Simulation Modeling and Analysis Simulation Optimization Session 13

advertisement

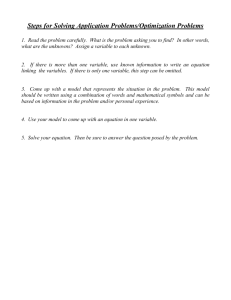

Simulation Modeling and Analysis Session 13 Simulation Optimization 1 Outline • • • • Introduction Evolutionary Algorithms Single Variable Optimization An inventory control problem 2 Introduction • Optimization is the science of determining “best” solutions to mathematically defined problems, which are often models of physical reality. • Simulation is a methodology to transform inputs (decision variables) into outputs (performance measures). 3 Simulation Optimization • Simulation Optimization is a methodology to discover the values of decision variables required to minimize or maximize specific measures of performance. • Typically, from a starting set of inputs simulation computes outputs. These are used in turn by an optimization algorithm to produce an improved set of inputs. 4 How to find optima? 1.- Identify all possible decision variables affecting the output of the system. 2.- Using all possible values of each decision variable identify all possible solutions (I.e. the response surface). 3.- Evaluate all solutions accurately 4.- Compare each solution fairly 5.- Select the best answer 5 Optimization of well posed problems • Well posed problems – Have unique solutions. – Small changes in inputs produce correspondingly small changes in output. • Numerical methods such as NewtonRaphson and Linear Programming are available to optimize well posed problems. 6 Optimization of stochastic simulation model problems • Stochastic simulation models – Not well posed – Complex response surfaces • Heuristic techniques are available to optimize stochastic simulation problems. 7 Evolutionary Algorithms • EA conduct search of response surface using a population of solutions. • Information about the response surface is then provided from many points at once. 8 Steps in Evolutionary Algorithms 1.- Generate a population of solutions by randomly distributing throughout solution space. 2.- Accurately compute the response of each solution. 3.- Select the best solutions and apply genetic operators to produce new offspring solutions. 4.- Return to step 2 until a single solution emerges. 9 Single Variable Optimization • The Transformed Ackley function – Local optima • Many maxima and minima – Global optima • Two maxima (x = +9.54 and x = -9.54) • One minimum (x = 0) 10 Ackley function • Randomly select 10 values of x (initial offspring size = 10) from -10 < x < -8 • Challenge: to evolve from the original offspring to the minimum without stopping at the local minima. • Result: Global minimum is determined after 8 generations. 11 Inventory Control Problem • What is the minimum amount of inventory required to support production in a JIT environment where parts are pulled through the system using kanban cards? • Number of kanban cards influences WIP. • Trigger values = number of kanban cards that must accumulate before a workstation begins production 12 Two-Stage Pull Production • Two-Stage Pull Production System – Customer demand pulls subassemblies from Stage One WIP to Assembly Lines. – Kanban card sent to Stage One Process. When trigger value is reached parts are pulled from Stage Two WIP to process. – Following processing, subassemblies and kanban cards are sent to Stage One WIP. 13 Two-Stage Pull Production contd – Stage Two Line processes raw materials into component parts to be pulled by Stage One. – As components are pulled from Stage Two WIP a kanban card is sent to the kanban post for Stage Two Line. When trigger value is reached production orders are issued to Stage Two Line. – As orders are completed at Stage Two Line, orders and kanban cards are sent to Stage Two WIP. 14 Two-Stage Pull Production contd • Goal: Minimize inventory at the State One WIP location. Maximize throughput while minimizing the number of kanban cards in the system. • Performance measure to be minimized f(a) = C1 (A + M) - C2 (TK1) - C3 (TK2) • Solution Vector (I = 11 part types) a = (K1i,K2i,TK2i) 15 Two-Stage Pull Production contd • Model: – Constant interarrival times for customer orders. – Number of defective subassemblies found at the assembly lines is stochastic. – Production times for Stage One Process and Stage Two Line are constant. – Set up time, time between failures and time to repair have triangular distributions. – Runs: 10 day warm up and 20 day steady state. 16 Two-Stage Pull Production contd • Four independent runs of the models are performed each time a solution is evaluated. • Performance score is the average of the four runs. • SimRunner finds 110 kanban cards and f = 37.945 after 150 generations. 17