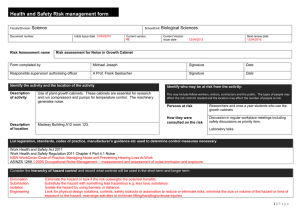

Health and Safety Risk management form Science Biological Sciences

advertisement

Health and Safety Risk management form Faculty/Division: Science Document number School/Unit: Biological Initial Issue date 12/04/2010 Risk Assessment name Current version 02 Sciences Current Version Issue date Next review date 12/04/2016 12/04/2013 Risk assessment for Noise in Workshop Form completed by Michael Joseph Signature Date Responsible supervisor/ authorising officer A Prof. Frank Seebacher Signature Date Identify the activity and the location of the activity Identify who may be at risk from the activity: Description of activity This may include fellow workers, visitors, contractors and the public. The types of people may affect the risk controls needed and the location may affect the number of people at risk Description of location Operation of various machinery in workshop including lathes, drills, saws, mills and other powered tools. VARIOUS WORSHOP AND MACHINERY SHED LOCATIONS Botany Annex A13 Persons at risk MACHINERY OPERATORS How they were consulted on the risk Discussion in regular workplace meetings including safety discussions as priority item. List legislation, standards, codes of practice, manufacturer’s guidance etc used to determine control measures necessary Work Health and Safety Act 2011 Work Health and Safety Regulation 2011 Chapter 4 Part 4.1 Noise NSW WorkCover Code of Practice: Managing Noise and Preventing Hearing Loss At Work AS/NZS 1269.1:2005 Occupational Noise Management – measurement and assessment of noise immission and exposure Consider the hierarchy of hazard control and record what controls will be used in the short term and longer term Elimination Substitution Isolation Engineering Eliminate the hazard or task if the risk outweighs the potential benefits. Substitute the hazard with something less hazardous e.g. less toxic substance. Isolate the hazard by using barriers or distance. Look for physical design solutions, controls, safety lockouts or automation to reduce or eliminate risks, minimise the size or volume of the hazard or time of exposure to the hazard, rearrange activities to minimise lifting/handling/overuse injuries 1|P a g e Administrative Establish Safe Work Practices e.g. restrict access, have Safe Work Practice documentation and procedures for hazardous tasks, provide training and supervision appropriate to level of expertise of the person(s) involved. Record training in SWP. Personal Protective Equipment Possible/not possible Use only as a secondary measure to supplement other risk controls e.g. gloves, lab coats, safety glasses. Identify hazards and control the risks. 1. An activity may be divided into tasks. For each task identify the hazards and associated risks. Also list the possible scenarios which could sooner or later cause harm. 2. Determine controls necessary based on legislation, codes of practice, Australian standards, manufacturer’s instructions etc. 3. List existing risk controls and any additional controls that need to be implemented Task or Scenario Using machinery Hazard Current risk Associated harm Any additional controls required? Residual risk Existing risk controls Noise Potential for loss of hearing Engineering Regularly maintain equipment to reduce noise due to friction and wear. Administrative Undertake noise assessment Audiometric testing to be conducted every 2 years Personal Protective Equipment Provision of earplugs and earmuffs Low no Low Medium 2|P a g e List emergency procedures and controls List emergency controls for how to deal with fires, spills or exposure to hazardous substances and/or emergency shutdown procedures Machinery has emergency stop buttons. Push button to stop machine. Implementation Control measures Engineering Institute maintenance regime Administrative Establish background level of noise in workshop with all machines running. Administrative Undertake audiometric testing every 2 years PPE Issue personal protective equipment Resources required Maintenance register Responsible person Michael Joseph/Rattan Bhandari Date of implementation Completed 1 April 2008 Noise assessment/sound monitoring Colin Chua WHSS Completed 1 April 2008 Audiometry Consultant Michael Joseph SoBSc Rattan Bhandari SoBSc Michael Joseph SoBSc Rattan Bhandari SoBsc Completed 12 April 2010 April 2016 Ear plugs/ear muffs REVIEW Scheduled review date: Are all control measures in place? April 2010 Yes April 2013 Yes Are controls eliminating or minimising the risk? Yes Yes Are there any new problems with the risk? Review by: (name) Review date (or if changes occurred): No Michael Joseph/Rattan Bhandari April 2013 No Michael Joseph/Rattan Bhandari April 2016 Completed 12 April 2010 Acknowledgement of Understanding All persons performing these tasks must sign that they have read and understood the risk management. Note: for activities which are low risk or include a large group of people (e.g. open days, BBQ’s, student classes etc), only the persons undertaking the key activities need to sign below. For all others involved in such activities, the information can be covered by other methods including for example a safety briefing, induction, and/or safety information sheet (ensure the method of communicating this information is specified here) Risk management name and version number: 2 Name I have read and understand this risk management form Signature Date Rattan Bhandari – Technical Officer 3|P a g e 4|P a g e