Thermal Effects of Welding A JT8D Magnesium Gearbox Housing Jeff Bode

advertisement

Thermal Effects of Welding A JT8D

Magnesium Gearbox Housing

Jeff Bode

Andrew Foose

MEAE6630

April 6, 2000

Table of Contents:

List of Symbols Used

…………………………………..

3

Abstract

…………………………………..

4

Introduction

…………………………………..

4

…………………..

5

Problem Discussion and Formulation

Results

…………………………………..

10

Conclusions

…………………………………..

14

Bibliography

…………………………………..

15

………..

16

Appendix I: Convection and Radiation Calculations

2

List of Symbols Used:

As

c

T

g

G

hf

h

k

Kii

L

Nu

P

p

Pr

q

q'

q"

Ra

t

S

T

Ts,Tsurf

T

Surface Area

Thermal Diffusivity

Volumetric Thermal Expansion Coefficient

Specific Heat

An Allowable Virtual Temperature

Emissivity

Internal Heat Generation Rate

Acceleration due to gravity

Outward Normal Vector

Film Coefficient

Convection Heat Transfer Coefficient

Thermal Conductivity

i Direction Thermal Conductivity

Grad Operator, Characteristic Length

Wavelength

Nusselt Number

Velocity Vector, Kinematic viscosity

Perimeter

Pressure

Prandtl Number

Heat Transfer Rate

heat transfer per unit length

heat flux

Rayleigh Number

Density

Stefan-Boltzmann Constant

Time, 0 t

Surface of Convection

Temperature

Surface Temperature

Ambient Temperature

3

Abstract:

Often in the aerospace overhaul industry, high priced parts demand repairs in order to

avoid the cost of replacement. One such part is the Pratt & Whitney JT8D gearbox

housing. A weld repair to the “snout” location of this magnesium housing has been

proposed in order to save time and money. Having used ANSYS to analyze the thermal

effects of this weld, it is determined that they are acceptable based on the following

results. The heat-affected zone is small enough that the post-welding inspection will be

minimal. Also, the key dimensional features such as the bearing bores are outside of the

heat-affected zone and will not be distorted during the repair.

Introduction:

In the aerospace overhaul and repair industry, there is a continual drive to lower costs and

turn-around time. Some parts are not cost effective to repair because it is more

economical for the customer to buy new replacement parts. However, there are parts that

are very expensive, therefore, very cost effective to repair. One example of these parts is

accessory gearbox housings on aircraft engines. When an overhaul facility uses puddle

welding to repair a large area of a magnesium gearbox housing, portions of the housing

can reach high temperatures. These repairs are often deemed risky because of the extent

of the heat affected zone on the casting

during this process. The heat affected zone is

the amount of material that sees exposure to

temperatures high enough to distort the

casting or affect its material properties.

Magnesium is notorious for its creep

properties, and the heating could cause

distortion. The major areas of concern are

the bearing bores, as they have very tight

tolerances.

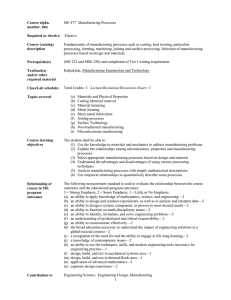

This paper assesses the effects of puddle

Figure 1: JT8D Gearbox Housing

welding the Pratt & Whitney JT8D

magnesium accessory gearbox housing “snout” location. This gearbox is shown in

Figure 1. The objective is to determine the amount of heat effected zone and thus the

area that will need to be inspected for distortion after the analysis. Determining the

minimal amount of area to be inspected will reduce cost and turn-around time on this

repair. Also, it is important to determine if the bearing bores are located in the heat

affected zone.

This analysis was performed using ANSYS thermal modeling. 2-D shell elements were

used because the thickness to length ration of the walls of the housing was relatively

small. The Boundary Conditions and Loading will be described in detail in the following

sections. The governing equation in the ANSYS thermal analysis package is the

following.

4

T

T

T

v LT L q g

t

c

Where {v} is the velocity vector for mass transport of heat, and {L} is the following.

L , ,

x y z

T

{q} is the heat flux vector, and g is the internal heat generation rate. Both g and {v} are

zero for this analysis because there is no internal heat generation or velocity of the

casting. This yields the following equation.

T

T

c

L q 0

t

The vector {q} is related to conduction and convection by the following two equations

respectively.

0

0

K xx

{q}cond 0

K yy

0 {L}T

0

0

K zz

{q}Tconv {} h f (T Tsurf )

{} is the element outward normal vector. With some manipulation the following

integral, I, must be minimized to find the approximate solution. This is what ANSYS

will do for us.

T

I cT

{L}T (T )([ D]{L}T ) d (vol) Th f (T Tsurf )dS

vol

S

t

Each element of the mesh must meet the above equations to minimize the overall

integral. What this means is that for a steady state analysis (T/t=0) the heat flowing

into the element by conduction must be equal to that flowing out by convection. For

transient analyses, the specific heat term comes into play.

Problem Description and Formulation:

The gearbox housing was modeled in Unigraphics. The 2-D modeling does not show

every fillet and detail of the casting, but does

give a very good representation of the overall

“Snout”

casting geometry. The time necessary for a

detailed model dictates that many minor features

be eliminated from consideration. Also, these

details will result in difficulties in creating finite

elements, often in areas that are unimportant.

This is often referred to as feature suppression.

Bores

The model was then imported into ANSYS for

the heat transfer analysis. Figure 2 shows the

model after it was imported into ANSYS.

Figure 2: 2-D Model of Housing

5

Material Properties:

The material properties used for the elements were those of AMS4439, an aerospace

grade magnesium alloy. These were directly input from a Pratt & Whitney database, and

are therefore proprietary and will not be shown in this report. However, they were

similar to other magnesium alloy properties. Also, this casting had various thicknesses.

These are shown in Figure 7.

Loading:

The loading of the model occurs where the welding takes place at the interface to the

“snout” shown in Figure 2. The heat flux applied to the casting during the welding

process could not be directly computed despite knowing the voltage and amperage used

during welding. The reason being that there are tremendous energy losses in the arc

itself. The air ionizes, taking away much of the energy that would otherwise go into the

casting. There is also a certain amount of heat that needs to be generated in order to melt

the casting area and weld wire. There is also a certain level of porosity in this area of the

casting, and the exact amount of material that is being melted would vary from casting to

casting. To be conservative, the average melting temperature of the magnesium alloy

(1065F) was considered as a boundary condition at the “snout” interface. Thus it is

assumed that the flux at the interface is high enough to maintain this temperature at all

times. It would actually only be this temperature at the point welding is taking place,

which is why this is conservative.

This problem cannot be solved by conduction alone, as the model would show a steady

state temperature of 1065F throughout the casting without any other heat losses.

Therefore boundary conditions are needed.

Boundary Conditions:

The two forms of energy dissipation considered are convection and radiation. During the

welding process, the casting is typically held in a fixture that does serve to remove heat

more readily than the convection and radiation modes. However, since there is nothing to

control where the fixtures are attached to the casting, we will evaluate a free standing

casting as a worst case scenario. Also, because there are no limits as to how long the

welding process can take, the first item evaluated was the steady-state case.

Convection

The convection heat transfer coefficient needs to be determined in order to solve the heat

conduction problem presented. This coefficient is heavily dependent on the surface

geometry, external airflow, and film temperature. As the casting is a very complex

shape, some rather broad assumptions need to be made in order to determine reasonable

values of h for differing surfaces of the casting, and how h changes based on the surface

temperature. Some of the major assumptions include the characteristic length used in the

6

determination of Rayleigh's number and the film temperature at which the air properties

were obtained. Air is also assumed to be an ideal gas. The free flow was assumed to be

turbulent because of the complex geometries involved in the detailed casting. The film

temperature was taken at the average of the surface temperature and the ambient air

temperature. In determining the convection heat transfer coefficients, the casting was

assumed to be in its normal operating orientation, with the "snout" in the upright position.

Calculations were done in Excel using SI units, as the English units were not readily

available. The final h values were converted into English units.

The basic equation for convection heat transfer is:

q" h(Ts T )

For this project, only free convection was assumed to act on the casting, as the welding is

typically only done in large, contained facilities where there are no active fans acting on

the casting. The general equation for determination of the convection heat transfer

coefficient is given by:

h

k

Nu

L

where k is determined for air in the film layer, L is the characteristic length for the

geometry involved, and Nu is a dimensionless quantity.

For a plate, the characteristic length may be determined by

A

L S

P

where AS is the surface area of the plate, and P is the perimeter of that plate. As the

casting is very complex, this is the best estimate we can use in determining the

convection heat transfer coefficient.

Table 1 shows the assumptions made to complete the calculations.

Vertical Area

5 ft2

Vertical Perimeter

5.5 ft

Vertical Characteristic Length

1 ft

Horizontal Area

5 ft2

Horizontal Perimeter

0.28 ft

Horizontal Char. Length

0.2 ft

Table 1: Assumptions Used in Convection Calculations

The Nusselt number then needs to be determined. This is usually a function of the

Rayleigh number and Prandtl number, both of which are dimensionless quantities. For

the upper surface of a heated plate,

7

1

Nu L .54 Ra L4 for (104RaL107)

1

3

L

NuL .15Ra for (107RaL1011)

For the lower surface of a heated plate, the following equation applies:

1

4

L

Nu L .27 Ra for (105RaL1010)

For a vertical plate, the Nusselt equation is a little more complex:

2

1

.387 Ra L 6

Nu L .825

over the entire range of RaL.

8

9

27

.492 16

1

Pr

The Rayleigh number may be determined by the following equation:

Ra L

g (TS T ) L3

For an ideal gas,

1

1 p

1

2

T p RT

T film

When all these equations are solved, the convection heat transfer coefficient may be

determined for different areas of the casting. ANSYS allows tables of heat transfer

coefficients to be used, so Table 2 shows the values that were generated for various

surface temperatures and plate orientations.

Temperature

(deg. F)

1065.002

980.33

890.33

800.33

710.33

Top Horizontal

Orientation

1.05406E-05

1.04475E-05

1.03028E-05

1.01911E-05

9.98138E-06

Bottom Horizontal

Position

5.2703E-06

5.22576E-06

5.16103E-06

5.09139E-06

4.99547E-06

Vertical

Position

7.68997E-06

7.65359E-06

7.59109E-06

7.52196E-06

7.41214E-06

8

620.33

530.33

440.33

350.33

260.33

170.33

80.33

9.78815E-06

4.88903E-06

9.44798E-06

4.74905E-06

9.19724E-06

4.58163E-06

8.68723E-06

4.33917E-06

8.04884E-06

4.01664E-06

6.97429E-06

3.49383E-06

4.08854E-06

2.03227E-06

Table 2: Coefficients of Convection (BTU/sec-in2-F)

7.28553E-06

7.10384E-06

6.87538E-06

6.52233E-06

6.02626E-06

5.17672E-06

2.81098E-06

Figure 3 shows the areas where each table of convection coefficients was applied. As

you can see many assumptions were made while doing this. The effects of these

assumptions will be discussed in the results section.

Top Horizontal Conv

Bottom Horiz. Conv

Vertical Conv

Figure 3: Applied Convection Boundary Conditions

Radiation

The model was not analyzed with radiation as a boundary condition. After obtaining

results with convection only it was determined that the key surfaces were not in the heataffected zone. Radiation would just result in further reducing the size of the heat-affected

zone. If we were to apply radiation, the following would be used.

In order to simplify the radiation analysis, the various casting features are assumed to not

absorb any incident radiation from other casting wall surfaces or any other nearby

objects. Thus the absorbitivity of the magnesium is assumed to be zero. The casting

walls are also assumed to be diffuse-gray surfaces. There was no available data to break

down the radiation by wavelength (). The governing equation for this heat transfer is

q" Ts4 T4

The emissivity of magnesium varies with temperature, and values were obtained from

some materials handbooks that were tabulated and input into Table 3. The data above

500F would be extrapolated linearly, which would be another assumption used in the

modeling.

9

Temperature (deg. F) Emissivity

1065.002

0.21475

980.33

0.20205

890.33

0.18855

800.33

0.17505

710.33

0.16155

620.33

0.14805

530.33

0.13455

440.33

0.12105

350.33

0.10755

260.33

0.09405

170.33

0.08055

80.33

0.06705

Table 3: Coefficients for Radiation Boundary Conditions

Results:

Three separate analyses will be discussed here. First, a coarse element mesh, steady state

analysis was performed to make sure the model was working. Second a Fine mesh,

steady state analysis was completed to determine convergence of the model. Finally, a

transient analysis of a coarse mesh was performed to understand the effects of welding

time on the heat affected zone

Coarse Mesh, Steady State.

The coarse model was constructed using an element spacing of 0.5”x0.5”. The mesh

create using the automesher in ANSYS is shown in Figure 4. The loading and boundary

conditions were applied and the results are shown in Figure 5 and 6. Figure 5 shows a

nodal temperature plot,

and Figure 6 shows the

heat flux throughout the

model. It makes sense that

the greatest heat flux is

seen where the

temperature changes the

most. Figure 5 shows that

the heat material does not

reach into the bearing

bores. In fact, only the top

section of the casting sees

any affects of the welding

process.

Figure 4: Coarse Mesh Element Plot

10

Figure 5: Coarse Mesh Temp. Plot

Figure 6: Coarse Mesh Flux Plot

Fine Mesh, Steady State:

Figure 7 shows the fine mesh element spacing of the model. The 0.5” spacing was

maintained on the bottom of the casing where the thermal gradient was not important as

.1825”

.3125”

.625”

1.00”

1.333”

Figure 7: Fine Element Spacing With Thickness Regions Specified

shown by the coarse model. However the element spacing in the area of the “snout” was

changed to 0.3”. The results are shown in Figure 8 and 9, showing Temperature and Heat

Flux respectively. Of primary importance is the very small change in the thermal profile

despite a 40% change in element size. This is a sign of a converging solution and

therefore, there was no need to pursue and further reduction is mesh size.

11

Figure 8: Fine Mesh Temp Plot

Figure 9: Fine Mesh Flux Plot

The results show that the heat effected zone is small enough that the bearing bores are not

at risk of being distorted. Also, The zone is small enough to minimize the amount of

inspections performed following the weld, and therefore the cost to perform these

inspections will be small.

Previously discussed were the assumptions of how the convection coefficients were

applied to the model. As you can see in Figure 3, some of the horizontal convections

were applied to not-so-horizontal surfaces. Being limited to horizontal or vertical it was

impossible to model everything completely. However, Figure 8 shows that a majority of

the surfaces that see high temperature were indeed horizontal. Therefore, the effect of the

assumptions can be considered negligible to the final results.

Finally, we have been in discussion with overhaul shops that have been performing this

repair. Mechanics at these shops have expressed that they can touch the outer regions of

the housing near the outer bores while welding without burning themselves. Although

this is not proof the model is accurate, it does show some correlation to the real world.

These results show that the transient analysis is not necessary. This steady state analysis

is very conservative and shows the effect of welding does not reach any critical features.

However for the sake of this report, we will perform the transient analysis using the

coarse mesh.

Coarse Mesh, Transient:

The coarse mesh was used for speed in

computation. The increased number of

elements with the fine mesh would drastically

increase computer time with little to gain in

accuracy as shown by the steady state

comparison.

The assumption was made that the 1065F

Figure 10: Transient, 1 sec.

12

loading to the “snout” would occur within 1 second. Figure 10 shows the housing after it

has been loaded to this temperature.

Figures 10-15 show the housing at several different time points following this initial

loading. It is shown that, after 2.5 minutes, the housing has reached approximately 90%

of the thermal increase it will see. Over the next 8 minutes or so, the thermals slowly

approach the steady state solution. Because the weld takes over 2 minutes to complete,

the steady state solution is a good conservative solution to this problem.

Figure 11: 31 Seconds

Figure 13: 156 Seconds

Figure 12: 70 Seconds

Figure 14: 321 Seconds

Figure 15: 600 Seconds

13

Conclusions:

The results showed less than a 5% change with a 40% change in element length. The

model was converged. Therefore the results are as accurate as the assumptions allow

them to be.

The extent of the heat-affected zone is limited to the upper surfaces of the housing.

The bearing bores remain approximately 70 degrees Fahrenheit and therefore will not

be distorted during the weld process.

The transient model shows that it will take less than 10 minutes to reach steady state.

It is concluded that this repair should pass heat generation and temperature criteria.

14

Bibliography:

ANSYS Theory Reference, 001099, Ninth Edition, SAS IP, Inc.; Section 6.1 Heat Flow

Fundamentals.

DeWitt and Incropera. Fundamentals of Heat and Mass Transfer, New York, John Wiley

and Sons, 1996.

Durocher, Larry et al. Introduction to ANSYS for Pratt & Whitney, 1998

Siegel and Howell. Thermal Radiation Heat Transfer, Washington DC, Taylor and

Francis, 1992.

15

Appendix I

Information on convection heat transfer and radiation heat transfer emissivities are

included on attached Excel Workbook "Convection Coefficients.xls".

16