Discrete-Event System Simulation Project Complex Manufacturing System Cheryl Yale

advertisement

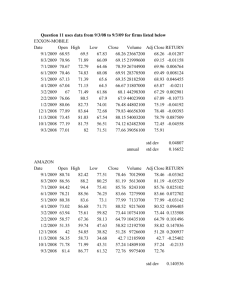

Discrete-Event System Simulation Project Complex Manufacturing System Cheryl Yale Simulation and Modeling Analysis 12/7/99 1 Introduction The manufacture of a propeller to engine shaft adapter is a complicated process involving as many as twenty operations in fifteen different machines. The simulation described in this paper is an analysis of the experimental manufacturing technique used to develop the first three propeller adapters. With the data accumulated here, the technique can be adjusted and refined through simulation before any further manufacturing is done. The end result will be a fine tuned, quicker and cheaper process. Problem Formulation Data will be obtained on a limited basis from the experimental manufacturing of the first three adapters. This will give an average machine time for each step of the process. Given this data, the current manufacturing process will be modeled. The objective is to model the known process and verify the simulation with experimental data. Given the verified known process, individual changes can be made and the results tallied. This will show the options available to ease the manufacturing process. Model Conceptualization Assumptions: 1. The model will be representative of the actual manufacturing facility. There will be the exact numbers of machines in the model as there are on the floor. 2. The number of machinist will be the number currently assigned to the propeller adapter line. 3. Each change in machine will be modeled as one process in ProModel. (For Example: if the Matsuura does two steps before the adapter is taken out, the simulation will model it as only one step) 4. The machines are dedicated to the adapter line (No downtime has been considered). 5. If an operation takes place outside this manufacturing floor it will not be in the model (Vendor operations are not modeled). 6. The end result will be an accurate manufacturing time per adapter and a better understanding of the potential cost savings in the process. Data Collection Since this is a new line for this particular manufacturing facility, there is limited data to use in collection. There is machine run time data for the first three adapters which is shown in Table 1 - Average Experimental Machine Times below. 2 There is a standing order for a total of 250 adapters over the next 15 years at this facility. There is no predicted order rate, so 3 adapters every 500 hours was chosen as an estimate of the arrival times. Table 1 - Average Experimental Machine Times Machine Bench VTL VTL BROACH VTL VTL Matsuura Gun drill Drill Press Matssura Gear shaper Deburr booth MPI Shot peen (Eng. Abrasives) Shot peen (Eng. Abrasives) Deburr booth VTL Warner Swasey Warner Swasey Matsuura M.P.I. Vendor Vendor Bench Bench Bench Bench Operation Description Est. Time(hr) Draw material 0 Rough turn flange end and mark 1.3 Rough turn shank end 1.5 Broach I.D. spline 0.7 Finish turn shaft end 1.5 Finish turn flange end 1 Machine flange holes 1.3 Drill oil holes (5) 1.6 Drill flange holes (2) 0.4 Machine shank holes 1.3 Shape O.D. spline 0.4 Deburr 0.7 M.P.I 0.5 Shot peen flange end 0.8 Shot peen shaft end Deburr and polish Diamond burnish 15 deg. Coneseat Grind pilot dia. (flange end) Grind shaft O.D. Machine flange holes and burnish M.P.I. Tin Zinc plate(or deviation to cadmium plate) Paint oil holes Draw materials Identification mark and assemble Assemble and bond Final inspect per B/P and PMP3050 Package and Preserve 1 0.3 0.5 0.5 0.7 0.5 0.5 0 0 0 0.4 0.7 1 0.2 19.8 3 Bench Final Inspect MPI Bench Deburr Booth VTL Warner Swasey Gear Shaper Shot Peen Drill Press Broach Matsuura Gun Drill Model Translation The model was made using ProModel version 4.20. Fourteen machines were used as locations. The machine layout and path network is shown below in Figure 1. The printed file is shown in Appendix A. Since the adapter returns more than once to several machines with different times and different processing, the adapter was divided into four separate entities. These were adapter_rough, adapter_semi, adapter_semi2, and adapter_finish. Each time it returns to a previously used machine the name changes. This bit of confusion caused problems in the overall processing, since it was difficult to tell what had processing and what still needed processing. The distributions were chosen to be normally distributed. This was used since there is such limited data available at this time. This is an easy parameter to change should more data become available, or the manufacturing engineers have a better understanding of the distributions then were given at this time. 4 Verification The verification of the program was a major step in the programming of the simulation due to the number of machines and paths within the analysis. The trace tool was used within the run environment to determine the mistakes and correct the errors. The major error found in the verification process was a hold up at the matsuura. This seemed to cause a very long list of blocked machines, such that it would take 100-250 hours to manufacture one set of adapters. Knowing that this was obviously incorrect, I used the process of elimination to determine the error. One machine at a time I changed the capacity to almost infinite. In the end it turned out I had forgotten the processing of a finished_adapter at the VTL, although the semi_finished, had processing. This blocked the entire line starting at the matsuura. Once this major error in processing was discovered, the model runs correctly. It was shown to run according to the process table shown in Table 1. Validation The simulation has been validated. The simulation was run for a warm-up period of 500 hours, with the simulation running 100000. This was done for 15 replications. The average time in the system for the Adapter for these runs was 20.025 with a standard deviation of .049. This agrees very well with the input total above of 19.8 hours. Increasing the run-time to 250000 hours changes the average time in the system very little (20.027) but decreases the standard deviation to .023. The number of replication was increased to 25 and again the average time in the system of the adapter was changed very little (20.029) but this time the standard deviation was also changed very little (.047). This simulation was done under the assumption that the machines were meant entirely for the adapter, which is untrue. Since the machines show very little utilization, it would be prudent to add in machine cycles belonging to other product lines. Or model them using machine downtimes. This would show the actual queuing of parts at each machine, which may cause significant delays in the adapter machining time. Production Runs and Analysis The model was run with multiple replications and with several varieties of run hours. Since the average time in system variable was changed very little by the increase the run length to 250000, the optimum time for running on this computer was decided to be 100000. The number of replications seems to be steady at fifteen. 5 The results shown in Appendix B are the results of the 25 replications of runtimes of 100000. The results are the expected results, including average times of each individual step. The production run uses two matsuura machines. The first runs used only one matsuura, but since this machine involves 20 percent of the overall manufacturing time this blocked the rest of the production. The other option was the addition of a queue, but the queue did not solve the problem, just gave it a place to wait. The addition of the queue on the deburr booth solved the problem that location was experiencing. The deburr booth was also blocking other machines, since this was only 5% of the total machining time, I realized this shouldn't be a problem. The addition of the queue added a place for the next adapter to wait while the process was completed. With these changes, the output desired is the time of manufacture for the finished adapter. Using twenty-five replications of 100,000 hours the time in the system is 22.05 hours with a standard deviation of .057 hours. The output is very dependent on the input. For instance, changing the arrival rate could change the output. If the arrival rate were changed to an greater amount this would greatly influence the results. Changing the arrival rate to 3 every 100 hours (from 3 every 500) causes failures due to blockages. Although for the adapters that make it through the system, the average time is 22.1 with a standard deviation of .42. To check the validation of using a normal distribution I chose the matsuura and used a triangular distribution with the same overall number spread. This changed the results only slightly. With an average system time of 22.0 and a standard deviation of .3. Conclusions The adapter-manufacturing model has been built, and validated. It is now ready as a baseline to begin modeling different processes. Changes could be made to the system to determine the effect of distances between machine, run times, multiple machines, multiple capacities or number of machinists. 1 Appendix A ******************************************************************************** * * * Formatted Listing of Model: * * C:\ProMod4\models\proj.mod * * * ******************************************************************************** Time Units: Distance Units: Hours Feet ******************************************************************************** * Locations * ******************************************************************************** Name ----------------Material_draw VTL Broach Matsuura Matsuura.1 Matsuura.2 Gun_Drill Drill_Press Gear_Shaper Deburr_Boothe Shot_Peen MPI Warner_sawseg Bench Inspect Material_Draw_que deburr_queue Appendix A Cap ---1 3 1 1 1 1 1 1 1 1 1 1 1 1 1 100 100E Units ----1 1 1 2 1 1 1 1 1 1 1 1 1 1 1 1 1 Stats ----------Time Series Time Series Time Series Time Series Time Series Time Series Time Series Time Series Time Series Time Series Time Series Time Series Time Series Time Series Time Series Time Series Time Series Rules Cost --------------- -----------Oldest, , Oldest, , Oldest, , First Oldest, , First Oldest, , Oldest, , Oldest, , Oldest, , Oldest, , Oldest, , Oldest, , Oldest, , Oldest, , Oldest, , Oldest, , Oldest, , Oldest, , 2 ******************************************************************************** * Entities * ******************************************************************************** Name -------------Adapter_Rough Adapter_semi Adapter_semi2 adapter_finish Speed (fpm) -----------0 0 0 0 Stats Cost ----------- -----------Time Series Time Series Time Series Time Series ******************************************************************************** * Path Networks * ******************************************************************************** Name Type T/S From -------- ----------- ---------------- -------Net1 Passing Speed & Distance N1 N2 N2 N5 N6 N7 N8 N10 N12 N9 N10 N2 N11 N5 N12 N13 Appendix A To -------N2 N3 N5 N6 N7 N8 N10 N12 N9 N10 N2 N11 N5 N12 N13 N14 BI ---Bi Bi Bi Bi Bi Bi Bi Bi Bi Bi Bi Bi Bi Bi Bi Bi Dist/Time ---------38.00 28.28 44.46 34.81 70.17 28.47 27.36 23.21 91.83 60.14 46.40 118.19 105.39 65.67 34.15 26.00 Speed Factor -----------1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 3 ******************************************************************************** * Interfaces * ******************************************************************************** Net Node ---------- ---------Net1 N1 N2 N3 N5 N6 N7 N8 N10 N12 N9 N11 N13 N14 Location ------------Material_draw VTL Broach Matsuura Gun_Drill Drill_Press Gear_Shaper Deburr_Boothe MPI Shot_Peen Warner_sawseg Bench Inspect ******************************************************************************** * Resources * ******************************************************************************** Res Name Units Stats Search --------- ----- -------- -----Machinist 3 By Unit None Ent Search Path Motion Cost ------ ---------- -------------- -----------Oldest Empty: 150 fpm Full: 150 fpm ******************************************************************************** * Processing * ******************************************************************************** Process Entity Appendix A Location Operation Routing Blk Output Destination Rule Move Logic 4 -------------Adapter_Rough Adapter_Rough machinist Adapter_Rough machinist Adapter_Rough machinist Adapter_semi ----------------- -----------------Material_Draw_que Material_draw VTL Broach VTL ---- -------------- ------------- ------1 Adapter_Rough Material_draw FIRST 1 1 Adapter_Rough VTL FIRST 1 -----------move with free machinist wait n(1.3,.2) get machinist wait .25 free machinist wait n(1.5,.2) 1 Adapter_Rough Broach FIRST 1 move with wait n(.7,.25) free machinist 1 Adapter_semi VTL FIRST 1 move with 1 Adapter_semi Matsuura FIRST 1 move with free machinist wait n(1.3, .3) 1 Adapter_semi Gun_Drill FIRST 1 move with wait n(1.6,.25) free machinist 1 Adapter_semi Drill_Press FIRST 1 move with wait n(.4,.1) free machinist 1 Adapter_semi2 Matsuura FIRST 1 move with free machinist wait n(1.3,.25) 1 Adapter_semi2 Gear_Shaper FIRST 1 move with free machinist wait n(.4,.05) 1 Adapter_semi2 deburr_queue FIRST 1 move with 1 ALL Deburr_Boothe FIRST 1 free machinist wait n(1.5, .25) get machinist wait .25 free machinist wait n(1,.25) machinist Adapter_semi machinist Adapter_semi machinist Adapter_semi machinist Adapter_semi2 machinist Adapter_semi2 machinist ALL Adapter_semi2 Appendix A Matsuura Gun_Drill Drill_Press Matsuura Gear_Shaper deburr_queue Deburr_Boothe free machinist free machinist 5 machinist Adapter_semi2 machinist Adapter_semi2 MPI Shot_Peen machinist adapter_finish Deburr_Boothe machinist adapter_finish VTL machinist adapter_finish Warner_sawseg machinist adapter_finish Matsuura machinist adapter_finish MPI machinist adapter_finish Bench machinist adapter_finish Inspect wait n(.7,.2) 1 Adapter_semi2 MPI FIRST 1 move with wait n(.5,.2) free machinist 1 Adapter_semi2 Shot_Peen FIRST 1 move with free machinist wait n(.8,.2) get machinist wait .2 free machinist wait n(1,.2) 1 adapter_finish deburr_queue FIRST 1 move with wait n(.3,.1) free machinist 1 adapter_finish VTL FIRST 1 move with free machinist wait n(.5,.15) 1 adapter_finish Warner_sawseg FIRST 1 move with free machinist wait n(.5,.05) get machinist wait .1 free machinist wait n(.7,.1) 1 adapter_finish Matsuura FIRST 1 move with free machinist wait n(.5, .1) 1 adapter_finish MPI FIRST 1 move with wait n(.5,.1) free machinist 1 adapter_finish Bench FIRST 1 move with wait n(1.2,.8) 1 adapter_finish Inspect FIRST 1 move with wait n(1,.2) free machinist 1 adapter_finish EXIT FIRST 1 ******************************************************************************** * Arrivals * ******************************************************************************** Appendix A 6 Entity Location Qty each First Time Occurrences Frequency Logic ------------- ----------------- ---------- ---------- ----------- ----------- -----------Adapter_Rough Material_Draw_que 3 inf n(500, 125) Appendix A 1 Appendix B -------------------------------------------------------------------------------General Report Output from C:\ProMod4\models\proj.mod [Adapter Manufacturing Project] Date: Nov/29/1999 Time: 08:39:26 PM -------------------------------------------------------------------------------Scenario : Normal Run Replication : Average Period : Final Report (500 hr to 100500 hr Elapsed: 100000 hr) Warmup Time : 500 hr (Std. Dev. 0 sec) Simulation Time : 100500 hr -------------------------------------------------------------------------------LOCATIONS Location Name ----------------Material draw Material draw VTL VTL Broach Broach Matsuura.1 Matsuura.1 Matsuura.2 Matsuura.2 Matsuura Matsuura Gun Drill Gun Drill Drill Press Drill Press Gear Shaper Gear Shaper Deburr Boothe Appendix B Scheduled Hours --------100000 0 100000 0 100000 0 100000 0 100000 0 200000 0 100000 0 100000 0 100000 0 100000 Capacity -------1 0 3 0 1 0 1 0 1 0 2 0 1 0 1 0 1 0 1 Total Entries ------599.52 9.82395 1798.8 29.3428 599.52 9.82395 1384.08 23.2933 415.08 12.3926 1799.16 29.1414 599.72 9.68039 599.72 9.68039 599.76 9.71802 1199.52 Average Hours Per Entry --------0.000000 0.000000 2.276678 0.007418 0.701052 0.009405 1.152240 0.007850 1.824243 0.029467 1.307175 0.009451 1.601693 0.009640 0.402881 0.004600 0.400072 0.001901 0.509848 Average Contents ----------0 0 0.0409541 0.000752585 0.00420327 0.000103546 0.0159477 0.00027526 0.00757038 0.000198696 0.011759 0.000205522 0.00960574 0.000169726 0.00241602 4.03533e-05 0.00239949 4.17217e-05 0.00611573 Maximum Contents -------1 0 3 0 1 0 1 0 1 0 2 0 1 0 1 0 1 0 1 Current Contents -------0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 % Util -----0.00 0.00 1.37 0.03 0.42 0.01 1.59 0.03 0.76 0.02 1.18 0.02 0.96 0.02 0.24 0.00 0.24 0.00 0.61 (Average) (Std. Dev.) (Average) (Std. Dev.) (Average) (Std. Dev.) (Average) (Std. Dev.) (Average) (Std. Dev.) (Average) (Std. Dev.) (Average) (Std. Dev.) (Average) (Std. Dev.) (Average) (Std. Dev.) (Average) 2 Deburr Boothe Shot Peen Shot Peen MPI MPI Warner sawseg Warner sawseg Bench Bench Inspect Inspect Material Draw que Material Draw que deburr queue deburr queue 0 100000 0 100000 0 100000 0 100000 0 100000 0 100000 0 100000 0 0 1 0 1 0 1 0 1 0 1 0 100 0 100 0 19.436 599.76 9.71802 1199.52 19.436 599.76 9.71802 599.8 9.72111 599.8 9.72111 599.52 9.82395 1199.52 19.436 0.004990 1.997765 0.013543 0.761315 0.013468 1.301282 0.006165 1.279090 0.025427 0.997633 0.007525 0.000000 0.000000 0.036022 0.002962 0.000116355 0.0119814 0.00018238 0.00913273 0.000243101 0.00780444 0.000123516 0.00767184 0.000192198 0.00598382 0.000108314 0 0 0.000432168 3.74758e-05 0 1 0 1 0 1 0 1 0 1 0 1 0 1.92 0.276887 LOCATION STATES BY PERCENTAGE (Multiple Capacity) Location Name ----------------VTL VTL Material Draw que Material Draw que deburr queue deburr queue Scheduled Hours --------100000 0 100000 0 100000 0 % Empty -----98.12 0.03 100.00 0.00 99.96 0.00 % Partially Occupied --------1.05 0.02 0.00 0.00 0.04 0.00 % Full ---0.83 0.02 0.00 0.00 0.00 0.00 | | | | | | | | | | % Down ---0.00 0.00 0.00 0.00 0.00 0.00 (Average) (Std. Dev.) (Average) (Std. Dev.) (Average) (Std. Dev.) LOCATION STATES BY PERCENTAGE (Single Capacity/Tanks) Location Name ------------Material draw Material draw Broach Broach Matsuura.1 Appendix B Scheduled Hours --------100000 0 100000 0 100000 % Operation --------0.00 0.00 0.42 0.01 1.32 % Setup ----0.00 0.00 0.00 0.00 0.00 % Idle -----100.00 0.00 99.58 0.01 98.40 % Waiting ------0.00 0.00 0.00 0.00 0.00 % Blocked ------0.00 0.00 0.00 0.00 0.28 % Down ---0.00 0.00 0.00 0.00 0.00 (Average) (Std. Dev.) (Average) (Std. Dev.) (Average) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0.01 1.20 0.02 0.91 0.02 0.78 0.01 0.77 0.02 0.60 0.01 0.00 0.00 0.00 0.00 (Std. Dev.) (Average) (Std. Dev.) (Average) (Std. Dev.) (Average) (Std. Dev.) (Average) (Std. Dev.) (Average) (Std. Dev.) (Average) (Std. Dev.) (Average) (Std. Dev.) 3 Matsuura.1 Matsuura.2 Matsuura.2 Matsuura Matsuura Gun Drill Gun Drill Drill Press Drill Press Gear Shaper Gear Shaper Deburr Boothe Deburr Boothe Shot Peen Shot Peen MPI MPI Warner sawseg Warner sawseg Bench Bench Inspect Inspect 0 100000 0 200000 0 100000 0 100000 0 100000 0 100000 0 100000 0 100000 0 100000 0 100000 0 100000 0 0.02 0.54 0.02 0.93 0.01 0.96 0.02 0.24 0.00 0.24 0.00 0.60 0.01 1.20 0.02 0.60 0.01 0.78 0.01 0.74 0.02 0.60 0.01 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.03 99.24 0.02 98.82 0.02 99.04 0.02 99.76 0.00 99.76 0.00 99.39 0.01 98.80 0.02 99.08 0.02 99.22 0.01 99.23 0.02 99.40 0.01 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.01 0.22 0.01 0.25 0.01 0.00 0.00 0.00 0.00 0.00 0.00 0.01 0.00 0.00 0.00 0.31 0.02 0.00 0.00 0.03 0.01 0.00 0.00 RESOURCES Resource Name ----------Machinist.1 Machinist.1 Machinist.2 Machinist.2 Machinist.3 Machinist.3 Machinist Machinist Appendix B Units ----1 0 1 0 1 0 3 0 Scheduled Hours --------100000 0 100000 0 100000 0 300000 0 Number Of Times Used -------4236.8 164.187 4190.48 141.008 4166.16 148.43 12593.4 204.459 Average Hours Per Usage -------0.320308 0.010741 0.323792 0.009322 0.325903 0.011584 0.322994 0.001557 % Util -----1.36 0.02 1.36 0.02 1.36 0.02 1.36 0.02 (Average) (Std. Dev.) (Average) (Std. Dev.) (Average) (Std. Dev.) (Average) (Std. Dev.) 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 (Std. Dev.) (Average) (Std. Dev.) (Average) (Std. Dev.) (Average) (Std. Dev.) (Average) (Std. Dev.) (Average) (Std. Dev.) (Average) (Std. Dev.) (Average) (Std. Dev.) (Average) (Std. Dev.) (Average) (Std. Dev.) (Average) (Std. Dev.) (Average) (Std. Dev.) 4 RESOURCE STATES BY PERCENTAGE Resource Name ----------Machinist.1 Machinist.1 Machinist.2 Machinist.2 Machinist.3 Machinist.3 Machinist Machinist Scheduled Hours --------100000 0 100000 0 100000 0 300000 0 % In Use -----1.36 0.02 1.36 0.02 1.36 0.02 1.36 0.02 % Idle ----98.64 0.02 98.64 0.02 98.64 0.02 98.64 0.02 % Down ---0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 (Average) (Std. Dev.) (Average) (Std. Dev.) (Average) (Std. Dev.) (Average) (Std. Dev.) FAILED ARRIVALS Entity Name ------------Adapter Rough Adapter Rough Location Name ----------------Material Draw que Material Draw que Total Failed -----0 0 (Average) (Std. Dev.) ENTITY ACTIVITY Entity Name -------------Adapter Rough Adapter Rough Adapter semi Adapter semi Adapter semi2 Adapter semi2 adapter finish adapter finish Appendix B Total Exits ------0 0 0 0 0 0 599.8 9.72111 Current Quantity In System --------0 0 0 0 0 0 0 0 Average Hours In System --------22.048766 0.057731 Average Hours In Move Logic -------0.000000 0.000000 Average Hours Wait For Res, etc. --------0.000000 0.000000 Average Hours In Operation --------20.029012 0.046845 Average Hours Blocked -------2.019754 0.038558 (Average) (Std. Dev.) (Average) (Std. Dev.) (Average) (Std. Dev.) (Average) (Std. Dev.) 5 ENTITY STATES BY PERCENTAGE Entity Name -------------Adapter Rough Adapter Rough Adapter semi Adapter semi Adapter semi2 Adapter semi2 adapter finish adapter finish Appendix B % In Move Logic ------0.00 0.00 % Wait For Res, etc. --------0.00 0.00 % In Operation -----------90.84 0.16 % Blocked ------9.16 0.16 (Average) (Std. Dev.) (Average) (Std. Dev.) (Average) (Std. Dev.) (Average) (Std. Dev.)