The Collegiate Student Hydration Device A Rube-Goldberg Device

advertisement

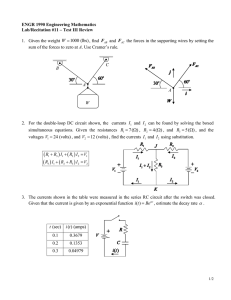

The Collegiate Student Hydration Device A Rube-Goldberg Device 26 April 2006 Team C1-7 Alexander Genaille William B. Nichols Kari Osborne William Calain Schuman Overview The project assigned was to devise a simple Rube-Goldberg device that would perform some simple task. The task chosen by the team was to dispense a beverage into a funnel for rapid consumption. The elevated device is initially set into motion by releasing a golf ball at the top of a ramp. Along the ramp, energy is conserved with the gravitational potential energy changing to kinetic energy. Close to the bottom of the ramp, an inelastic collision occurs between the moving golf ball and a stationary guillotine blade and they both continue down the ramp. At the bottom, the blade cuts a string of dental floss that is tied to one end of a hinged pivoting arm whose center of mass is balanced on a support. At the other end of the arm is a can of beverage. When the floss is cut, the center of mass of the arm is moved towards the can, causing the arm to pivot at the hinge dumping the contents of the can into a funnel and through a tube. The beverage travels through the funnel and tube to a thirsty individual waiting below the tube. The Design Process After being given the Rube Goldberg assignment, we came up with the idea of making a hydration device for chugging “beverages.” We originally came up with the idea to have a pool ball roll along a raised bored until it reached an inverted plane, but we scratched that idea when we decided the ball would lose control. The ball would then roll into a block with a razor blade mounted on top and then slide into dental floss. The pool ball was ditched in favor of a smaller and more controllable golf ball. After the floss was cut, a spring would be uncompressed causing a can to flip over into a funnel. We decided that the spring would have to be very stiff in order to push the can completely over the hinge, and a spring that stiff would break the floss holding it. Therefore we had to redesign how the aluminum can would change from the vertical position to the horizontal position without a spring. The concept of center of mass was discussed and the idea of a board with a support that balances the tension in the floss and weight of the can came into concept. The Construction Process Step One A 31.25” ramp was constructed out of .5”x4” wood. A grove was cut in the center of the broad side of the board as a track for the golf ball. The ramp is elevated by a 13.4” tall piece of .5”x4” wood. The ramp is attached to a base of plywood. Small strips of .5”x .5” wood were placed along the sides of the ramp at the bottom of the ramp to contain the cutting blade. A guillotine-style blade was constructed by gluing a razor blade to a small block of wood. Nails in the track provide a small amount friction on the sides of the blade to hold it up until the golf ball strikes it. Step Two A stand was constructed out of a 19” length of 2”x4” wood to hold a hinged .5”x4”wooden arm. A can koozie was attached to the top of one end of the arm and a nail was hammered into the side of the other end to provide a location to tie the floss. The stand was attached to the base with nails and wood glue. Step Three A stand was constructed out of 8.25” of 2”x4” wood to support a platform used to hold the funnel. A hole was cut in the center of the platform to allow the funnel and tube to be supported by the platform. Energy Conservation All calculations were performed without taking into consideration energy loss, and the datum is set at the base of the project. The following values were measured: Mcan= 0.024 slugs Mblade= 0.002 slugs Mball= 0.003 slugs The initial energy comes from a golf ball, which is released at the top of a ramp. Its gravitational potential energy becomes kinetic energy as it rolls down the ramp. The energy lost is due to friction between the ball and the track and a very small amount of air resistance. PEball=KEball + Eloss mghball=½mv2ball mghball=½mv2ball [(32.2 ft/s)(.96 ft)]/.5= v2ball 61.824 ft/s= vball2 7.86 ft/s=vball The momentum from the first step is transferred to a guillotine blade during the second step. A collision, which is assumed to be perfectly inelastic, occurs between the golf ball and the blade. The result is momentum of the blade, which was previously at rest. The blade’s velocity is calculated to determine its ability to cut a tensioned length of dental floss. Energy is lost in the form of heat, sound, and friction. mballvball+ mbladevblade= m(ball+blade)v(ball+blade) + Eloss (0.003 slugs)(7.86 ft/s) + (0.002 slugs)(0)=( 0.002 slugs +0.003 slugs) v(ball+blade) 4.7 ft/s= v(ball+blade) The tension in the length of dental floss, which is equal to the mass of the can, places the center of mass of the arm over a support which is in the direct center of the arm. The initial center of mass of the arm is directly over a hinge attached to a support, and can be calculated: x0=[(mtension)(xtension) + (mcan)(xcan)]/[mtension+mcan] x0=[(0.024 slugs)(-.375 ft) + (0.024 slugs)(.175 ft)]/[( 0.024 slugs)+( 0.024 slugs)] x0= -1.2 feet from the hinge When the tension is removed, the center of mass moves, which tilts the hinged arm towards the funnel to pour the beverage. The resulting center of mass of the arm can be calculated: x1=[(mcan)(xcan)]/(mcan) x1=[(0.024 slugs)(.175 in)]/( 0.024 slugs) x1= 2.1 feet from the hinge The final energy change is from the gravitational potential energy of the beverage to the kinetic energy of the beverage at the bottom of the funnel. The datum is set at the bottom of the funnel, and the energy loss is due to friction during the pouring of the beverage and its journey through the funnel. PE=KE+ Eloss mghbeverage=½mv2beverage (32.2 ft/s)(2 ft)= ½v2beverage 128.8=v2beverage 11.3 ft/s= vbeverage The CSHD is extremely inefficient. The initial energy put into the system is not directly related to the energy of the liquid being dispensed. The initial energy conversions only provide the trigger to release the final energy, which is initially in the form of gravitational potential energy. Cost Summary Materials Purchased Cost to Purchace Qty. Purchaced Amount Used Cost of Items Used Hinge $1.97 1 1 $1.97 Dental Floss $0.97 50 yard 1 yard ~$.02 Razor Blades $1.99 5 1 $0.40 Cost: $ 2.39 Materials Owned Plywood Wood- .5"x4" Nails Wood Glue Funnel & Tube Golf Ball Amount Used 3'x1.5' 10' 12 1/4 Bottle 1 1 $ Value: $ Total Cost to Construct: $ Value ~$3.00 ~$3.00 $1.00 $1 $5.00 1.50 14.50 16.89 Conclusion As a whole the design, construction, and operation of the Collegiate Student Hydration Device was a success. The design process simplified the process and also made it more reliable. Construction took about three hours, which is the amount of time we had planned on. The golf ball stays on its track, the blade cuts the floss, and a minimal amount of liquid is lost during the transfer. Team participation was evenly distributed with each member of the group focusing on one part of the project yet still contributing to each area. We did learn, however, that working with others can sometimes be difficult but if you stick to the task, it can be accomplished. Fortunately, our ideas worked when the device was constructed and no major design component had to be changed. We consider the overall project a success and the only thing we would do differently is make provisions for a larger beverage container.