WELCOME CUSTOMIZED ENVIRONMENTAL TRAINING UNDERGROUND STORAGE TANKS

advertisement

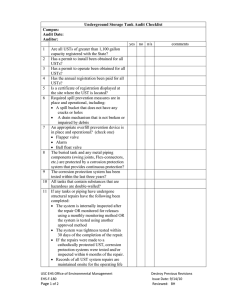

UNDERGROUND STORAGE TANKS CUSTOMIZED ENVIRONMENTAL TRAINING WELCOME UST 1/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. INSTRUCTOR Insert Instructor Name Here UST 2/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. OBJECTIVES Define Underground Storage Tanks (USTs) Discuss the Pollution Problem Associated with USTs. Discuss Regulations Applicable to USTs. Discuss Leak Detection Requirements. Discuss Upgrade Requirements. Discuss Financial Responsibility. Discuss Tank Closure. Discuss Reports and Records. Recommend Inspection Items. Discuss Use of Contractors. UST 3/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. GOALS Understand the Definition of USTs. Understand Why UST Compliance is Important. Understand the Need for Leak Detection and Be Familiar with the Different Types of Leak Detection. Be Familiar With Upgrade Requirements. Understand the Concept of Financial Responsibility. Understand the Different Types of Closure. Be Familiar With Required Reports and Records. UST 4/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. BACKGROUND EPA estimates there are 1.1 million underground storage tanks located at 400,000 sites throughout the United States. Nearly all tanks built prior to 1984 were built only of steel and eventually leak. New RCRA regulations written in 1984 require upgrades to underground storage tanks to prevent leaking. Nearly 50% of the U.S. population receives its drinking water from groundwater. Leaks from underground storage tanks threaten the safety of drinking water. UST 5/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. LEARNERS Supervisors Facility Engineers Maintenance Personnel Department Managers Building Occupants Process Specialists Environmental and Safety Committees UST 6/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. OVERVIEW The goal of this course is to provide supervisors with the tools needed to help prevent Underground Storage Tanks from leaking. It recommends practical, actions that can be carried out by facility management, maintenance personnel and building occupants. The course will help you to integrate good UST management activities into your existing organization and identify which of your staff have the necessary skills to carry out those activities. UST 7/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. WHAT THIS COURSE DOES NOT DO The course is not intended to provide information to install, repair, calibrate equipment or remove USTs. These specialties required training beyond the intended scope of this course. Where this expertise is needed, outside assistance should be solicited. UST 8/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. RESOURCE CONSERVATION AND RECOVERY ACT (RCRA) RCRA addresses both hazardous waste and solid waste. Subtitle I addresses leaking Underground Storage Tanks (USTs) UST 9/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. FEDERAL REGULATIONS Pertinent Regulations: 40 CFR 280 Subparts A-G – Technical Standards and Corrective Action Requirements for Owners and Operators of Underground Storage Tanks (USTs). 40 CFT 280 Subpart H – Financial Responsibility for USTs. 40 CFR 281 – Approval of State Underground Storage Tank Programs. UST 10/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. WHAT IS AN UNDERGROUND STORAGE TANK? Tanks that have 10 percent or more of their volume below the surface of the ground. This includes the tank, connected underground piping, underground ancillary equipment, and containment system. Further, this definition specifically pertains to UST systems that contain regulated substances such as solvents, methanol, and ethylene glycol (anti-freeze). UST 11/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. TANK REGISTRATION UST owners are required to notify designated State or local agencies of the existence of their tanks or when the tanks are taken out of service. UST owners are required to provide information on the age, size, type, location, and use of each tank when a tank is newly registered. Notification must occur within 30 days of bringing the tank into use. UST 12/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. LEAK DETECTION REQUIREMENTS UST 13/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. THIRD-PARTY EVALUATION Look For The "Proof" Of A Third-Party Evaluation This evaluation should show that a leak detection system can work as designed. EPA and third parties have developed evaluation procedures for all leak detection systems. Be familiar with the evaluation’s "results" form and, when provided, its "description" form. UST 14/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. “PROBABILITIES” OF LEAK DETECTION The regulations require not only that leak detection methods be able to detect certain leak rates, but that they also give the correct answer consistently. In general, methods must detect the specified leak rate with a probability of detection of at least 95 percent and a probability of false alarm of no more than 5 percent. Simply stated, this means that, of 100 tests of USTs leaking at the specified rate, at least 95 of them must be correctly detected. It also means that, of 100 tests of nonleaking USTs, no more than 5 can be incorrectly called leaking. This is what is meant by the "probabilities" noted in this course. UST 15/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. WHICH LEAK DETECTION IS BEST? There is no one leak detection system that is best for all sites. There is no one leak detection system that is consistently the least expensive. Identifying the best leak detection choice for your UST depends on a number of factors including: - Cost - Facility configuration - Groundwater depth - Soil type, seasonal rainfall and temperature ranges, availability of experienced installers, and other variables. UST 16/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. REFERENCES Use experienced, professional vendors and installers of leak detection. Your state may also have an assistance fund that may be able to help you pay for your UST's leak detection. EPA provides a free publication— List Of Leak Detection Evaluations For UST Systems. UST 17/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. SECONDARY CONTAINMENT WITH INTERSTITIAL MONITORING UST 18/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. SECONDARY CONTAINMENT WITH INTERSTITIAL MONITORING How does the Leak Detection Method work? Secondary containment provides a barrier between the tank and the environment. The barrier is shaped so that a leak will be directed towards the interstitial monitor. Barriers include: - Double-walled or "jacketed" tanks - Concrete vaults, with or without lining; - Internally fitted liners (“bladders”); and - Leak proof excavation liners that surround the tank. Clay and other earthen materials cannot be used UST 19/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. SECONDARY CONTAINMENT WITH INTERSTITIAL MONITORING Interstitial Monitors Monitors are used to check the area between the tank and the barrier for leaks and alert the operator. Some monitors indicate the physical presence of the leaked product, either liquid or gaseous. Other monitors check for a change in condition that indicates a hole in the tank. Monitors can be as simple as a dipstick or they can be sophisticated automated systems that continuously check for leaks. UST 20/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. SECONDARY CONTAINMENT WITH INTERSTITIAL MONITORING What are the Regulatory Requirements? The barrier must be immediately around or beneath the tank. The interstitial monitor must be checked at least once every 30 days. A double-walled system must be able to detect a release through the inner wall. There are restrictions on the excavation liner. A bladder must be compatible with the product stored and must be equipped with an automatic monitoring device. UST 21/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. SECONDARY CONTAINMENT WITH INTERSTITIAL MONITORING Will it work at your site? In areas with high groundwater or a lot of rainfall, it may be necessary to select a secondary containment system that completely surrounds the tank. Works effectively only if the barrier and the interstitial monitor are installed correctly. Trained and experienced installers are necessary. UST 22/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. AUTOMATIC TANK GAUGING SYSTEMS UST 23/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. AUTOMATIC TANK GAUGING SYSTEMS How does the Leak Detection Method Work? The product level and temperature in a tank are measured continuously and automatically analyzed and recorded by a computer. In the "inventory mode," the ATGS replaces the use of the gauge stick to measure product level and perform inventory control. In the "test mode," the tank is taken out of service and the product level and temperature are measured for at least one hour. Some methods combine aspects of automatic tank gauges with statistical inventory reconciliation. UST 24/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. AUTOMATIC TANK GAUGING SYSTEMS What are the Regulatory Requirements? The ATGS must be able to detect a leak of 0.2 gallons per hour Will it Work at Your Site? ATGS have been used primarily on tanks containing gasoline or diesel, with a capacity of up to 15,000 gallons. Water around a tank may hide a leak by temporarily preventing the product from leaving the tank. To detect a leak in this situation, the ATGS should be capable of detecting water in the bottom of a tank. UST 25/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. AUTOMATIC TANK GAUGING SYSTEMS Anything else you should consider? Probe should be permanently installed. Probe should be connected to a display console. Should be equipped with alarms for high and low product level, high water level, and theft. ATGS can be linked with computers at other locations For “non-continuous" type ATGS, no product should be delivered or withdrawn from tank for at least 6 hours before the monthly test or during the test. An ATGS can be programmed to perform a test more often than once per month (a recommended practice). UST 26/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. VAPOR MONITORING UST 27/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. VAPOR MONITORING How does the leak detection method work? Vapor monitoring senses or measures "fumes" from leaked product in the soil around the tank. Fully automated vapor monitoring systems have permanently installed equipment to continuously or periodically gather and analyze vapor samples. Manually operated vapor monitoring systems range from equipment that immediately analyzes a gathered vapor sample to devices that gather a sample that must be sent to a laboratory for analysis. Manual systems must be used at least once a month to monitor a site. Devices need to be periodically calibrated. UST 28/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. VAPOR MONITORING What are the Regulatory Requirements? Backfill must be sand, gravel or another porous material. Backfill should be clean. The substance stored in the UST must vaporize easily. Some vapor monitoring systems do not work well with diesel fuel. High groundwater, excessive rain, or other sources of moisture must not interfere with the operation of vapor monitoring for more than 30 consecutive days. Monitoring wells must be secured and clearly marked. UST 29/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. VAPOR MONITORING Will it Work at Your Site? Before installing a vapor monitoring system, a site assessment must be done to determine whether vapor monitoring is appropriate at the site. A site assessment usually includes: – Groundwater level, – Background contamination – Stored product type – Soil type UST 30/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. GROUNDWATER MONITORING UST 31/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. GROUNDWATER MONITORING How does the Leak Detection Method work? Uses permanent monitoring wells placed close to the UST. The two main components of a groundwater monitoring system are the monitoring well (typically a well of 2-4 inches in diameter) and the monitoring device. Detection devices may be permanently installed in the well for automatic, continuous measurements for leaked product. Detection devices are also available in manual form. Manual devices must be used at least once a month. UST 32/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. GROUNDWATER MONITORING How does the leak detection method work? continued Before installation, a site assessment is necessary to determine the soil type, groundwater depth and flow direction, and the general geology of the site. The number of wells and their placement is very important. A minimum of two wells is recommended for a single tank excavation. Three or more wells are recommended for an excavation with two or more tanks. Some state and local agencies have developed regulations for monitoring well placement. UST 33/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. GROUNDWATER MONITORING What are the Regulatory Requirements? Used if the stored substance does not easily mix with water and floats on top of water. If it is the sole method of leak detection, the groundwater must not be more than 20 feet below the surface with course soil between the well and UST. Product detection devices must detect 1/8 inch or less of leaked product on top of the groundwater. Monitoring wells must be properly designed and sealed and be clearly marked and secured. Wells should be placed in the UST backfill so that they can detect a leak as quickly as possible. UST 34/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. GROUNDWATER MONITORING Will it Work at Your Site? In general, groundwater monitoring works best at UST sites where: - Monitoring wells are installed in the tank backfill; and - There are no previous releases of product that would falsely indicate a current release. A professionally conducted site assessment is critical for determining these site-specific conditions. UST 35/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. STATISTICAL INVENTORY RECONCILIATION (SIR) Will You be in Compliance? Statistical Inventory Reconciliation (SIR), when performed according to the vendor's specifications, meets federal leak detection requirements for USTs if: SIR has a 0.2 gallon/hour leak detection capability meets the federal requirements for monthly monitoring for the life of the tank and piping. UST 36/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. STATISTICAL INVENTORY RECONCILIATION (SIR) How does the Leak Detection Method Work? It analyzes inventory, delivery, and dispensing data collected over a period of time. Each operating day, the product level is measured. You also keep complete records of all withdrawals from and all deliveries to the UST. After data has been collected for the period of time required by the SIR vendor, you provide the data to the SIR vendor. The SIR vendor uses sophisticated computer software to conduct a statistical analysis of the data. The SIR vendor provides you with a test report of the analysis. Some methods combine aspects of automatic tank gauges with statistical inventory reconciliation. UST 37/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. STATISTICAL INVENTORY RECONCILIATION (SIR) What are the Regulatory Requirements? Must be able to detect a leak at least as small as 0.2 gallons per hour. Data must be submitted at least monthly. Must be evaluated with a test procedure to certify that it can detect leaks at the required level. The method’s evaluation must reflect the way the method is used in the field. If the test report is not conclusive, you must take the steps to lead to finding out if tank is leaking. Must keep test reports and documentation that the SIR method used is certified as valid for your UST system on file. UST 38/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. STATISTICAL INVENTORY RECONCILIATION (SIR) Will it Work at Your Site? SIR has been used primarily on tanks no more than 18,000 gallons in capacity. A SIR method’s ability to detect leaks declines as throughput increases. Water around a tank may hide a hole in the tank or distort the data to be analyzed by temporarily preventing a leak. To detect a leak in this situation, you should check for water at least once a month. UST 39/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. STATISTICAL INVENTORY RECONCILIATION (SIR) Anything Else You Should Consider? Data should all be carefully collected according to the SIR vendor's specifications. Poor data collection produces inconclusive results and noncompliance. Requires detailed filling out of forms. Not to be confused with other release detection methods that also rely on periodic reconciliation of inventory, withdrawal, and delivery data. UST 40/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. TANK TIGHTNESS TESTING WITH INVENTORY CONTROL Will you be in compliance? • NO! This method was allowed prior to December 22, 1998 as a temporary method. You must use one of the previous mentioned methods for leak detection. • Though the use of tank tightness testing with inventory control alone cannot be used for leak detection, it could be used as a secondary means to help confirm a leak. UST 41/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. MANUAL TANK GAUGING Will You be in Compliance? Manual tank gauging can be used only on tanks 2,000 gallons or less capacity. Tanks 1,000 gallons or less can use this method alone. Tanks from 1,0012,000 gallons can temporarily use manual tank gauging only when it is combined with tank tightness testing. Manual tank gauging cannot be used on tanks over 2,000 gallons. Manual tank gauging detects leaks only from tanks and does not detect piping leaks. UST 42/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. MANUAL TANK GAUGING How does the Leak Detection Method Work? EPA has a booklet, Manual Tank Gauging, that fully explains how to do manual tank gauging correctly. Four measurements of the tank's contents must be taken weekly, two at the beginning and two at the end of at least a 36-hour period. The average of the two consecutive ending measurements are subtracted from the average of the two beginning measurements to indicate the change in product volume. Every week, the calculated change in tank volume is compared to the standards shown in the table on the next slide. UST 43/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. MANUAL TANK GAUGING Tank Size Min. Weekly Monthly Duration of Standard (1 Standard (4Test Test) test Average) Up to 550 gallons 36 hours 10 gallons 5 gallons 551-1000 gallons (when tank diameter is 64”) 44 hours 9 gallons 4 gallons 551-1000 gallons (when tank diameter is 48”) 58 hours 12 gallons 6 gallons 551-1000 gallons (requiring tank tightness testing) 36 hours 13 gallons 7 gallons 1,001-2000 gallons 36 hours 26 gallons 13 gallons (requires tank tightness testing) UST 44/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. MANUAL TANK GAUGING Anything Else You Should Consider? You can perform manual tank gauging yourself. Correct gauging, recording, and math are the most important factors for successful tank gauging. The accuracy of tank gauging can be greatly increased by spreading product-finding paste on the gauge stick before taking measurements. UST 45/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. LEAK DETECTION FOR UNDERGROUND PIPING Will You be in Compliance? When installed and operated according to the manufacturer's specifications, the leak detection methods discussed here meet the federal regulatory requirements for the life of underground piping systems. UST may have suction or pressurized piping. UST 46/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. LEAK DETECTION FOR UNDERGROUND PIPING What are the Regulatory Requirements for Suction Piping? No leak detection is required if the suction piping has: (1) enough slope so product in the pipe drains back into the tank when suction is released and (2) has only one check valve, located close beneath the pump in the dispensing unit. If a suction line does not meet all of the design criteria noted above, other monthly monitoring that meets performance standards can be used. Must detect a leak as small as 0.1 gallon/hour. Interstitial monitoring, vapor monitoring, groundwater monitoring, and SIR have the same regulatory requirements for piping as they do for tanks. UST 47/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. LEAK DETECTION FOR UNDERGROUND PIPING What are the Regulatory Requirements for Pressurized Piping? Each pressurized piping run must have one leak detection method from each set below: An Automatic Line Leak Detector: Automatic flow restrictor; or automatic flow shutoff; or continuous alarm system. And One Other Method: Annual line tightness test; or Monthly interstitial monitoring; or Monthly vapor monitoring; or Monthly groundwater monitoring; or Monthly SIR; or Other monthly monitoring that meets performance standards. UST 48/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. LEAK DETECTION FOR UNDERGROUND PIPING The automatic line leak detector (LLD) must be designed to detect a leak as small as 3 gallons/ hour at a line pressure of 10 pounds per square inch within 1 hour by shutting off the product flow, restricting the product flow, or triggering an audible or visual alarm. The line tightness test must detect a leak as small as 0.1 gallon/hour when the line pressure is 1.5 times its normal operating pressure. The test must be annual. Automatic LLDs and line tightness tests must meet the federal requirements for probabilities of detection and false alarm. Interstitial monitoring, vapor monitoring, groundwater monitoring, and SIR have the same regulatory requirements for piping as they do for tanks. UST 49/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. LEAK DETECTION FOR UNDERGROUND PIPING How do the Leak Detection Methods work? •Automatic line leak detectors (LLDs) •Flow restrictors and flow shutoffs can monitor the pressure within the line in a variety of ways. •If a suspected leak is detected, a flow restrictor keeps the product flow through the line well below the usual flow rate. If a suspected leak is detected, a flow shutoff completely cuts off product flow. •A continuous alarm system constantly monitors line conditions. •Both automatic flow restrictors and shutoffs are permanently installed directly into pipe or pump housing. UST 50/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. LEAK DETECTION FOR UNDERGROUND PIPING Line Tightness Testing Tracer methods use a tracer chemical to determine if there is a hole in the line. With tracer methods, all of the factors below may not apply. The line is taken out of service and pressurized, usually above the normal operating pressure. A drop in pressure over time, usually an hour or more, suggests a possible leak. Most line tightness tests are performed by a testing company. Some permanently installed electronic systems (which often include ATGS) can meet the requirements of monthly monitoring for a line tightness test. UST 51/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. LEAK DETECTION FOR UNDERGROUND PIPING Secondary containment with interstitial monitoring A barrier is placed between the piping and the environment. Double-walled piping or a leakproof liner in the piping trench can be used. A monitor is placed between the piping and the barrier to sense a leak if it occurs. Monitors range from a simple stick to continuous automated systems that monitor for the presence of liquid product or vapors. Proper installation of secondary containment is the most important and the most difficult aspect of this leak detection method. Secondary containment for piping is similar to that for tanks. UST 52/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. LEAK DETECTION FOR UNDERGROUND PIPING Vapor or Groundwater Monitoring Vapor monitoring detects product that leaks into the soil and evaporates. Groundwater monitoring checks for leaked product floating on the groundwater near the piping. A site assessment must be used to determine monitoring well placement and spacing. UST systems using vapor or groundwater monitoring for the tanks are well suited to use the same monitoring method for the piping. Use of these methods with piping is similar to that for tanks. UST 53/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. UPGRADE REQUIREMENTS As of December 22, 1998, all UST systems must be upgraded to include: Corrosion protection Installing devices to protect against spills and overfills. Without the protection provided by upgrading, USTs are more likely to leak, be damaged by the environment, or possibly open you to third-party lawsuits, and leave you with costly cleanups. UST 54/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. UPGRADE REQUIREMENTS Corrosion Protection Federal rules require corrosion protection for UST systems because unprotected steel USTs and piping corrode and release product through corrosion holes. Existing steel tanks must be upgraded to meet one of the following requirements according to a code of practice developed by a nationally recognized organization or independent testing laboratory. You have three options for upgrading existing steel USTs: 1.Interior lining 2.Cathodic protection 3.Internal lining combined with cathodic protection. UST 55/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. UPGRADE REQUIREMENTS The interior of a structurally sound tank may be lined with a thick layer of noncorrodible material. Tanks using only an interior lining for corrosion protection must pass an internal reinspection in 10 years and every 5 years after that to make sure that the lining (and tank itself) is sound. You must keep records of these inspection results. UST 56/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. UPGRADE REQUIREMENTS Cathodic protection is one option for protecting an UST from corrosion. There are two types of systems for cathodic protection: 1.Sacrificial Anode, and 2.Impressed Current. UST 57/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. UPGRADE REQUIREMENTS Regulations require that the cathodic protection systems installed at UST sites be designed by a corrosion expert. Must be tested by a qualified cathodic protection tester within 6 months of installation and at least every 3 years thereafter. Need to keep the results of the last two tests to prove that the cathodic protection is working. Must inspect an impressed current system every 60 days to verify that the system is operating. Keep results of your last three 60-day inspections to prove that the impressed current system is operating properly. UST 58/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. UPGRADE REQUIREMENTS It should be noted that prior to adding cathodic protection, the integrity of the UST must be ensured using one of the following methods: UST is internally inspected UST has been installed for less than 10 years and uses monthly monitoring for releases, UST has been installed for less than 10 years and is assessed for corrosion holes by conducting two tightness tests Alternative Integrity Assessment: UST is assessed for corrosion holes by a method that is determined by the implementing agency UST 59/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. UPGRADE REQUIREMENTS Spill Protection USTs must have catchment basins to contain spills. New USTs must have catchment basins when they are installed--older tanks can have catchment basins retrofitted to them. You and your fuel deliverer must follow industry standards for correct filling procedures. UST 60/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. UPGRADE REQUIREMENTS Basically, a catchment basin is a bucket sealed around the fill pipe. Basins range in size from those capable of holding only a few gallons to those that are much larger--the larger the catchment basin, the more spill protection it provides. There needs to be a way to remove liquid from catchment basins. Keep water out of catchment basins. UST 61/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. CORRECT FILLING PROCEDURES Correct Filling Practices Many releases at UST sites come from spills. Spills often occur at the fill pipe when the delivery truck's hose is disconnected. Though these spills are usually small, repeated small releases can cause big environmental problems. Human error causes most spills. These mistakes can be avoided by following standard tank filling practices. If an UST never receives more than 25 gallons at a time, the UST does not have to meet the spill protection requirements. UST 62/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. OVERFILL PROTECTION Overfill Protection USTs must have overfill protection. New USTs must have overfill protection devices when they are installed. The three main types of overfill protection devices are: 1.Automatic shutoff devices, 2.Overfill alarms, and 3.Ball float valves You and your fuel deliverer must follow industry standards for correct filling practices. UST 63/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. AUTOMATIC SHUTOFF DEVICE An automatic shutoff device installed in an UST's fill pipe can slow down and then stop the delivery when the product has reached a certain level in the tank. Some automatic shutoff devices work in two stages. The first stage drastically reduces the flow of product to alert the driver that the UST is nearly full. The second stage stops delivery completely. UST 64/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. OVERFILL ALARMS Overfill alarms use probes installed in the tank Alarms activate when the tank is either 90 percent full or within 1 minute of being overfilled. Either way, the alarm should provide enough time for the driver to close the truck's shutoff valve before an overfill happens. Alarms must be located where the driver can see or hear them easily. Overfill alarms are often a part of automatic tank gauging systems. UST 65/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. BALL FLOAT VALVES Ball float valves are fitted on the bottom of the vent line and hang down several inches below the top of the UST. When the product level is below the cage, the ball rests at the bottom of the cage and the vent line is open. As the level of the product rises, the ball floats on the product and rises in the cage. The ball eventually seats in the vent line and restricts vapor flowing out the vent line BEFORE the tank is full. UST 66/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. OVERFILLS Overfills usually release much larger volumes than spills. You can solve overfill problems by: - Making sure there is enough room in the tank for the delivery BEFORE the delivery is made; - Watching the entire delivery to prevent overfilling or spilling; and - Using overfill protection devices. If an UST never receives more than 25 gallons at a time, the UST does not have to meet the overfill protection requirements. UST 67/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. UST System Upgrading Requirements Equipment Corrosion Protection Method New Tanks 3 Choices 1. Coated and Cathodically Protected Steel 2. Fiberglass 3. Steel Tank Clad with Fiberglass Existing Tanks 4 Choices 1. 2. 3. 4. UST 68/82 Same Options as for New Tanks Add Cathodic Protection System Interior Lining Interior Lining and Cathodic Protection © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. UST System Upgrading Requirements Equipment New Piping 3 Choices Existing Piping 2 Choices UST 69/82 Corrosion Protection Method 1. Coated and Cathodically Protected Steel 2. Fiberglass 3. Another Approved Material 1. Same Options as for New Piping 2. Cathodically Protected Steel © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. UST System Upgrading Requirements Equipment All Tanks UST 70/82 Spill/Overfill Prevention Method • Catchment basins -andAutomatic Shutoff Devices -or • Overfill Alarms -or • Ball Float Valves © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. FINANCIAL RESPONSIBILITY Subpart H of the federal underground storage tank (UST) regulations require UST owners and operators to demonstrate financial responsibility. Financial responsibility ensures the timely completion of corrective action and third-party compensation and thus reduces the risk to human health and the environment posed by leaks. The financial responsibility regulations can be met in several ways. UST 71/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. CLOSURE Tank closure is one way to help protect human health and the environment, particularly groundwater, from the threats posed by many older underground storage tanks. Closure of a UST can be either temporarily or permanently. UST 72/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. CLOSURE Closing Temporarily You may temporarily close UST for up to 12 months by following these requirements for temporary closure: - Monitor for leaks maintaining UST's leak detection. - Monitor and maintain any corrosion protection systems. - If a release is discovered, quickly stop the release, notify your regulatory authority, and take appropriate action to clean up the site. If the UST remains temporarily closed for more than 3 months, leave vent lines open, but cap and secure all other lines, pumps, man ways, and ancillary equipment. UST 73/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. CLOSURE After 12 months of Temporary Closure, You have Three Options: 1.You must permanently close your UST if it doesn't meet the applicable requirements. 2. You can ask your regulatory authority for an extension beyond 12 months, if you provide an assessment that determines whether contamination is present at your site. 3.Your UST can remain temporarily closed without needing an extension granted by the regulatory authority if the UST meets the applicable requirements for new or upgraded USTs (except for spill and overfill) and the requirements noted above for temporary closure. UST 74/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. CLOSURE Closing Permanently If you decide to close your UST permanently, follow these requirements for permanent closure: Notify the regulatory authority at least 30 days before you close your UST. Determine if contamination from your UST is present in the surrounding environment. Either remove the UST from the ground or leave it in the ground. Safe Closure Is A Must! UST 75/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. REPORTS What do You Need to Report? You need to report to the regulatory authority on the following occasions: - When you install an UST. - When you suspect a leak. - When a release is confirmed. - 30 Days prior to permanently closing a tank. You should check with your regulatory authority about the particular reporting requirements in your area. UST 76/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. RECORDS What Records Must You Keep? You will have to keep records that can be provided to an inspector during an on-site visit that prove your facility meets certain requirements. These records must be kept long enough to show your facility's recent compliance status in four major areas: 1. Leak detection performance and maintenance. 2. Required inspections and tests of corrosion protection. 3. Records of repair or upgrade. 4. Records of financial responsibility. UST 77/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. RECOMMENDED INSPECTION ITEMS 1. Are aboveground portions of tank system free of corrosion or other forms of deterioration? 2. Are there any leaks or releases visible on or near the aboveground portion of the UST? 3. Do impervious areas (i.e. paved areas, floors etc.) immediately surrounding UST show signs of leaks or releases? 4. Do the impervious areas show cracks or deterioration? 5. Does the secondary containment (i.e. dikes, berms etc.) show signs of leaks or releases? 6. Does the secondary containment show cracks or deterioration? UST 78/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. RECOMMENDED INSPECTION ITEMS 7. For uncovered tanks, is the level of tank contents low enough to prevent overlapping from a storm? 8. Are spill prevention controls and overfill prevention controls in good working order? 9. Is the cathodic protection system functioning properly and has the source of impressed current been tested? 10. Data from monitoring and leak detection equipment recorded in the inspection log. 11. Does data from the monitoring and leak detection equipment indicate that tank system is working properly. 12. Are tanks labeled and are contents stored within the applicable time limit. UST 79/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. TIPS FOR USING CONTRACTORS Remember, You Control Your Facility or Area! Review Procedures With Them Before Starting the Job! Ensure They Are Properly Trained! Determine Their Environmental Compliance Record! Determine Who Is in Charge of Their People! Determine How They Will Affect Your Facility’s Environmental Compliance! UST 80/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. ELEMENTS OF A SUCCESSFUL UST PROGRAM 1. DETAILED WRITTEN UST INSPECTION GUIDELINES. 2. DETAILED WRITTEN UST BEST MANAGEMENT PRACTICES. 3. EXTENSIVE EMPLOYEE TRAINING PROGRAMS 4. PERIODIC REINFORCEMENT OF TRAINING 5. SUFFICIENT DISCIPLINE REGARDING IMPLEMENTATION 6. PERIODIC FOLLOW-UP UST 81/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. THE IMPORTANCE OF A CLEAN ENVIRONMENT “I would ask all of us to remember that protecting our environment is about protecting where we live and how we live. Let us join together to protect our health, our economy, and our communities -- so all of us and our children and our grandchildren can enjoy a healthy and a prosperous life.” UST 82/82 © Copyright Training 4 Today 2000 Published by EnviroWin Software LLC. Carol Browner Former EPA Administrator