Sevier Solid Waste Inc. (SSWI) Study

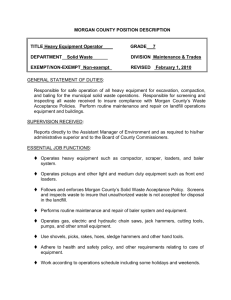

advertisement

Sevier Solid Waste Inc. (SSWI) Study by MTAS and CTAS, 2003 Introduction The Sevier Solid Waste Inc. (SSWI) Authority asked consultants from The University of Tennessee=s County Technical Assistance Service and Municipal Technical Advisory Service to study the operations of SSWI activities. The purpose of the study is as follows: A. B. C. To identify long-term alternatives for disposal of solid waste in Sevier County. To make recommendations regarding the compost plant. To identify potential areas of improvement in the management and operations of the solid waste facility and/or collection practices which may affect SSWI. The study team is composed of Pat Hardy - MTAS Management Consultant, Alan Major - MTAS Finance Consultant, Chris Garkovich, CTAS Solid Waste Consultant, and Tom Leonard - SSWI Director. Long-Term Alternatives For Disposal and Recommendations For the Compost Plant Long-term decisions regarding the landfill must be made on a proactive basis, since the length of time it takes to realize many solid waste decisions can be quite long. Therefore a lot of unknowns exist, only a limited number of which can be identified today. This being the case, results can only be estimated or projected based on sometimes unclear assumptions. For this part of the study we independently analyzed options for both today through year 10, and years 10 through 20. This breakdown is important because an immediate question must be answered, ADo we need a new digester?@ The answer is affected by both short and long-term considerations. So, the Adigester@ question can only be answered in a context which examines long-term alternatives as well as immediate concerns. It is also important to remember that we have an estimated 8 years of life remaining on the landfill. However, we believe an additional Acell@ can be added to the landfill which will extend its life by approximately 5 years. It is extremely important that this be accomplished. RECOMMENDATION: Support all efforts to expand the current landfill by acquiring and permitting an additional cell. (Note: budgetary requirements for this recommendation have been included in the proposed FY 2003-04 budget). With the probable addition of a new cell, the remaining life on the landfill is estimated at approximately 12-13 years. However, the remaining 12-13 years cannot be guaranteed and is dependent on the appropriate site testing with state permit approval. This being the case, there is a possibility that 7-8 years will be the remaining life of the landfill. This would be the bare 1 minimum required to site and permit a new landfill (if this were the chosen alternative). Thus, depending on the alternative implementation may take years. So at this point, Ano decision@ on this issue may in fact be a decision, as key alternatives could easily be lost through the passage of time. Waiting will narrow the choices. RECOMMENDATION: The preferred long-term alternative should be decided by the Board within the next year, and adequate resources (which may be political, financial, and administrative) to pursue this alternative should be committed and included in each year=s budget, beginning in FY 2004-05. Our recommendations regarding these alternatives are discussed below. There appears to be four main alternatives for long-term solid waste disposal. Each of these, and the basic related costs, operational consequences, and pros and cons are as follows: 1. Do Not Purchase a New Digester and Transfer Waste To Another Facility, Beginning Soon - This option focuses on operating the plant as long as it will hold out, then closing it, and transferring SSWI solid waste to another facility. 20-year cost of this option: $101,332,198 Average per ton cost of this option: $36.70 Pros: a. We don=t incur the cost of a new digester. Cons: a. We abandon the co-composting technology. b. We incur the costs of transferring sooner (however, we save some operational costs). c. By transferring waste we lose control over disposal costs and landfill operations. d. There will be increased transfer traffic on our county and city roads. 2. Purchase a New Digester Now and Later Begin Transferring Waste To Another Facility - This option involves immediate purchase of a new digester to operate the plant as long as it will hold out. We will then close it and transfer our solid waste to another facility. 20-year cost of this option: $102,114,748 Average per ton cost of this option: $37.20 Pros: a. If we are going to get out of the business this gives us the maximum plant life before we do so, thus staying with the co-composting technology as long as possible and incurring the costs of transferring waste at the latest possible date. 2 Cons: a. We immediately incur the cost of a new digester. b. We don=t know how long the plant will operate, even with a new digester. Thus we risk buying a new digester and still have to close the plant early. c. We abandon the co-composting technology (although we stay with it a little longer). d. By transferring we lose control over landfill operations and disposal costs. e. We increase transfer traffic on our county and city roads. f. This is the most expensive option. 3. Do Not Purchase a New Digester and Construct and Operate a New Landfill - This option focuses on operating the plant as long as it will hold out (without additional investment). In the meantime, we will construct and operate a new landfill. 20-year cost of this option: $79,052,578 Average per ton cost of this option: $30.01 Pros: a. We do not incur the cost of a new digester. b. We will control the operations of a landfill (e.g. 6 or 7-day access) and its costs. c. We will not increase transfer traffic on our county and city roads. Cons: a. We have to locate a new landfill and this may not be possible or at least will be difficult (NIMBY). b. We do not think our existing plant will be operational long enough to locate, permit and begin operating a new landfill. Thus, there may be interim transfer costs which could be substantial (although limited in time). These interim transfer costs have not been included in the option estimates. 4. Purchase a New Digester Now and Construct and Operate a New Landfill - This option focuses on staying with the co-composting technology. In the meantime, we will construct and operate a new landfill. 20-year cost of this option: $83,515,469 Average per ton cost of this option: $30.96 Pros: a. We stay with the co-composting technology. b. We will control landfill operational costs (e.g. 6 or 7-day access). c. We will not increase transfer traffic on county and city roads. Cons: a. We have to locate a new landfill and this may not be possible or at least will be 3 difficult (NIMBY). The cost estimates used in these scenarios include all costs associated with each option, including debt service, capital replacement, closure of facilities, personnel, etc. The spreadsheets used for these calculations are provided in Appendix A (where costs are shown for years 1-10, years 10-20 and years 1-20). A comparison of the expenditures for each option is shown as follows: 20 Year Cost Of Options In $Millions $120 $102 $101 $100 $83 $79 $80 $60 $40 $20 $0 No New Dig. & Transfer No New Dig. & New Landfill 4 New Dig. & Transfer New Dig. &New Landfill 20 Year Cost Of Options $ Per Ton $50 $40 $37.20 $36.70 $30.96 $30.01 $30 $20 $10 $0 No New Dig. & Transfer No New Dig. & New Landfill New Dig. & Transfer New Dig. &New Landfill The projections assume basically the same revenues for each option, and thus revenues are kept constant in this analysis (the only difference is in the area of capital revenues). This being the case, the expenditure side was used for comparative purposes. RECOMMENDATION: Option 4, the immediate purchase of a new digester and the construction and operation of a new landfill, should be pursued as the most desirable longterm alternative. We are recommending this alternative for a number of reasons: $ By purchasing a new digester, there is maximum use of current resources, providing a safeguard in the event of another failed digester. $ Allowance for the Atakedown@ of each digester in order to do routine maintenance and thus extend their useful life. $ Provides additional capacity as the volume of solid waste grows (the plant is now at full capacity with the current 225 tons per day). $ A new digester will add approximately 85 tons per day of additional capacity. Potential Areas of Improvement In Facility Operations Of utmost concern to both the short and long-term health of SSWI operations is the potential loss of volume and the control of waste flow into the facility. Mr. Leonard has been 5 warned that most of the waste currently being brought to the facility by private haulers will soon be diverted to a private transfer station. This is estimated to be about 47 tons per day, or about 20% of the current daily flow. This would result in a revenue reduction of about $300,000 per year to the facility. Needless to say, the facility would have enormous difficulty operating with a reduction of this size. One potential solution would be to require that all solid waste generated in the County and the three cities be disposed at the SSSWI facility. However, a number of court cases have ruled Aflow control@ as unconstitutional (generally the courts have ruled that such practices restrict commerce - see for example ). MTAS attorney Sid Hemsley has researched this issue for us at length. In order then to capture this 47 tons of flow, the overall solid waste operation in the County and all three cities must become more competative and actively work to capture the flow generated as new customers and residents move into the area. RECOMMENDATION: Each jurisdiction should develop a marketing strategy to capture the largest solid waste flow from new customers, businesses and residents. A problem which prevents SSWI jurisdictions from competing effectively for much of this flow is the inability to provide compactor service. Many of the larger customers require compactor units in addition to the front-loader boxes now being used. It is estimated that there are approximately 12 potential compactor sites in Gatlinburg, 20 in Pigeon Forge, and 19 in Sevierville. All convenience center sites operated by Sevier County could also be serviced with roll-off compaction equipment. Because the number of planned sites for locating compaction equipment for each jurisdiction are insufficient to warrant owning multiple roll-off trucks, it is recommended that SSWI purchase the necessary hauling equipment to operate collections of compaction units at each container site location. RECOMMENDATION: The SSWI should purchase a roll-off (compactor) truck and begin providing hauling service in all three cities and the county. When this recommendation is implemented, SSWI should be authorized to actively market roll-off compactor service in order to recover lost waste flow. The benefit realized with this recommendation would be both financial and operational. In addition to providing the capacity to compete for the tonnage, which may soon be lost to private haulers, the financial implications of the compactor operation itself are substantial. Here are the calculations: Estimated annual savings to SSWI* minus $72,000 operational cost minus $10,000 truck cost ($100K/10 year life) Total Projected SSWI Annual Savings $175,000 Compactor Cost (36 @ $10,000 each) $360,000 6 $ 93,000 Projected Payback = 3.8 years ($360,000/$93,000) * Includes closing on Sunday and a reduction in maintenance budget. We have not addressed the issue of paying for the compactors. There are a number of options for this: $ $ $ $ each business can be required to purchase their own compactor(s), each jurisdiction can purchase compactors and businesses pay for them over time, lease compactor units, and/or, each jurisdictions can own the compactors and charge for pick-up service. These estimates are the savings to SSWI only. The larger potential savings lie with the three cities and Sevier County. We project the potential savings to the cities only as approximately $612,456 per year (this is an average cost of $58.89 per ton X 10,400 tons per year reduction in the amount hauled - SSWI would now be hauling this). This assumes that the cities will be able to translate the 10,400 ton reduction in the amount they haul into operational savings. So the payback for the cities and SSWI if the compactor program is fully implemented is as follows: Estimated savings-SSWI $ 93,000 Estimated savings-cities $612,456 Total Estimated Savings $705,456 Compactor Cost (36 @ $10,000 each) $360,000 Projected Payback = 7 months ($360,000/$705,456) Based on these projections we believe it is important to invest in the SSWI compactor program and the cities begin to work toward realizing the operational savings they can achieve. We have not included Sevier County in these calculations because they will need to phase-in the roll-off compactor system while phasing out the front-end loader system. The projected savings for the change of operating the collection system presently with front-end loader trucks and dumpsters to a roll-off system with compactor units and receiver containers is: Estimated savings of roll-off system $155,435 Other benefits of a compactor operation are: $ $ Reduction in traffic on county and city streets. Businesses will gain additional space if compactors are used (for example, there is 7 $ a business with 120 4-yard dumpsters - these would be replaced with 2 compactors and the recovered space, which is substantial, will be used for additional parking). Reduced traffic at the SSWI facility reducing vehicle cuing and tipping floor maintenance. There are two additional problems which will partially be solved if SSWI begins compactor operations. Currently, about 10% of the waste hauled to the compost facility has already been banned (it contains washers, carpet, bungee cords, refrigerators, etc). These components clog the digester, effectively shutting down the facility (the annual cost of dealing with these shutdowns is estimated by Tom to be in the range of $176,000 plus the loss of landfill space). The use of compactors will likely eliminate most of the unwanted and banned waste components because they simply will not fit into the throat of the compactor=s opening. But the problem will still exist at sites without compactors. It is very important that a concerted, long-term effort be made to reduce the banned waste entering the facility. RECOMMENDATION: All jurisdictions should post new signs, address letters to violating customers, and take other necessary measures to reduce identified banned waste. Additional measures should include refusal to pick up any of the identified banned waste. Regarding the collection and transport of solid waste, it has been said that AIt=s all about full loads@ (this is the most significant impact which would be realized with compactors). But another operational technique which would greatly help reduce the number of loads would be the tamping of waste at transfer stations in order to increase the volume which can be carried in each load. We are not making this a recommendation, but we believe it will contribute to reduced traffic, shorter lines at the facility, and assisting with the possibility of closing on Sundays (which will save substantial dollars), etc. Potential Management Improvements As a part of this study Alan Major and Chris Garkovich worked with the Finance Directors in each jurisdiction to develop a Afull cost accounting@ program for solid waste collections. This program gives an in-depth method of identifying and tracking the actual costs of providing solid waste collection services in each jurisdiction. The data resulting from this program has been used here to determine per ton costs in order to identify potential savings. This can be done in the future as well, as each jurisdiction examines alternatives to achieve efficiencies as operational changes are considered. RECOMMENDATION: Continue full cost accounting in each jurisdiction on an annual basis. On-going full cost accounting implemented on a monthly basis provides actual costs for the services measured. Those costs include overhead or centralized managerial expenses. 8 Analysis of the costs on a monthly basis enables changes required to maintain a consistent service within budget parameters. An adoption of full cost accounting for all your waste and utility operations is recommended. For the cities, cost estimates were estimated from audit figures. We were able to approximate the full cost accounting result in determining the total cost of providing solid waste services. This approach is appropriate for planning and projecting service delivery costs. 9 SUMMARY OF RECOMMENDATIONS 1. Support all efforts to expand the current landfill by acquiring and permitting an additional cell. 2. The preferred long-term alternative should be decided by the Board within the next year, and adequate resources (which may be political, financial, and administrative) to pursue this alternative should be committed and included in each year=s budget, beginning in FY 2004-05. 3. Option 4, the immediate purchase of a new digester and the construction and operation of a new landfill, should be pursued as the most desirable long-term alternative. 4. Each jurisdiction should develop a marketing strategy to capture the solid waste flow from new customers. 5. The SSWI should purchase a roll-off (compactor) truck and begin providing compactor service in all three cities and the county. 6. All jurisdictions should post new signs, address letters to violating customers, and take other necessary measures to reduce band waste. 7. Continue full cost accounting in each jurisdiction on an annual basis. 10 APPENDIX A Revenue and Expenditure Projections for Long-Term Alternatives 11 Alternative 1: Do Not Purchase a New Digester and Transfer Waste Soon 12 Alternative 2: Purchase a New Digester Now and Transfer Waste Later 13 Alternative 3: Do Not Purchase a New Digester and Develop a New Landfill 14 Alternative 4: Purchase a New Digester Now and Develop a New Landfill 15