Alpine Ski Stress Analysis: Finite Element Modeling

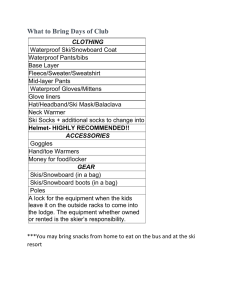

advertisement

Finite Element Analysis of the Stresses in a Modern Alpine Ski by David Scott Grant An Engineering Project Submitted to the Graduate Faculty of Rensselaer Polytechnic Institute in Partial Fulfillment of the Requirements for the degree of MASTER OF ENGINEERING Major Subject: MECHANICAL ENGINEERING Approved: _________________________________________ Norberto Lemcoff, Project Adviser Rensselaer Polytechnic Institute Hartford, Connecticut May 2015 © Copyright 2015 by David Scott Grant All Rights Reserved ii CONTENTS LIST OF TABLES ............................................................................................................ iv LIST OF FIGURES ........................................................................................................... v NOMENCLATURE ........................................................................................................ vii ACKNOWLEDGMENT ................................................................................................ viii ABSTRACT ..................................................................................................................... ix 1. Introduction.................................................................................................................. 1 1.1 Background ........................................................................................................ 1 1.2 Project Objective ................................................................................................ 2 2. Analysis Methodology and Approach ......................................................................... 3 2.1 Analysis Overview ............................................................................................. 3 2.2 ABAQUS Model Development ......................................................................... 3 2.3 ABAQUS Model Mesh ...................................................................................... 6 2.4 Material Properties Used in ABAQUS Model ................................................... 7 2.5 Loads and Boundary Conditions Used in ABAQUS Model ............................ 10 2.6 Stage 2 ABAQUS Ski Analysis ....................................................................... 10 3. Results........................................................................................................................ 13 4. Conclusions................................................................................................................ 17 5. References.................................................................................................................. 18 6. Appendices ................................................................................................................ 20 6.1 Stage 2 ABAQUS Input Deck-Damaged Ski .................................................. 20 6.2 Stage 2 ABAQUS Undamaged Ski Stress by Layer ........................................ 41 iii LIST OF TABLES Table 2-1 Mechanical Properties of Poplar Wood ............................................................ 8 Table 2-2 Mechanical Properties of Fiberglass Ply ........................................................... 8 Table 2-3 Mechanical Properties of Basalt Ply ................................................................. 9 Table 2-4 Mechanical Properties for P-Tex Bottom.......................................................... 9 Table 2-5 Mechanical Properties for Nylon Topsheet ....................................................... 9 iv LIST OF FIGURES Figure 1-1 Modern Alpine Skis ......................................................................................... 1 Figure 2-1 Alpine Ski Geometry ....................................................................................... 4 Figure 2-2 P-Tex 4504-1/16inch ....................................................................................... 4 Figure 2-3 Thicknesses for Poplar Wood Vary ................................................................. 5 Figure 2-4 Fiberglass for 0°, 45°, -45°-0.033 inches ......................................................... 5 Figure 2-5 Basalt 0°- 0.011 inches .................................................................................... 5 Figure 2-6 Nylon Topsheet- 0.02 inches ........................................................................... 6 Figure 2-7 Composite Cross-section ................................................................................. 6 Figure 2-8 Finite Element Model with 1 inch Mesh Size .................................................. 7 Figure 2-9 Finite Element Model with 0.5 inch Mesh Size ............................................... 7 Figure 2-10 Locations of Boundary Conditions and Loads ............................................. 10 Figure 2-11 Figure from Bose [19] .................................................................................. 11 Figure 2-12 Figure from Chawla [10] ............................................................................. 12 Figure 3-1 Unloaded Ski Position.................................................................................... 13 Figure 3-2 35lb Loaded Ski Position ............................................................................... 14 Figure 3-3 ABAQUS 35lb Load Deflection Plot ............................................................ 14 Figure 3-4 ABAQUS 100lb Load Deflection Model ...................................................... 15 Figure 3-5 ABAQUS 100lb Load Ply 10 Stress .............................................................. 15 Figure 3-6 Stress (psi) Through Thickness (inches) at Mid-Ski...................................... 16 Figure 3-7 ABAQUS 100lb Load Damaged Deflection Model ...................................... 16 Figure 6-1 Ply 1 Base Layer Stress.................................................................................. 41 Figure 6-2 Ply2 Fiberglass 0° Stress ................................................................................ 41 Figure 6-3 Ply 3 Fiberglass 45° Stress ............................................................................. 41 Figure 6-4 Ply 4 Fiberglass -45° Stress ........................................................................... 42 Figure 6-5 Ply 5 Poplar Wood Stress .............................................................................. 42 Figure 6-6 Ply 6 Poplar Wood Stress .............................................................................. 42 Figure 6-7 Ply7 Poplar Wood Stress ............................................................................... 43 Figure 6-8 Ply 8 Poplar Wood Stress .............................................................................. 43 Figure 6-9 Ply 9 Poplar Wood Stress .............................................................................. 43 Figure 6-10 Ply 10 Fiberglass 0° Stress ........................................................................... 44 v Figure 6-11Ply 11 Fiberglass 45° Stress.......................................................................... 44 Figure 6-12 Ply 12 Fiberglass -45° Stress ....................................................................... 44 Figure 6-13 Ply 13 Basalt 0° Stress ................................................................................. 45 Figure 6-14 Ply14 Nylon Stress ....................................................................................... 45 vi NOMENCLATURE E Young’s Modulus G Shear Modulus S ABAQUS Directional Stress V Volume Fraction Greek letters v Poisson Ratio 𝜎 Ultimate Stress 𝜎’ Strength at fiber strain to fracture Subscripts 11 Direction along primary axis 12 On face with normal to 1 and in direction of 2 22 Direction along transverse axis 23 On face with normal to 2 and in direction of 3 f Property for Fiber m Property for Matrix ACKNOWLEDGMENT I would like to thank my professor for his advisement on this project. I would also like to thank my friends and loved ones for their understanding when I told them I was otherwise occupied for the night, the week or the weekend. viii ABSTRACT This project explored the latest technology of alpine skis and the damaging effect of skiing over a small trench or gully in the off-trail glades. This was accomplished by analyzing the stiffness and stress values of the ski, and applying this stress over three years of moderate use. A modern alpine ski, consisting of multiple layers of composite materials, was modeled using finite elements in the computer program ABAQUS. The validity of the model was verified by comparing a simply supported ski at both ends with the measured deflection of actual skis loaded with a dumbbell. Once deflections were confirmed, a second stage representing a skier going over a gully was analyzed. In this stage, the highest stress among the fiberglass portions of the ski was determined, and using this value over a simulated period of 3 years, the damage of the ski was determined from the loss of stiffness. This study determined that the analyzed ski just going over the gully under moderate use will result in little damage to the ski. ix 1. Introduction 1.1 Background The modern alpine ski has changed drastically since its wooden plank beginnings and the technology continues to rapidly grow. Most notably, the shape of the skis have changed. Skis are not straight planks anymore, but more of a stretched hourglass shape as shown in Figure 1-1. This hour-glass shape allows the skis’ geometry to aid in turning. Figure 1-1 Modern Alpine Skis While many alpine skis still contain a wooden core, there are now many more materials that are used in ski design and construction. These include: wood, foam board, fiberglass, Kevlar, aluminum, titanium, steel, nylon, and a material called P-Tex, as listed in [1]. These ski materials form a composite structure much stiffer and stronger than the wood itself. The properties of some materials, such as foam board and fiberglass, can also 1 change noticeably throughout the skis life. This degradation of material often results on what skiers call losing “power” or “spring”, which is basically a result of the loss of stiffness of the ski. Skis whose stiffness has degraded are less responsive to the skier’s efforts to maintain control and direction. No technical papers were found on the alpine ski fatigue, and this project explores fatigue damage done to the skis stiffness under a specific loading. 1.2 Project Objective The objective of this project is to analyze a composite layered ski under the condition of crossing a small gully in the glades over the course of three years of moderate use. The analysis will be accomplished in two stages. In Stage 1, a 35lb load will be applied to a finite element model of the ski, and a 35 lb. dumbbell will be attached to the actual ski under simply supported condition. The second stage will analyze fatigued fiber glass layers and its effect on the overall stiffness of the ski. . 2 2. Analysis Methodology and Approach 2.1 Analysis Overview The modern ski analyzed for this project was the Rossignol Experience 88 ski. This ski was chosen as it is contemporary to latest ski designs today, and a pair of these skis is owned by the author, making measuring the geometries of the ski convenient. This alpine ski was modeled using finite elements in the computer program ABAQUS [2]. Composition of the ski was mainly obtained from the Rossignol website [3]. Other materials were assumed based on common ski construction layering. This project will make use of composite conventional shell layups in ABAQUS to form the structure of the ski. This project consisted of multiple stages: 1. The validity of the model was tested by comparing the predicted deflection of a simply supported ski at both ends with the measured deflection of the author’s skis. 2. Once deflections were confirmed, fiberglass stresses of the ski were determined in ABAQUS by applying the static load of the skier on one ski. These stresses were used in assessing the damage of the ski. The damaged ski material properties were rerun in ABAQUS and the overall effect on stiffness was determined. 2.2 ABAQUS Model Development Geometry for the modeled ski was measured directly from a pair of Rossignol skis. Data points were collected at various points along the ski. These data points were later used to make geometry nodes in the software HyperWorks [4]. HyperWorks is a user friendly geometry creator, and is quite robust in creating a geometry, as opposed to directly modeling in ABAQUS [1]. Geometry was exported from HyperWorks as an .IGES file, which was later imported into ABAQUS. The geometry imported can be seen in Figure 2-1. 3 Figure 2-1 Alpine Ski Geometry Partitions were created at intervals along the ski for where material thicknesses changed. From the partitions shown in Figure 2-1, the composite layup feature in ABAQUS could be used. Materials used in the finite element model were P-Tex 4504, fiberglass, poplar wood, basalt fiber, and nylon. Figure 2-2 shows the whole bottom of the ski, known as the base layer, made of P-Tex 4504. Figure 2-3 shows the various layers of poplar wood used for the core of the ski. It should be noted that, unlike the other layers in this ski, individual layers of poplar wood, except for the bottom-most layer, do not span the whole length of the ski. Figure 2-4 through Figure 2-6 show the thicknesses of the layers covering the whole ski. Two instances of fiberglass, consisting of three plies, were used above and below the wood. A cross-section of the ski layers, as well as the fiber directions, can be seen in Figure 2-7. Figure 2-2 P-Tex 4504-1/16inch 4 Figure 2-3 Thicknesses for Poplar Wood Vary Figure 2-4 Fiberglass for 0°, 45°, -45°-0.033 inches Figure 2-5 Basalt 0°- 0.011 inches 5 Figure 2-6 Nylon Topsheet- 0.02 inches Figure 2-7 Composite Cross-section 2.3 ABAQUS Model Mesh The alpine ski finite element model in ABAQUS used first order quad S4 element. An initial mesh size of one inch was used (Figure 2-8). A mesh density study was conducted and resulted in that the initial mesh size was adequate after running the model with double the mesh density (Figure 2-9). Differences in deflection at mid ski between the two models were only 0.01 inches. As a result, the mesh was considered converged for a mesh size of one inch. 6 Figure 2-8 Finite Element Model with 1 inch Mesh Size Figure 2-9 Finite Element Model with 0.5 inch Mesh Size 2.4 Material Properties Used in ABAQUS Model In general alpine skis are made from many layers of materials stacked on top of each other. The layers are held together by epoxy, the same material used in the matrix of several of the skis structural layers. The most important layers of the ski are those that make up the core of the ski. For the core, wood is generally used, for its blend of stiffness, cost and its ability to damp out undesirable vibrations in the ski. The other layers of the ski are composite reinforcements, a base layer of P-tex at the bottom, and a layer of nylon at the top. Skis also contain a very thin metal edge along the sides of the ski for grip. However, this material is very thin and does not extend across the full width of the ski, and therefore it was not modeled in this project. Materials for the composite layers of the ski were determined initially from [3]. However, very little information was provided other than that it was made out of wood, fiberglass and basalt fibers. Further research was required to come up with a type of wood used in the core of the ski, as wood species vary greatly in mechanical properties. A couple of references [5, 6] list the ski having a poplar wood core. Using the properties of poplar wood [7] and converting to units of psi, a longitudinal modulus of 1,738,910 psi 7 was determined. Using tables in [7] that expressed moduli as ratios of the longitudinal modulus, the rest of the calculated properties were obtained, and are shown in Table 2-1. Table 2-1 Mechanical Properties of Poplar Wood E11 E22 G12 G13 G23 v12 1738910 159980 130418 130418 19128 0.318 Several layers of reinforcement plies were applied to the composite layup in ABAQUS. These plies were composites themselves. For the fiberglass layers, fiberglass fibers in an epoxy matrix were used. E-glass fiber properties were obtained from AZoM [8]. Matrix modulus properties of marine epoxy, commonly used in skis, were obtained from TAP Plastics [9]. Since no Poisson ratio was given in [9], its value was assumed from typical data given by Chawla [10]. Fiber glass volume fractions were obtained from a commercially available mesh that could be used for skis [11]. For the composite plies, properties were determined using the law of mixtures and equations given by Chawla [10] for entry into ABAQUS as anisotropic material properties. Equations (2.1) through (2.6) show the equations used [10]. These equations lead to the fiberglass ply properties listed in Table 2-2. 𝐸11 = 𝐸𝑓 𝑉𝑓 + 𝐸𝑚 𝑉𝑚 𝐸22 = (2.1) 𝐸𝑚 𝐸 1−√𝑉𝑓 (1− 𝑚⁄𝐸 ) 𝑓2 (2.2) 𝐸 𝑚 𝐺𝑚 = 2(1+𝑣 (2.3) 𝑚) 𝐺12 = 𝐺𝑚 𝐺 1−√𝑉𝑓 (1− 𝑚⁄𝐺 ) 𝑓12 𝐺23 = 𝐺𝑚 𝐺 1−√𝑉𝑓 (1− 𝑚⁄𝐺 ) 𝑓23 (2.4) (2.5) 𝑣12 = 𝑣𝑓12 𝑉𝑓 + 𝑣𝑚 𝑉𝑚 (2.6) Table 2-2 Mechanical Properties of Fiberglass Ply E11 E22 G12 G13 G23 v12 6225300 1123462 478798 478798 478798 0.2098 8 For the composite plies of basalt fibers, the same epoxy matrix was assumed. Basalt fiber modulus information was obtained from Gencarelle [12]. Poisson ratio was obtained from Piergiorgio et al. [13], which also contained the same modulus property. Fiber volume fractions for fiber fabrics were not given in [12]; however the mass in grams per square meter of fabric was reported. From this information and the density of basalt 2.8 g/cc from [14], a fiber volume fraction of 0.64 was obtained. Similarly to the fiberglass ply, basalt composite ply properties were determined from equations (2.1) through (2. 6). Table 2-3 Mechanical Properties of Basalt Ply E11 E22 G12 G13 G23 v12 8390950 1619352 629914 629914 629914 0.2384 The ply base layer for P-tex [15] was considered isotropic and the properties are listed in Table 2-4. P-tex is abrasion resistant and is selected for skis for its ability to accept ski wax and glide over snow. Poisson’s Ratio was not given in [15], however P-tex is a popular brand name for UHMWPE (Ultra High Molecular Weight Polyethylene), and the value was obtained from Fang et al. [16]. Table 2-4 Mechanical Properties for P-Tex Bottom E v 87023 0.46 The ply topsheet layer of nylon [17] was considered isotropic and its properties are listed in Table 2-5. Nylon is used on skis for its ability to be dyed and display brand name and artwork on the top of the ski. Table 2-5 Mechanical Properties for Nylon Topsheet Nylon V 377098 0.41 The layering of these materials was obtained by looking at the similar materials of [3] used in [18]. Kilchenstein and Alary [18] state that, from the bottom up, the layers are base 9 layer, fiberglass layers, wood core, fiberglass and or basalt reinforcement layers, and topped off with a nylon topsheet. 2.5 Loads and Boundary Conditions Used in ABAQUS Model The alpine ski model applied simply supported conditions at the inflection points near the ends of the ski (Figure 2-10). In stage one, the 35 lb load was applied approximately in the middle of the ski, corresponding to where the weight of a skier would be applied. These locations correspond to the model validation locations of the actual ski loading with the dumbbell. Figure 2-10 Locations of Boundary Conditions and Loads 2.6 Stage 2 ABAQUS Ski Analysis In stage two, the ski was modeled to analyze the damage to the ski after about 3000 cycles of higher stress. The situation modeled is a representation of a skier going over a small gully in the glades on a mountain. In this condition, the ski is in a similar position as analyzed in stage one, with simply supported conditions near the tips of the ski. The ABAQUS input deck for stage two is provided in Appendix Section 6.1. In this stage, the ski deflection and fiberglass stresses at the middle of the ski were obtained. These stresses will be further used to determine the damage to the fiberglass reinforcement of the ski after three years of use. Once the damage is determined, the damaged fiberglass modulus will be introduced into the model and the overall effect on the ski stiffness will be determined. Using the ultimate strength of fiberglass from AZoM [8], 282.8 ksi, the modulus of 12.3 Msi, as well as the modulus of the epoxy 360 ksi from TAP [9], and the equation from Bose [19] 𝜎𝑐 = 𝜎𝑓 𝑉𝑓 + 𝜎𝑚 ′(1 − 𝑉𝑓 ), (2.7) 10 an ultimate strength of the ply can be determined (Figure 2-11). Figure 2-11 Scan of Bose [19] 11 Chawla [10] shows a graph of E glass fiber displaying the maximum stress as a fraction of the ultimate tensile monotonic strength being cycled versus the number of cycles with several data lines for damage ratios (Figure 2-12). Figure 2-12 Figure from Chawla [10] 12 3. Results In stage one, the deflection at the middle of the ski was determined to be 2.35 inches. Measuring the actual ski deflection, a recording of 2.25 inches was obtained. Prior to measuring the deflection, the ski was removed from all bindings, since there is no binding representation in the model. Measurements of the deflection of the ski were determined by analyzing a photograph taken with a camera on a tripod. Photos were taken both before and after loading the ski with a 35 lb. dumbbell. A measuring tape was placed on a wall behind the ski for measurement. Figure 3-1 shows the undeflected ski position. Figure 3-2 shows the deflected ski position with the 35 lb. load. Figure 3-3 shows the ABAQUS finite element deflection with the 35 lb. load. Figure 3-1 Unloaded Ski Position 13 Figure 3-2 35lb Loaded Ski Position Figure 3-3 ABAQUS 35lb Load Deflection Plot In stage two, the maximum deflection was determined to be 6.71 inches, as shown in Figure 3-4. A maximum stress of 22.9 ksi was determined in the fiberglass portion of the ski with the original material properties. Stress was obtained in the axial fiber direction, S11. The S11 stress for ply 10 (fiberglass) can be seen in Figure 3-5. Stress results for other plies are shown in Appendix Section 6.2 14 Figure 3-4 ABAQUS 100lb Load Deflection Model Figure 3-5 ABAQUS 100lb Load Ply 10 Stress A plot of stresses through the thickness of the middle of the ski is provided in Figure 3-6. Comparing the fiberglass S11 stress over a calculated ultimate tensile stress (150 ksi) for the composite, using the properties obtained from AZoM [8] and the equations from Bose [19], the damage at a certain number of cycles can be determined [10]. The 100lb stage two load represents the weight of a man on one ski skiing over a gully in the glades. If this feature is assumed to happen a 100 times per outing and the skier goes 10 times a year, about 3000 cycles of this load have occurred after 3 years. Using these cycles and figure 13.14 of Chawla [10], the change in modulus of the fiberglass is found to be about 95%. A new deflection of 6.85 inches was obtained after applying this ratio to the fiberglass modulus. The deflection of the damaged ski is shown in Figure 3-7. 15 Figure 3-6 Stress (psi) Through Thickness (inches) at Mid-Ski Figure 3-7 ABAQUS 100lb Load Damaged Deflection Model 16 4. Conclusions For stage one, the Rossignol ski was analyzed with the materials identified on the website [3], but the other materials and material layering were assumed from other references. Despite the assumptions on the materials of the Rossignol ski, the analyzed ski and the physically loaded ski showed similar vertical deflections. These deflections were within 5 percent. After validating the overall stiffness of the modeled ski in stage one, the fatigue damage of the ski for the specified terrain obstacle was analyzed in stage two. This analysis showed that the damaged stiffness was about 2 percent less than the original stiffness. Therefore, the damaging effect of skiing 3000 cycles over the terrain, which was statically modeled in stage two, resulted in little impact on the stiffness of this ski. Either a higher fiberglass stress as a result of a higher load, such as landing from a jump on the gully, or larger number of cycles may be needed to see a noticeable impact to the overall ski stiffness. This study concludes that just skiing over the glade gully under over three years of use will not have, by itself, a huge and noticeable effect on the overall ski stiffness, ensuring its ability to be reactive and turn as designed. 17 5. References 1. Mechanic of Sport, Ski Construction, Copyright 2007-2015. http://www.mechanicsofsport.com/skiing/equipment/skis/ski_construction.html, date accessed February 28, 2015. 2. Abaqus/ CAE 6.13-1, Dassault Systèmes, 2013 3. Rossignol, Experience 88 BSLT Open, http://www.rossignol.com/US/US/experience-88-bslt-open--2014--RADED02-product--alpine-men-skis.html#close, date accessed on March 1, 2015. 4. Altair HyperWorks 13.0 Student Edition, Altair Engineering Inc., 2015. 5. Evo.com, Rossignol Experience 88 BSLT Skis 2015, copyright 2001-2015, http://www.evo.com/skis/rossignol-experience-88.aspx accessed April 1, 2015 6. Skis.com, Rossignol Experience 88 Skis 2015, copyright 1990-2015, http://www.skis.com/Rossignol-Experience-88-Skis2015/350606P,default,pd.html, date accessed April 1, 2015. 7. Forest Products Laboratory, United States Department of Agriculture Forest Service, Wood Handbook, Wood as an Engineering Material, Madison, Wisconsin, 2010. 8. AZoM.com, E-Glass Fibre, Copyright 2000-2015. http://www.azom.com/properties.aspx?ArticleID=764, accessed March 31, 2015. 9. TAP Premium Marine Grade Epoxy System, Tap Plastics Product Bulletin, June 2010. http://www.tapplastics.com/uploads/pdf/Product%20Bulletin%2012- 2010.pdf accessed April 1, 2015. 10. Chawla, Krishan K., Composite Materials: Science and Engineering, Third Edition, Springer, New York, 2012. 11. Fiber Glass Industries, 5=1+4 Stitched Bonded Warp Triaxial 0°/±45°/±45°, http://www.fiberglassindustries.com/warp-triax.htm copyright 2007-2013. date accessed March 28, 2015. 12. Gencarelle, Nick. Basalt FAQs, Smarter Building Systems-Smarter Building Materials for a Cleaner Environment, http://smarter-building- systems.com/smarter-building-basalt-faqs/ Copyright 2014, date accessed March 28, 2015. 18 13. Piergiorgio Valentino, Franco Furgiuele, Marco Romano, Info Ehrlich, Geebbeken Norbert, Mechanical Characterization of basalt fibre reinforced plastic with different fabric reinforcements-Tensile tests and FE calculations with representative volume elements (RVEWs), Roma Italy, 2013. 14. Singha, Kunal. A Short Review on Basalt Fiber. International Journal of Textile Science 2012. http://article.sapub.org/pdf/10.5923.j.textile.20120104.02.pdf, date accessed April 12, 2015. 15. P-tex 4504 black. Cps GmbH, Creative Plastic Solutions http://cpsgmbh.net/download/datenblaetter/4504_P-tex_DS_black_v130228.pdf. Date accessed March 28, 2015 16. Fang, Hsu-Wei; Hsu, Stephen M.; Sengers, Jan V.. NIST Special Publication 1002: Ultra-High Molecular Weight Polyethylene Wear Particle Effects on Bioactivity. September 2003. http://www.ccp14.ac.uk/ccp/ccp14/ftp-mirror/nist- texture/NISTSP1002.pdf. Date accessed March 28th, 2015. 17. Mechanical Properties of Plastic Materials. Professional Plastics. http://www.professionalplastics.com/professionalplastics/MechanicalPropertiesof Plastics.pdf. Copyright 2015. Date accessed March 28, 2015. 18. Kilchenstein, Michael; Alary, Christian. Skis and methods of making same: US 20140062064 A1. March 6, 2014. https://www.google.com/patents/US20140062064. Date accessed February 28, 2015. 19. Bose, Sudhangshu, Mechanics of Composites:MANE6180 G01;H01, 7.0 Strength, Fracture, Fatigue and Design - slide11, PowerPoint slides distributed in MANE6180 at Rensselelaer Poly Technic Institute on October 27, 2014. 19 6. Appendices 6.1 Stage 2 ABAQUS Input Deck-Damaged Ski *Heading ** Job name: stage2_fiber_change Model name: Model-1 ** Generated by: Abaqus/CAE 6.13-1 *Preprint, echo=NO, model=NO, history=NO, contact=NO ** ** PARTS ** *Part, name=SKI *End Part ** ** ** ASSEMBLY ** *Assembly, name=Assembly ** *Instance, name=SKI-1, part=SKI *Node 1, 60., 0.00272241514, 2.14694977 2, 60., 0.00272241188, -2.14694977 3, 62.5000076, 1.64821074e-07, -2.23241854 4, 62.5000076, 1.41106753e-07, 2.23241854 5, 56., 0.10109701, 1.97272778 6, 56., 0.10109701, -1.97272778 7, 50., 0.187148646, 1.81556082 8, 50., 0.187148631, -1.81556082 9, 48., 0.193056166, -1.78263509 10, 48., 0.193056166, 1.78263509 11, 45.0000038, 0.19177781, 1.71871567 12, 45.0000038, 0.19177781, -1.71871567 13, 42., 0.184938744, 1.67498231 14, 42., 0.184938744, -1.67498231 15, 36., 0.166981131, 1.69037664 16, 36., 0.166981131, -1.69037664 17, 30., 0.147715434, 1.68687606 18, 30., 0.147715434, -1.68687606 19, 24., 0.130517229, -1.8080883 20, 24., 0.130517229, 1.80808806 21, 20., 0.122324422, 1.93353283 22, 20., 0.122324422, -1.93353283 23, 16.0000019, 0.109580077, 2.05654335 24, 16.0000019, 0.109580077, -2.05654335 25, 12.0000038, 0.0589322411, 2.24670768 26, 12.0000038, 0.0589322411, -2.24670768 20 27, 9.99999905, -3.92250605e-08, 2.30999875 28, 9.99999905, -3.92251103e-08, -2.30999875 29, 5.04551268, 2.63805244e-08, 2.38059473 30, 5.04551268, 2.62739963e-08, -2.38059473 31, 8., -0.0781052113, -2.31144738 32, 8., -0.0781052113, 2.31144738 33, 67., 0.875, 1.08539784 34, 65.7109299, 0.295828104, 2.33478713 35, 67., 0.875, -1.08539784 36, 65.7109299, 0.295828223, -2.33478713 37, 1.8151263, 1.05138421, 2.49414539 38, 1.8151263, 1.05138421, -2.49414539 39, 0., 2.125, -0.745357692 40, 0., 2.125, 0.745357692 41, 60., 0.00272241188, 1.07347488 42, 60., 0.00272241188, -3.67684994e-09 43, 60., 0.00272241188, -1.07347488 44, 60.8332939, -0.00774414092, -2.17619967 45, 61.6666603, -0.00978280604, -2.20486712 46, 62.5000076, 1.6482106e-07, -1.12055182 47, 62.5000076, 1.64821046e-07, -0.00556838512 48, 62.5000076, 1.64821017e-07, 1.11303055 49, 61.6666603, -0.00978280604, 2.20486712 50, 60.8332939, -0.00774413953, 2.17619967 51, 56., 0.10109701, 0.986363888 52, 56., 0.10109701, 53, 56., 0.10109701, -0.986363888 0. 54, 56.9997635, 0.0746188164, -2.02066159 55, 57.9995728, 0.0477082655, -2.06739163 56, 58.999649, 0.022786539, -2.10923004 57, 58.999649, 0.022786539, 2.10923004 58, 57.9995728, 0.0477082655, 2.06739163 59, 56.9997635, 0.0746188164, 2.02066159 60, 50., 0.187148631, 0.907780409 61, 50., 0.187148631, -1.7583992e-09 62, 50., 0.187148631, -0.907780409 63, 50.9999771, 0.181051835, -1.84720933 64, 51.9999084, 0.17227006, -1.87949014 65, 52.9997635, 0.160326391, -1.91331935 66, 53.9998322, 0.144728631, -1.93667197 67, 55., 0.125000015, -1.95293474 68, 55., 0.125000015, 1.95293474 69, 53.9998322, 0.144728631, 1.93667197 70, 52.9997635, 0.160326391, 1.91331935 71, 51.9999084, 0.17227006, 1.87949014 72, 50.9999771, 0.181051835, 1.84720933 73, 49.0000534, 0.191011667, -1.79608238 21 74, 49.0000534, 0.191011667, 1.79608238 75, 48., 0.193056166, 0.891317546 76, 48., 0.193056166, -6.59950317e-10 77, 48., 0.193056166, -0.891317546 78, 45., 0.19177781, 0.859357893 79, 45., 0.19177781, 4.76379505e-08 80, 45., 0.19177781, -0.859357774 81, 45.9997444, 0.193132862, -1.75123036 82, 46.9998169, 0.193653971, -1.76934457 83, 46.9998169, 0.193653971, 1.76934457 84, 45.9997444, 0.193132862, 1.75123036 85, 42., 0.184938744, 0.837491155 86, 42., 0.184938744, -1.00798925e-10 87, 42., 0.184938744, -0.837491155 88, 43.0001564, 0.187500387, -1.67857981 89, 44.0002365, 0.189831898, -1.69083548 90, 44.0002365, 0.189831898, 1.69083548 91, 43.0001564, 0.187500387, 1.67857981 92, 36., 0.166981131, 0.84518832 93, 36., 0.166981131, -8.63950245e-10 94, 36., 0.166981131, -0.84518832 95, 37., 0.170162857, -1.6878109 96, 38., 0.173295423, -1.68524516 97, 39., 0.17636092, -1.68267941 98, 40., 0.179339334, -1.68011379 99, 41., 0.182207629, -1.67754805 100, 41., 0.182207629, 1.67754805 101, 40., 0.179339334, 1.68011379 102, 39., 0.17636092, 1.68267941 103, 38., 0.173295423, 1.68524516 104, 37., 0.170162857, 1.6878109 105, 30., 0.147715434, 0.843438029 106, 30., 0.147715434, 107, 30., 0.147715434, -0.843438029 0. 108, 30.9999943, 0.150875166, -1.68277144 109, 31.9999943, 0.154074445, -1.68391824 110, 32.9999962, 0.157298848, -1.68553281 111, 33.9999962, 0.160534263, -1.68714738 112, 34.9999962, 0.163766518, -1.68876207 113, 34.9999962, 0.163766518, 1.68876207 114, 33.9999962, 0.160534263, 1.68714738 115, 32.9999962, 0.157298848, 1.68553281 116, 31.9999943, 0.154074445, 1.68391824 117, 30.9999943, 0.150875166, 1.68277144 118, 24.9997482, 0.133075133, -1.77677786 119, 25.9995632, 0.135786533, -1.74868393 120, 26.9996719, 0.138627157, -1.73323202 22 121, 27.9997826, 0.141574636, -1.71777999 122, 28.9998913, 0.144609824, -1.70232797 123, 28.9998913, 0.144609824, 1.70232797 124, 27.9997826, 0.141574636, 1.71777999 125, 26.9996719, 0.138627157, 1.73323202 126, 25.9995632, 0.135786533, 1.74868393 127, 24.9997482, 0.133075133, 1.77677786 128, 24., 0.130517229, 0.904043972 129, 24., 0.130517229, -1.35455849e-07 130, 24., 0.130517229, -0.904044211 131, 20., 0.122324422, 0.966766417 132, 20., 0.122324422, 9.95000526e-10 133, 20., 0.122324422, -0.966766417 134, 21., 0.124081515, -1.90217173 135, 22., 0.12598376, -1.87081063 136, 23., 0.128141418, -1.83944941 137, 23., 0.128141418, 1.83944941 138, 22., 0.12598376, 1.87081063 139, 21., 0.124081515, 1.90217173 140, 16., 0.109580062, 1.02827156 141, 16., 0.109580062, -6.28595487e-08 142, 16., 0.109580062, -1.02827168 143, 16.9998608, 0.114543892, -2.02162051 144, 18.0000134, 0.117971085, -1.9960047 145, 19.0000324, 0.120412476, -1.96570158 146, 19.0000324, 0.120412476, 1.96570158 147, 18.0000134, 0.117971085, 1.9960047 148, 16.9998608, 0.114543892, 2.02162051 149, 12., 0.0589321479, 1.12335384 150, 12., 0.0589321479, -6.32975983e-08 151, 12., 0.0589321479, -1.12335396 152, 13.0007477, 0.0781319216, -2.21829772 153, 14.0011711, 0.0922549739, -2.17927432 154, 15.0005732, 0.102416508, -2.11790895 155, 15.0005732, 0.102416508, 2.11790895 156, 14.0011711, 0.0922549739, 2.17927432 157, 13.0007477, 0.0781319216, 2.21829772 158, 9.99999905, -3.92872401e-08, 1.15499938 159, 9.99999905, -3.92872224e-08, 0. 160, 9.99999905, -3.92872082e-08, -1.15499938 161, 10.9999495, 0.0333827808, -2.28071713 162, 10.9999495, 0.0333827808, 2.28071713 163, 5.04551268, 2.6273451e-08, 1.07010841 164, 5.04551268, 2.62734652e-08, -0.0123947263 165, 5.04551268, 2.62734812e-08, -1.06514084 166, 6.02809429, -0.0789344907, -2.35120749 167, 7.01394033, -0.0969520137, -2.32697678 23 168, 8., -0.0781052113, -1.15572369 169, 8., -0.0781052113, 3.26349614e-10 170, 8., -0.0781052113, 1.15572369 171, 7.01393986, -0.0969520137, 2.32697678 172, 6.02809429, -0.0789344832, 2.35120749 173, 9.0000782, -0.0406163074, -2.31324816 174, 9.0000782, -0.0406163074, 2.31324816 175, 64.4897156, 0.105551839, 2.29640698 176, 63.4661942, 0.0324999467, 2.26376343 177, 63.4338646, 0.0309408028, -2.26273084 178, 64.4415054, 0.100862458, -2.29488683 179, 66.4180832, 0.538165271, -2.13329387 180, 66.8853455, 0.801585555, -1.60117698 181, 67., 0.875, -0.0266806278 182, 66.9031143, 0.812877357, 1.56661832 183, 66.4142914, 0.53637284, 2.13545585 184, 1.27556169, 1.34975207, 2.42266703 185, 0.819489777, 1.61905563, 2.22056675 186, 0.411377043, 1.8689034, 1.85584521 187, 0.110171437, 2.05623579, 1.33559597 188, 0.256464899, 1.96506786, -1.64373386 189, 0.91421932, 1.56209636, -2.27225709 190, 2.71831441, 0.619204164, -2.46084476 191, 3.72103882, 0.261727005, -2.42500448 192, 3.70280075, 0.26697132, 2.42564368 193, 2.70283389, 0.625787139, 2.46140909 194, 60.8332939, -0.0077441521, 1.08809984 195, 60.8332939, -0.0077441521, -2.35041542e-09 196, 60.8332939, -0.0077441521, -1.08809984 197, 61.6666603, -0.00978280604, 1.10243344 198, 61.6666603, -0.00978280604, -1.12296394e-09 199, 61.6666603, -0.00978280604, -1.10243356 200, 56.9997635, 0.0746188387, 1.0103308 201, 56.9997635, 0.0746188387, 0. 202, 56.9997635, 0.0746188387, -1.0103308 203, 57.9995728, 0.0477082245, 1.03369582 204, 57.9995728, 0.0477082245, 0. 205, 57.9995728, 0.0477082245, -1.03369582 206, 58.999649, 0.0227865167, 1.05461502 207, 58.999649, 0.0227865167, 0. 208, 58.999649, 0.0227865167, -1.05461502 209, 50.9999771, 0.181051821, 0.923604667 210, 50.9999771, 0.181051821, -2.20488561e-09 211, 50.9999771, 0.181051821, -0.923604667 212, 51.9999084, 0.172270074, 0.939745069 213, 51.9999084, 0.172270074, -1.88539317e-09 214, 51.9999084, 0.172270074, -0.939745069 24 215, 52.9997635, 0.160326391, 0.956659675 216, 52.9997635, 0.160326391, -1.41406886e-09 217, 52.9997635, 0.160326391, -0.956659675 218, 53.9998322, 0.144728661, 0.968335986 219, 53.9998322, 0.144728661, -4.94017716e-10 220, 53.9998322, 0.144728661, -0.968335986 221, 55., 0.125, 0.976467371 222, 55., 0.125, -1.81748838e-10 223, 55., 0.125, -0.976467371 224, 49.0000534, 0.191011667, -0.898041189 225, 49.0000534, 0.191011667, -3.94929422e-10 226, 49.0000534, 0.191011667, 0.898041189 227, 45.9997444, 0.193132862, 0.87561518 228, 45.9997444, 0.193132862, 8.40700842e-10 229, 45.9997444, 0.193132862, -0.87561518 230, 46.9998169, 0.193653971, 0.884672284 231, 46.9998169, 0.193653971, 2.05427675e-10 232, 46.9998169, 0.193653971, -0.884672284 233, 43.0001564, 0.187500387, 0.839289904 234, 43.0001564, 0.187500387, -3.16680016e-10 235, 43.0001564, 0.187500387, -0.839289904 236, 44.0002365, 0.189831898, 0.845417738 237, 44.0002365, 0.189831898, -3.66617403e-10 238, 44.0002365, 0.189831898, -0.845417738 239, 37., 0.170162871, 0.843905449 240, 37., 0.170162871, 1.13205978e-09 241, 37., 0.170162871, -0.843905449 242, 38., 0.173295423, 0.842622578 243, 38., 0.173295423, 9.06704933e-10 244, 38., 0.173295423, -0.842622578 245, 39., 0.176360935, 0.841339707 246, 39., 0.176360935, 6.81350087e-10 247, 39., 0.176360935, -0.841339707 248, 40., 0.179339334, 0.840056896 249, 40., 0.179339334, 4.5599613e-10 250, 40., 0.179339334, -0.840056896 251, 41., 0.182207629, 0.838774025 252, 41., 0.182207629, 2.30641284e-10 253, 41., 0.182207629, -0.838774025 254, 30.9999943, 0.150875166, 0.841385722 255, 30.9999943, 0.150875166, 0. 256, 30.9999943, 0.150875166, -0.841385722 257, 31.9999943, 0.154074445, 0.841959119 258, 31.9999943, 0.154074445, 0. 259, 31.9999943, 0.154074445, -0.841959119 260, 32.9999962, 0.157298848, 0.842766404 261, 32.9999962, 0.157298848, 0. 25 262, 32.9999962, 0.157298848, -0.842766404 263, 33.9999962, 0.160534248, 0.843573689 264, 33.9999962, 0.160534248, 0. 265, 33.9999962, 0.160534248, -0.843573689 266, 35., 0.163766533, 0.844381034 267, 35., 0.163766533, 0. 268, 34.9999962, 0.163766518, -0.844381034 269, 24.9997463, 0.133075133, -0.888388932 270, 25.9995613, 0.135786518, -0.874341965 271, 26.9996719, 0.138627157, -0.866616011 272, 27.9997807, 0.141574636, -0.858889997 273, 28.9998913, 0.144609824, -0.851163983 274, 24.9997444, 0.133075133, 0. 275, 25.9995594, 0.135786518, 0. 276, 26.99967, 0.138627157, 0. 277, 27.9997807, 0.141574636, 0. 278, 28.9998894, 0.144609824, 0. 279, 24.9997425, 0.133075118, 0.888388932 280, 25.9995575, 0.135786518, 0.874341965 281, 26.99967, 0.138627157, 0.866616011 282, 27.9997807, 0.141574636, 0.858889997 283, 28.9998894, 0.144609824, 0.851163983 284, 20.9999981, 0.124081515, 0.951085865 285, 21., 0.124081515, 7.21080085e-10 286, 21., 0.124081515, -0.951085865 287, 21.9999981, 0.12598376, 0.935405314 288, 21.9999981, 0.12598376, 4.80651074e-10 289, 22., 0.12598376, -0.935405314 290, 22.9999962, 0.128141403, 0.919724703 291, 22.9999981, 0.128141403, 2.40222064e-10 292, 23., 0.128141418, -0.919724703 293, 16.9998608, 0.114543885, 1.01081026 294, 16.9998608, 0.114543885, 0. 295, 16.9998608, 0.114543885, -1.01081026 296, 18.0000134, 0.117971085, 0.99800235 297, 18.0000134, 0.117971085, 0. 298, 18.0000134, 0.117971085, -0.99800235 299, 19.0000324, 0.120412476, 0.98285079 300, 19.0000324, 0.120412476, 0. 301, 19.0000324, 0.120412476, -0.98285079 302, 13.0007448, 0.0781318694, 1.10914886 303, 13.0007458, 0.0781318843, 0. 304, 13.0007467, 0.0781318992, -1.10914886 305, 14.0011683, 0.0922549441, 1.08963716 306, 14.0011692, 0.092254959, 0. 307, 14.0011702, 0.0922549665, -1.08963716 308, 15.0005713, 0.102416486, 1.05895448 26 309, 15.0005722, 0.102416493, 0. 310, 15.0005732, 0.1024165, -1.05895448 311, 10.9999475, 0.033382725, 1.14035857 312, 10.9999485, 0.033382751, 0. 313, 10.9999495, 0.0333827771, -1.14035857 314, 6.02809429, -0.0789344907, 1.17560375 315, 6.02809429, -0.0789344907, 1.4809185e-09 316, 6.02809429, -0.0789344907, -1.17560375 317, 7.01393986, -0.0969520211, 1.16348839 318, 7.01393986, -0.0969520211, 2.08223661e-09 319, 7.01393986, -0.0969520211, -1.16348839 320, 9.0000782, -0.040616326, -1.15662408 321, 9.0000782, -0.040616326, 0. 322, 9.0000782, -0.040616326, 1.15662408 323, 63.3666801, 0.0278195497, -0.0118458271 324, 64.2263947, 0.0816788971, -0.0251919031 325, 65.0980911, 0.179829329, -0.0493958592 326, 65.7352829, 0.301717013, -0.0631025434 327, 66.1512604, 0.426419765, -0.0742223859 328, 66.6351166, 0.650693357, -0.0812095404 329, 66.6384659, 0.652577937, 0.597128272 330, 66.3476105, 0.50585258, 0.821596384 331, 65.8803024, 0.339574099, 1.01584256 332, 65.3108749, 0.21415244, 1.10670507 333, 64.3845596, 0.0955144763, 1.12542689 334, 63.4519768, 0.0318097062, 1.12259328 335, 66.6720657, 0.671726882, -0.821064115 336, 63.4127464, 0.0299424659, -1.14146233 337, 64.3065338, 0.0885070041, -1.17124975 338, 65.3025436, 0.212707177, -1.23036945 339, 65.9968414, 0.374010324, -1.16677701 340, 66.3752289, 0.518269479, -0.977165103 341, 1.87190557, 1.02154672, -0.855156183 342, 1.84335601, 1.03650904, 1.83019519 343, 1.83277845, 1.04207337, 1.16923451 344, 1.85188603, 1.03202999, 0.530577898 345, 1.86433518, 1.02550626, -0.140333772 346, 1.86649477, 1.02437615, -1.61917925 347, 0.619292498, 1.74083281, -0.667519569 348, 1.2179985, 1.38299394, -0.762866139 349, 3.66795897, 0.277122825, 1.00393772 350, 3.70130897, 0.267402381, -0.851431787 351, 2.53113532, 0.700840414, 1.12187743 352, 3.18215203, 0.436622471, 1.06424749 353, 4.09324503, 0.165199116, 1.45082831 354, 2.55665064, 0.689452827, -0.896702409 355, 3.21011806, 0.426543832, -0.889005065 27 356, 3.74934077, 0.253683656, 0.481883883 357, 3.87043548, 0.220573932, -0.268507004 358, 4.1168046, 0.159759134, -1.37621105 359, 2.61012387, 0.665851235, 1.7733407 360, 3.38834357, 0.36486575, 1.67848587 361, 2.51064277, 0.710044622, 0.476233959 362, 2.52394438, 0.704064369, -0.196601152 363, 3.15151262, 0.447788179, 0.449190736 364, 3.18222427, 0.436596245, -0.226230621 365, 2.63555217, 0.654753923, -1.63999736 366, 3.41216087, 0.356960118, -1.58252597 367, 4.31350803, 0.117280975, 0.736629963 368, 4.3903017, 0.102068476, -0.0587022305 369, 4.34981012, 0.109996669, -0.691969991 370, 1.00163531, 1.50997055, 1.82955205 371, 0.589087546, 1.75934935, 0.13197422 372, 0.691419244, 1.69675958, 0.864313841 373, 0.829957724, 1.61273873, 1.41443849 374, 1.39125395, 1.2836957, 1.83801293 375, 1.23155367, 1.37514436, -0.0304159522 376, 1.26631534, 1.35507536, 0.649561882 377, 1.32812536, 1.31961215, 1.26781225 378, 0.675490797, 1.70647466, -1.29382789 379, 1.16582727, 1.41332626, -1.48741841 *Element, type=S4 1, 1, 41, 194, 50 2, 41, 42, 195, 194 3, 42, 43, 196, 195 4, 43, 2, 44, 196 5, 50, 194, 197, 49 6, 194, 195, 198, 197 7, 195, 196, 199, 198 8, 196, 44, 45, 199 9, 49, 197, 48, 4 10, 197, 198, 47, 48 11, 198, 199, 46, 47 12, 199, 45, 3, 46 13, 5, 51, 200, 59 14, 51, 52, 201, 200 15, 52, 53, 202, 201 16, 53, 6, 54, 202 17, 59, 200, 203, 58 18, 200, 201, 204, 203 19, 201, 202, 205, 204 20, 202, 54, 55, 205 21, 58, 203, 206, 57 22, 203, 204, 207, 206 28 23, 204, 205, 208, 207 24, 205, 55, 56, 208 25, 57, 206, 41, 1 26, 206, 207, 42, 41 27, 207, 208, 43, 42 28, 208, 56, 2, 43 29, 7, 60, 209, 72 30, 60, 61, 210, 209 31, 61, 62, 211, 210 32, 62, 8, 63, 211 33, 72, 209, 212, 71 34, 209, 210, 213, 212 35, 210, 211, 214, 213 36, 211, 63, 64, 214 37, 71, 212, 215, 70 38, 212, 213, 216, 215 39, 213, 214, 217, 216 40, 214, 64, 65, 217 41, 70, 215, 218, 69 42, 215, 216, 219, 218 43, 216, 217, 220, 219 44, 217, 65, 66, 220 45, 69, 218, 221, 68 46, 218, 219, 222, 221 47, 219, 220, 223, 222 48, 220, 66, 67, 223 49, 68, 221, 51, 5 50, 221, 222, 52, 51 51, 222, 223, 53, 52 52, 223, 67, 6, 53 53, 9, 73, 224, 77 54, 73, 8, 62, 224 55, 77, 224, 225, 76 56, 224, 62, 61, 225 57, 76, 225, 226, 75 58, 225, 61, 60, 226 59, 75, 226, 74, 10 60, 226, 60, 7, 74 61, 11, 78, 227, 84 62, 78, 79, 228, 227 63, 79, 80, 229, 228 64, 80, 12, 81, 229 65, 84, 227, 230, 83 66, 227, 228, 231, 230 67, 228, 229, 232, 231 68, 229, 81, 82, 232 69, 83, 230, 75, 10 29 70, 230, 231, 76, 75 71, 231, 232, 77, 76 72, 232, 82, 9, 77 73, 13, 85, 233, 91 74, 85, 86, 234, 233 75, 86, 87, 235, 234 76, 87, 14, 88, 235 77, 91, 233, 236, 90 78, 233, 234, 237, 236 79, 234, 235, 238, 237 80, 235, 88, 89, 238 81, 90, 236, 78, 11 82, 236, 237, 79, 78 83, 237, 238, 80, 79 84, 238, 89, 12, 80 85, 15, 92, 239, 104 86, 92, 93, 240, 239 87, 93, 94, 241, 240 88, 94, 16, 95, 241 89, 104, 239, 242, 103 90, 239, 240, 243, 242 91, 240, 241, 244, 243 92, 241, 95, 96, 244 93, 103, 242, 245, 102 94, 242, 243, 246, 245 95, 243, 244, 247, 246 96, 244, 96, 97, 247 97, 102, 245, 248, 101 98, 245, 246, 249, 248 99, 246, 247, 250, 249 100, 247, 97, 98, 250 101, 101, 248, 251, 100 102, 248, 249, 252, 251 103, 249, 250, 253, 252 104, 250, 98, 99, 253 105, 100, 251, 85, 13 106, 251, 252, 86, 85 107, 252, 253, 87, 86 108, 253, 99, 14, 87 109, 17, 105, 254, 117 110, 105, 106, 255, 254 111, 106, 107, 256, 255 112, 107, 18, 108, 256 113, 117, 254, 257, 116 114, 254, 255, 258, 257 115, 255, 256, 259, 258 116, 256, 108, 109, 259 30 117, 116, 257, 260, 115 118, 257, 258, 261, 260 119, 258, 259, 262, 261 120, 259, 109, 110, 262 121, 115, 260, 263, 114 122, 260, 261, 264, 263 123, 261, 262, 265, 264 124, 262, 110, 111, 265 125, 114, 263, 266, 113 126, 263, 264, 267, 266 127, 264, 265, 268, 267 128, 265, 111, 112, 268 129, 113, 266, 92, 15 130, 266, 267, 93, 92 131, 267, 268, 94, 93 132, 268, 112, 16, 94 133, 19, 118, 269, 130 134, 118, 119, 270, 269 135, 119, 120, 271, 270 136, 120, 121, 272, 271 137, 121, 122, 273, 272 138, 122, 18, 107, 273 139, 130, 269, 274, 129 140, 269, 270, 275, 274 141, 270, 271, 276, 275 142, 271, 272, 277, 276 143, 272, 273, 278, 277 144, 273, 107, 106, 278 145, 129, 274, 279, 128 146, 274, 275, 280, 279 147, 275, 276, 281, 280 148, 276, 277, 282, 281 149, 277, 278, 283, 282 150, 278, 106, 105, 283 151, 128, 279, 127, 20 152, 279, 280, 126, 127 153, 280, 281, 125, 126 154, 281, 282, 124, 125 155, 282, 283, 123, 124 156, 283, 105, 17, 123 157, 21, 131, 284, 139 158, 131, 132, 285, 284 159, 132, 133, 286, 285 160, 133, 22, 134, 286 161, 139, 284, 287, 138 162, 284, 285, 288, 287 163, 285, 286, 289, 288 31 164, 286, 134, 135, 289 165, 138, 287, 290, 137 166, 287, 288, 291, 290 167, 288, 289, 292, 291 168, 289, 135, 136, 292 169, 137, 290, 128, 20 170, 290, 291, 129, 128 171, 291, 292, 130, 129 172, 292, 136, 19, 130 173, 23, 140, 293, 148 174, 140, 141, 294, 293 175, 141, 142, 295, 294 176, 142, 24, 143, 295 177, 148, 293, 296, 147 178, 293, 294, 297, 296 179, 294, 295, 298, 297 180, 295, 143, 144, 298 181, 147, 296, 299, 146 182, 296, 297, 300, 299 183, 297, 298, 301, 300 184, 298, 144, 145, 301 185, 146, 299, 131, 21 186, 299, 300, 132, 131 187, 300, 301, 133, 132 188, 301, 145, 22, 133 189, 25, 149, 302, 157 190, 149, 150, 303, 302 191, 150, 151, 304, 303 192, 151, 26, 152, 304 193, 157, 302, 305, 156 194, 302, 303, 306, 305 195, 303, 304, 307, 306 196, 304, 152, 153, 307 197, 156, 305, 308, 155 198, 305, 306, 309, 308 199, 306, 307, 310, 309 200, 307, 153, 154, 310 201, 155, 308, 140, 23 202, 308, 309, 141, 140 203, 309, 310, 142, 141 204, 310, 154, 24, 142 205, 27, 158, 311, 162 206, 158, 159, 312, 311 207, 159, 160, 313, 312 208, 160, 28, 161, 313 209, 162, 311, 149, 25 210, 311, 312, 150, 149 32 211, 312, 313, 151, 150 212, 313, 161, 26, 151 213, 29, 163, 314, 172 214, 163, 164, 315, 314 215, 164, 165, 316, 315 216, 165, 30, 166, 316 217, 172, 314, 317, 171 218, 314, 315, 318, 317 219, 315, 316, 319, 318 220, 316, 166, 167, 319 221, 171, 317, 170, 32 222, 317, 318, 169, 170 223, 318, 319, 168, 169 224, 319, 167, 31, 168 225, 31, 173, 320, 168 226, 173, 28, 160, 320 227, 168, 320, 321, 169 228, 320, 160, 159, 321 229, 169, 321, 322, 170 230, 321, 159, 158, 322 231, 170, 322, 174, 32 232, 322, 158, 27, 174 233, 48, 47, 323, 334 234, 334, 323, 324, 333 235, 333, 324, 325, 332 236, 332, 325, 326, 331 237, 331, 326, 327, 330 238, 330, 327, 328, 329 239, 328, 181, 33, 329 240, 4, 48, 334, 176 241, 176, 334, 333, 175 242, 175, 333, 332, 34 243, 34, 332, 331, 183 244, 183, 331, 330, 182 245, 182, 330, 329, 33 246, 35, 181, 328, 335 247, 328, 327, 340, 335 248, 327, 326, 339, 340 249, 326, 325, 338, 339 250, 325, 324, 337, 338 251, 324, 323, 336, 337 252, 323, 47, 46, 336 253, 46, 3, 177, 336 254, 336, 177, 178, 337 255, 337, 178, 36, 338 256, 338, 36, 179, 339 257, 339, 179, 180, 340 33 258, 340, 180, 35, 335 259, 37, 342, 359, 193 260, 342, 343, 351, 359 261, 193, 359, 360, 192 262, 359, 351, 352, 360 263, 192, 360, 353, 29 264, 360, 352, 349, 353 265, 343, 344, 361, 351 266, 344, 345, 362, 361 267, 345, 341, 354, 362 268, 351, 361, 363, 352 269, 361, 362, 364, 363 270, 362, 354, 355, 364 271, 352, 363, 356, 349 272, 363, 364, 357, 356 273, 364, 355, 350, 357 274, 341, 346, 365, 354 275, 346, 38, 190, 365 276, 354, 365, 366, 355 277, 365, 190, 191, 366 278, 355, 366, 358, 350 279, 366, 191, 30, 358 280, 349, 356, 367, 353 281, 356, 357, 368, 367 282, 357, 350, 358, 369 283, 353, 367, 163, 29 284, 367, 368, 164, 163 285, 368, 369, 165, 164 286, 369, 358, 30, 165 287, 39, 347, 371, 40 288, 40, 371, 372, 187 289, 187, 372, 373, 186 290, 186, 373, 370, 185 291, 347, 348, 375, 371 292, 348, 341, 345, 375 293, 371, 375, 376, 372 294, 375, 345, 344, 376 295, 372, 376, 377, 373 296, 376, 344, 343, 377 297, 373, 377, 374, 370 298, 377, 343, 342, 374 299, 342, 37, 184, 374 300, 374, 184, 185, 370 301, 346, 341, 348, 379 302, 379, 348, 347, 378 303, 347, 39, 188, 378 304, 188, 189, 379, 378 34 305, 189, 38, 346, 379 *Element, type=S3 306, 357, 369, 368 *Nset, nset=_PickedSet60, internal, generate 1, 379, 1 *Elset, elset=_PickedSet60, internal, generate 1, 306, 1 *Nset, nset=_PickedSet62, internal, generate 1, 379, 1 *Elset, elset=_PickedSet62, internal, generate 1, 306, 1 ** Region: (CompositeLayup-1-5: Generated From Layup) *Elset, elset=CompositeLayup-1-5 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 225, 226, 227, 228 229, 230, 231, 232 ** Section: CompositeLayup-1-5 *Shell Section, elset=CompositeLayup-1-5, composite, layup=CompositeLayup-1 0.06125, 3, Base, 0., Ply-1 0.011, 3, fiberglass, 0., Ply-2 0.011, 3, fiberglass, 45., Ply-3 0.011, 3, fiberglass, -45., Ply-4 0.06125, 3, Poplar, 0., Ply-5 0.06125, 3, Poplar, 0., Ply-6 0.011, 3, fiberglass, 0., Ply-10 0.011, 3, fiberglass, 45., Ply-11 0.011, 3, fiberglass, -45., Ply-12 0.011, 3, basalt, 0., Ply-13 0.02, 3, nylon, 0., Ply-14 ** Region: (CompositeLayup-1-2: Generated From Layup) *Elset, elset=CompositeLayup-1-2 13, 14, 15, 16, 17, 18, 19, 20, 21, 22, 23, 24, 25, 26, 27, 28 189, 190, 191, 192, 193, 194, 195, 196, 197, 198, 199, 200, 201, 202, 203, 204 205, 206, 207, 208, 209, 210, 211, 212 ** Section: CompositeLayup-1-2 *Shell Section, elset=CompositeLayup-1-2, composite, layup=CompositeLayup-1 0.06125, 3, Base, 0., Ply-1 0.011, 3, fiberglass, 0., Ply-2 0.011, 3, fiberglass, 45., Ply-3 0.011, 3, fiberglass, -45., Ply-4 0.06125, 3, Poplar, 0., Ply-5 0.06125, 3, Poplar, 0., Ply-6 0.06125, 3, Poplar, 0., Ply-7 0.011, 3, fiberglass, 0., Ply-10 0.011, 3, fiberglass, 45., Ply-11 0.011, 3, fiberglass, -45., Ply-12 0.011, 3, basalt, 0., Ply-13 0.02, 3, nylon, 0., Ply-14 35 ** Region: (CompositeLayup-1-4: Generated From Layup) *Elset, elset=CompositeLayup-1-4 29, 30, 31, 32, 33, 34, 35, 36, 37, 38, 39, 40, 41, 42, 43, 44 45, 46, 47, 48, 49, 50, 51, 52, 173, 174, 175, 176, 177, 178, 179, 180 181, 182, 183, 184, 185, 186, 187, 188 ** Section: CompositeLayup-1-4 *Shell Section, elset=CompositeLayup-1-4, composite, layup=CompositeLayup-1 0.06125, 3, Base, 0., Ply-1 0.011, 3, fiberglass, 0., Ply-2 0.011, 3, fiberglass, 45., Ply-3 0.011, 3, fiberglass, -45., Ply-4 0.06125, 3, Poplar, 0., Ply-5 0.06125, 3, Poplar, 0., Ply-6 0.06125, 3, Poplar, 0., Ply-7 0.06125, 3, Poplar, 0., Ply-8 0.011, 3, fiberglass, 0., Ply-10 0.011, 3, fiberglass, 45., Ply-11 0.011, 3, fiberglass, -45., Ply-12 0.011, 3, basalt, 0., Ply-13 0.02, 3, nylon, 0., Ply-14 ** Region: (CompositeLayup-1-3: Generated From Layup) *Elset, elset=CompositeLayup-1-3, generate 53, 172, 1 ** Section: CompositeLayup-1-3 *Shell Section, elset=CompositeLayup-1-3, composite, layup=CompositeLayup-1 0.06125, 3, Base, 0., Ply-1 0.011, 3, fiberglass, 0., Ply-2 0.011, 3, fiberglass, 45., Ply-3 0.011, 3, fiberglass, -45., Ply-4 0.06125, 3, Poplar, 0., Ply-5 0.06125, 3, Poplar, 0., Ply-6 0.06125, 3, Poplar, 0., Ply-7 0.06125, 3, Poplar, 0., Ply-8 0.06125, 3, Poplar, 0., Ply-9 0.011, 3, fiberglass, 0., Ply-10 0.011, 3, fiberglass, 45., Ply-11 0.011, 3, fiberglass, -45., Ply-12 0.011, 3, basalt, 0., Ply-13 0.02, 3, nylon, 0., Ply-14 ** Region: (CompositeLayup-1-1: Generated From Layup) *Elset, elset=CompositeLayup-1-1 213, 214, 215, 216, 217, 218, 219, 220, 221, 222, 223, 224, 233, 234, 235, 236 237, 238, 239, 240, 241, 242, 243, 244, 245, 246, 247, 248, 249, 250, 251, 252 253, 254, 255, 256, 257, 258, 259, 260, 261, 262, 263, 264, 265, 266, 267, 268 269, 270, 271, 272, 273, 274, 275, 276, 277, 278, 279, 280, 281, 282, 283, 284 285, 286, 287, 288, 289, 290, 291, 292, 293, 294, 295, 296, 297, 298, 299, 300 301, 302, 303, 304, 305, 306 36 ** Section: CompositeLayup-1-1 *Shell Section, elset=CompositeLayup-1-1, composite, layup=CompositeLayup-1 0.06125, 3, Base, 0., Ply-1 0.011, 3, fiberglass, 0., Ply-2 0.011, 3, fiberglass, 45., Ply-3 0.011, 3, fiberglass, -45., Ply-4 0.06125, 3, Poplar, 0., Ply-5 0.011, 3, fiberglass, 0., Ply-10 0.011, 3, fiberglass, 45., Ply-11 0.011, 3, fiberglass, -45., Ply-12 0.011, 3, basalt, 0., Ply-13 0.02, 3, nylon, 0., Ply-14 *End Instance ** *Nset, nset=Set-23, instance=SKI-1 3, 4, 29, 30, 46, 47, 48, 163, 164, 165 *Elset, elset=Set-23, instance=SKI-1 9, 10, 11, 12, 213, 214, 215, 216, 233, 240, 252, 253, 283, 284, 285, 286 *Nset, nset=load261, instance=SKI-1 261, *End Assembly ** ** MATERIALS ** *Material, name=Base *Elastic 87023., 0.46 *Material, name=Poplar *Elastic, type=LAMINA 1.73891e+06,159980., 0.318,130418.,130418., 19128. *Material, name=basalt *Elastic, type=LAMINA 8.39095e+06, 1.61935e+06, 0.238, 629914., 629914., 629914. *Material, name=fiberglass *Elastic, type=LAMINA 5.92322e+06, 1.1197e+06, 0.21, 477732., 477732., 477732. *Material, name=nylon *Elastic 377098., 0.41 ** ** BOUNDARY CONDITIONS ** ** Name: BC-1 Type: Displacement/Rotation *Boundary Set-23, 1, 1 Set-23, 2, 2 Set-23, 3, 3 37 Set-23, 4, 4 Set-23, 5, 5 ** ---------------------------------------------------------------** ** STEP: Stage1_Weight35 ** *Step, name=Stage1_Weight35, nlgeom=NO, perturbation *Static ** ** LOADS ** ** Name: Load-2 Type: Concentrated force *Cload load261, 2, -100. ** ** OUTPUT REQUESTS ** ** ** FIELD OUTPUT: F-Output-1 ** *Output, field *Node Output U, UR, UT *Element Output, directions=YES LE, S ** ** FIELD OUTPUT: stage2compos ** *Element Output, elset=SKI-1.CompositeLayup-1-1, directions=YES 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16 ALPHA, CS11, CTSHR, E, EE, ER, IE, LE, MISES, MISESMAX, MISESONLY, NE, PE, PEEQ, PEEQMAX, PEEQT PEMAG, PEQC, PRESSONLY, PS, S, SALPHA, SE, SEE, SEP, SEPE, SPE, SSAVG, THE, TRIAX, TSHR, VE VEEQ, VS *Element Output, elset=SKI-1.CompositeLayup-1-1, directions=YES 17, 18, 19, 20, 21, 22, 23, 24, 25, 26, 27, 28, 29, 30 ALPHA, CS11, CTSHR, E, EE, ER, IE, LE, MISES, MISESMAX, MISESONLY, NE, PE, PEEQ, PEEQMAX, PEEQT PEMAG, PEQC, PRESSONLY, PS, S, SALPHA, SE, SEE, SEP, SEPE, SPE, SSAVG, THE, TRIAX, TSHR, VE VEEQ, VS ** ** FIELD OUTPUT: stage2compos ** *Element Output, elset=SKI-1.CompositeLayup-1-2, directions=YES 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16 ALPHA, CS11, CTSHR, E, EE, ER, IE, LE, MISES, MISESMAX, MISESONLY, NE, PE, PEEQ, PEEQMAX, PEEQT PEMAG, PEQC, PRESSONLY, PS, S, SALPHA, SE, SEE, SEP, SEPE, SPE, SSAVG, THE, TRIAX, TSHR, VE VEEQ, VS *Element Output, elset=SKI-1.CompositeLayup-1-2, directions=YES 38 17, 18, 19, 20, 21, 22, 23, 24, 25, 26, 27, 28, 29, 30, 31, 32 ALPHA, CS11, CTSHR, E, EE, ER, IE, LE, MISES, MISESMAX, MISESONLY, NE, PE, PEEQ, PEEQMAX, PEEQT PEMAG, PEQC, PRESSONLY, PS, S, SALPHA, SE, SEE, SEP, SEPE, SPE, SSAVG, THE, TRIAX, TSHR, VE VEEQ, VS *Element Output, elset=SKI-1.CompositeLayup-1-2, directions=YES 33, 34, 35, 36 ALPHA, CS11, CTSHR, E, EE, ER, IE, LE, MISES, MISESMAX, MISESONLY, NE, PE, PEEQ, PEEQMAX, PEEQT PEMAG, PEQC, PRESSONLY, PS, S, SALPHA, SE, SEE, SEP, SEPE, SPE, SSAVG, THE, TRIAX, TSHR, VE VEEQ, VS ** ** FIELD OUTPUT: stage2compos ** *Element Output, elset=SKI-1.CompositeLayup-1-3, directions=YES 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16 ALPHA, CS11, CTSHR, E, EE, ER, IE, LE, MISES, MISESMAX, MISESONLY, NE, PE, PEEQ, PEEQMAX, PEEQT PEMAG, PEQC, PRESSONLY, PS, S, SALPHA, SE, SEE, SEP, SEPE, SPE, SSAVG, THE, TRIAX, TSHR, VE VEEQ, VS *Element Output, elset=SKI-1.CompositeLayup-1-3, directions=YES 17, 18, 19, 20, 21, 22, 23, 24, 25, 26, 27, 28, 29, 30, 31, 32 ALPHA, CS11, CTSHR, E, EE, ER, IE, LE, MISES, MISESMAX, MISESONLY, NE, PE, PEEQ, PEEQMAX, PEEQT PEMAG, PEQC, PRESSONLY, PS, S, SALPHA, SE, SEE, SEP, SEPE, SPE, SSAVG, THE, TRIAX, TSHR, VE VEEQ, VS *Element Output, elset=SKI-1.CompositeLayup-1-3, directions=YES 33, 34, 35, 36, 37, 38, 39, 40, 41, 42 ALPHA, CS11, CTSHR, E, EE, ER, IE, LE, MISES, MISESMAX, MISESONLY, NE, PE, PEEQ, PEEQMAX, PEEQT PEMAG, PEQC, PRESSONLY, PS, S, SALPHA, SE, SEE, SEP, SEPE, SPE, SSAVG, THE, TRIAX, TSHR, VE VEEQ, VS ** ** FIELD OUTPUT: stage2compos ** *Element Output, elset=SKI-1.CompositeLayup-1-4, directions=YES 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16 ALPHA, CS11, CTSHR, E, EE, ER, IE, LE, MISES, MISESMAX, MISESONLY, NE, PE, PEEQ, PEEQMAX, PEEQT PEMAG, PEQC, PRESSONLY, PS, S, SALPHA, SE, SEE, SEP, SEPE, SPE, SSAVG, THE, TRIAX, TSHR, VE VEEQ, VS *Element Output, elset=SKI-1.CompositeLayup-1-4, directions=YES 17, 18, 19, 20, 21, 22, 23, 24, 25, 26, 27, 28, 29, 30, 31, 32 ALPHA, CS11, CTSHR, E, EE, ER, IE, LE, MISES, MISESMAX, MISESONLY, NE, PE, PEEQ, PEEQMAX, PEEQT PEMAG, PEQC, PRESSONLY, PS, S, SALPHA, SE, SEE, SEP, SEPE, SPE, SSAVG, THE, TRIAX, TSHR, VE VEEQ, VS *Element Output, elset=SKI-1.CompositeLayup-1-4, directions=YES 33, 34, 35, 36, 37, 38, 39 ALPHA, CS11, CTSHR, E, EE, ER, IE, LE, MISES, MISESMAX, MISESONLY, NE, PE, PEEQ, PEEQMAX, PEEQT PEMAG, PEQC, PRESSONLY, PS, S, SALPHA, SE, SEE, SEP, SEPE, SPE, SSAVG, THE, TRIAX, TSHR, VE VEEQ, VS ** ** FIELD OUTPUT: stage2compos 39 ** *Element Output, elset=SKI-1.CompositeLayup-1-5, directions=YES 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16 ALPHA, CS11, CTSHR, E, EE, ER, IE, LE, MISES, MISESMAX, MISESONLY, NE, PE, PEEQ, PEEQMAX, PEEQT PEMAG, PEQC, PRESSONLY, PS, S, SALPHA, SE, SEE, SEP, SEPE, SPE, SSAVG, THE, TRIAX, TSHR, VE VEEQ, VS *Element Output, elset=SKI-1.CompositeLayup-1-5, directions=YES 17, 18, 19, 20, 21, 22, 23, 24, 25, 26, 27, 28, 29, 30, 31, 32 ALPHA, CS11, CTSHR, E, EE, ER, IE, LE, MISES, MISESMAX, MISESONLY, NE, PE, PEEQ, PEEQMAX, PEEQT PEMAG, PEQC, PRESSONLY, PS, S, SALPHA, SE, SEE, SEP, SEPE, SPE, SSAVG, THE, TRIAX, TSHR, VE VEEQ, VS *Element Output, elset=SKI-1.CompositeLayup-1-5, directions=YES 33 ALPHA, CS11, CTSHR, E, EE, ER, IE, LE, MISES, MISESMAX, MISESONLY, NE, PE, PEEQ, PEEQMAX, PEEQT PEMAG, PEQC, PRESSONLY, PS, S, SALPHA, SE, SEE, SEP, SEPE, SPE, SSAVG, THE, TRIAX, TSHR, VE VEEQ, VS ** ** HISTORY OUTPUT: H-Output-1 ** *Output, history, variable=PRESELECT *End Step 40 6.2 Stage 2 ABAQUS Undamaged Ski Stress by Layer Figure 6-1 Ply 1 Base Layer Stress Figure 6-2 Ply2 Fiberglass 0° Stress Figure 6-3 Ply 3 Fiberglass 45° Stress 41 Figure 6-4 Ply 4 Fiberglass -45° Stress Figure 6-5 Ply 5 Poplar Wood Stress Figure 6-6 Ply 6 Poplar Wood Stress 42 Figure 6-7 Ply7 Poplar Wood Stress Figure 6-8 Ply 8 Poplar Wood Stress Figure 6-9 Ply 9 Poplar Wood Stress 43 Figure 6-10 Ply 10 Fiberglass 0° Stress Figure 6-11Ply 11 Fiberglass 45° Stress Figure 6-12 Ply 12 Fiberglass -45° Stress 44 Figure 6-13 Ply 13 Basalt 0° Stress Figure 6-14 Ply14 Nylon Stress 45