Border Security and Smart Sensors Dr. Michael Eastman Department of Chemistry

advertisement

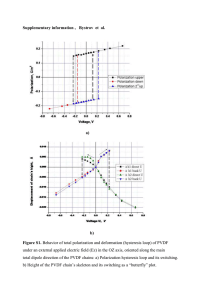

Border Security and Smart Sensors Dr. Michael Eastman Department of Chemistry The University of Texas at El Paso UTEP and Border Security • The University of Texas at El Paso is the home of the National Center for Border Security and Immigration. • The center, a U.S Department of Homeland Securitysupported research and degree program focused on producing border, homeland security and immigration experts, will be a partnership with the University of Arizona. Funding $1M/year. • Border Security Conference: 2007,2006,2005 UTEP-Research for Today Education for Tomorrow UTEP Indio Mountains Research Station Smart Sensors • We will use the term “Smart Sensor” to refer to systems that employs a sensor device mated to microelectronics. In lab work a computer will take the place of the microelectronics. Lab systems are not engineered to minimize size and power consumption but clearly those would be goals in any widely deployed practical device. • We also want our “Smart Sensors” to be rugged and inexpensive. Smart Sensors and Border Security Areas of Interest • Bioterrorism-disease organisms, biodisrupters • Clandestine monitoring-vibration, pressure, chemicals, temperature • Health and health monitoring-humans as well as plants and animals – Effectiveness of first responders (hydration/heat stress) – “Slow” Bioterrorism – “Test to treat”(fast)-who should receive scarce vaccines/antidotes-triage Piezoelectric and Piezoresistive Materials With piezoelectric materials there is a separation of charge which generates a net dipole- stressing the material generates a voltage . Examples: Inorganic: barium titanate (BiTiO3) and lithium niobate (LiNbO3); Biological materials: bone, tendons, sugar, dentin. Polymers: PVDF. Piezoresistive materials respond to mechanical stress with a change in electrical resistance. Examples: Silicon, Germanium. http://en.wikipedia.org/wiki/Piezoelectricity Chemisensors and Biosensors Utilizing Piezoresistive Microcantilevers • Robust, small and inexpensive allows sensing of both biological agents and chemical agents from a single platform. 1 ohm response for 400 angstrom change in the thickness of the sensing layer. • Patents awarded, currently being developed as hydration sensor & “test to treat” sensor by Cantimer Corporation, Menlo Park, CA Piezoresistive Microcantilever Sensor Element Substrate Schematic of Sensor Based on Cantilever Technolog y Piezoresistive Microcantilever Biolayer Substrate Schematic of Biosensor Based on Cantilever Technology Viral Detection Glass slide with antibody layer attached After exposure to dilute vaccinia virus solution Dr. Tim Porter Physics, N.A.U Viral Detection in Solution (virus sizes 100 to 3000 angstroms) Dr. Tim Porter Physics, N.A.U Sensor Array Scanning Ohmmeter Many different bioactive sensor substrates, may be specific or may respond in a characteristic pattern Dr. Tim Porter Physics, N.A.U Cantimer Corporation Menlo Park California Vision: Cantimer is developing piezoresistive sensors for a wide range of applications including determination of hydration state and medical diagnostics Potential Sensor Applications Medical: Saliva, Blood Serum, and Urine Osmolality pH Ratio of key electrolytes such as sodium and potassium Pregnancy indicator (HCG) Drug testing (amphetamine, cocaine, marijuana, etc.) Glucose Chemical: Toxic gas sensors (Homeland Security, Industrial) Chemicals in water (TCE, MTBE, CCl4 etc.) Air quality, point sensors, process streams Biological: DNA sequence detection Viruses, proteins, antibodies Protein binding and drug discovery Principal Developers of the Piezoresistive Microcantilever Systems • Dr. Ray Stewart & Co-workers, Bay Materials/Cantimer Corporation, Menlo Park, CA. • Dr. Tim Porter & Co-workers, Department of Physics and Astronomy, Northern Arizona University, Flagstaff, AZ • Dr. Michael Eastman, Professor of Chemistry, UTEP, El Paso, TX Cantimer’s Technology Platform • Saliva is a proven hydration biomarker • Patented MEMs “Universal Sensor” • Proprietary analyte responsive polymers • Integrated electronics and microfluidics MicroCantilever R Sensing Polymer (a) As Fabricated Swollen Polymer R (b) Response to Target Analyte First Responders and Military are concerned about dehydration • Lack of adequate hydration impairs the body's ability to maintain a stable core temperature, and decreases strength, endurance, and blood volume. Core body temperature rises 0.150.20°C for each 1% loss in body mass. Furthermore, for each 1% loss in body mass, heart rate increases by 3-5 beats/min. Progressive acute dehydration can lead to a significant increase in cardiovascular strain. Medical Effects of Dehydration Acute Dehydration Primary Diagnosis Secondary Diagnosis Hospitalizations Days of Care Cost 568,000 2,094,000 ~ $2 billion 2,590,000 N/A ~ $10 billion Chronic Dehydration Impact Population at Risk Pressure ulcers Time to heal > 1,000,000 in SNF alone Urinary Infections Increased incidence 8,300,000 Anually Renal failure Increased incidence > 80,000 Annually in elderly Diabetes Insulin response 18,000,000 diabetics in U.S. Falls Increased risk 40% of elder injuries Pneumonia Increased incidence 4,800,000 in U.S. per year Phase II Product Development --- Digital Osmometer Features --- Phase II deliverable Point in time measurement More portable, less power, less cost Close to vision of end product simple electronic package signal analysis algorithm Future physiological studies Incline Walking Challenge - 2% Water Loss 180 2% Body Water Loss 160 140 No Body Water Loss Osmolality 120 100 80 60 Exercise Recovery 40 20 0 0:00 0:28 0:57 1:26 1:55 Cum ulative Tim e 2:24 2:52 3:21 50 Mile Bike Ride – Santa Cruz Mtns. 50 mile Bike Ride: Active Hours vs Saliva Osmolality Saliva Osmolality (mOsm) 120 110 100 90 80 70 60 50 40 30 20 0 1 2 3 Hours on Ride 4 5 6 Phase II Product Development --- Three Products --PDA Digital Osmometer All have dual roles: ● Immediate utility & ● Initial member of product family RF Work on PVDF Piezoelectric Sensors • Done in conjunction with a Materials Science educational project sponsored by the Army • Mr. Guillermo Carbajal, Dr. C. V. Ramana, UTEP, Department of Metallurgy/Materials • Dr. R. C. Hughes, Sandia National Labs PVDF- Basics • Polyvinylidene difluoride (PVDF),is also known under various trade names including _KYNAR (Trade Mark: Elf Atochem North American) SOEF (Trade Mark: Solvay S. A.) • PVDF is prepared by the polymerization of 1,1-vinylidene difluoride • The structure of the monomer is: • The structure of the polymer is: F H F H Representations of the molecular structure of the vinylidene difluoride (VD) monomer and of the a and b forms of the PVDF polymer. F H F H VD-wire PVDF-b form PVDF-a form VD-space filling PVDF Sensors • PVDF is piezoelectric and the voltage induced by bending PVDF films can be measured. The surface of the PVDF is coated with metal to allow electrical measurements. • PVDF is pyroelectric and readily absorbs thermal radiation with a wavelength at l ~104 nm . The voltage induced by exposing metalized PVDF films to thermal radiation can be measured. • By virtue of its piezoelectric properties PVDF possibly could be fabricated into a surface acoustic wave based sensing system. Commercially available metal coated piezoelectric PVDF sensor elements A Film in (mm) B Electrode in (mm) C Film in (mm) D Electrode in (mm) t (µm) Cap (nF) .520 (13) .400 (10) .980 (25) .580 (14.70) 205 .500 .640 (16) .484 (12) 1.63 (41) 1.19 (30.17) 205 1.38 PVDF sensors mounted on a solid substrate and interfaced to circuit similar to “Circuit A” PVDF sensor elements, Circuit (A) and USB data port Output PVDF sensors on flexed ruler damped motion-Note polarity (green/yellow) and combined signal. Pyroelectric Matrix Array • PVDF is pyroelectric (pyroelectric materials are also piezoelectric) and readily absorbs radiation with a wavelength at l ~104 nm . • Four sensors in matrix array. • Array capable of quantifying the heat intensity and the location of the heat source. Four Panel Thermal Detection Voltage output 4 panel Pyroelectric Sensor when exposed to an asymmetrically located heat source Suite of Sensors for Comprehensive Reconnaissance Thermal Chemical Biochemical Vibration/Motion Collection and Transmission of Data Microprocessor and radio transmitter Chemical Biosensor Sensor Motion Sensor Thermal Sensor Acknowledgements • This material is based upon work supported in part by the U. S. Army Research Laboratory and the U.S. Army research Office under Contract W911NF0410052. • Dr. Ray Stewart- Cantimer Corporation • Dr. Tim Porter- Northern Arizona University • Mr. Guillermo Carbajal and Dr. C. V. Ramana Thank You