SEEA Revision Issues from a corporate accounting perspective –meeting 13th London Group

advertisement

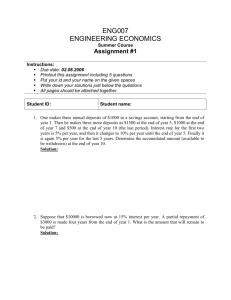

SEEA Revision Issues from a corporate accounting perspective 13th London Group –meeting on Environmental-Economic Accounting Brüssel, September 30th 2008 Dr. Christine Jasch Institute for environmental management and economics, IÖW, Vienna, Austria www.ioew.at EMA challenges Preventive environmental protection is often hampered by the lack of systematic recording of environmental data and costs, limiting the scope and comparability of environmental management of production, distribution and consumption at the corporate level, across industries, at national and international level. At the same time industry representatives are pressing to reduce data collecting burden to a relevant set of available information. For an economist and accountant, consistent data, that can be aggregated, benchmarked and verified is of core interest. This can only be achieved, if company internal standards and definitions are being implemented, that confirm to international accounting and statistic standards. 1 EMA Micro Macro Link Project • Comparison of definitions and disclosure requirements on a national and corporate level • Participation in the revision process of the London Group on Environmental Accounting which has accepted the request by the UN Committee of Experts on Environmental-Economic Accounting to take a leading role in the revision of the SEEA-2003, the worldwide handbook of national environmental-economic accounting (UN SEEA 2003) • Funded by the Austrian Ministry of Transport, Innovation and Technology within the research framework „Factory of Tomorrow“ 2 Project goals Improve consistency of data requirements for statistical purposes with the structure of financial accounting systems and the UN DSD and IFAC guidance documents, the guideline on Sustainability Performance Indicators by the Global Reporting Initiative and the upcoming ISO standard on Material Flow Cost Accounting. Improve relevance of this data set for internal corporate and external policy decision making, thus raising acceptance by industry and industry representatives for data collection. This will significantly support the design of harmonised corporate information systems and help provide consistent and comparable data on a micro and macro level and along supply chains (product life cycle assessments). 3 The UN DSD EMA Workinggroup The Expert Working Group on ”Improving the Role of Government in the Promotion of Environmental Management Accounting (EMA)” was set up in 1999 by the United Nations Division for Sustainable Development (UN DSD) in cooperation with a number of government agencies and non-governmental experts to promote Environmental Management Accounting (EMA) through publications, pilot projects and by establishing an international forum for discussion on the role of governments in the promotion of EMA. 4 Jasch Ch., EMA, Procedures and Principles, United Nations, New York, 2001 The book was prepared for the UN DSD, EMA WG. It was commissioned by the Austrian Ministry for Transport, Innovation and Technology, the Austrian Ministry for Agriculture, Forestry, Environmental Protection and Water Management and the Austrian Chamber of Commerce. Translations available into German, Spanish, Portuguese, Japanese, Korean, Chinese, Czech, Lithuanian, Estonian, etc You can also find the excel tool and case studies under www.ioew.at 5 Board Of Directors Deborah Savage, Ph.D. Director, EMARIC Arlington, MA USA Tel 617-848-8305 Fax 617-848-4193 dsavage@emaric.org www.EMAwebsite.org INTERNATIONAL GUIDANCE DOCUMENT ON ENVIRONMENTAL MANAGEMENT ACCOUNTING (EMA) Christine Jasch, Ph.D. Director, IOEW Vienna, Austria Tel 43-1-5872189 Fax 43-1-585-616868 jasch.christine@ioew.at www.ioew.at EMA Definition from UN DSD EMA WG Environmental Management Accounting (EMA) is broadly defined to be the identification, collection, analysis, and use of two types of information for internal decision-making: • physical information on the use, flows, and fates of energy, water, and materials (including wastes) and • monetary information on environmentrelated costs, earnings, and savings. 7 System boundaries for mass balances INPUT Materials Energy Water System boundaries Nations Regions Corporations Processes Products OUTPUT Products Waste Emissions 8 Physical Mass Balance: Input and Output Types Materials Inputs Product Outputs Raw and Auxiliary Materials Products (including Packaging) Packaging Materials By-products Packaging) Merchandise Non-Product Outputs (Waste and Emissions) Operating Materials Solid Waste Water Hazardous Waste Energy Wastewater Air Emissions (including 9 Physical Flow Accounts SEEA INPUTS OUTPUTS Products Products Natural Ressources Residuals Ecosystem Inputs 10 Recommendations related to material flow accounting • Apply a distinction between material inputs and product outputs throughout the document. • Definition of materials (= inputted goods, but not services and products) and consistent application throughout SEEA. • Classification of material inputs into raw and auxiliary materials, which become products, as well as packaging in opposition to operating materials. • Clarification, if and when energy and water inputs are part of material inputs. • Clarification of related disclosure requirements in statistical assessments. 11 Only environmental industries or products have related environmental expenditure? Ideally what SEEA wants to measure are “expenditures connected with the designated environmental purposes”. The “practical” approach taken by SEEA in identifying environmental activity is to subdivide products and industries into those which are typical, or characteristic, of environmental activity and those which are not. But this neglects the fact that nowadays practically in all sectors environmental management systems have been installed and within them initiatives are being taken to reduce the environmental impact of production and products and in addition develop more sustainable products. 12 Recommendations related to sector classification • Separate recording of NACE code inputs of materials, water and energy. • Separate recording of NACE code outputs of products and services. • Reconsider the concept of “environmental industries” and “environmental products”. In all sectors some companies are taking measures to reduce environmental impact of production and products. 13 Cost categories in the IFAC Document: • Materials Costs of Product Outputs • Materials Costs of Non-Product Outputs • Waste and Emission Control Costs • Prevention and other Environmental • Management Costs Research and Development Costs • Less Tangible Costs 14 15 Recommendations related to the assessment templates • Separation of costs for treatment and costs for prevention as a general structure for all environmental costs. • Classification of sub-categories of environmental expenditure according to accounting terminology. • Assessment of data from management and financial accounting (costs and/or expenditures), but not relating to potential savings or actual cash flow. • Top down approach from total costs by financial accounts to the distribution by environmental domain effected. (This requires changing the CEPA classification into a format that first distinguishes between costs for treatment and prevention, then lists the accounting categories and only lastly classifies them by environmental domain effected.) 16 SEEA environmental expenditure criteria A) The pure purpose criterion: Activities and expenditure where the main objective is protecting the environment are included in full. This criterion works best where the main objective of protecting the environment is clear and unambiguous, for example end-of-pipe capital expenditure. B) The extra-cost criterion: is used to identify the portion of the cost of more environmentally friendly technologies and changes in processes and products to be attributed to environmental protection. The investment and operating expenditure are compared to those of a “standard” or less environmentally beneficial alternative, if there is one, or the estimated additional cost of incorporating the environmentally beneficial feature. Only the extra expenditure is included. C) The net-cost criterion: Only expenditure undertaken for environmental protection purposes which leads to a net increase in cost (that is where spending exceeds any savings or income arising before the net cost was actually incurred) is included. When expenditure is recorded, this criterion only applies to operating expenditure. D) The compliance criterion: Expenditure undertaken with the main objective of protecting the environment but specifically in order to comply with environmental protection legislation, conventions and voluntary 17 agreements. Efficiency gains and cost savings The SEEA approach to environmental expenditure explicitly only “concentrates on steps taken to deal with residuals and does not consider explicitly protection of the environment through means of water and energy conservation or the effects of recycling” (p. 215). In effect, this means that the SEEA approach only focuses on the output of waste and emissions and neglects all activities to reduce the inputs of materials, water and energy. It is thus in complete contrast to the approach of cleaner production and pollution prevention. It is also in complete contrast with the focus of the work of corporate environmental managers . “Excluded are measures undertaken for cost saving reasons. (e.g. energy saving).” 18 Designated environmental purpose The solution taken by SEEA not to include the energy (and material) efficient equipment, is not really understandable also from an environmental point of view. This has e.g. let to a strong decline in environmental investments since 1990 (Statistisches Bundesamt, 2006) which is not at all related to a degradation in the state of environment, as companies at the same time have invested in integrated pollution prevention techniques and management systems and actually improved environmental performance in relation to production. It has also let to a strong decline of acceptance of the relevance of the collected data. 19 Recommendations related to the purpose of environmental costs •Reconsider the concept of environmental protection as a “satellite system” to general production and establish a more integrated environmental management approach. •Reconsideration of the definition of environmental protection activities. •Get rid of the net-cost and extra-cost criterion •Allow for the inclusion of measures which result in cost savings (e.g. energy efficiency measures), measures related to reduction of the input of materials, water and energy, improving resource efficiency and resource management activities (e.g. measures related with improving material, energy and water efficiency). •Clarification, if water withdrawal costs are part of environmental expenditure. •Inclusion of a criterion of “actual environmental impact reduction” in addition to the “environmental purpose criterion” for the classification 20 of environmental protection activities. Recommendations related to data assessment • Apply the term “costs” to allow for more flexibility and not requiring the application of strict accounting rules. Many of the requested data have to be estimated and are thus not “expenditure” in the strict sense of financial accounting. • Enable cost assessments by cost centres, e.g. for environmental management and percentage distribution to environmental media effected • Avoid the need to further disaggregate accounts and cost centre reports by tracing invoices to the extend possible • All this would significantly facilitate data gathering and increase acceptance by companies. 21 IFAC Classification of technologies End of pipe equipment – emission control traditional focus of reporting requirements, comparatively easy to trace, as stand alone equipment not related to production – additional burden, expensive Cleaner technologies much more effective from an environmental protection point of view, much more cost efficient, as integrated into production processes, but difficult to estimate the „environmental share“. Inconsistent reporting requirements by statistical agencies, awareness problems. Product oriented prevention measures reducing the environmental impact of products, e.g. desulphurisation of petrol, part of integrated prevention NPO equipment relating material loss percentages to the responsible inefficient production equipment, most relevant for internal cost accounting 22 Pollution Prevention Technologies In opposition to IFAC, SEEA: •Does not include measures to reduce the input of materials, energy and water and increase resource efficiency •Does not include measures for energy efficiency and renewable resources as they would qualify under “resource management” •Does not allow for measures which have a positive pay back (without defining pay back cycles and interest rates) •Does not allow for measures, where the primary purpose is not environmental protection but resource and production efficiency, even if they result in significant reductions of environmental burden. •Does not allow for measures related to reduction of the environmental impact of products. 23 Recommendations related to the classification of environmental investment •Redraft the definition for integrated pollution prevention technologies and include profitable efficiency measures, input substitutions and product improvements. •Reconsider the criteria and allow for estimates for an environmental share of costs based on environmental impact reduction. •Record investments at the point of put in function when depreciation starts and not during the project development phase. •Clarification, that depreciation should not be recorded as part of annual costs. •Linking of investments grants to the definition of environmental relevant equipment. That means, if an equipment has been considered as 40 % environment, than 40 % of a related investment grant should be recorded at the time when the grant is being granted, regardless of who is granting it and why. The annual depreciation of the grant should not be considered. 24 Final remarks Environmental protection shifted from End-of-pipe and clean up of contaminated sites to EMS, Integrated Prevention, Cleaner Production, Ecodesign and –labbeling, Emission Trading, Rising prices for materials and energy and legislation requests Pollution Prevention Pays! But is not reflected in national statistics! Reconsider actual information needs for policy makers and corporate environmental management Reconsider the SEEA definitions, which make corporate data collection so cumbersome Thus improve relevance and acceptance of the data set! 25