Olives Olive Production Manual Louise Ferguson, G. Steven Sibbett, and George C. Martin

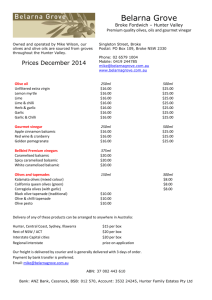

advertisement

Olives Olive Production Manual Louise Ferguson, G. Steven Sibbett, and George C. Martin Classification • Family - Oleaceae – Genera • Fraxinus (ash) • Ligustrum (privet) • Syringa (lilac) • Olea (olive) Olea europaea • • • • • Long lived evergreen trees Wood resists decay Top dies - stock sprouts Roots only 3 - 4 ft (1 m) deep Dense foliage, poor light penetration, cascading multiple branches, heavy fruit on terminals Leaves • Thick, leathery, oppositely arranged • Each leaf grows for 2 yrs – Spring abscission in 2 to 3 years • Stomata on lower surface only – nestled in peltate trichomes Cultivars • Ascolano 9 gm / 18.8% Blk Grn • Manzanillo 5 gm / 20% Fr, Blk, Oil • Sevillano 13.5 gm / 14.4% Blk, Grn, SpGm • Barouni 7.4 gm / 16.5% Fr Blk • Mission 4.1 gm / 21.8% Blk Gr Oil Manzanillo • • • • • • Most widely planted Most popular for canning Low spreading 15 - 30 ft. Rooted Stem cuttings Not tolerant to cold Olive knot - Verticillium wilt Sevillano • • • • • • • Second most popular Spreading 25 - 35 ft tall Trained low for easy harvest Largest fruit in California Grafting 1 yr rooted cuttings Somewhat resistant to cold Bruises easily Ascolana • • • • • Rounded shape 20 - 30 ft tall Bruises easily Only 3 % of acreage in CA Canned ripe olives Fairly resistant to olive knot Mission • • • • • • From Mexico in 1769, not Italy Tall upright, 40 - 50 ft Topped to facilitate harvest Small, low 6.5 : 1 fruit-to-pit ratio Rooted cuttings Trees survive 8oF Mission Harvest • Picked green - Spanish Green Processing because they are late and need to avoid frost. • Red coloration - Ripe olive processin • For oil because of high (21.8% oil) • High monounsaturated fatty acid Barouni • • • • • • From Tunisia in 1905 Small tree 15 - 25 ft. spreading Large fruit, low fruit to pit ratio Resistant to cold For fresh use - process quality low Used for black-ripe table olives Flowering • • • • Summer 2000 - Induction in veg buds Nov. 2000 - Floral induction Winter 2000 / 2001 - Chilling Spring 2001 - Flowers open Chilling is Critical • Optimum Flowering if chilling temps – Maximum 60 to 65oF – Minimum 35 to 40oF • Poor flowering if – Constant 55oF • No flowering if – No temp > 45oF or < 60oF Influence of Leaves • Very little dormancy – Veg. Buds grow at or > 70oF • Inflorescence formation – Requires leaves on fruiting shoots – Thus, prevent defoliation • Hot winds can defoliate Flower Buds • Abnormally cold spring temps – Detrimental to flower buds • Floral differentiation 8 - 10 weeks before May bloom – Irrigate to prevent stress – Start season with moist profile • Playing catch up will not do Stress • Causes predominance – Of male flowers – Why? • Girdling can increase flowering – Danger of Olive Knot – Not a problem in Israel – Root reduction Pollination • Monoecious • Flowers borne axially along shoot in panicles • Self and cross pollination occurs Fruit Set • 500,000 flowers per tree • Need maximum of 10,000 fruit (2%) – 98% abscise in 14 days – Goal is 3 tons per acre yield • Sometimes insufficient perfect flowers to set full crop • Need 10% set if inflorescence limited Fruit Formation • • • • Embryo development Mature ovule (seed) Mature ovary (fruit) Requires rapid pollen growth – Delays caused by cool temperature • Parthenocarpic fruit (shotberries) Sigmoidal Fruit Growth • Endocarp (pit) enlarges to full size and hardens in 6 weeks • Endosperm (liquid to solid) • Embryo development • Embryo maturity (September) Maturation • Gradual growth – Mesocarp (flesh) – Exocarp (skin and peel) • Color change (harvest index) – Green straw (optimal) Red (maybe) Black (unacceptable) Harvesting • Profit or loss depends on accuracy of harvest in October • Delaying harvest = heavier fruit (more valuable) • Delaying too long = black fruit & frost damage • Oil content increases in January Fruit Thinning to Avoid Alternate Bearing • Hand thinning – Both hands - heavy rubber gloves – Strip fruit while leaving leaves • Leave 6 fruit / foot of twig • Complete 3 weeks after full bloom • Effective but not cost effective Thinning by Pruning • Prune more heavily on “on” years • Prune more lightly on “off” years • However, not cost effective Chemical Thinning • NAA effective but must treat prior to knowledge of crop size • Treat 12-18 days after full bloom (FB) • Apply 10 ppm for each day after FB – 15 days after FB = 150 ppm – Dilute spray (300 - 400 gal water per acre Thinning Ornamental Olives • Olives in landscape are more desirable if all the fruit are removed • Use 200 ppm 2-3 days before FB – Use second spray 1 week later • Large trees require power sprayer – 10 - 15 gal per tree • Detrimental if temperature > 100oF Processing Olives • Types – Black-ripe (BR) - 99% in CA – California-style green – Spanish-style green (<1%) • Pickling - process of adding lactic or acetic acid Chemical Composition of Ripe Mission Olives (%) • • • • • • Water Brix Oil Sugars Protein Mannitol 55.0 13.1 21.4 4.6 1.7 4.4 Oleuropein • A glucoside (bitter factor in fresh olives) • Destroyed by dilute alkali at room temperature • Remove alkali (1 - 2% lye) and bitterness does not return Pigments • • • • • Anthocyanins are major pigment Increases until fruit is ripe Decreases in overripened fruit Light increases formation 10 times more anthocyanin in fruit ripened in light vs dark Salt Free Storage • Acidulant solution – 0.67% lactic acid – 1.00% acetic acid – 0.30% sodium benzolate – 0.30% potassium sorbate Traditional Brine System • Concrete or wooden tanks • Capacity - 20 tons • 5.0 - 7.5% NaCl – 20 - 30o Salometer – Saturated solution - 26.5% salt = 100o on Salometer Storage Containers • Open-top redwood tanks 5x6 ft • Holds 2.5 tons of olives • Polyethylene 6 mil plastic prevents contact between olives and inside of tank • No fermentation in this system • Flavor better than in brine California Style Black Olives • Paraffin or plastic lined 20 T tank • Four overhead pipes – Water – Dilute dye – Dilute brine – Compressed air Lye (NaOH) Treatment • 3 - 5 applications of 0.5 - 1.5% • Better color by – Reducing lye concentration – Increasing treatment numbers – Reducing duration Color Formation • Lye helps – Natural phenolic compounds to oxidize and polymerize – Causing formation of black pigment – Provided aeration is present Calcium Helps Fix Color • Color formation most rapid at 8.0 to 9.5 pH • Retention better in hard water • Ca(Cl)2 (0.1 - 0.5%) improves color retention Lye Removal • Lye removed by changing water in tanks at least twice daily • Solution stirred frequently with paddles of compressed air • Lye removed in 3 - 4 days Canning • 7.0 - 7.5 pH at time of canning retains color • Packed in C-enamel lined cans • Filled with 2 - 2.5 % salt brine • Cans exhausted at 199 to 205oF for 5 min to reach 170oF or higher Finish Canning • Rebrined and sealed at 170oF in a double seamer • Olives in glass containers processed in retort for 70 min. at 240oF Spanish-Style Pickled Green Olives • Fruit reaches full size but harvested before color changes • Promptly placed in shallow paraffin or plastic-coated concrete pickling vats Lye Treatment • Dilute lye (1.25 - 1.75%) at 54 - 70oF penetrates 3/4 way to pit in 8 - 12 hrs. • Small amt of untreated bitter flesh characteristic of green olives • 1 drop of phenolphthalein to cut surface shows depth of lye penetration Post Lye Treatment • Olives washed in cold H2O 24-36 hrs • Water changed every 4 - 6 hrs • Then response to indicator very faint Fermentation • Washed, lye-treated olives transferred to 50 gal oak barrels • Head replaced and hoops driven • 11% brine added through side bung – Lactic acid content 0.8 - 1.2% – 3.8 pH or less • Fermentation at 75 - 80oF for 1-12 mo Producing Olive Oil • Spain, Italy, and Greece (in that order) produce 80% of world’s oil • They consume 75% • USA < 1% of world’s olive oil • International Olive Oil Agreement • Administered by International Olive Oil Council in Madrid, Spain Fatty Acid Profile • • • • • • • • Oil Saturated Unsaturated Mono Poly Olive 1st CP 3 88 9 Olive 2nd CP 11 83 5 Pecan C P 9 73 18 Cardin Pecan 5 85 10 Walnut EP 9 18 73 CP = Cold Pressed, EP= Expeller Pr Definition of Olive Oil • Olive oil - obtained solely from olives • Excludes oil extracted by solvents or reesterification processes, or any mixtures with other oils • Pure olive oil cannot be any olive residue oils Virgin Oil • Mechanically pressed from olive fruit without using heat - cold pressing • Only washed, decantation, and centrifugation (natural product) • May have vintage years on label Grades of Virgin Oil • Virgin Olive Oil Extra – Extra Vergine (Italian) – Vierge Extra (French) • Pure unadulterated oil from top quality olives • Perfect taste and odor • Max of 1% acid and strong odors Other Olive Oils • Virgin Olive Oil Fine or Fino – Almost perfect taste but 1.5% acid • Semi-fine or Ordinary Olive Oil – Good taste maximum acidity 3.3% • Virgin Olive Oil Lampante > 3.3% – Not for human consumption Poorer Grades • Refined oils – Caustic soda used to purify virgin oil from cull fruits • Blended oil – Blend of refined and virgin oil – Most imported olive oil in USA Residue Oil • Olive-residue oil obtained by treating pomace with solvents THE END