 59(3): 629–633. Corsetti A, De Angelis M, Dellaglio F, Paparella A, Fox P F, Settanni L and Gobbetti M. (2003). Characterization of sourdough lactic acid bacteria based on genotypic and cell-wall protein analyses. Journal of Applied Microbiology 94(4): 641-654. Corsetti A, Settanni L, Valmorri S, Mastrangelo M and Suzzi G (2007) Identification of subdominant sourdough lactic acid bacteria and their evolution during laboratory-scale fermentations. Food Microbiology 24: 592–600. De Vuyst L, Schrijvers V. Paramithiotis S, Hoste B, Vancanneyt M, Swings J, Kalantzopoulos G, Tsakalidou E and Messens W. (2002). The biodiversity of lactic acid bacteria in Greek traditional wheat sourdoughs is reflected in both composition and metabolite formation. Applied and Environmental Microbiology 68(12): 6059–6069. De Vuyst L and Neysens P. (2005). The sourdough microflora: biodiversity and metabolic interactions. Trends in Food Science & Technology 16(1-3): 43–56. De Vuyst L and Vancanneyt M. (2007). Biodiversity and identification of sourdough lactic acid bacteria. Food Microbiology 24(2): 120-127. 12 De Vuyst L, Vrancken G, Ravyts F, Rimaux T and Weckx S. (2009). Biodiversity, ecological determinants, and metabolic exploitation of sourdough microbiota. Food Microbiology 26(7): 666-675. Dueñas S, Irastorza A, Fernandez K, Bilbao A and Huerta A. (1994). Microbial populations and malolactic fermentation of apple cider using traditional and modified methods. Journal of Food Science 59(5): 1060–1064. Eglezos S. (2010). Microbiological Quality of Wheat Grain and Flour from Two Mills in Queensland, Australia. Journal of Food Protection 73(8): 1533-1536. Foschino R, Terraneo R, Mora D and Galli A. (1999). Microbial characterization of sourdoughs for sweet baked products. Italian Journal of Food Science 11: 19–28. Gatto V and Torriani S. (2004). Microbial population changes during sourdough fermentation monitored by DGGE analysis of 16S and 26S rRNA gene fragments. Annals of Microbiology 54 (1): 31-42. Gobbetti M, Simonetti M S, Corsetti A, Santinelli F, Rossi J and Damiani P. (1995). Volatile compound and organic acid productions by mixed wheat sour dough starters: influence of fermentation parameters and dynamics during baking. Food Microbiology, 12: 497-507. Gordún E, Carbó R, De Castro J J and Sancho J. (1991). Associazione binaria di lieveti in fermentazioni controllate. Vini d’Italia. Rivista Internazionale di Enologia 4: 35-42. Guerzoni M E, Vernocchi P, Ndagijimana M, Gianotti A and Lanciotti R. (2007). Generation of aroma compounds in sourdough: Effects of stress exposure and lactobacilli–yeasts interactions. Food Microbiology 24: 139-148. Häggman M and Salovaara H. (2008). Effect of fermentation rate on endogenous leavening of Candida milleri in sour rye dough. Food Research International 41: 266–273. Hansen E H., Nissen P, Sommer P, Nielsen J C and Arneborg N. (2001). The effect of oxygen on the survival of non-Saccharomyces yeasts during mixed culture fermentations of grape juice with Saccharomyces cerevisiae. Journal of Applied Microbiology 91(3): 541-547. Hansen A and Schieberle P. (2005). Generation of aroma compounds during sourdough fermentation: applied and fundamental aspects. Trends in Food Science & Technology 16(1-3): 85-94. Huys G, Daniel H M and De Vuyst, L. (2013). Taxonomy and biodiversity of sourdough yeast and lactic acid bacteria. Gobetti M and Gänzle M (eds). Handbook on sourdough biotechnology. Springer, New York, USA, p. 114-116. Iacumin L, Cecchini F, Manzano M, Osualdini M, Boscolo D, Orlic S and Comi G. (2009). Description of the microflora of sourdoughs by culture-dependent and culture-independent methods. Food Microbiology 26(2): 128-135. Jolly N P, Augustyn OP H and Pretorius I S. (2006). The Role and Use of Non-Saccharomyces Yeasts in Wine Production. South African Journal for Enology and Viticulture 27(1): 15-39. 13 Kühle AV and Jespersen, L (1998). Detection and identification of wild yeast in lager breweries. International Journal of Food Microbiology 43(3): 205-213. Lattanzi A, Minervini F, Di Cagno R, Diviccaro A, Antonielli L, Cardinali G, Cappelle S, Angelis M and Gobbetti M. (2013). The lactic acid bacteria and yeast microbiota of eighteen sourdoughs used for the manufacture of traditional Italian sweet leavened baked goods. International Journal of Food Microbiology 163(2-3): 71-79. Lefebvre D, Gabriel V, Vayssier Y and Fantange-Faucher C. (2002). Simultaneous HPLC determination of sugars, organic acids and etanol in sourdough process. LebensmittelWissenschaft & Technologie 35(5): 407-414. McFeeters R F,Thompson R L and Fleming H P. (1984). Liquid chromatographic analysis of sugars, acids, and ethanol in lactic acid vegetable fermentations Journal of the Association of Official Analytical Chemists. 67(4): 711-714. Meignen B, Onno B, Gelinas P, Infantes M, Guilois S and Cahagnier B. (2001). Optimization of sourdough fermentation with Lactobacillus brevis and baker’s yeast. Food Microbiology 18(3): 239-245. Minervini F, Lattanzi A, De Angelis M, Di Cagno R and Gobbetti M. (2012). Influence of artisan bakery or laboratory propagated sourdoughs on the diversity of lactic acid bacterium and yeast microbiotas. Applied and Environmental Microbiology 78(15): 5328–5340. Minitab Inc. (2007). Minitab Statistical Software, Release 15 for Windows, State College, Pennsylvania. Minitab® is a registered trademark of Minitab Inc. National Center for Biotechnology Information, U.S. National Library of Medicine, Bethesda MD. http://www.ncbi.nlm.nih.gov. Accessed 21 July 2011. Pando R, Querol A and Suárez B. (2010). Genetic and phenotypic diversity of autochthonous cider yeasts. Food Microbiology 27(4): 503-508. Pelliccia C, Antonielli L, Corte L, Bagnetti A, Fatichenti F and Cardinali F. (2011). Preliminary prospection of the yeast biodiversity on apple and pear surfaces from Northern Italy orchards. Annals of Microbiology 61: 965–972. Salih, AG and Drilleau J F. (1988). A survey of microbiological aspects of cider making. Journal of the Institute of Brewing 94(1): 5−8. Sánchez A, Rodríguez R, Coton M, Coton E, Herrero M, García L A and Díaz M. (2010). Population dynamics of lactic acid bacteria during spontaneous malolactic fermentation in industrial cider. Food Research International 43: 2101-2107. Sánchez A, Coton M, Coton E, Herrero M, García L A and Díaz M. (2012). Prevalent lactic acid bacteria in cider cellars and efficiency of Oenococcus oeni strains. Food Microbiology 32: 32-37. Scheirlinck I, Van der Meulen R, Van Schoor A, Vancanneyt M, De Vuyst L, Vandamme P and Huys G. (2008). Taxonomic structure and stability of the bacterial community in Belgian 14 sourdough ecosystems as assessed by culture and population fingerprinting. Applied and Environmental Microbiology 74(8): 2414–2423. Tofalo R, Schirone M, Telera G C, Manetta AC, Corsetti A and Suzzi G. (2011). Influence of organic viticulture on non-Saccharomyces wine yeast populations. Annals of Microbiology 61(1): 57-66. Vadkertiová R, Molnárová J, Vránová D and Sláviková E. (2012). Yeasts and yeast-like organisms associated with fruits and blossoms of different fruit trees. Canadian Journal of Microbiology 58: 1344–1352. Van der Meulen R, Scheirlinc I, Van Schoor A, Huys G, Vancanneyt M, Vandamme P and De Vuyst L. (2007). Population dynamics and metabolite target analysis of lactic acid bacteria during laboratory fermentations of wheat and spelt sourdough. Applied and Environmental Microbiology 73(15): 4741-4750. Vera A, Rigobello V and Demarigny Y. (2009).Comparative study of culture media used for sourdough lactobacilli. Food Microbiology 26(7): 728-733. Vrancken G, De Vuyst L, Van der Meulen R, Huys G, Vandamme P and Daniel H M. (2010). Yeast species composition differs between artisan bakery and spontaneous laboratory sourdoughs. FEMS Yeast Research 10(4): 471–481. Vranckren G, Rimaux T, Weckx S, Leroy F, De Vuyst L. (2011). Influence of temperature and backslopping time on the microbiota of a type I propagated laboratory wheat sourdough fermentation. Applied and Environmental Microbiology 77(8): 2716-2726. Viiard E, Mihhalesvski A, Rühka T, Paalme T and Sarand I. (2013). Evaluation of the microbial community in industrial rye sourdough upon continuous back-slopping propagation revealed Lactobacillus helveticus as the dominant species. Journal of Applied Microbiology 114(2): 404412. Watanabe K, Fujimoto J, Tomii Y, Sasamoto M, Makino H, Kudo Y and Okada S. (2009). Lactobacillus kisonensis sp nov., Lactobacillus otakiensis sp nov., Lactobacillus rapi sp nov and Lactobacillus sunkii sp nov., heterofermentative species isolated from sunki, a traditional Japanese pickle. International Journal of Systematic and Evolutionary Microbiology 59: 754760. Weckx S, Van der Meulen R, Allemeersch J, Huys G, Vandamme P,Van Hummelen P and De Vuyst L. (2010). Community dynamics of bacteria in sourdough fermentations as revealed by their metatranscriptome. Applied and Environmental Microbiology (16): 5402–5408. Wlodarczyk M. (1985). Associated cultures of lactic acid bacteria and yeast in the industrial production of bread. Acta Alimentaria Polonica 11: 345-359. Zapparoli G, De Benedictis P, Salardi C, Veneri G, Torriani S and Dellaglio F. (1996). Lactobacilli of sourdoughs from Verona bakery: a preliminary investigation. Advances in Food Sciences 18: 163–166. 15 Zapparoli G, Torriani S and Dellaglio F. (1998). Differentiation of Lactobacillus sanfranciscensis strains by randomly amplified polymorphic DNA and pulsed- field gel electrophoresis. FEMS Microbiology Letters 166(2): 325–332. Zhang J, Liu W, Sun Z, Bao Q, Wang F, Yu J, Chen W and Zhang H. (2011). Diversity of lactic acid bacteria and yeasts in traditional sourdoughs collected from western region in Inner Mongolia of China. Food Control 22(5): 767-774. 16 Table 1. Sourdoughs process, preparation and refreshments of ripe sourdoughs prepared with grape (GS), or apple (AS), or yogurt (YS). First phase: Preparation of differential ingredient AS YS GS 0.3 Kg of apples (with skin) 0.3 L of white grape must 0.3 L of water + 10 g of honey just pressed 5 days, 40ºC. 2 days, 20ºC Second phase: Pre-sourdough 0.3 Kg of preceding apple 0.3 Kg of plain 0.3 Kg of preceding grape juice fermented yogurt must lightly fermented + 0.1 Kg Whole wheat flour, 48 h at 22ºC P1 Similar process for AS, YS, GS Preceding sour (Kg) Wheat flour (Kg) Water at 28ºC (L) Time and temperature 0.1 0.5 0.6 24h, 22ºC P2 0.3 0.5 0.5 2h, 22ºC + 22h, 5ºC P3 0.4 1 1 2h, 22ºC + 22h, 5ºC P4 Third phase: Ripe sourdough (3 daily refreshments: at 9 a.m., 1 p.m. and 5 p.m.) Preceding sour (Kg) Wheat flour (Kg) Water at 28ºC (L) Time and temperature 0.4 0.4 0.2 4 h, 29ºC (at 9 a.m.) R* 0.4 0.4 0.2 4 h, 29ºC (at 1 p.m.) 0.2 0.4 0.2 16 h, 29ºC (at 5 p.m.) R*: Refreshment ripe sourdough was propagated for 5 days in this study (R1, R2, R3, R4, R5) P (P1 to P4) and R (R1 to R5) are the sourdough sampling codes. 17 Table 2. Identification of sourdough LAB isolates by means of 16S rDNA sequencing. Sourdoughsa Identificationb Specie Fermentationc Lactobacillus sunkii AB366385.1 (95%)1 HE-F 2 Pediococcus pentosaceus EU180605.1 (92%) HO AS/ First phase Pediococcus pentosaceus HM130536.1 (96%)2 HO Pediococcus pentosaceus AB494722.1 (95%)2 HO Leuconostoc mesenteroides JN863681.1 (95%)3 HE 2 Pediococcus pentosaceus EU180605.1 (85%) HO AS/ Second Pediococcus pentosaceus AB494722.1 (98%)2 HO phase Pediococcus pentosaceus EU080993.1 (97%)2 HO Lactobacillus brevis HM067023 (98%)2 HE 2 Pediococcus pentosaceus HM130536.1 (99%) HO Lactobacillus sakei GU125609.1 (98%)3 HE-F Lactobacillus sakei GU125609.1 (98%)3 HE-F AS/ Third phase Pediococcus pentosaceus AB481102.1 (99%)2 HO Lactobacillus plantarum GU195643.1 (98%)4 HE-F Pediococcus pentosaceus AB494722 (99%)2 HO Lactobacillus plantarum GU138610.1 (98%)2 HE-F Pediococcus pentosaceus AB481102.1 (99%)2 HO Pediococcus pentosaceus AB481102.1 (99%)2 HO Pediococcus pentosaceus AB481102.1 (99%)2 HO YS/ Second Pediococcus pentosaceus AB481102.1 (99%)2 HO phase Lactobacillus sakei GU125609.1 (99%)3 HE-F Pediococcus pentosaceus AB481102.1 (99%)2 HO Pediococcus pentosaceus AB481102.1 (98%)2 HO Pediococcus pentosaceus AB481102.1 (98%)2 HO Pediococcus pentosaceus AB494722.1 (93%)2 HO YS/ Third phase Pediococcus pentosaceus AB481102.1 (99%)2 HO 2 Pediococcus pentosaceus AB481102.1 (99%) HO GS/Second phase Pediococcus pentosaceus AB481102.1 (99%)2 HO Pediococcus pentosaceus AB481102.1 (99%)2 HO Lactobacillus sakei GQ222408.1 (98%)3 HE-F Weisella cibaria GU138616.1 (99%)4 HE 3 GS/ Third phase Lactobacillus plantarum GU195643.1 (98%) HE-F Pediococcus pentosaceus AB550294.1 (99%)2 HO Lactobacillus plantarum GU195643.1 (98%)3 HE-F Lactobacillus brevis AB494718.1 (96%)2 HE a Sourdough: type of sourdough/ elaboration phase) b GenBank Acces (Maximum identity, %). (1) Watanabe et al., 2009; (2) Iacumin et al., 2009; (3) Catzeddu et al., 2006; (4) Corsetti et al., 2003. c Fermentation: (HE) Heterolactic, (HE-F) Heterolactic-Facultative, (HO) Homolactic. 18 Table 3. Mean values (and their corresponding standard errors) of some organic compounds, maltose, acetic acid, and ethanol, during the evolution of the sourdoughs prepared with grape (GS), apple (AS) and yogurt (YS). Sample (Days) P3 P4 R1 R2 R3 R4 R5 GS 1.51 1.35 1.19 1.61 1.68 0.47 0.47 Maltose (g/100 g) AS YS (0.03) (0.03) (0.06) (0.02) (0.03) (0.16) (0.02) 2.55 2.27 3.05 3.27 3.16 0.46 0.43 (0.01) (0.06) (0.13) (0.08) (0.10) (0.07) (0.12) 0.24 1.61 3.11 2.94 0.25 0.41 0.33 (0.02) 0.07) (0.06) (0.14) (0.05) (0.10) (0.07) Acetic acid (g/100 g) GS AS YS NQ NQ NQ NQ NQ NQ NQ NQ: Not quantificable 19 0.20 0.23 0.25 0.32 0.33 0.23 0.23 GS Ethanol (g/100 g) AS YS (0.02) 0.18 (0.01) 0.94 (0.05) 0.15 (0.03) 1.70 (0.00) 0.20 (0.02) 0.42 (0.02) 0.03 (0.03) 0.26 (0.01) 0.22 (0.01) 0.20 (0.03) 0.14 (0.02) 0.59 NQ (0.03) 0.25 (0.02) 0.17 (0.02) 0.95 NQ (0.03) 0.50 (0.01) 0.20 (0.02) 1.89 NQ (0.02) 0.89 (0.13) 1.93 (0.08) 2.72 NQ (0.02) 1.16 (0.26) 1.84 (0.08) 2.20 (0.20) (0.06) (0.14) (0.20) (0.39) (0.16) (0.30) Figure captions Figure 1. Time-course of the populations of microorganisms in sourdoughs prepared with a) grape (GS), b) apple (AS), and c) yogurt (YS). Count (CFU/g of sourdough) in P1, P2, P3, and P4 stages of the pre-sourdough. Count (CFU/g of sourdough) in R1, R2, R3, R4, R5 stages of ripe sourdough. Mean values and their corresponding standard errors. Figure 2. Frequency of different yeast types in laboratory sourdough phases (P, pre-sourdough, R, ripe-sourdough) prepared with different ingredients (apples, yogurt and grapes). The data are based on cell and colony color and morphology on WL agar. Type 1 is non-Saccharomyces yeast (grown on WL and Lysine agar): Type 1.1, group of white, creamy convex colonies and Type 1.2, group of pale green, creamy flat colonies. Type 2 Saccharomyces yeast (only grew on WL agar): Type 2.1 group of white, creamy colonies with a peaked center and Type 2.2 like 2.1 but green in color. Figure 3. Physical and chemical characteristics of sourdoughs prepared with grape (GS), apple (AS), and yogurt (YS). a) pH changes in the processing of sourdough. b) Total titratable acidity (TTA) of sourdoughs; TTA was expressed as mL Na0H 0.1 mol/L used to titrate a 10 g sample (blended with 90 ml) to pH 8.5. c) Lactic acid (g/100 g) in sourdoughs. Mean values and their corresponding standard errors. 20 Figure 1. GS (CFU/g) a) 1,E+10 1,E+09 1,E+08 1,E+07 1,E+06 1,E+05 1,E+04 1,E+03 1,E+02 1,E+01 1,E+00 LAB Tot Yeast Non-Saccha P1 AS (CFU/g) b) 1,E+10 1,E+09 1,E+08 1,E+07 1,E+06 1,E+05 1,E+04 1,E+03 1,E+02 1,E+01 1,E+00 LAB Tot Yeast Non-Saccha P1 YS (CFU/g) c) P2 P3 P4 R1 R2 R3 R4 R5 Sample (Days) 1,E+10 1,E+09 1,E+08 1,E+07 1,E+06 1,E+05 1,E+04 1,E+03 1,E+02 1,E+01 1,E+00 P2 P3 P4 R1 R2 R3 R4 R5 Sample (Days) LAB Tot Yeast Non-Saccha P1 P2 P3 P4 R1 R2 R3 R4 R5 Sample (Days) 21 Figure 2. Type 1.1 Type 1.2 Type 2.1 Type 2.2 100 60 40 Grape Apple 22 P1 P2 P3 P4 R1 R2 R3 R4 0 P1 P2 P3 P4 R1 R2 R3 R4 20 P1 P2 P3 P4 R1 R2 R3 R4 Frequency (%) 80 Yogurt Figure 3 7 a) GS AS 6 pH YS 5 4 3 P3 b) P4 R1 R2 R3 Sample (Days) R4 R5 10 Titratable acidity (mL) 8 6 4 GS AS 2 YS 0 P3 1,5 c) R1 R2 R3 R4 Sample (Days) R5 R1 R2 R3 R4 Sample (Days) R5 GS AS 1,2 Latic acid (g/100g) P4 YS 0,9 0,6 0,3 0 P3 P4 23