AN INVESTIGATION INTO BRIDGMAN FURNACE SOLIDIFICATION OF TITANIUM ALLOYS

advertisement

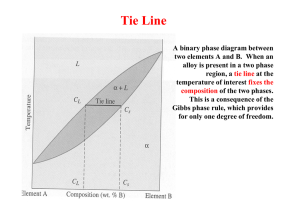

AN INVESTIGATION INTO BRIDGMAN FURNACE SOLIDIFICATION OF TITANIUM ALLOYS R.P. Mooney¹ and S. McFadden1 1. Department of Mechanical & Manufacturing Engineering, Trinity College Dublin, Dublin 2, Ireland. ABSTRACT Titanium alloys are emerging as a candidate to replace nickel superalloys in the aerospace industry due to their very low density and exceptional mechanical properties at high temperatures. Casting these materials can be difficult due to the tendency of molten titanium to react with other elements, and due to a lack of understanding of the material solidification process. This paper provides an overview of a body of research being carried out as part of the European Space Agency backed research project GRADECET (GRAvity DEpendance of Columnar to Equiaxed Transition in Ti-Al alloys). Four key activities of the work are identified: a Bridgman furnace solidification model; model verification; furnace characterisation; and columnar to equiaxed transition experiments by power down technique. A method outline for each activity is given. A front tracking model for Bridgman furnace solidification is demonstrated. Model verification with an analytical model, for pure Titanium, is discussed. A possible procedure for furnace characterisation is presented. Finally, some preliminary modelling work of power down experiments is given. KEYWORDS: ‘Titanium Aluminide’ ‘Casting’ ‘Columnar to Equiaxed Transition’ 1. INTRODUCTION Titanium alloys – specifically peritectic titanium aluminide alloys – have emerged as a candidate to replace nickel superalloys in the aerospace industry [1]. This is on account of their very low density (approximately half that of nickel superalloys [2]) and their exceptional mechanical properties at high temperatures. The main application of interest is in the production of turbine blades for aero engines and stationary gas turbines [3]. The material offers clear advantages, in terms of engine efficiency and power-to-weight ratio improvements, for engine designers. However, casting this alloy is made difficult due to its high liquidus temperature (approx. 1550°C) and because of the high reactivity of molten Ti. Other common casting problems include; shrinkage porosity, hot tearing, and misrun [4]. Numerical modelling of the casting process can help to guide experimental research, and industry, so that these problems can be predicted and avoided as necessary. One particular phenomenon of interest is the occurrence of Columnar to Equiaxed Transition (CET) in castings. A CET is said to occur when the progress of constrained (columnar) grain growth is blocked by the nucleation and subsequent growth of unconstrained (equiaxed) grains [5]. Fig. 1 shows a CET achieved in a Ti-Al based alloy, taken from a study Lapin and Gabalcová [6]. Fig. 1 CET in a Ti-Al based alloy [6] In normal casting scenarios either a fully columnar or fully equiaxed grain structure is desired, so that consistent mechanical properties are achieved throughout the casting. For example, castings with a columnar grain structure are used in directionally solidified turbine blades in order to reduce creep at high temperatures. Whereas, fully equiaxed cast components are used in applications where strength is important, to improve feeding, or reduce the possibility of hot tearing. It is therefore vital to understand the conditions that produce a CET in order to avoid it as necessary [7]. Microgravity experiments are unique in that the complicating effects of gravity on solidification are suppressed. In terrestrial (1-g) casting experiments thermal and solutal transport, due to natural convection in the melt, produce sedimentation and macro-segregation. By carrying out microgravity experiments and comparing to identical ground based experiments it is possible to distinguish the effect of these phenomena from others – common to both environments – and therefore refine and improve theoretical models for casting [8]. The European Space Agency (ESA) backed research project IMPRESS (Intermetallic Materials Processing in Relation to Earth and Space Solidification) looked in detail at the effect of casting Ti-Al in microgravity environments [9] as part of the MAXUS 8 sounding rocket mission. Notably, a clear CET was not present in any of the four samples processed in microgravity. The work presented in this paper began when the IMPRESS project was coming to an end, and another ESA backed project GRADECET (GRAvity DEpendance of Colunmar to Equaixed Transition in Ti-Al Alloys) was beginning. GRADECET has similar objectives to IMPRESS in that another MAXUS sounding rocket experiment is planned (early 2015) where the experiment designers hope to achieve a CET in the microgravity processed sample. As part of the GRADECET team, we are engaged to carry out mathematical modelling to aid the experiment design process through simulation of the solidification, using the front tracking model (FTM) of McFadden and Browne [10]. More specifically, we were asked to model a set of terrestrial Bridgman furnace experiments – carried out by a fellow GRADECET collaborator – where a CET was achieved in a Ti-Al based alloy. This paper outlines a summary of our activities, thus far, in respect of this request. 2. BUILDING A BRIDGMAN FURNACE FRONT TRACKING MODEL (BFFTM) 2.1 The Bridgman & Power Down Methods Front tracking has been used to model the solidification of Ti-Al in a ‘power down’ scenario as part of the IMPRESS project [11]. In power down experiments a cylindrical sample is fixed in a stationary crucible with two (or sometimes more) tubular heaters positioned along the length of the sample – see Fig. 2(b). Once the sample is melted, the heaters begin to cool in a controlled manner, at fixed cooling rates (dTH/dt in the hot zone, and dTC/dt in the cold zone). A solidification interface (solid-liquid) travels at a velocity, v, from the cold region, through an adiabatic zone, to the hot region. In traditional Bridgman solidification a pointed bottom crucible is drawn through the furnace, at some velocity, u, where the hot heater temperature (TH) and cold heater temperature (TC) are fixed – thereby constraining the temperature gradient in the sample during solidification, as shown in Fig. 2(a). In this case, in steady state solidification, the solid-liquid interface appears stationary in the adiabatic zone – however, relative to the crucible, it is moving at some velocity, v. In principle both methods are different forms of directional solidification; however, the movement of the sample adds a complexity to the modelling task not previously tackled using an FTM. For alloys an additional mushy zone – containing solid columnar dendrites surrounded by liquid – will form in the sample between the fully liquid and fully solid regions [12]. In this case the FTM tracks the location of the columnar dendrite tips (a columnar front). Fig. 2 Directional solidification by (a) the Bridgman method and (b) the power down method 2.2 Fundamentals of the BFFTM for Binary Alloys A detailed account of a BFFTM for binary alloys, as applied to an Al-7wt.%Si alloy, was given by Mooney et al. [13]. The fundamental workings of the model are briefly explained here. Considering one dimensional heat flow in a long cylindrical rod (the sample), with radius r, cross sectional area, A, perimeter, p, moving at velocity, u, and transferring heat laterally with its surroundings with a heat transfer coefficient, h, we get Eq. (1) – as adapted from Carslaw and Jaeger [10]. C pT k T uC p T hp T T E t x x x A hLc k Bi (1) (2) Where, Cp, and k are the sample density, specific heat capacity at constant pressure, and thermal conductivity, respectively. Axial position and axial temperature are given by x and T, respectively, T∞ is the temperature in the hot or cold zones, and finally E is a term that deals with latent heat released during solidification. This equation was solved using an explicit finite difference control volume (CV) formulation where the sample was free to translate through a fixed domain of CVs. A Dirichlet boundary condition was applied at the extremities of the domain. Thermophysical properties were evaluated by polynomial functions of temperature, taken from a study by McFadden et al. [14]. The dendrite growth kinetics for the alloy were given by an exponential function of dendrite tip undercooling, values for which were taken from the same study. The Biot number, Bi in Eq. (2), relates the thermal resistance to heat flow at the surface of a body (h), to the thermal resistance to heat flow inside that body (Lc/k), where Lc is the characteristic length of the body. If Bi<0.1 it can be said that the temperature inside the body is approximately equal to the temperature at the surface of the body, for any axial location [15]. This number was used to justify the assumption that the majority of heat flow in the sample was in the axial direction. The latent term in Eq. (1), E, is the summation of the latent heat released due to; advancement of the columnar front, Ea, and thickening of the mush behind the columnar front, Et, as given by Eq. (3) and Eq. (4). Ea Et L VCV gs Vm t g L Vm s VCV t (3) (4) Where L is the latent heat of fusion for the alloy per unit volume, VCV is the volume of one CV, Vm is the captured volume of mush in a CV, and gs is the fraction of solid in a CV, calculated as a function of temperature using the Scheil equation [16]. The model assumes that the eutectic solidification of Al-Si occurs in equilibrium using a conservative enthalpy model based on isothermal freezing, as given by Swaminathan and Voller [17]. Note that this model can be adapted easily for use with titanium alloys – or any alloy – once a there is an available function of temperature for the calculation of solid fraction, gs. 2.3 Simulation using the BFFTM for Binary Alloys Two notional Bridgman furnace scenarios were numerically simulated for a 100mm long rod of Al-7wt.%Si. The temperatures in the hot and cold zones were set to values 50°C above and 50°C below the equilibrium liquidus and solidus temperatures for the alloy, respectively. The first scenario demonstrated how a fixed sample found a steady state temperature profile, initially having a constant temperature in the hot and cold zones, and linear temperature profile in the adiabatic zone. Fig. 3 Thermal history and temperature profile evolution for scenario 2 In the second scenario the sample underwent two step changes in pulling velocity – initially having the steady state temperature profile from the first scenario. In each scenario the position of the columnar front and the evolution of temperature profile were recorded – Fig. 3 shows the thermal history with front position, and evolution of temperature profile for the second scenario. 3. MODEL VERIFICATION A one-dimensional analytical model for heat flow in a rod solidified in a Bridgman furnace was given by Naumann [18]. The solution of which is applicable where there is no mushy zone present in the sample, rather the Stefan condition for a planar front (liquid-solid, non-dendritic interface) is used to solve a dimensionless form of Eq. (1). Planar fronts normally occur with pure materials and using slow pulling velocities [5]. It is possible, therefore, to verify the BFFTM with the Naumann analytical model using pure titanium as the sample material. The key equation in the Naumann solution is given by Eq. (5). Where, k is the thermal conductivity of the sample, Pe is the Peclet number, TH and TC are the temperatures of the hot and cold zones, TM is the alloy melting temperature, LF is latent heat of fusion, and are constants, the subscripts ‘L’ and ‘S’ refer to liquid and solid, respectively, and ±X1 defines the limits of the adiabatic zone. The solution for the front position, X0, in this transcendental equation, requires an iterative technique achievable using mathematical software such as Matlab®. Note the solution is only valid for front positions within the adiabatic zone limits. k L PeL TH TM exp( PeL X 0 ) k S PeS TM TC exp( PeS X 0 ) Lf PeL Pe exp( PeS X 1 ) S 1 exp( PeS X 0 ) exp( PeL X 1 ) 1 exp( PeL X 0 ) * * 4. (5) FURNACE CHARACTERISATION The BFFTM relies heavily on knowledge of the heat transfer coefficient, h, between the furnace heater and the sample curved surface. In order to apply the model in a useful way – for example, using the model to predict growth velocity and temperature gradient at the mush-liquid interface for a particular experimental procedure – we must first determine the heat transfer coefficients in the furnace. This can be done using steady state temperature measurements from the crucible wall, at various positions along its length, in an experiment where the crucible is static in the furnace. The temperature at the outside edge of the crucible can be used to calculate the radiative heat transfer coefficient, hrad. The thermal effect of the crucible can then be added, using Eq. (6) [19], to get a combined heat transfer coefficient, hcomb, which can be inserted directly into the BFFTM as h. Where ri and ro are the inside and outside radii, respectively, of the hollow cylindrical crucible, and kcru is the thermal conductivity for the crucible material. hcomb ln ro / ri 1 ri k h r cru rad i 1 (6) Where the Bridgman furnace chamber is rarefied, it would be expected that radiative heat transfer would be dominant [20] – in other words, the convective heat transfer at the crucible wall becomes negligible. In this case, the radiative heat transfer coefficient, and hence the combined heat transfer coefficient, would be a function of temperature [21]. It is the intention of the authors to investigate this by application of an inverse heat transfer method to a set of static Bridgman furnace experiments carried out by a fellow GRADECET research partner at the Slovak Academy of Sciences (SAS). The results of this exercise will ‘characterise’ the furnace so that the BFFTM can be applied to other experimental data from the same furnace. 5. POWER DOWN EXPERIMENTS Power down experiments have been completed by the SAS where a CET has been achieved in samples of GRADECET alloy 445 (Ti-44.5at.%Al-4.5at.%Nb0.2at.%B-0.2at.%C). The experimental procedure combined traditional Bridgman solidification with the power down method, by initially pulling the sample into the cold zone (to initiate columnar grain growth) and then arresting the sample, before cooling the heaters at a constant rate. The procedure was repeated at three other cooling rates. CET occurred in all four experiments. The BFFTM has been applied to this experiment scenario using an estimate for the heat transfer coefficient based on initial calculations taken from the characterisation exercise referred to in section 4. It has been possible to generate a Hunt plot [22] (growth velocity versus temperature gradient) for each cooling rate, and to overlay the CET locations (achieved by experiment) onto this. Initial calculations show that the fully equiaxed region in each sample occurred in an unconstrained growth regime. This means that the equiaxed grains grew in a negative temperature gradient [23]. This result is interesting from a CET theory perspective. Similar results have been observed in directional solidification of Al-Si alloys [24]. However, the results are preliminary. 6. CONCLUSION A brief and clear summary of our work to date, as part of the ESA GRADECET research project, has been given here. The fundamental workings of a Bridgman furnace front tracking model (BFFTM) have been explained with a simple example simulation outlined. A method for verification of the model was presented. A detailed study on a method for Bridgman furnace characterisation has been carried out, and some key concepts to determine the furnace heat transfer coefficient have been briefly discussed here. It is our intention to apply a verified BFFTM to a set of experimental data (provided by a GRADECET coworker) where a power down technique was used to achieve a CET at four different cooling rates in samples of Ti-44.5at.%Al-4.5at.%Nb-0.2at.%B0.2at.%C. Some initial results point towards an unconstrained growth regime for fully equiaxed grain growth. This may be an important result from a CET theory point of view, however results are preliminary. The entire body of work here will provide valuable data – in terms of growth velocity and temperature gradient required for CET – to the designers of the GRADECET microgravity solidification experiment, due to fly on the MAXUS 9 sounding rocket mission in 2015. ACKNOWEDGEMENTS The authors would like to thank the European Space Agency PRODEX programme for funding this work via Enterprise Ireland. Thanks go to Juraj Lapin and Zuzana Gabalcová of the Slovak Academy of Sciences for sharing their experimental data with us. Special thanks go to Ulrike Hecht of ACCESS e.V. Ulrike’s guidance has been invaluable and much appreciated. REFERENCES [1] [2] [3] R. R. Boyer, “An overview on the use of titanium in the aerospace industry,” Mater. Sci. Eng., A, vol. 213, no. 1–2, pp. 103–114, 1996. D. M. Dimiduk, “Gamma titanium aluminide alloys—an assessment within the competition of aerospace structural materials,” Mater. Sci. Eng., A, vol. 263, no. 2, pp. 281–288, May 1999. D. J. Jarvis and D. Voss, “IMPRESS Integrated Project—An overview paper,” Mater. Sci. Eng., A, vol. 413–414, pp. 583–591, Dec. 2005. [4] [5] [6] [7] [8] [9] [10] [11] [12] [13] [14] [15] [16] [17] [18] H. Wang, G. Djambazov, K. A. Pericleous, R. A. Harding, and M. Wickins, “Modeling of the Tilt-Casting Process for the Tranquil Filling of Titanium Alloy Turbine Blades,” in Proc. Modeling of Casting, Welding, and Advanced Solidification Processes XII, 2009, pp. 53–60. D. M. Stefanescu, Science and Engineering of Casting Solidification, 2nd ed. Springer, 2008. J. Lapin and Z. Gabalcová, “Solidification behaviour of TiAl-based alloys studied by directional solidification technique,” Intermetallics, vol. 19, no. 6, pp. 797–804, Jun. 2011. J. A. Spittle, “Columnar to equiaxed grain transition in as solidified alloys,” Int. Mater. Rev., vol. 51, no. 4, pp. 247–269, Aug. 2006. F. Lemoisson, S. McFadden, M. Rebow, D. J. Browne, L. Froyen, D. Voss, D. J. Jarvis, A. V. Kartavykh, S. Rex, W. Herfs, D. Groethe, J. Lapin, O. Budenkova, J. Etay, and Y. Fautrelle, “The Development of a Microgravity Experiment Involving Columnar to Equiaxed Transition for Solidification of a Ti-Al Based Alloy,” Materials Science Forum, vol. 649, pp. 17–22, May 2010. R. Mooney, D. J. Browne, O. Budenkova, Y. Fautrelle, L. Froyen, A. Kartavykh, S. Mc Fadden, S. Rex, B. Schmitz, and D. Voss, “Review of the Maxus 8 Sounding Rocket Experiment to Investigate Solidification in a Ti-Al-Nb Alloy,” in Proc. 20th ESA Symposium on European Rocket and Balloon Programmes and Related Research, 2011, pp. 453–458. S. McFadden and D. J. Browne, “A front-tracking model to predict solidification macrostructures and columnar to equiaxed transitions in alloy castings,” Appl. Math. Model., vol. 33, no. 3, pp. 1397–1416, Mar. 2009. R. P. Mooney, S. McFadden, M. Rebow, and D. J. Browne, “A front tracking model of the MAXUS-8 microgravity solidification experiment on a Ti-45.5at.% Al-8at.%Nb alloy,” IOP Conference Series: Materials Science and Engineering, vol. 27, no. 1, p. 12020, 2012. W. Kurz and D. J. Fisher, Fundamentals of solidification. Aedermannsdorf: Trans Tech Publications, 1986. R. P. Mooney, S. McFadden, M. Rebow, and D. J. Browne, “A Front Tracking Model for Transient Solidification of Al–7wt%Si in a Bridgman Furnace,” T. Indian I. Metals, vol. 65, no. 6, pp. 527–530, 2012. S. McFadden, D. J. Browne, and C.-A. Gandin, “A Comparison of Columnar-to-Equiaxed Transition Prediction Methods Using Simulation of the Growing Columnar Front,” Metallurgical and Materials Transactions A, vol. 40, no. 3, pp. 662–672, Jan. 2009. F. P. Incropera, D. P. Dewitt, T. L. Bergman, and A. S. Lavine, Fundamentals of Heat and Mass Transfer, 6th ed. New York: John Wiley & Sons, 2007. E. Scheil, “Bemerkungen zur schichtkristallbildungle,” Z. Metallkd., no. 34, pp. 70–72, 1942. C. R. Swaminathan and V. R. Voller, “On the enthalpy method,” Int. J. Numer. Method. H., vol. 3, pp. 233–244, 1993. R.J. Naumann, “An analytical approach to thermal modeling of Bridgmantype crystal growth: I. One-dimensional analysis,” J. Cryst. Growth, vol. 58, no. 3, pp. 554–568, 1982. [19] J. M. Kay and R.M. Nedderman, Fluid mechanics and transfer processes. Cambridge University Press, 1985. [20] R. Siegel and J. R. Howell, Thermal Radiation Heat Transfer, 3rd ed. London: Hemisphere, 1992. [21] H. R. N. Jones, Radiation heat transfer. Oxford University Press, 2000. [22] J. D. Hunt, “Steady State Columnar and Equiaxed Growth of Dendrites and Eutectic,” Materials Science and Engineering, pp. 75–83, 1984. [23] J. A. Dantzig and M. Rappaz, Solidification, 1st ed. Lausanne: EPFL Press, 2009. [24] C.-A. Gandin, “From Constrained to Unconstrained Growth During Directional Solidification,” Acta Mater., vol. 48, no. 10, pp. 2483–2501, Jun. 2000.