Discrete Event Simulation of Dept. 110/114 by Robert Griffiths 2

advertisement

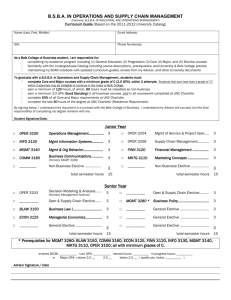

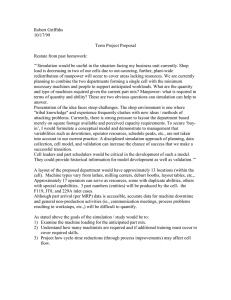

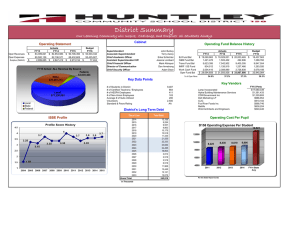

Discrete Event Simulation of Dept. 110/114 by Robert Griffiths 2nd Draft Simulation Modeling and Analysis 12/7/99 Problem Definition The resources of two manufacturing cells are to be combined due to reduced load in both departments. In addition, other areas of the shop have declared “needs” for both manpower and equipment. Early voluntary retirement will have (has had) an impact on available manpower and skills. The layout of the new department will therefore be impacted by both availability of machines and machinists to staff the cell. A preliminary design of the layout of the department projects costs of approximately $850,000 for the proposed restructuring effort. The initial work to develop a layout has been based on “tribal knowledge” and basic consideration of machine loading in light of projected schedule. A simulation of the proposed new department is to be developed, producing the proposed part numbers and utilizing machinists with known skill sets. Introduction The resources of large manufacturing facilities were organized several years ago as “villages”. Like machines were frequently grouped together giving shop floor control the “flexibility” of routing parts to whatever machines were available. Redundancy in machines and machinists was a common occurrence, organizing machines and operators in “villages” was a perceived effective method for flowing parts though the shop. Those were days when inventory levels were high, floor space to accommodate the large machining groups was amble, and there was an abundance of labor. The shop floor continues to evolve today. Over the past decade, the drive has been to reduce inventory levels by moving parts more efficiently through the shop. To accomplish this, “machining cells” were setup. Each cell / department would contain the minimum required equipment to produce their product. In addition, the departments were arranged into “U-shaped flowlines”- this served a many goals, among them: 1) reduced the floor space of the department 2) allowed for one machinist to perform multiple tasks 3) aided in the development of the “visual factory” in which department personnel as well as customers could easily understand the part ”flow” and where the problems were If the parts running in a department change to a degree that causes the cell in its current configuration not to run as efficiently, it is time to change the part mix or reorganize the cell. This is often a challenge in the current environment where men and machines are in limited supply. The planner must reconcile the requirements for capacity that the schedule demands to the availability of resources. Another point to note concerning “lean-manufacturing” systems. These are “engineered systems”, that is, cells should be designed such that the inputs to the cell will result in predictable outputs. This is required without large redundancies built-in (recall the minimalist approach). Therefore, unplanned events such as machine downtime, absenteeism, large schedule surges, etc., can have a severe impact on the cell’s performance. Statement of Objectives Develop a 5 machinist, 1st shift model of the proposed department. The department should produce two assemblies and two detail part numbers- a total of four entities Simulation should highlight any bottlenecks in terms of operators and / or equipment Simulation should verify cells capability to maintain schedule through mid-2002 Model Planning The proposed layout CAD file was utilized in the model development to aid in determination of locations. All the relevant machines in the department were captured in the model: 2 N/C VTL (Vertical Turning Lathe) 1 Layout table 1 4-axis horizontal milling center 1 5-axis horizontal milling center 1 Vertical milling center (3axis) 1 Manual vertical drill press 1 Alkali washer 1 Deburr booth 1 Power Washer 1 Assembly table 1 inspection bench 2 material incoming / outgoing areas 1 outside processing location Graphic 1 The resources utilized were five machinists with different skills / responsibilities: VTL operator- operates the two VTLs HMC operator- operates the 4-axis and / or 5-axis HMC VMC operator- operates the 3-axis VMC and the manual drill Deburr operator- performs manual deburr as well as washing part and various layout functions Inspector- performs visual in-process and final inspection of parts The entities in the simulation were defined as the four parts numbers scheduled to be produced by the department. The JT8 inlet case- this is received to the department as a weldment. The cell is responsible for some light machining early in the process and then the part spends a majority of its lead-time outside the cell at braze, paint, and various nondestructive testing activities. The F119 inner and outer shrouds. These parts are machined by the cell in detail, are brazed together with struts to form an inlet assembly. Machining is then performed by the cell on the assembly. External files are utilized which contain arrival information (dependant on schedule), and shift definition. In accordance with the objectives, the model is first simulated using only a 1st shift defined for all locations. A 15-minute break is defined mid-morning and a 30 minute lunch break starts at 12:15pm. No machine downtime has been modeled. This is an acceptable omission based on the premise that this will be a limited shift operation (1 or 2 shifts). It is envisioned that one could take advantage of off-shift time to perform preventative maintenance and necessary repairs. Therefore machine downtime should have at minimal impact on production. This is also a realistic expectation in practice. Many “disciplined” shops do schedule regular maintenance activities on the off-shifts. The model file is located in Appendix II. Data Collection Arrival Schedule Raw material arrival to the cell can be modeled as deterministic in nature, that is, the part scheduler’s task is to insure that material is available for processing based on delivery dates. Material must arrive early enough to account for the processing lead-time to insure on-time delivery. Lead-times for the parts produced through the department are diagrammed below: outer case [3 wks] F119_Assembly [8wks] inner shroud [2] JT8_Assembly [2.5wks] So, if a F119_Assembly were due for delivery on 2/28, an outer case detail should be started no later than 11 weeks prior. Actual delivery dates for the hardware is charted below: JT8 Delivery Schedule 1 Cut date 7/26/02 5/26/02 3/26/02 1/26/02 11/26/01 9/26/01 7/26/01 5/26/01 3/26/01 1/26/01 11/26/00 9/26/00 7/26/00 5/26/00 3/26/00 0 1/26/00 Quanitity 2 F119 Delivery Schedule Quanitity 4 3 2 1 Ja n00 M ar -0 0 M ay -0 0 Ju l-0 0 Se p00 No v00 Ja n01 M ar -0 1 M ay -0 1 Ju l-0 1 Se p01 No v01 Ja n02 M ar -0 2 M ay -0 2 Ju l-0 2 Se p02 0 Cut Date Based on delivery requirements, the simulation is determined to start on October 28 1999, with the arrival of raw material for an outer shroud. To implement an arrival schedule in ProModel, it is necessary to develop interarrival times which are tabulated and read in as an external file. Note that while the F119 delivery schedule is fairly well distributed (with the exception of the 2002 ramp-up), the JT8 exhibits “clustering” early during 2000. We referred to this as a schedule (or demand) that is “front loaded”. The Unit manager has options: he/she could attempt to have the department continue to function as normal, absorbing the increased load (which will have to be accommodated in terms of increased overtime). A second option would be to instruct the part scheduler to “level load” the schedule for the department. The scheduler would attempt to adjust the arrival of raw material to provide a more uniform flow of material through the department. As this simulation will initially assume the cell operates first shift only, this may be necessary. Processing Data for operation processing time was obtained. The data largely contained “engineered time standards”, that is, the time given per operation is an average of observations. Appendix I has tabulated operations and the times associated with them. Column F of this table contains the total time at that operation. Obtaining variation data on these time standards is a difficult and a somewhat inaccurate task based on current practices. It has been decided (based in experience) to assume the following distributions: Task Distribution Setup of machines or inspection tasks Normal – s.d. approx 20% of engineered times processing (outside processing, deburr, Triangular inspection, etc.,) Normal- small deviation from mean <1.5 n/c machining Simulation Results / Validation The model was created by adding one part number at a time and visually verifying correct routing and resource behaviors. Allowance for shifts was not initially taken into accountthat is, the cell operated 24 hours per day, 7 days per week. At this point, model results were encouraging. Each part spent about 50 – 60% of its anticipated lead-time in the system. In addition, the number of exits for the F119 assembly confirmed that logic for combining inner and outer details was working correctly. Parts did not appear to be excessively “blocked”. These results confirmed the interactions and routings were somewhat reasonable. Appendix III contains the results file . Experimentation and recommendations Several experiments are currently underway. After verifying the basic “behavior” of the system, shift assignments were then added. Recall the goal of the study is determine the capability of this cell operating with a 1st shift only. The results (not included in this paper) showed the cell incapable of absorbing the increased workload generated by the JT8 schedule. Investigations will occur (results to be placed in FINAL paper) as to the cause and potential fixes. Preliminary results appear to show the deburr resource over-taxed. This in and of itself seems to make sense as most of the deburr tasks are manual in nature and require a captive resource. However, another issue could be at work. The model does not include “incoming queues” for the workstations (would exceed ProModel- Student capability). Therefore, a part is required to have its next location clear before vacating its current workstation. This dynamic interaction may be the reason the cell fails to produce hardware with only one shift. This is not necessarily a failure of the model. In fact, one could argue that in the ideal flowline / pull system, the parts “never hit the floor”. Individual queues at workstations represent inventory that is not producing hours for the shop, hence, high inventory is bad. Until further investigation proofs otherwise, I would suggest that this model reflects an ideal flowline. It demonstrates the need to either: 1) level-load the schedule, or, 2) additional capacity (maybe a 2nd shift deburr?) is required Senstivity experiments, results of which will be available in the FINAL paper, may shed light on this issue. Appendix I- Processing time detail A B F119_ass'y 0010 F119_ass'y 0020 F119_ass'y 0050 F119_ass'y 0070 F119_ass'y 0100 F119_ass'y 0110 F119_ass'y 0130 F119_ass'y 0140 F119_ass'y 0170 F119_ass'y 0190 F119_ass'y 0200 F119_ass'y 0220 F119_ass'y 0230 F119_ass'y 0240 F119_ass'y 0250 F119_ass'y 0260 F119_ass'y 0265 F119_ass'y 0270 F119_ass'y 0290 F119_ass'y 0470 F119_ass'y 0570 F119_ass'y 0590 F119_ass'y 0600 F119_ass'y 0610 F119_ass'y 0625 F119_ass'y 0630 F119_ass'y 0640 F119_ass'y 0650 F119_ass'y 0660 F119_ass'y 0670 C D 10 210 396 462 0.001 66 0.001 34.5 19.8 66 6.6 4 20 47.4 300 100 5 90 0.001 0.001 19.8 0.001 55 60 0 38 100 100 11.37 200 F119_ass'y F119_ass'y F119_ass'y F119_ass'y F119_ass'y F119_ass'y F119_ass'y F119_ass'y F119_ass'y F119_ass'y F119_ass'y F119_ass'y 0680 0685 0690 0700 0705 0707 0710 0712 0715 0720 0725 0740 100 20.45 70 70 0 60 100 9.5 24 360 16.91 0.001 F119_ass'y F119_ass'y 0750 0755 9.5 210 E F 0 REQUISITION DETAILS 0 DRY STACK OPERATION 0 SET UP FOR TACK WELD 0 APPLY BRAZE ALLOY TO OD OF 0 INSPECT FOR BRAZE COVERAGE 0 APPLY BRAZE MATERIAL 0 INSPECT FOR BRAZE COVERAGE 0 LOAD STRESS RELIEVE FIXTURE 0 UNLOAD STRESS RELIEVE FIXTURE 0 LAYOUT CASE FOR MACHINING 0 LOAD STRESS RELIEVE FIXTURE 0 UNLOAD STRESS RELIEVE FIXTURE 0 LAYOUT CASE FOR MACHINING 17.48 MACHINE REAR OUTER FLANGE AND I.D. 666 MACHINE ANTI-ICE CAVITY & WELD PRE 164 MILL PS2 CAVITY AND WELD PREP. INS 40 ROUGH DRILL (21) HOLES IN ANTI-ICE 30 POWER WASH AND DEBURR PART 0 RECEIVING INSPECTION FOR OP 280 0 WELD JTS #2,#3,#6,#7,#8,#9,#10 0 UNLOAD STRESS RELIEVE FIXTURE 0 WELD JOINT #4 0 LAYOUT CASE FOR MACHINING 64 FINISH MACHINE INNER AND OUTER REA 0 INSTALL DIA. -C- ON REAR SIDE OF O 30 FINISH MACHINE INNER AND OUTER FRO 230 FINISH MILL FLANGE SURFACES AT BOT 230 ROUGH AND FINISH STRUT ENDS, BOSS 55.54 SEMI-FINISH AND FINSH MACHINE EYEL 262 ROUGH, AND FINSH FORWARD FLANGE FA 120 FACE MILL PS2 BOSSES,DRILL AND TAP 23.66 DRILL (21) HOLES ON FORWARD FLANGE 70 ROUGH, AND FINSH SCALLOPS ON 71 FACE MILL MANIFOLD BOSS AND (4) MO 0 DRILL, REAM AND TAP INNER AND OUTE 0 TAP (18) HOLES IN OUTER AFT FLANGE 50 MOUNTS FOR BUSHING INSTALLATION. I 24.8 WASH PART 0 BACK SPOTFACE (4) HOLES IN GOOSENE 0 DEBURR ALL HOLES, BOSSES 35.43 FLUSH 0 RECEIVING INSPECTION FOR OPERATION 24.8 ALKALI CLEAN PER POP 384 0 BENCH 10.8 210 396 462 0.001 66 0.001 33 19.8 66 9.9 5.94 21.6 70.07 966 264 45 90 0.001 0.001 20 0.001 55 124 0 68 330 330 132 462 220 30 132 165 0 64.8 150 64.8 24 360 12 0.001 36.976 210 F119_ass'y F119_ass'y F119_ass'y F119_ass'y F119_ass'y F119_ass'y F119_outer F119_outer F119_outer F119_outer F119_outer F119_outer F119_outer F119_outer F119_outer F119_outer F119_outer F119_outer F119_outer F119_outer F119_outer F119_outer F119_inner JT8 0760 0780 0800 0810 0820 0830 0010 0020 0030 0040 0045 0050 0055 0070 0080 0090 0105 0110 0120 0130 0150 0170 0090 0010 16.91 0.001 16.91 26 39 0.001 60 60 20 200 4.75 42 4.75 50.75 70 20 90 300 300 400 138 0.001 16.56 85.03 JT8 JT8 JT8 JT8 JT8 JT8 JT8 JT8 0020 0030 0040 0050 0060 0070 0080 0090 358.72 122.6 140.54 28 8.5 27.83 9.29 271.2 JT8 0100 9.29 JT8 JT8 0150 0160 0.001 20.5 JT8 JT8 JT8 JT8 JT8 JT8 JT8 JT8 JT8 JT8 JT8 JT8 0168 0170 0180 0200 0210 0220 0230 0250 0260 0270 0280 0300 5.8 37.92 7.22 31.54 51.72 6.95 5.9 16.4 4.1 13.3 2.7 42.99 35.43 FLUSH 0 35.43 FLUSH 0 AND PIN-SD,HEADLESS 0 FINISH BURR AND CORRECT 0 FINAL INSPECTION 0 FACE AND TURN 60 ROUGH I.D. FLOW PATH. 28 MILL KEY SLOT 250 ROUGH POCKETS 12.4 WASH 0 BREAK EDGES 12.4 WASH 42.96 FACE TO CLEAN 70 FINISH TURN I.D. FLOW PATH 28 MILL KEY SLOT 0 DEBURR SHARP EDGES 438 ROUGH AND FINISH POCKET FLOOR 536 FINISH POCKET SIDE WALLS 524 R. MILL BUTTRESS SLOTSINSTALL (21) 0 BREAK EDGES 0 FINAL INSPECTION 0 0 MASK VANE & BOSS OPENINGS LAYOUT I 0 ROUGH AND FINISH MACHING L.E. OF 214.7 ROUGH & FINISH MACHINE T.E. OF 101.03 DRILL, CHAM., TAP, AND MILL INNER 254.9 DRILL, CHAM.,TAP & MILL INNER & O 0 DRILL (2) HOLES THRU CONNECTOR & I 0 COUNTERSINK RIVET HOLES IN INNER F 35 FLUSH CASE AND VANES 0 DEBURR & INSPECT OUTER FRONT FLAN 35 FLUSH INLET CASE VANE AND SHROUD P 0 DETAIL INSPECT. (QAI) 0 ABRASIVE CLEAN MAS TUBE ASSY CONNE 0 FLUX, ASSEM, BRAZE MAS TUBE ASSY 0 FLUX, ASSEM, BRAZE MAS TUBE ASSY 18.99 REMOVE FLUX 0 RIVET CONNECTOR & MAS TUBE ASSY 0 FLUX, ASSEMBLE & BRAZE MAS TUBE A 18.99 CLEAN BRAZED AREA TO REMOVE FLUX 0 CHECK FOR FLOURIDES 0 REBRAZE JOINTS AT INNER SHROUD 0 REMOVE FLUX (1782) AS REQ'D 0 BRAZED JOINTS 0 (2) WIRES TO PASS FREELY THRU I.D. 12 PRESSURE TEST TUBES BF,BG,BH,&BJ 30 0.001 14 26 39 0.001 60 116 48 450 12 42 12 50 116 48 90 738 836 924 138 0.001 16.56 61.6 347.6 312.4 174.323 304.7 27.5 30.06 10.033 275 46.753 0.001 22.14 6.264 40.954 28.307 11 55.858 19.8 15.66 17.712 3.3 3.672 2.916 62.532 JT8 JT8 JT8 JT8 JT8 JT8 F119_inner F119_inner F119_inner F119_inner F119_inner F119_inner F119_inner F119_inner 0380 0385 0390 120.78 0 9.29 0410 0415 0450 0010 0020 0035 0045 0047 0080 0100 0130 0.001 4.6 0.001 228.26 108 18 200 45 0.001 23.4 0.001 0 ASSEMBLE HELICAL COIL INSERTS IN I 0 SCOPE PART, CHECK FOR AND 35 FLUSH VANE AND SHROUD ASSEMBLY PAS 0 INSPECT (FINAL). (QAI) 0 ASSEMBLE TUBE (BAKE TOOL) 0 FINAL INSPECT (SURFACE TREAT) 100 ROUGH FACE & TURN REAR SIDE & 100 ROUGH FACE & TURN FRONT SIDE & OD 0 MILL TIMING SLOT 403 MILL BUTTRESS SLOTS 0 DEBURR BUTTRESS SLOTS & O.D. 0 VERIFY ACCEPTANCE OF OP. 30, 40, 5 0 0 66 0 10.033 0.001 8.132 0.001 228.26 208.06 18 603 45 0.001 16.9 0.001 Appendix II- Model file ******************************************************************************** * Formatted Listing of Model: * * C:\My Documents\grad_school\sma\termproj1.mod * ******************************************************************************** Time Units: Minutes Distance Units: Feet ******************************************************************************** * Locations * ******************************************************************************** Name Cap Units Stats Rules Cost ------------------ -------- ----- ----------- ---------- -----------NC_VTL_BT538472 1 1 Time Series Oldest, , NC_VTL_BT538471 1 1 Time Series Oldest, , LAYOUT_TABLE 1 1 Time Series Oldest, , TOYODA_4AX 1 1 Time Series Oldest, , HBM_5AX 1 1 Time Series Oldest, , VMC_BT540991 1 1 Time Series Oldest, , RADIAL_ARM_DRILL 1 1 Time Series Oldest, , DEBURR_BOOTH 1 1 Time Series Oldest, , INSPECTION_AREA 1 1 Time Series Oldest, , ALKALI_WASH 1 1 Time Series Oldest, , POWER_WASH 1 1 Time Series Oldest, , ASSEMBLY_BENCH 1 1 Time Series Oldest, , INCOMING infinite 1 Time Series Oldest, , Outside_processing INFINITE 1 Time Series Oldest, , OUTGOING infinite 1 Time Series Oldest, , ******************************************************************************** * Entities * ******************************************************************************** Name Speed (fpm) Stats Cost ------------- ------------ ----------- -----------F119_inner 10 Time Series F119_Assembly 50 Time Series F119_outer 50 Time Series JT8_Assembly 50 Time Series ******************************************************************************** * Path Networks * ******************************************************************************** Name Type T/S From To BI Dist/Time Speed Factor -------- ----------- ---------------- -------- -------- ---- ---------- -----------net1 Passing Speed & Distance N1 N2 Bi 40.00 1 N2 N4 Bi 6.00 1 N4 N5 Bi 81.00 1 N5 N6 Bi 77.00 1 N6 N7 Bi 98.12 1 N7 N2 Bi 97.08 1 N5 N8 Bi 46.47 1 N8 N9 Bi 40.05 1 N9 N6 Bi 13.70 1 N3 N7 Bi 105.13 1 net2 Passing N7 N11 Bi 67.35 1 N11 N10 Bi 15.00 1 N10 N1 Bi 23.83 1 N6 N13 Bi 30.30 1 N6 N14 Bi 10.04 1 N6 N15 Bi 19.72 1 N15 N13 Bi 9.68 1 N9 N16 Bi 20.00 1 Speed & Distance N1 N2 Bi 76.24 N2 N3 Bi 75.00 1 N3 N5 Bi 16.00 1 N5 N2 Bi 92.12 1 N5 N4 Bi 25.41 1 N4 N6 Bi 66.00 1 N4 N7 Bi 59.00 1 N6 N7 Bi 21.00 1 N7 N8 Bi 17.00 1 N8 N9 Bi 14.00 1 N9 N10 Bi 33.00 1 N10 N11 Bi 16.00 1 N6 N12 Bi 49.00 1 N13 N5 Bi 33.09 1 N4 N14 Bi 5.00 1 N15 N10 Bi 10.00 1 1 ******************************************************************************** * Interfaces * ******************************************************************************** Net Node Location ---------- ---------- -----------------net1 N1 INCOMING N2 NC_VTL_BT538472 N4 NC_VTL_BT538471 N5 TOYODA_4AX N8 HBM_5AX N9 ALKALI_WASH N6 DEBURR_BOOTH N11 INSPECTION_AREA N7 Outside_processing N10 OUTGOING N13 LAYOUT_TABLE N14 POWER_WASH N15 ASSEMBLY_BENCH N16 RADIAL_ARM_DRILL net2 N1 INCOMING N2 Outside_processing N4 NC_VTL_BT538472 N6 HBM_5AX N7 VMC_BT540991 N8 RADIAL_ARM_DRILL N9 ALKALI_WASH N10 ASSEMBLY_BENCH N12 TOYODA_4AX N5 LAYOUT_TABLE N13 DEBURR_BOOTH N14 NC_VTL_BT538471 N3 N15 INSPECTION_AREA POWER_WASH ******************************************************************************** * Resources * ******************************************************************************** Res Ent Name Units Stats Search Search Path Motion Cost -------------- ----- -------- ------- ------ ---------- -------------- -----------VTL_oper 1 By Unit Closest Oldest net1 Empty: 120 fpm Home: N2 Full: 120 fpm (Return) HMC_oper 1 By Unit Closest Oldest net2 Empty: 150 fpm Home: N6 Full: 150 fpm (Return) VMC_oper 1 By Unit Closest Oldest net2 Empty: 120 fpm Home: N7 Full: 120 fpm (Return) DEBURR_oper 1 INSPECTOR_oper 1 By Unit Closest Oldest net1 Empty: 120 fpm Home: N6 Full: 120 fpm (Return) By Unit Closest Oldest net1 Empty: 150 fpm Home: N11 Full: 150 fpm (Return) ******************************************************************************** * Processing * ******************************************************************************** Process Routing Entity Location Operation Blk Output Destination Rule Move Logic ------------- ------------------ ------------------ ---- ------------- ------------------ ------- -----------F119_inner INCOMING WAIT 0 1 F119_inner NC_VTL_BT538472 FIRST 1 MOVE ON net1 F119_inner NC_VTL_BT538471 ALT MOVE ON net1 F119_inner NC_VTL_BT538472 GET VTL_oper WAIT N(128.26,4.5) FREE VTL_oper WAIT N(100,1.2) 1 F119_inner NC_VTL_BT538471 FIRST 1 MOVE ON net1 F119_inner NC_VTL_BT538471 GET VTL_oper WAIT N(108,4) FREE VTL_oper WAIT N(100,1.2) 1 F119_inner TOYODA_4AX FIRST 1 MOVE ON net1 F119_inner TOYODA_4AX GET HMC_oper WAIT N(218,3) FREE HMC_oper WAIT N(403,10) 1 F119_inner DEBURR_BOOTH FIRST 1 MOVE ON net1 F119_inner DEBURR_BOOTH GET DEBURR_oper WAIT T(30,45.00,120) FREE DEBURR_OPER 1 F119_inner Outside_processing FIRST 1 MOVE ON net1 F119_inner Outside_processing WAIT T(2880,6000,14400) F119_inner F119_inner F119_inner F119_inner F119_inner F119_inner F119_outer net1 F119_outer F119_outer F119_outer F119_outer F119_outer F119_outer F119_outer F119_outer 1 F119_inner INSPECTION_AREA FIRST 1 MOVE ON net1 INSPECTION_AREA GET INSPECTOR_oper WAIT T(15,30,60) FREE INSPECTOR_OPER 1 F119_inner ALKALI_WASH FIRST 1 MOVE ON net1 ALKALI_WASH GET DEBURR_oper WAIT N(3,.5) FREE DEBURR_oper WAIT 15 GET DEBURR_OPER WAIT N(5,.2) FREE DEBURR_oper 1 F119_inner DEBURR_BOOTH FIRST 1 MOVE ON net1 DEBURR_BOOTH GET DEBURR_oper WAIT T(10,16.9,50) FREE DEBURR_oper 1 F119_inner Outside_processing FIRST 1 MOVE ON net1 Outside_processing WAIT T(60,180,240) 1 F119_inner INSPECTION_AREA FIRST 1 MOVE ON net1 INSPECTION_AREA GET INSPECTOR_oper WAIT T(20,30,60) FREE INSPECTOR_oper INC inner_detail 1 F119_inner OUTGOING FIRST 1 MOVE FOR 0 OUTGOING WAIT UNTIL outer_detail>=1 COMBINE 1 AS F119_Assembly 1 F119_inner EXIT FIRST 1 MOVE FOR 0 INCOMING WAIT 0 1 F119_outer NC_VTL_BT538472 FIRST 1 MOVE ON F119_outer NC_VTL_BT538471 ALT MOVE ON net1 NC_VTL_BT538472 GET VTL_oper WAIT N(10,2.5) FREE VTL_oper WAIT N(60,.87) 1 F119_outer NC_VTL_BT538471 FIRST 1 MOVE ON net1 NC_VTL_BT538471 GET VTL_oper WAIT N(15,1.5) FREE VTL_oper WAIT N(116,.9) 1 F119_outer TOYODA_4AX FIRST 1 MOVE ON net1 TOYODA_4AX GET HMC_oper WAIT N(65,3.8) FREE HMC_oper WAIT N(450,.1) 1 F119_outer ALKALI_WASH FIRST 1 MOVE ON net1 ALKALI_WASH GET DEBURR_oper WAIT N(3,1) FREE DEBURR_oper WAIT 15 GET DEBURR_oper WAIT N(5,.3) FREE DEBURR_oper 1 F119_outer DEBURR_BOOTH FIRST 1 MOVE ON net1 DEBURR_BOOTH GET DEBURR_oper WAIT T(100,187,240) FREE DEBURR_oper 1 F119_outer Outside_processing FIRST 1 MOVE ON net1 Outside_processing WAIT T(700,1440,5000) 1 F119_outer NC_VTL_BT538472 FIRST 1 MOVE ON net1 NC_VTL_BT538472 GET VTL_oper WAIT N(20,4) FREE VTL_oper WAIT N(50.75,.7) 1 F119_outer NC_VTL_BT538471 FIRST 1 MOVE ON net1 NC_VTL_BT538471 GET VTL_oper F119_outer F119_outer F119_outer F119_outer net1 F119_outer F119_outer ON net1 F119_outer WAIT N(30,6) FREE VTL_oper WAIT N(95,.8) 1 F119_outer Outside_processing FIRST 1 MOVE ON net1 Outside_processing WAIT T(1000,1997,5760) 1 F119_outer TOYODA_4AX FIRST 1 MOVE ON net1 TOYODA_4AX GET HMC_oper WAIT N(120,5) FREE HMC_oper WAIT N(600,1) 1 F119_outer HBM_5AX FIRST 1 MOVE ON net1 HBM_5AX GET HMC_oper WAIT N(300,19) FREE HMC_oper WAIT N(500,3) GET HMC_oper WAIT N(100,11) FREE HMC_oper WAIT N(400,2) 1 F119_outer ALKALI_WASH FIRST 1 MOVE ON net1 ALKALI_WASH GET DEBURR_oper WAIT 3 FREE DEBURR_oper WAIT 15 GET DEBURR_oper WAIT 5 FREE DEBURR_OPER 1 F119_outer DEBURR_BOOTH FIRST 1 MOVE ON DEBURR_BOOTH GET DEBURR_oper WAIT 138 FREE DEBURR_oper 1 F119_outer Outside_processing FIRST 1 MOVE ON net1 Outside_processing WAIT 180 1 F119_outer INSPECTION_AREA FIRST 1 MOVE INSPECTION_AREA GET INSPECTOR_oper WAIT 60 FREE INSPECTOR_oper INC outer_detail 1 F119_outer OUTGOING FIRST 1 F119_outer OUTGOING WAIT UNTIL inner_detail>=1 COMBINE 1 AS F119_Assembly 1 F119_outer EXIT FIRST 1 MOVE FOR 0 JT8_Assembly INCOMING WAIT 0 1 JT8_Assembly LAYOUT_TABLE FIRST 1 MOVE JT8_Assembly LAYOUT_TABLE GET DEBURR_oper WAIT n(90,22.3) FREE DEBURR_oper 1 JT8_Assembly NC_VTL_BT538472 FIRST 1 MOVE ON net2 JT8_Assembly NC_VTL_BT538472 GET VTL_oper WAIT N(58.7,10) FREE VTL_oper WAIT N(300,2) 1 JT8_Assembly NC_VTL_BT538471 FIRST 1 MOVE JT8_Assembly NC_VTL_BT538471 GET VTL_oper WAIT N(122,10) FREE VTL_OPER WAIT N(214.7,2) 1 JT8_Assembly HBM_5AX FIRST 1 MOVE JT8_Assembly HBM_5AX GET HMC_oper WAIT N(101.03,9) FREE HMC_oper WAIT N(70,.4) JT8_Assembly JT8_Assembly JT8_Assembly JT8_Assembly GET HMC_oper WAIT N(28,2) FREE HMC_OPER WAIT N(254,3) 1 JT8_Assembly RADIAL_ARM_DRILL FIRST 1 RADIAL_ARM_DRILL GET VMC_oper WAIT 35 FREE VMC_oper 1 JT8_Assembly POWER_WASH FIRST 1 POWER_WASH GET DEBURR_oper WAIT 10 FREE DEBURR_oper WAIT 35 GET DEBURR_oper WAIT 10 FREE DEBURR_oper 1 JT8_Assembly DEBURR_BOOTH FIRST 1 DEBURR_BOOTH GET DEBURR_oper WAIT T(100,271,300) FREE DEBURR_oper 1 JT8_Assembly POWER_WASH FIRST 1 POWER_WASH GET DEBURR_oper WAIT 10 FREE DEBURR_oper WAIT 35 GET DEBURR_oper WAIT 10 FREE DEBURR_oper 1 JT8_Assembly Outside_processing FIRST 1 Outside_processing WAIT 240 1 JT8_Assembly INSPECTION_AREA FIRST 1 JT8_Assembly MOVE ON net1 JT8_Assembly INSPECTION_AREA GET INSPECTOR_oper WAIT 40 FREE INSPECTOR_oper 1 JT8_Assembly Outside_processing FIRST 1 JT8_Assembly Outside_processing WAIT 4500 1 JT8_Assembly ASSEMBLY_BENCH FIRST 1 JT8_Assembly ASSEMBLY_BENCH GET DEBURR_oper WAIT T(35,120.78,195) FREE DEBURR_oper 1 JT8_Assembly DEBURR_BOOTH FIRST 1 JT8_Assembly DEBURR_BOOTH GET DEBURR_oper WAIT 20 FREE DEBURR_oper 1 JT8_Assembly POWER_WASH FIRST 1 JT8_Assembly POWER_WASH GET DEBURR_oper WAIT 9.29 FREE DEBURR_oper WAIT 35 GET DEBURR_oper WAIT 10 FREE DEBURR_oper 1 JT8_Assembly INSPECTION_AREA FIRST 1 JT8_Assembly INSPECTION_AREA GET INSPECTOR_oper WAIT 40 FREE INSPECTOR_oper 1 JT8_Assembly EXIT FIRST 1 F119_Assembly OUTGOING DEC inner_detail DEC outer_detail 1 F119_Assembly Outside_processing FIRST 1 MOVE FOR 0 F119_Assembly Outside_processing WAIT T(2000,3600,6000) 1 F119_Assembly INSPECTION_AREA FIRST 1 MOVE FOR 0 F119_Assembly INSPECTION_AREA GET INSPECTOR_oper WAIT 150 FREE INSPECTOR_oper 1 F119_Assembly LAYOUT_TABLE FIRST 1 MOVE FOR 0 F119_Assembly LAYOUT_TABLE GET DEBURR_oper WAIT 40 FREE DEBURR_oper 1 F119_Assembly Outside_processing FIRST 1 MOVE FOR 0 F119_Assembly Outside_processing WAIT 1440 1 F119_Assembly LAYOUT_TABLE FIRST 1 F119_Assembly LAYOUT_TABLE GET DEBURR_oper WAIT 90 FREE DEBURR_oper 1 F119_Assembly NC_VTL_BT538472 FIRST 1 F119_Assembly NC_VTL_BT538472 GET VTL_oper WAIT 17.48 FREE VTL_oper WAIT 47.4 1 F119_Assembly NC_VTL_BT538471 FIRST 1 MOVE ON net1 F119_Assembly NC_VTL_BT538471 GET VTL_oper WAIT 180 FREE VTL_oper WAIT 500 1 F119_Assembly HBM_5AX FIRST 1 MOVE ON net2 F119_Assembly HBM_5AX GET HMC_oper WAIT 60 FREE HMC_oper WAIT 120 GET HMC_oper WAIT 60 FREE HMC_oper WAIT 180 1 F119_Assembly DEBURR_BOOTH FIRST 1 MOVE FOR 0 F119_Assembly DEBURR_BOOTH GET DEBURR_oper WAIT 5 FREE DEBURR_oper WAIT 20 GET DEBURR_oper WAIT 90 FREE DEBURR_oper 1 F119_Assembly Outside_processing FIRST 1 MOVE FOR 0 F119_Assembly Outside_processing WAIT 5000 1 F119_Assembly INSPECTION_AREA FIRST 1 MOVE ON net2 F119_Assembly INSPECTION_AREA GET INSPECTOR_oper WAIT 35 FREE INSPECTOR_oper 1 F119_Assembly Outside_processing FIRST 1 MOVE ON net1 F119_Assembly Outside_processing WAIT 7200 1 F119_Assembly LAYOUT_TABLE FIRST 1 MOVE ON net2 F119_Assembly LAYOUT_TABLE GET DEBURR_oper WAIT T(60,90,240) FREE DEBURR_oper 1 F119_Assembly NC_VTL_BT538472 FIRST 1 MOVE ON net2 F119_Assembly NC_VTL_BT538472 GET VTL_oper WAIT N(90,12) FREE VTL_oper WAIT N(220,2) 1 F119_Assembly VMC_BT540991 FIRST 1 MOVE ON net2 F119_Assembly VMC_BT540991 GET VMC_oper WAIT N(150,13.9) FREE VMC_oper WAIT N(40,.3) 1 F119_Assembly NC_VTL_BT538472 FIRST 1 MOVE ON net2 F119_Assembly NC_VTL_BT538471 ALT MOVE FOR 0 F119_Assembly NC_VTL_BT538472 GET VTL_oper WAIT N(60,5) FREE VTL_oper WAIT N(90,.4) 1 F119_Assembly HBM_5AX FIRST 1 MOVE ON net2 F119_Assembly HBM_5AX GET HMC_oper WAIT N(480,21) FREE HMC_oper WAIT N(1600,4.9) 1 F119_Assembly VMC_BT540991 FIRST 1 MOVE ON net2 F119_Assembly VMC_BT540991 GET VMC_oper WAIT 60 FREE VMC_oper WAIT 180 1 F119_Assembly Outside_processing FIRST 1 MOVE FOR 0 F119_Assembly Outside_processing WAIT T(540,1440,2200) 1 F119_Assembly RADIAL_ARM_DRILL FIRST 1 MOVE FOR 0 F119_Assembly RADIAL_ARM_DRILL GET DEBURR_oper WAIT 30 FREE DEBURR_oper 1 F119_Assembly ALKALI_WASH FIRST 1 MOVE ON net2 F119_Assembly ALKALI_WASH GET DEBURR_oper WAIT 5 FREE DEBURR_oper WAIT 20 GET DEBURR_oper WAIT 10 FREE DEBURR_oper 1 F119_Assembly DEBURR_BOOTH FIRST 1 MOVE ON net2 F119_Assembly DEBURR_BOOTH GET DEBURR_oper WAIT 300 FREE DEBURR_oper 1 F119_Assembly Outside_processing FIRST 1 MOVE FOR 0 F119_Assembly Outside_processing WAIT 5760 1 F119_Assembly INSPECTION_AREA FIRST 1 MOVE ON net2 F119_Assembly INSPECTION_AREA GET INSPECTOR_oper WAIT T(20,30,60) FREE INSPECTOR_oper 1 F119_Assembly ALKALI_WASH FIRST 1 MOVE ON net2 F119_Assembly ALKALI_WASH GET DEBURR_oper WAIT 5 FREE DEBURR_oper WAIT 20 GET DEBURR_oper WAIT 10 FREE DEBURR_oper 1 F119_Assembly Outside_processing FIRST 1 MOVE FOR 0 F119_Assembly Outside_processing WAIT T(480,1440,2880) 1 F119_Assembly POWER_WASH FIRST 1 MOVE ON net2 F119_Assembly POWER_WASH GET DEBURR_oper WAIT 10 FREE DEBURR_oper WAIT 30 GET DEBURR_OPER WAIT 30 FREE DEBURR_oper 1 F119_Assembly ASSEMBLY_BENCH FIRST 1 MOVE ON net2 F119_Assembly ASSEMBLY_BENCH GET DEBURR_oper WAIT T(45,90,120) FREE DEBURR_oper 1 F119_Assembly INSPECTION_AREA FIRST 1 MOVE ON net2 F119_Assembly INSPECTION_AREA GET INSPECTOR_oper WAIT T(120,240,300) FREE INSPECTOR_oper 1 F119_Assembly EXIT FIRST 1 MOVE FOR 0 ******************************************************************************** * Shift Assignments * ******************************************************************************** Locations Resources Shift Files Priorities Disable Logic ---------- ---------- ------------------------------ ------------ ------- -----------------C:\My Documents\grad_school\sm 99,99,99,99 No ******************************************************************************** * Variables (global) * ******************************************************************************** ID Type Initial value Stats ------------ ------------ ------------- ----------inner_detail Integer 0 Time Series outer_detail Integer 0 Time Series ******************************************************************************** * External Files * ******************************************************************************** ID Type File Name Prompt ------------ ----------------- -------------------------------------------------- ---------INNER_ARRIVE Arrival C:\My Documents\grad_school\sma\inner_arrivals.wk1 OUTER_ARRIVE Arrival C:\My Documents\grad_school\sma\outer_arrivals.wk1 (null) Shift C:\My Documents\grad_school\sma\termproj.sft JT8_ARRIVE Arrival C:\My Documents\grad_school\sma\JT8_arrivals.wk1 Appendix III- Results Output (24/7 operation) --------------------------------------------------General Report -------------------------------------------------------------------------------Scenario : Normal Run Replication : 1 of 1 Simulation Time : 25072.98333 hr -------------------------------------------------------------------------------LOCATIONS Average Location Scheduled Total Minutes Average Maximum Current Name Hours Capacity Entries Per Entry Contents Contents Contents % Util ------------------ ----------- -------- ------- ------------- ---------- -------- -------- -----NC VTL BT538472 25072.98333 1 324 227.096420 0.04891 1 0 4.89 NC VTL BT538471 25072.98333 1 242 361.371694 0.0581316 1 0 5.81 LAYOUT TABLE 25072.98333 1 192 104.374542 0.0133211 1 0 1.33 TOYODA 4AX 25072.98333 1 150 688.499240 0.0686495 1 0 6.86 HBM 5AX 25072.98333 1 192 1088.140557 0.138877 1 0 13.89 VMC BT540991 25072.98333 1 100 215.567110 0.0143293 1 0 1.43 RADIAL ARM DRILL 25072.98333 1 92 34.602185 0.00211609 1 0 0.21 DEBURR BOOTH 25072.98333 1 384 133.275820 0.0340193 1 0 3.40 INSPECTION AREA 25072.98333 1 434 73.503700 0.0212052 1 0 2.12 ALKALI WASH 25072.98333 1 250 32.051056 0.00532629 1 0 0.53 POWER WASH 25072.98333 1 176 66.422665 0.00777091 1 0 0.78 ASSEMBLY BENCH 25072.98333 1 92 101.442185 0.00620368 1 0 0.62 INCOMING 25072.98333 999999 142 23.085359 0.00217905 4 0 0.00 Outside processing 25072.98333 999999 684 3185.211406 1.44823 6 0 0.00 OUTGOING 25072.98333 999999 100 348605.015170 23.1727 50 50 0.00 LOCATION STATES BY PERCENTAGE (Multiple Capacity) % | Location Scheduled % Partially % | % Name Hours Empty Occupied Full | Down ------------------ ----------- ----- --------- ---- | ---INCOMING 25072.98333 99.81 0.19 0.00 | 0.00 Outside processing 25072.98333 25.86 74.14 0.00 | 0.00 OUTGOING 25072.98333 0.54 99.46 0.00 | 0.00 LOCATION STATES BY PERCENTAGE (Single Capacity/Tanks) Location Scheduled % % % % % % Name Hours Operation Setup Idle Waiting Blocked Down ---------------- ----------- --------- ----- ----- ------- ------- ---NC VTL BT538472 25072.98333 3.81 0.00 95.11 0.03 1.05 0.00 NC VTL BT538471 25072.98333 4.74 0.00 94.19 0.06 1.01 0.00 LAYOUT TABLE 25072.98333 1.12 0.00 98.67 0.03 0.18 0.00 TOYODA 4AX 25072.98333 6.17 0.00 93.14 0.17 0.52 0.00 HBM 5AX 25072.98333 13.89 0.00 86.11 0.00 0.00 0.00 VMC BT540991 25072.98333 1.43 0.00 98.57 0.00 0.00 0.00 RADIAL ARM DRILL 25072.98333 0.20 0.00 99.79 0.01 0.00 0.00 DEBURR BOOTH 25072.98333 3.40 0.00 96.60 0.00 0.00 0.00 INSPECTION AREA 25072.98333 2.12 0.00 97.88 0.00 0.00 0.00 ALKALI WASH 25072.98333 0.46 0.00 99.47 0.07 0.00 0.00 POWER WASH 25072.98333 0.69 0.00 99.22 0.09 0.00 0.00 ASSEMBLY BENCH 25072.98333 0.60 0.00 99.38 0.02 0.00 0.00 RESOURCES Average Average Average Number Minutes Minutes Minutes Resource Scheduled Of Times Per Travel Travel % Blocked Name Units Hours Used Usage To Use To Park In Travel % Util -------------- ----- ----------- -------- ---------- -------- -------- --------- -----VTL oper 1 25072.98333 566 69.673714 0.022085 0.050000 0.00 2.62 HMC oper 1 25072.98333 484 155.753913 0.101707 0.326000 0.00 5.01 VMC oper 1 25072.98333 142 84.690761 0.041704 0.141000 0.00 0.80 DEBURR oper 1 25072.98333 1620 52.257656 0.108604 0.136944 0.00 5.64 INSPECTOR oper 1 25072.98333 434 73.503700 0.000000 0.000000 0.00 2.12 RESOURCE STATES BY PERCENTAGE % % Resource Scheduled % Travel Travel % % Name Hours In Use To Use To Park Idle Down -------------- ----------- ------ ------ ------- ----- ---VTL oper 25072.98333 2.62 0.00 0.00 97.38 0.00 HMC oper 25072.98333 5.01 0.00 0.00 94.98 0.00 VMC oper 25072.98333 0.80 0.00 0.00 99.20 0.00 DEBURR oper 25072.98333 5.63 0.01 0.01 94.35 0.00 INSPECTOR oper 25072.98333 2.12 0.00 0.00 97.88 0.00 FAILED ARRIVALS Entity Location Total Name Name Failed ------------ -------- -----F119 inner INCOMING 0 F119 outer INCOMING 0 JT8 Assembly INCOMING 0 ENTITY ACTIVITY Average Average Average Average Average Current Minutes Minutes Minutes Minutes Minutes Entity Total Quantity In In Move Wait For In Name Exits In System System Logic Res, etc. Operation Blocked ------------- ----- --------- ------------ --------- ------------ ------------ ---------F119 inner 49 1 29349.266082 72.777000 19731.834714 9297.403918 247.250449 F119 Assembly 50 0 32104.554080 26.662000 38.944180 31743.334580 295.613320 F119 outer 1 49 17473.483000 19.443000 9289.986000 8164.054000 0.000000 JT8 Assembly 42 0 6745.820643 1.855000 32.620929 6619.224952 92.119762 ENTITY STATES BY PERCENTAGE % % Entity In Move Wait For % % Name Logic Res, etc. In Operation Blocked ------------- ------- --------- ------------ ------F119 inner 0.25 67.23 31.68 0.84 F119 Assembly 0.08 0.12 98.87 0.92 F119 outer 0.11 53.17 46.72 0.00 JT8 Assembly 0.03 0.48 98.12 1.37 VARIABLES Average Variable Total Minutes Minimum Maximum Current Average Name Changes Per Change Value Value Value Value ------------ ------- ------------ ------- ------- ------- --------inner detail 100 14020.810510 -1 1 0 -0.278751 outer detail 100 13886.940870 0 3 0 0.0816856

![11th grade 2nd quarter study guide[1]](http://s2.studylib.net/store/data/010189415_1-a4e600e9fc2ee42639f67b298d930b48-300x300.png)