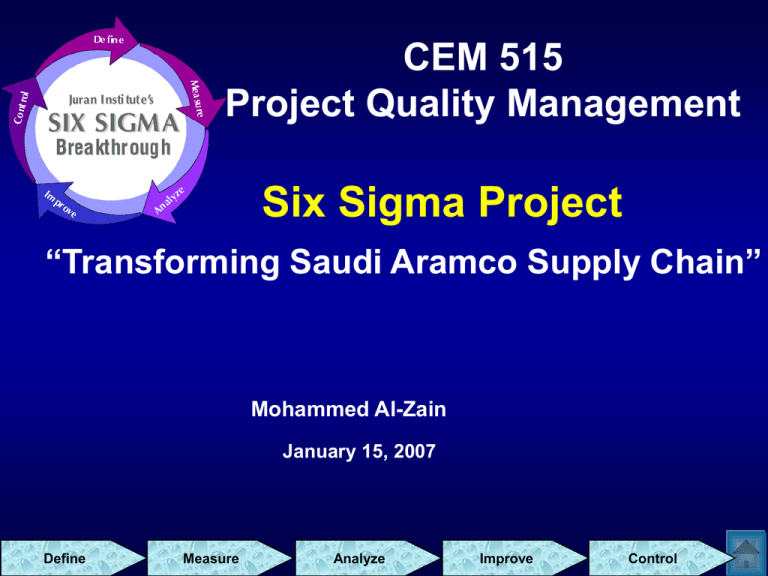

Six Sigma Project CEM 515 Project Quality Management “Transforming Saudi Aramco Supply Chain”

advertisement

CEM 515 Project Quality Management Six Sigma Project “Transforming Saudi Aramco Supply Chain” Mohammed Al-Zain January 15, 2007 Define Measure Analyze Improve Control Six Sigma Defined WHY six sigma? Satisfaction of customers WHO does it? Structured top-down hierarchy of trained personnel WHAT is it? Statistical thinking using data to combat process variation WHERE is it? Standardized framework of “DMAIC”. WHEN is it done? Sustained effort via projects HOW is it done? Software packages for information analysis Define Measure Analyze Improve Control Six Sigma Defined Alters the paradigm from fixing defective products to correcting the process so that perfect products are made Formal methodology for measuring, analyzing, improving and then controlling processes Reduces the occurrence of defects from a three sigma level or 66,800 defects per million (average for most companies) to a six-sigma level – no more than 3.4 defects per million Define Measure Analyze Improve Control Why Six Sigma? It has technical power to find root causes of serious problems faced by organizations It provides designs that respond proactively to customers’ requirements It provides clear cost-savings and revenuegenerating benefits that flow to the bottom line It offers a process and customer focused framework It improves product and service performance It can change organizational culture for the better Define Measure Analyze Improve Control How Six-Sigma is Different from other Quality Programs? Requires discipline to execute Leadership team selects six sigma projects with the maximum pay-off Emphasis is on breakthrough rates of improvement Goals flow down from customers and senior leadership’s strategic objectives No six sigma project is approved unless the bottomline impact has been clearly identified and defined Creates an infrastructure of champions, master black belts (MBBs), black belts (BBs) and green belts (GBs) that lead, deploy and implement the approach. Define Measure Analyze Improve Control Some Real Benefits Realized from Six-Sigma Organization GE Motorola AlliedSignal Benefits Saved more than $2 billion Saved $2.2 billion in reducing COPQ Honored with the Malcom Baldrige award (1988) Increased stockholders share value four-fold Reduced new product introduction time by 16% Reduced manufacturing costs by more than $1 billion (19921996) Honeywell Saved $500 million in 1998, $500 million in 1999 and $700 million in 2000 Johnson & Johnson Saved $200 million in 1999, $350 million in 2000 and $500 million in 2001 Define Measure Analyze Improve Control CSFs for Six-Sigma Implementation Strong Leadership and Management commitment and Involvement Six Sigma Training The Customer Connection Organizational Cultural Change Organization infrastructure Aligning Six Sigma Projects to Corporate Business Strategy and objectives Linking six sigma to human resources Linking six sigma to suppliers Understanding Six Sigma Tools, Techniques and Key Metrics Project management skills Project Prioritization and Selection Define Measure Analyze Improve Control Define Measure Analyze Improve Control Assemble Team & Assign Roles ID Project Scope Develop Team Charter Create Project Timeline ID Customer CTQ’s ID Compliance CTQ’s High Level Process Map Estimate Benefits Formal Champion Approval Select Key Product/Process Create Product Tree/Process Map Define Performance Variables Baseline Performance Measures Develop & Execute Data Collection Plan Formal Champion Approval Map CTQ’s to Function/Process Select Key Performance Variable/Sub process Benchmark Performance ID Variation Sources & Improvement Opportunities Root Cause Analysis Define Performance Objective Formal Champion Approval Diagnose Variable Performance Establish Operating Tolerances Develop Solution Cost Benefit Analysis Develop & Implement Execution Plan Formal Champion Approval Validate Control System Develop & Implement Monitoring Plan Implement Sustainable Process Controls Develop & Deploy Response Plan Standardize & Translate Net Income Benefit Tracking System In Place Formal Champion Approval Tools/Attachments: Tools/Attachments: Tools/Attachments: Tools/Attachments: Tools/Attachments: • One Page Plan • Sigma / DPMO Calculations • Workforce Optimization Analyze Improve • Charter • One Page Plan • High Level Process Map • Sigma / DPMO • CTQ Matrix Calculations Define Measure • Monthly Retention Tracking Tool & Review Control Business Drivers Outsource the logistic services Lean Supply Chain: • • • Streamlined delivery process Paperless environment End-to-End tracking and monitoring of orders Customers Define Measure Analyze Improve Control Project Scope Materials collected from local market and delivered •Activities and resources related to delivery process: • End Customer (Requester for materials) • Purchasing • Vendors • Saudi Aramco Carrier, or Logistics Service Provider • Materials Distribution Center (MDC) • Materials Service Center (MSC) • Systems that link the supply chain Define Measure Analyze Improve Control Project Team Project Sponsor: Materials Logistics Department Project Team Leader: Mohammed Al-Zain Project Core Team Members: • Selected MS employees Ad Hoc Members and SMEs: • Customers • Suppliers • Saudi Aramco Carrier Define Measure Analyze Improve Control Project Justification & Expected Results Relevant Metrics: • Cycle Time (hours, days) • Cost of Poor Quality ($) Improvement Targets: • Reduction in delivery delay by 80% • Reduction in delivery cost: 50% Operational/Strategic Impact: • Smooth uninterrupted operations • Customer satisfaction • Minimize the abuse of delivery priority system Define Measure Analyze Improve Control High Level Process Map (SIPOC) S UPPLIER INPUT P ROCESS End User •Identified need •Create PR Purchasing •Approved PR •Place PO •Print MDD Vendors Logistic Provider Define •Materials •PO •Trucks •Drivers •MDDs Measure O UTPUT CUSTOMER •PR •Purchasing •Approved PO •Printed MDD •Process PO •Ready Materials •Prepare Mat’s •Collect Mat’s •Deliver Mat’s Analyze •Materials Delivered •Vendors •LSP •LSP •End User Improve CTQ CRITICAL TO QUALITY •Correct PR •Correct POs •Correct MDDs •Timely printed MDDs •Availably of Mat’s •On time delivery •Right Mat’s Control Current Process Materials Order as-is Date: 3ed April, 2006 Drawn By: Jasem, Hilal J Cross-Functional Flow Chart (underdevelopment) PURCHASING Department CUSTOMER MDC - MSC - Al-Midra Receive PO No VTD/VTC/SAT B Create Outbound Print MDDs @ 10:30 & 13:30 before 2 days of delivary date SAC MDDs Yes Receive Material by MDC (receiving area) Yes MSC No Al-Midra Issue Material Affix Label Print Label Shipping Material (shipping area) Yes Create Requisition Send to Vendor Inspection Department (VID) No Pipes, Bulk Load / Send Forklift or Mule (by MSC R&S Function) Yes Stock Local No No Issue Material Yes Review Stock Available ? Send back to PD System Shipping Material (shipping area) Load / Send Truck (by MSC R&S Function) Local No Deliver material to remote shipping Scan Label Segregate by Rout Segregate by Destination Sort MDDs By Truck Provide PD with New ETA Prepare Truck Manifest Return MDD to PD Driver Pickup MDDs & Manifest Next Day Segregate Material by Truck Type Load Truck Deliver to customer Print Manifest and gate passes Load Truck Enter Data into System Match MDD's with PO A Deliver MDDs to Vendor Print Manifest and gate passes Deliver Material No Customer Receive material (By MSC R&S function) Deliver Material to Logistics Contractor MDC Send material to Store No MSC Full Truck Count Package Sign MDD No Emergency Yes Others Province Yes Legend Print Inbound Logistics Contractor End MDC Material Ready for Collection (SAC Materials) Collect material from Vendor Unload Truck Store Material Transport Material to Customer/ Nearest MSC Go to B To MSC To Customer To MDC Yes E.P. To Customer Define Measure Yes Prepare Material Put Label on Packages No Deliver Material to MSC End Update System with New ETA Go to Unload Material Print Manifest and gate passes Archive MDD Hold P.O. Pending MDDs Receipt Receive MDDs No MSC Scan Label Yes Receive Materials from Supplier Load Material Segregate by Rout Material Available ? Segregate Material Load Truck Receive Materials Yes Yes Scan Label Deliver to customer Sort MDDs By Vendor Transport Material to MDC/ Nearest MSC/ Customer Affix Label Small Material Yes SAC Log MDDs in System Print Label Pack Material Issue Material Inspectable 9COM Order Material from Supplier (Local, Out of Kingdom) To DH MDC Segregate Material by location Printed Outbound No Sort MDDs by INCO terms SAC,SAT,VTC,VTD Unload Material Print Outbound in required area Create P.O. Sign MDD VENDOR Pick up MDDs @ 8:00 & 16:00 Update System with New ETA No LOGISTICS CONTRACTOR MDC Fax Po / MDDs to Vendor A Start Mapped By: Checked By : Analyze Improve Control Measure Process Capability Variance from Planned Delivery Date Target USL P rocess D ata LS L * Target 0.00000 USL 0.00000 S ample M ean 3.37886 S ample N 265425 S tD ev (Within) 0.00005 S tD ev (O v erall) 2.50268 W ithin O v erall P otential (Within) C apability Z.Bench * Z.LS L * Z.U S L -67441.59 C pk -22480.53 C C pk 0.00 O v erall C apability Z.Bench Z.LS L Z.U S L P pk C pm 0 O bserv ed P erformance P P M < LS L * P P M > U S L 989221.06 P P M Total 989221.06 3 6 E xp. Within P erformance P P M < LS L * P P M > U S L 1000000.00 P P M Total 1000000.00 9 12 15 E xp. O v erall P erformance P P M < LS L * P P M > U S L 911507.72 P P M Total 911507.72 Process mean = 3.37 days (falls short of the target) Hence: we must reduce variability and center the process on the target Define Measure Analyze Improve Control -1.35 * -1.35 -0.45 0.00 Validate Measurement System • • • • Compare SAP data with the data content in actual MDDs Survey end users Survey Logistics Service Provider Survey Receiving & Shipping Personnel Process Capability of C1 LSL USL P rocess D ata LS L 0.00000 T arget * USL 1.00000 S ample M ean 3.80000 S ample N 20 S tD ev (Within) 1.94532 S tD ev (O v erall) 1.98880 W ithin O v erall P otential (Within) C apability Cp 0.09 C PL 0.65 C PU -0.48 C pk -0.48 C C pk 0.09 O v erall C apability Pp PPL PPU P pk C pm 0 O bserv ed P erformance P P M < LS L 0.00 P P M > U S L 1000000.00 P P M T otal 1000000.00 Define E xp. PPM PPM PPM 2 Within P erformance < LS L 25385.66 > U S L 924974.73 T otal 950360.39 Measure 4 6 8 E xp. O v erall P erformance P P M < LS L 28021.41 P P M > U S L 920417.60 P P M T otal 948439.01 Analyze 0.08 0.64 -0.47 -0.47 * • Process Mean = 3.8 • Sample Size = 20 MDDs Improve Control Pareto Chart Variance from Planned Delivery Date 300000 100 250000 Count 60 150000 100000 40 50000 20 0 Variance Count Percent Cum % Define 2 63812 24.0 24.0 3 52391 19.7 43.8 Measure 1 52004 19.6 63.4 4 36487 13.7 77.1 Analyze 5 20491 7.7 84.8 6 10807 4.1 88.9 7 7098 2.7 91.6 Improve Other 22335 8.4 100.0 Percent 80 200000 0 Control Cause-Effect Diagram Cause-and-Effect Diagram Methods Logistics Prov ider Planned delivery dates are not realistic Purchasing Keeping materials in his facility MDDs are not printed on time No use of direct delivery No follow-up with vendors Routes are assigned by vendors Late confirmation on goods receipt No corrective actions with vendors Collection trucks differ from delivery trucks Deliv ery Delay s Work overload Asking LSP to come back for collection Keeping materials in the facility Shipping wrong materials Insufficient manpower Insufficient delivery trucks Receiv ing & shipping Sites Define Measure Analyze Materials are not ready for shipping Materials are not available Vendors Improve Control Potential X’s --Hypothesis to be Tested X1: The current business model with our suppliers and logistics service provider X2: The derived planned delivery date is not realistic X3: Vendors are not meeting the planned delivery date X4: Materials are kept more than 12 hours in LSP facility X5: Materials are kept more than 12 hours in R&S facility Define Measure Analyze Improve Control PO 9 MDDs Workstations 3.9 MM Sheet/Y Vendor Manual Sorting By vendor Data Entry MDDs Update Segregation New ETA Match MDDs PO (Hardcopy/Auto Fax) Materials Supply Temporary Archive Returned MDDs (30%) 2500 MDDs/Day ETA Manifest Update Carrier Materials Supply Data Entry Stock 20 printers Scan/Archive Define Measure Customer Analyze Improve Match MDD w/Pkg Control Where is the Pain? MATERIAL Papers $642,720 Toners MAN-HOURS MDD Process $58,855 Process Components Barcode Labels MATERIAL Yellow Labels MACHINES LABOR MDD MACHINES Printers Imaging Machine Printers (Barcode) Define Service COST/Year Measure Maintenance Expediting Total Cost (PD) $13,855 Receiving $777,830 / Year $62,400 (MSC) COST $13.8 Millions Customer / Year Expedite $409,375 $611,907 / Track COST/Year $2.3MM $1.2MM $9.2MM $ $450,250 $75,000 $87,500 $40,032 Analyze Improve Control Where is the Pain? Material delivery delay 900 expediting requests daily Lack of process-wide tracking No single point of contact Define Measure Analyze Improve Control X2: The derived planned delivery date is not realistic • Required Delivery Date and Delivery Lead Time • Example1: Purchase Agreement with 10 days delivery lead time • Request for materials • MDD printing & collection • Material ready at Vendor site • Material Collection • Segregation and consolidation • Delivery to 1st Receiver • Delivery to 2nd Receiver • Delivery to Final Receiver July 1 July 8 July 3 July 9 July 9 July 10 July 11 July 12 • Is the Delivery Lead time realistic for: • Vendors, LSP, R&S? Define Measure Analyze Improve Control X3: Vendors are not meeting the planned delivery date • Vendors normally return MDDs with new ETA • About 500-800 MDDs out of 2000-2500 MDDs – every day • Order-to-order System Define Measure Analyze Improve Control X4: Materials are kept more than 12 hours in LSP facility Deliveries should be within 1-2 Days of MDD Print # of Days from printing Define Measure Total % 15 2710 0.9% 14 3195 1.0% 13 3693 1.2% 12 3851 1.2% 11 4471 1.4% 10 3921 1.3% 9 6759 2.2% 8 10136 3.3% 7 16662 5.4% 6 36760 11.9% 5 54310 17.6% 4 35051 11.4% 3 57940 18.8% 2 5571 1.8% 1 609 0.2% Analyze Improve Control X5: Materials are kept more than 12 hours in R&S facility • Dhahran Receiving & Shipping • Consolidation center – another point of delay! • Kingdom-wide Receiving & Shipping • Effective cross-docking for local deliveries • Reasons for Keeping Materials more than 12 hours • Unavailability of TD trucks • Consolidation • Late arrival of the materials – customer is not available • Returned materials due to reasons such as wrong delivery address Define Measure Analyze Improve Control Improvement Plan Develop a new business model: Enable electronic information sharing and collaboration Provide paperless delivery environment Allow process-wide tracking Define Measure Analyze Improve Control PO 9 Workstations 3.9 MM Sheet/Y Carrier Materials Supply Data Entry 2500 MDDs/Day Returned MDDs (30%) Vendor Manual Sorting By vendor Data Entry MDDs Update Segregation Match MDDs PO (Hardcopy/Auto Fax) Materials Supply Temporary Archive Stock 20 Printers Scan/Archive Define Measure Customer Analyze Improve Match MDD w/Bkg Control Transformation Plan DURATIO N (Months) ACTION ITEMS RESOURCES 1 SCM consultant SAP Portal Bar-Code Scanners SCM Coordinator s Carrier Define Develop System Interface with Carrier Enhance SAP Tracking System 5 Introduce Advance Shipping Notice (ASN) Allow vendors to print Barcode label Electronic Update of ETA/Qty Enroll top 700 vendors (99% of L/Is) 6 3 Develop “Dashboard” Group Formation & Training 3 Measure Analyze $480,000 – $640,000 2 Portal 160 Scanners to Capture Receiver Details Develop System Interface with SAP/R3 1 ABAP Programmer Improve 4 Consultants 1 ABAP Programmer ($330,000) H/W + S/W $500,000 In-house Provided by Carrier Control Return on Investment MS Savings $29 Millions Projected Cost Savings Partners Customer Vendors Carrier MS Millions Cost Savings/Year $450,250 10 $216,000 $218,000 6 $14,750,000 14 2 Implementatio n $1.5 Millions Define -2 2006 Measure 2007 2008 Analyze 2009 2010 Improve 2011 Control Improvement Plan • Availability of Materials at Vendors • Instead of revising the ETA, check with vendor first. If he does not have the material available, place the PO with other vendor who has the material • Don’t restrict PA with only one vendor especially those who have bad history in revising ETAs • MDDs should be printed 6 or 7 days before the required date • Dhahran MDC should be receiving material for Dhahran area only Define Measure Analyze Improve Control Improvement Plan • Receiving & Shipping scheduling arrangement • Shipping people should pay attention to the required delivery date and priority • Materials should not stay in the shipping area for the second day • If customer is not available to receive his/her order, deliver to office services people or any designated coordinator in the customer premises • Emergency shipments should be directly delivered to customer bypassing R&S or warehouse Define Measure Analyze Improve Control Improvement Plan • The current practice of collecting materials from local market need to be changed. • Collection trucks should be scheduled to be dispatched based on material destination instead of vendor Define Measure Analyze Improve Control Count of L/I MDD Printed On 11/01/2005 11/02/2005 11/03/2005 11/04/2005 11/05/2005 11/06/2005 11/07/2005 11/08/2005 11/09/2005 11/10/2005 11/11/2005 11/12/2005 11/13/2005 11/14/2005 11/15/2005 11/16/2005 11/17/2005 11/18/2005 11/19/2005 11/20/2005 11/21/2005 11/22/2005 11/23/2005 11/24/2005 11/25/2005 11/26/2005 11/27/2005 11/28/2005 11/29/2005 11/30/2005 Define Grand Total MSC M001 M002 70 53 116 156 8 15 98 390 338 114 87 120 239 62 141 347 321 15 22 67 84 70 135 119 145 142 183 79 109 393 332 44 31 103 83 84 105 133 248 136 295 145 150 297 437 13 38 98 94 133 123 230 247 287 428 163 371 354 597 Measure 4276 5761 M003 M004 8 6 2 7 22 7 7 7 67 4 8 9 22 19 17 41 31 9 13 15 22 11 67 15 6 16 63 33 126 58 Analyze 738 M005 2 7 6 3 67 30 52 14 29 49 25 26 62 25 30 36 78 33 62 67 61 29 53 41 94 29 56 93 32 44 1235 M006 175 66 3 26 251 177 258 61 252 9 75 79 81 128 78 383 97 183 52 278 151 356 457 53 70 308 279 220 186 441 Improve 5233 M007 15 14 5 3 10 13 14 4 145 4 9 6 4 18 12 18 3 6 19 38 36 14 47 5 2 16 24 21 14 65 604 M008 41 56 21 147 26 51 52 152 3 28 50 156 44 48 179 12 70 43 92 66 41 177 6 34 56 123 91 81 199 Control 2145 56 47 1 8 83 52 32 26 34 16 8 48 76 52 8 58 7 18 38 35 73 68 62 4 9 31 45 39 28 92 1154 Count of L/I MDD Printed On 12/01/2005 12/02/2005 12/03/2005 12/04/2005 12/05/2005 12/06/2005 12/07/2005 12/08/2005 12/09/2005 12/10/2005 12/11/2005 12/12/2005 12/13/2005 12/14/2005 12/15/2005 12/16/2005 12/17/2005 12/18/2005 12/19/2005 12/20/2005 12/21/2005 12/22/2005 12/23/2005 12/24/2005 12/25/2005 12/26/2005 12/27/2005 12/28/2005 12/29/2005 12/30/2005 12/31/2005 (blank) Define Grand Total M001 M002 48 74 130 155 213 259 478 48 95 150 345 262 180 555 51 104 126 275 255 74 471 43 142 99 281 276 120 432 14 102 109 5966 Measure M003 M004 191 141 311 255 360 218 471 57 137 201 335 335 249 508 130 156 197 243 266 243 497 59 130 272 269 240 269 401 7 128 127 39 21 22 26 31 41 99 17 12 17 32 45 35 38 14 16 45 38 19 14 45 9 3 19 42 12 69 46 12 31 17 7403 926 Analyze M005 14 21 32 57 104 21 50 33 13 45 115 107 27 35 17 21 28 53 23 17 110 42 13 16 33 117 12 86 16 15 26 1319 M006 70 252 125 193 109 180 428 69 135 194 229 193 141 311 66 98 107 153 158 84 351 36 178 142 262 162 174 616 16 297 82 Improve 5611 M007 16 8 21 8 46 30 58 9 16 11 63 35 24 41 7 12 40 20 38 27 34 5 8 38 47 12 19 81 9 7 15 805 M008 22 43 73 87 92 89 216 24 65 47 88 164 92 251 22 43 85 115 113 55 186 9 51 74 162 84 79 199 5 43 79 Control 2757 44 21 36 34 26 37 57 10 35 41 40 36 21 72 4 20 53 44 34 27 88 6 14 24 36 44 21 146 5 13 16 1105 Maintain Improvement • Periodic Measurement of Performance • Customer Satisfaction Surveys • System Generated Data on Delivery Performance • Site Visits and Observations etc. Define Measure Analyze Improve Control Conclusion Reduce process cost Improve data accuracy and provide real-time information Allow monitoring of process performance Reduce missing Goods Receipt Enable the corporate strategy for outsourcing initiatives Improve the On Time Delivery performance, customer satisfaction Reduce process overheads and time by enabling electronic flow of information Allow end to end visibility of shipments throughout the delivery process Help in measuring and evaluating suppliers and logistics provider delivery performance Define Measure Analyze Improve Control Thank You Define Measure Analyze Improve Control Define Measure Analyze Improve Control Items Material Labors Machines Services Define Formula Saving/Yr Paper (Sheets) 2500MDDsX6sheetX260day =3.9MM Answer X $824/5000sheets=$642,720 $642,720 Labels (Barcode) + Toners 85 Box X $163 X 2 (to count toners cost) $27,710 Labels (Yellow label) 2500MDDX312DaysX$0.08 ($8/100 labels) $62,400 Toners Box(8 bottle)=90 box X $500/box =45,000 $45,000 MDD Processing 10 employees (7 Dh+ 3 CRWR) X 2080 $1.07 Million Expediting 14 employees (10 Dh + 4 CRWR) X.40 = 4.9 employees X 2080 $554,216 Carrier man hours Dh Receiving: 15 BTT employees X $8/H X 8HX.45 Hour Saving X290 day =$125,280 MDD Process: 5 BTT employees X $8/H X 8HX290day =$92,800 $218,000 Customer man hours 1000 Expedite Rqst dailyX5 Minutes X60X260 days =$667,250 Vendor man hours 2500 MDD daily X 5 Minutes / 60 H X $8/H X .5 Hour Saving x 260 days $216,000 Rec/Ship man-hours 9 MSCs X 11 Employees X .45 Hour Saving = 39.6 Employees X 2080 $4.3 Million MDD Printers (Advance) 4 X $105,000 $315,000 MDD Printers 5 X $2500 $12,500 Printers (Barcode Label) 20 X $3000 $60000 MDD Scanners 2 X $35,000 $70,000 Services charges 7% X 457,500 $32,025 Measure Analyze Improve Control