1)Find the schedule minimising the average flow time. Calculate the...

advertisement

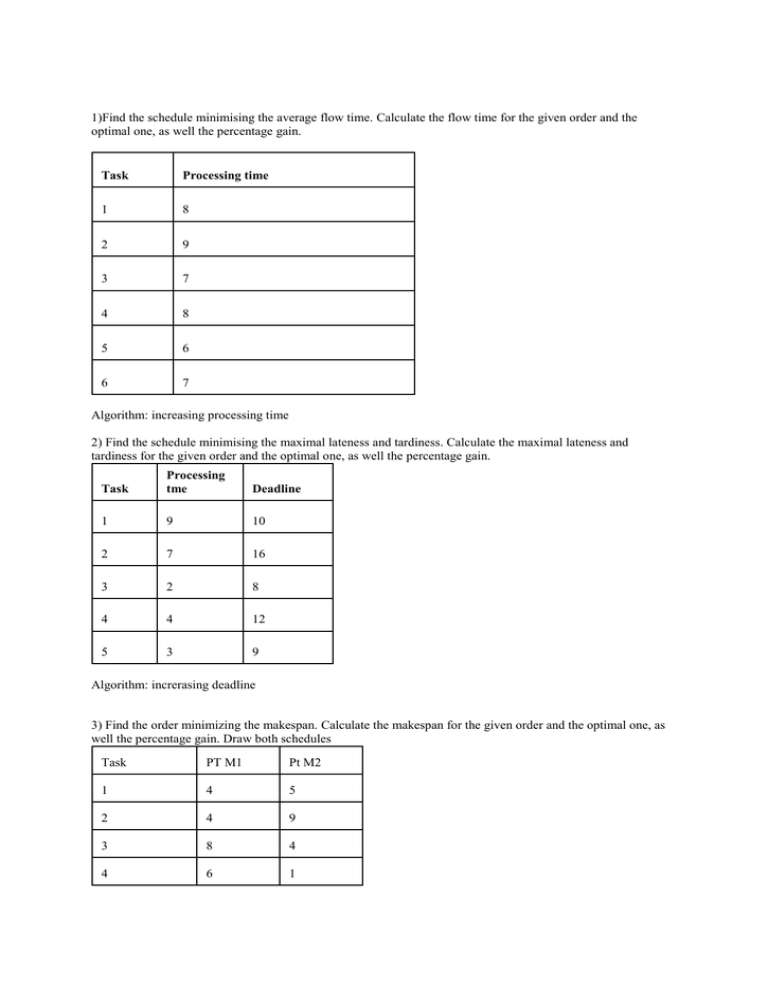

1)Find the schedule minimising the average flow time. Calculate the flow time for the given order and the optimal one, as well the percentage gain. Task Processing time 1 8 2 9 3 7 4 8 5 6 6 7 Algorithm: increasing processing time 2) Find the schedule minimising the maximal lateness and tardiness. Calculate the maximal lateness and tardiness for the given order and the optimal one, as well the percentage gain. Task Processing tme Deadline 1 9 10 2 7 16 3 2 8 4 4 12 5 3 9 Algorithm: increrasing deadline 3) Find the order minimizing the makespan. Calculate the makespan for the given order and the optimal one, as well the percentage gain. Draw both schedules Task PT M1 Pt M2 1 4 5 2 4 9 3 8 4 4 6 1 5 2 3 Johnson algorithm: 1. Find minimim of PT 2. If this min is on M2, place the task in the end (from the inner side), if o M1, in the beginning (from the inner side) , eliminate the element 3. If the table is empty, STOP, otherwise Step 1 4) ) Find the order minimizing the makespan. Calculate the makespan for the given order and the optimal one, as well the percentage gain. Draw both schedules Zadanie PT M1 PT M2 PT M3 1 5 8 3 2 4 5 9 3 4 1 5 4 3 1 7 Algorytm: 1) „Create” two machines: L1 (M1 + M2) i L2 (M2 + M3) 2) apply the Johnson algorithm 3) Draw the 3 machines schedule with the obtained order. 5) Conduct one simulation run of the below job-shop problem Task Arrival sequence and PT 1 0 M(4)- L(10) - D(2) 2 0 G(4)- D(2) - L(20) 3 20 D(3)- M(10) - L(10) 4 30 L(15) - G(8) - M(20) Applying a) The shortest processing time rule b) The minimal remaining processing time rule c) The minimal number of operations rule d) The first come first served rule 6) Determine the critical path and the slacks for the following project (algorithm plus EXCEL) Activity Duration predecessors A 5 - B 6 - C 3 A D 2 B E 4 C,D F 1 E For the below crashing times and costs, determine the cheapest way of crashing the project by n days. Activity Crash duration Total crashing cost A 3 100 B 5 400 C 1 500 D 1 600 E 2 700 F 1 - 7) A company makes two products (X and Y) using two machines (A and B). Each unit of X that is produced requires 40 minutes processing time on machine A and 20 minutes processing time on machine B. Each unit of Y that is produced requires 10 minutes processing time on machine A and 30 minutes processing time on machine B. At the start of the current week there are 40 units of X and 100 units of Y in stock. Available processing time on machine A is forecast to be 10 hours and on machine B is forecast to be 35 hours. The demand for X in the current week is forecast to be 75 units and for Y is forecast to be 95 units. Company policy is to maximise the combined sum of the units of X and the units of Y in stock at the end of the week. 8) A company is involved in the production of two items (X and Y). The resources need to produce X and Y are twofold, namely machine time for automatic processing and craftsman time for hand finishing. The table below gives the number of minutes required for each item: Item X Y Machine time Craftsman time 10 20 15 10 The company has 100 hours of machine time available in the next working week but only 50hours of craftsman time. Machine time is costed at £10 per hour worked and craftsman time is costed at £2 per hour worked. Both machine and craftsman idle times incur no costs. The revenue received for each item produced (all production is sold) is £30 for X and £10 for Y. The company has a specific contract to produce 20 items of X per week for a particular customer. 9) Blending problem Consider the example of a manufacturer of animal feed who is producing feed mix for dairy cattle. In our simple example the feed mix contains two active ingredients and a filler to provide bulk. One kg of feed mix must contain a minimum quantity of each of four nutrients as below: Nutrient gram A 30 B 50 C 20 D 20 The ingredients have the following nutrient values and cost Ingredient 1 (gram/kg) Ingredient 2 (gram/kg) A 10 22 B 80 15 C 40 20 D 10 20 Cost/kg 50 60 What should be the amounts of active ingredients and filler in one kg of feed mix? 10) Capital budgeting There are four possible projects, which each run for 3 years and have the following characteristics. Project 1 2 3 4 Available Capital requirements (£m) Year 1 2 3 0.5 0.3 0.2 1.0 0.8 0.2 1.5 1.5 0.3 0.1 0.4 0.1 3 3 3 Return (£m) 4 8 3 3 capital (£m) We have a decision problem here: Which projects would you choose in order to maximise the total return? What if at least, exactly, one of the projects 1 or 2 has to be selected? 11) Determine the shortest path in the below network (by means of the algorithm and using SOLVER) 2 6 4 3 5 1 4 1 8 6 4 12) Solve the below problem using the problem of the minimal path and SOLVER Demand: 31 I, 28 II, 31 III – 2 pieces Inventory capacity 2 pieces, 1 I and 31 III inventory empty Inventory cost (1 piece/1 month) 5, the production cycle takes exactly one month. Production cost: 1 piece: 13, 2 pieces: 14, 3 pieces: 16, 4 pieces: 18. Find the optimal production/inventory plan. 13) Solve the below (symmetric - complete the matrix) travelling salesman problem A A B C D E ∞ 2 4 5 4 ∞ 2 8 1 ∞ 4 2 ∞ 9 B C D ∞ E using a) The nearest neighbour heuristic b) the branching algorithm using Solver 14) Solve the below cheapest coverage problem A B C I 1 II III 1 IV 1 1 1 1 1 1 1 8 F 1 V VI E 1 1 1 D 5 2 6 1 1 1 3 3 Using a) Heuristics b) Solver Describe a real problem to which the cheapest coverage problem might be applied. 15) Find the shortest/longest path by means of the dynamic algorithm B D G A C E I H F AB – 300, AC – 280, BD-240, BE-180, BF-220, CD-250, CE-130, CF-190. DG-200, DH-250, EG-200, EH280, FG-150, FH-110, GI-220, HI-230. 16) . Solve the following problem and give an example of application 2 x1 x 2 max x1 2 x 2 30 3x1 5 x 2 20 x1 , x 2 0 17) Find the solution of the following knapsack problem (knapsack capacity 10), using the dynamic programming algorithm and the greedy algorithm Element 1 2 3 4 5 Volume 4 2 2 5 4 Value 9 5 9 2 5 18). Colour the map, using both algorithms learnt