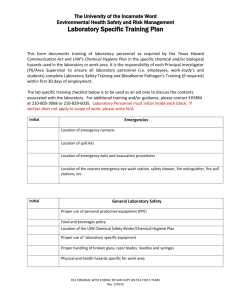

Chemical Hygiene Plan Laboratory name here

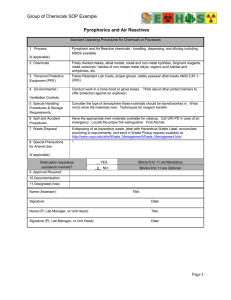

advertisement