REPORT Table of Contents Error! 2. LIST OF FIGURES……………………………………………………………..........v

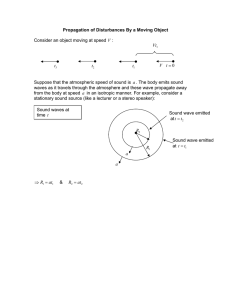

advertisement

REPORT Table of Contents 1. LIST OF TABLES ………………………………………………………………….Error! Bookmark not defined.v 2. LIST OF FIGURES……………………………………………………………..........v 3. ACKNOWLEDGMENT …………………………………………………………...vi 4. ABSTRACT………………………………………………………………………….1 Waves are an excellent source of energy, are a natural resource, and are renewable. Waves in shallow water are one of the best ways to capture this energy as this is when the wave energy is at its maximum (potential and kinetic) points. How much energy is captured depends upon a number of factors: wave translation, wave height, the number of waves in a set period, the type of converter used and its efficiency of capturing both the potential and kinetic wave energy. To maximize the amount of energy that can be extracted from a near shore wave the simplest method of converting the mechanical energy of this natural renewable resource to a very usable medium (i.e. electricity) is via piezoelectricity. This paper will touch upon fundamentals of efficient and economical extraction of energy from ocean waves as well as discuss design considerations utilizing piezoelectricity as an energy converter. It can be shown that the capture and storage of shallow wave energy in this manner is comparable to energy generated from other sources, such as fossil fuels, solar power, and hydrodynamic. 5. INTRODUCTION / BACKGROUND……………………………………………….4 5.1. Why Near Shore Ocean Waves are a Good Choice for Energy Extraction Ocean wave are a naturally occurring phenomenon as well as a renewable energy source. Waves form in water when it is excited by external forces, such as wind, vibrations, displacement, etc. Waves are efficient carriers of energy, imparted by the wind most commonly. The water medium translates this energy from its point of initiation outward forming visible waves as the environmental conditions change. “The global power potential represented by waves that hit all coasts worldwide, has been estimated to be in the order of 1TW (1 terawatt = 1012W). Although this is only a small proportion of the world’s wind power potential, which, in turn, is only a small portion of global solar power, ocean waves represent an enormous source of renewable energy. From (Musial, 2008) we find wave energy increases with latitude and has greater potential on the west coast of the United States because global winds tend to move west to east across the Pacific Ocean. The total energy contained in the waves is dependent on the linear length of wave crest, the wave height and the wave period. Wave energy resource assessments have been performed by the Electric Power Research Institute (EPRI) and the methods for calculation are well documented. Table 1 shows the gross wave energy resource by region. This is an estimate of the energy contained in the incident waves if it were converted to electricity. US Wave Resource Regions (>10kW/m) TWh/yr New England and Mid-Atlantic States 100 Northern California, Oregon and Washington 440 Alaska (exclusive of waves from the Bering Sea) Hawaii and Midway Islands 1,250 330 Table 1 – Wave Resource by Region Just below the ocean surface, average power flow intensity is typically 2–3kW/m2 of envisaged area perpendicular to direction of wave propagation. This increase in power intensity, and also the fact that wave energy is more persistent than wind energy, stimulate motivation and hope for developing the, still rather undeveloped, wave-power technology to a prosperous mature level in the future. If the technology can be successfully developed, the market potential is enormous. This paper will focus on the visible waves that form at the shore as this is where the most energy can be harnessed. The energy per unit surface area in a wave is related to the square of the wave height. The wave speed and wave length decrease in shallow water, therefore the energy per unit area of the wave has to increase, so the wave height increases. This is known as wave shoaling. In fluid dynamics, wave shoaling is the effect by which surface waves entering shallower water increase in wave height (which is about twice the amplitude). It is caused by the fact that the group velocity, which is also the wave-energy transport velocity, decreases with the reduction of water depth. Under stationary conditions, this decrease in transport speed must be compensated by an increase in energy density in order to maintain a constant energy flux. Shoaling waves will also exhibit a reduction in wavelength while the frequency remains constant. In shallow water and parallel depth contours, non-breaking waves will increase in wave height as the wave packet enters shallower water. Cresting and breaking usually occurs when wave height = depth of water. By capturing the energy of a wave while it is at maximum mechanical motion that energy can be most efficiently captured. This energy can be harnessed to be used in other forms. It can be applied to a selective apparatus to be translated into usable energy, in this case electricity. “Exploiting the low, variable frequency motion of waves, and coupling the power to a fixed frequency and fixed voltage grid system, is a challenging task which device designers have tackled in different ways”. One of the benefits of near shore wave energy extraction over offshore is that it is next to the power grid systems that such as system would feed into. This would result in saving energy loss as a result of transmission. The many different proposals and principles for wave energy conversion may be classified in several ways. These are useful for seeing the differences and similarities between various wave energy converters (WECs). They may be classified, e.g. according to location (off-shore, nearshore or onshore; floating, submerged or bottom-standing), according to type of energy conversion machinery (mechanical, hydraulic, pneumatic or directly electrical), and according to type of energy for end use (electricity, water pumping, desalination of seawater, refrigeration, water heating, propulsion). WECs may also be classified according to their horizontal extension and orientation. If the extension is very small compared to a typical wavelength, the WEC is called a point absorber. On the contrary, if the extension is comparable to or larger than a typical wavelength, the WEC is called a line absorber, but the terms attenuator and terminator are more frequently used. A line absorber is called an attenuator or a terminator if it is aligned parallel or normal to the prevailing direction of wave propagation, respectively. An early example of a terminator was proposed by Salter, several “ducks” pitching with respect to a common horizontal cylindrical cylinder, the socalled spine. It was found necessary to divide the long cylinder into shorter cylindrical sections, hinged together. The spine still resists twisting, but complies to bending moments. This spine development has now evolved to the Pelamis, which is a device of the attenuator type. A typical device of the point-absorber type is a heaving axisymmetric body, a pulsating submerged volume, such as the AWS device, or an open-sea located oscillating water column (OWC) device. Most of the proposed OWC devices have pneumatic power take-off. A list of various wave energy converters is located in APPENDIX 10.6. It can be observed that the majority of these applications are designed to operate in off shore conditions and few have application for near shore. This thesis proposes that by capturing wave energy at maximum mechanical motion an optimized extraction of this energy can occur from near shore waves. Then by coupling this energy extraction to a device that efficiently converts the mechanical motion into electricity, such as piezoelectric materials, that can be fed into local power grid systems this model becomes a comparable solution in comparison to conventional energy generation techniques. To perform this thesis, research of wave energy background and theory will be performed with specific interest in coastal applications and interaction with submerged surfaces. An analysis of an ideal wave will be reviewed and energy extraction calculations generated. From these formulas, a device will be conceived to extract the most amount of energy from the wave form with the intent to minimize loss and maximum output of usable energy. This device should take into the environmental conditions and location, durability, and service life. 5.2. Near Shore Considerations Waves lose energy, in particular in shallow water, mainly by wave breaking and by friction against the seabed. If the shore is rocky and steep sufficiently down into the water, then wave reflection may be more important than wave dissipation. The variability of wave conditions in coastal waters is, generally, very large compared to offshore waters. Near-shore variation in the wave climate is compounded by shallow-water physical processes such as wave refraction, which may cause local ‘‘hot spots’’ of high energy due to wave focusing particularly at headlands and areas of low energy in bays due to defocusing. In addition, other coastal wave processes such as wave reflection, diffraction, bottom friction, and depth-induced breaking effects may have some influence. As such, it can be concluded that these influences will generally result in variation of expected energy inputs to a system or at most energy loss from ocean waves prior to extraction. This should be evaluated when considering where to place a near shore wave energy extraction device. Other considerations: Beach / Shore Erosion and Changes Over Time Marine life Navigation and Interaction with people In the generation of electricity from fossil fuels as a resource for public consumption in the form of a utility there rises cost externalities. Cost externalities, defined in Managerial Economics, are defined as an unaccounted for cost that the producer does not always have to pay as part of production. In fossil fuel electricity generation these externalities come in forms such as pollution. Additional costs abound with fossil fuel energy generation. Costs such as purchase of the fossil fuel, shipment to an electric plant, and waste heat through inefficiencies in the transition of the fuel to electricity all add to the overall costs of the end product. Externalities, like fossil fuel pollution, and these extra costs can be overcome either through government regulation (currently in the form of pollution credits) and expensive technology or through utilizing alternative energy forms that do not result in these extra externalities or costs, such as near shore wave energy. Near shore wave energy generation, one form of alternative energy, can create usable energy in the form of electricity efficiently, renewably, and competitively as compared to fossil fuels and other alternative fuels. 5.3. Wave Energy and Extraction The APPENDIX 1 wave formulas can be used to understand wave motion and energy and be used to help formulate ways to utilize that energy. In this section, we will focus on the energy extraction requirements. a typical ocean wave in shallow offshore water. It is characterized by the following expressions: where d = water depth and T = wave period. the water particles under the wave travel in orbits that are circular in deep water, gradually becoming horizontal-elliptical (flat-elliptical) near the surface. The kinetic energy in the wave motion is determined by integrating the incremental energy over the depth and averaging over the wavelength: The potential energy of the wave is determined by integrating the incremental potential energy in the height of a small column width over one wavelength: Note that the wave’s potential energy and kinetic energy are equal in magnitude, which is expected in an ideal wave with no energy loss. Therefore, the total energy per unit length of the wave, E1, is twice that value, i.e.: The total energy E in one wavelength L is given by the following: The mechanical power in the wave is the energy per unit time. It is obtained by multiplying the energy in one wavelength by the frequency (number of waves per second) as follows: In general ocean waves are unsteady, irregular, and directional. An instantaneous picture of the ocean offshore will generally reveal several wave trains with different wavelengths and directions. In contrast to a single-frequency sinusoidal wave propagating in a particular direction, a real sea wave may be considered as composed of many elementary waves of different frequencies and directions. Per unit area of sea surface a stored energy amounting to an average of E gH 2 mo / 16 g S ( f )df (1) 0 is associated with the wave, where = 1030 kg/m3 is the mass density of sea water, and g = 9.81 m/s2 is the acceleration of gravity, whereas H mo is the significant wave height for the actual sea state. This stored energy is equally partitioned between kinetic energy, due to the motion of the water, and potential energy. The latter half-portion is due to mechanical work performed when the flat water surface is being deformed to a wave. This work corresponds to water lifted against the gravity force from wave troughs to wave crests. For wavelengths exceeding a few centimeters, the capillary force (surface tension) has a negligible contribution to the potential energy. The integrand S(f) is the wave spectrum. Its unit is m2/Hz, and it describes quantitatively how the different wave frequencies, f, contribute to the wave energy. In practice, the integral in Eq. (1) is, as an approximation, replaced by a summation over a finite number of wave frequencies. For a sinusoidal wave with amplitude H/2, where H is the wave height (the vertical distance between crest and trough of the wave), Eq. (1) for E is applicable provided H mo is replaced by H 2 . Taking as a typical value, H = 2m or H mo = 2.83 m, we get E = 5.05 kJ/m2. The physical law of conservation of energy requires that the energy-extracting device must interact with the waves such as to reduce the amount of wave energy that is otherwise present in the sea. The device must generate a wave, which interferes destructively with the sea waves. ‘‘In order for an oscillating system to be a good wave absorber it should be a good wave generator’’. As discussed above, total wave energy is a combination of potential and kinetic energy that results from the vertical (Z - heave) and horizontal (X – surge; Y – is known as sway) translations. As such, an apparatus that would maximize energy transfer would have to be able to utilize both the vertical and horizontal energy. By understanding what the maximum energy that can be extracted from both the heave and surge, was can design and optimized damper to absorb. When considering heave, it should be considered as an advantage that practically all the volume, of e.g. a heaving-float system, could be ‘‘used to displace fluid and thus to generate outgoing waves’’. Falnes advocates that an economic wave-energy converter should have a large working area (wave-oscillator interface) relative to its size, and that this area should have a relatively large oscillating speed. Secondly, he indicates that the working area should preferably be resonant or ‘‘quasi-resonant’’. Corresponding to optimum wave interference, there is an upper limit, P, to the amount of absorbed wave power (energy) that can be extracted from a wave by means of a particular oscillating system, PA. P PA c T H 2 (9) where c (h / ) 3 / 128 245Wm 2 s 3 , 3 , and T is the wave period. According to inequality (9) the values of absorbed power, as well as of converted useful power are bound to the region below the, fully drawn, increasing curve in Fig. 2. Taking physical limitations into account, another limit to P exists, Budal’s upper bound, for the ratio of extracted energy to the volume of the immersed oscillating system, PB. Unless the recommendations are followed, the performance of a WEC may typically correspond to figures that are one to two orders of magnitude below Budal’s upper bound. P PB c0VH / T Where the wave height H 2A0 , where c0 g / 4 7.9kW / m 4 / s , with 1 , where V is the volume of the heaving body, and A0 is the elevation amplitude of the incident wave. These two formulas help us set limits to our wave energy absorber design volume based around anticipated wave T and H for a known location for heave (see Fig. 2). Need to now do translational (Surge / Sway) energy extraction considerations. Moment of Inertia: Cylinder - http://hyperphysics.phy-astr.gsu.edu/hbase/icyl.html Heave is best mode for converting energy. Need to evaluate particle. Two ways to extract linear and vertical energy are through the use of two forces, namely buoyancy and drag. http://en.wikipedia.org/wiki/Neutral_buoyancy http://en.wikipedia.org/wiki/Buoyancy Buoyancy is historically defined by Archimedes Principle: Any object, wholly or partly immersed in a fluid, is buoyed up by a force equal to the weight of the fluid displaced by the object. This results from the fact that fluid pressure increases with depth and from the fact that the increased pressure is exerted in all directions (Pascal's principle) so that there is an unbalanced upward (Lift) force on the bottom of a submerged object as shown in Figure 1: Buoyancy. The buoyant force, Fb, exerted on a body can be calculated by integrating the stress tensor, s, over the surface of the body, A, Fb = ∫ σdA Figure 2: Buoyancy (1) Drag force is caused mainly by separated flow in viscous fluid. Drag force is a function of the Reynolds number and surface roughness of a body, and the Keulegan-Carpenter number, especially in oscillating flow. Drag force, Fd, can be defined as10 where in this case the velocity, v, is equal to u, the wave horizontal velocity: (2) Where = force of drag = the density of the fluid = the speed of the object relative to the fluid = the reference Area = drag coefficient (dimensionless) = the unit vector indicating the direction of the velocity. Through a free body diagram and the conservation of energy, we can relate the vertical and horizontal forces between the wave and a partially submerged object. We would want to choose a partially submerged object prior to the wave breaking because this is where the energy is at maximum. The extractor should also be positioned prior to the dispersion of this energy during wave breaking. This is explained by Blenkinsopp as “Wave breaking is associated with the generation of high levels of turbulence, air entrainment, noise and splash, all of which must contribute to the energy dissipation and which are seen to increase with wave breaking intensity as waves become more plunging in nature. A relationship between breaking intensity and initial energy dissipation, showing that the total energy dissipated in the breaking event for each wave case increases as the relative cavity area becomes larger, i.e. as the intensity of breaking increases.” i.e. This is when the wave is at its highest point and right before it crashes over. Weight of Extractor Fd Force of wave Fb Figure 3 - Picture from Blenkinsopp = angle of the tether From figure 3, we can take the sum of the forces in X and Z direction (assuming that the extractor is of a uniform thickness and small compared to the wave in the Y direction, we can assume that Fy is << than Fx or Fz and equate to 0). As a result, an object that resists both the translation of the wave and vertical movement of the wave would transfer a portion of this energy through the tether to an apparatus where is could be transformed. 5.4. Piezoelectricity as Energy Converter Understanding these concepts it is possible to transfer the mechanical wave energy through a medium to generate electricity. This could happen in a number of ways. Machines such as pistons, generators, flywheels, and piezo-electric would be ideal for generating electricity from mechanical energy. Energy-Harvesting Rubber Chips Could Power Pacemakers, Cell Phones - “Of all piezoelectric materials, PZT is the most efficient, able to convert 80% of the mechanical energy applied to it into electrical energy.” http___www.azom.com_details.pdf http___www.noliac.com_Material_characteristics_-143.pdf For energy conversion, there are two principal desires: One or the other of the two parameters e233 / eS33 or e231 / eS33 should be as large as possible. The maximum tensile strain before fracture occurs should be as large as possible. Kpiezo = 1.1x10-12 m2/N for PZT Insert Calculations for piezo electric disks for heave Insert Calculations for piezoelectric disks/strips/rod for surge/sway. 5.5. Energy Storage and Transmission Considerations 6. THEORY / METHODOLOGY………………………………………………………5 6.1. Design Considerations In consulting (Wave Energy), when thinking of location the author recommends, “For designers to convert the slow movement of water to a more easily used and transmitted form, normally electricity, they must choose a converter that changes the mechanical wave energy. In interfacing with the waves, any converter must be constrained so that wave forces are resisted. Ways of constraining a converter for consideration are (shown in Figure 2): —using the sea-bed for fixing or mooring; —mounting several converters on a common frame or spine so that relative motion is obtained between them; —using the inertial force due to the gyroscopic action of a flywheel; —relying on the mass and inertia of the device.” Figure 1. Devices such as the Salter duck are primarily geared toward large-scale power generation and would operate in deep seas. Devices being considered for small-medium-scale power generation would, however, tend to operate in shallower waters. Recent examples of shallow-water devices have been discussed by Salter. These include devices tested at sea by the Guangzhou Institute in China, IIT Madras in India, and Queen’s University, Belfast, in the UK, as well as others currently being studied in Norway and Portugal. Despite the generally lower power levels in shallower waters, the possibility of local focusing of waves due to bottom-topography-induced refractions makes these devices attractive. A row of such devices would virtually eliminate transmission of waves over a region. They could thus replace conventional breakwaters in addition to being generators of energy. Due to their potentially multiple benefits, shallow-water devices are likely to continue to receive attention in the future. Therefore, the question of cost-effective sizing of such devices may be considered important. Currently, the hydrodynamic design of most shallow-water devices appears to be based on linear theory, which assumes the wave amplitudes to be small. This is unlikely to be true during most of the operation of such devices, especially if these are to be placed in a region where focusing effects are noticeable. Furthermore, the effects of wave nonlinearity begin to be important in any event as the water depth decreases. Wind-generated waves with a period of 1 to 30 sec are the most important in determining the wave power and force acting on ocean structures. 6.1.1. Environment and Impacts 6.1.2. Sustainability Corrosion consideration – use non corrosion materials. Design in elastic zone, ensure has long life. MAINTENANCE Maintenance of the wind turbine and foundation is important for its longevity and for keeping the energy cost down. Regularly scheduled inspections are absolutely necessary, particularly because offshore towers do not get incidental periodic visits. No federal regulations exist in regard to inspecting the equipment in offshore wind farms. The Naval Facilities Engineering Command outlines procedures for inspecting offshore structures based on good engineering practices. Although not mandatory, their implementation would reduce the maintenance cost in the long run. The inspections must be planned taking into consideration weather conditions and the wave height. Presently wind farms are built to operate for 20 yr with minimal maintenance. Visual inspections of the turbine and tower should be conducted periodically during the plant’s lifetime to search for apparent physical signs of deterioration, damage, etc. The procedures for inspecting the tower follow those laid out for inspecting the underwater foundation. Inspections of the foundation and the tower at the splash line are important as this part of the structure is exposed to corrosion due to galvanic action. A level-one inspection is conducted annually for the underwater structures. A level-two inspection is conducted biannually for the underwater structures, and a level-three inspection is made every 6 yr. The procedures and equipment used to carry out these inspections are listed in the Underwater Inspection Criteria published by the Naval Facilities Engineering Service Center. 6.2. Wave Energy Conversion Calculations 6.2.1. Mechanical Capture 6.2.2. Damping 6.2.3. Piezoelectric Energy-Harvesting Rubber Chips Could Power Pacemakers, Cell Phones - “Of all piezoelectric materials, PZT is the most efficient, able to convert 80% of the mechanical energy applied to it into electrical energy.” Rubberized Pieziolectric http___www.sciencedaily.com_releases_2010_01_100127152504.pdf From (Thiam) a rough estimate of energy from piezoelectric material is 1 Watt from 1.5*104 cubic centimeters resulting from a 0.03” deflection (of common PVF-2 polyvinylidene fluoride). This shows a great efficiency that a small movement creates a lot of electricity. To achieve energy equal to 1 barrel of oil (1700 kWh) this single piece of crystal would have to be flexed 1,700,000 times in one hour. But if we were to create an array of 1000 crystals, we would only have to flex the array 1700 times in one hour. This is a simplified understanding of how the system would work. As shown in (Thiam), the power output (Pmax) of a cantilever crystal array would be P¬max(n) = Sum from n = 1 to n : (K*(wd/wL)(L2/3H2)(m2w4)(x2))n where: n is the number of crystals in the array; K is the electrolytic factor for the chosen crystal; w = the wave period; d = distance between waves; L = length of the crystal; H = height of the crystal; m = mass of the crystal; x is the point of measurement. What this shows is that through selection of the crystal properties and sizes, by combining in an array you can maximize the power output. Losses in the system would be from: friction; loss of wave energy from wave to damper, and damper to the crystal, and crystal to the energy storage device via transmition line. Other considerations for a device such as this is installation are as follows: Manufacturability – Piezoelectric crystals and ceramics are commonly manufactured today. They can come in many forms for various applications. In this case, we would manufacture crystal or ceramic rods. To protect them and act as a binding agent we could encase the rods in rubber (Wojciechowski). This rubber would also act as the damper for absorbing wave energy and transmitting to the crystals. Wires could be attached to the rod ends to create a circuit and the output transmitted to a storage device or input into an electrionic grid. Installability and Survivability The array would have to be moored near the shore to keep it from floating away. Being near the shore would help to keep costs down by not requiring long distance transmission wires. Additionally, an ideal shore would have to be identified where the influence of the tides would be minimized to ensure maximum wave energy transmission. Lower tides would result in smaller waves due to drag from the ocean bottom. The rubber damper encasing the array would resist the salt water corrosion. Nor would there be any oils or lubricants that could leak. This would keep the ocean environment safe. Ideally, the rubber could be translucent and minimize the impact on the ocean life. Operability – Operating in the shallows, the rubber would cause the array to float. By optimizing the amount of rubber we can achieve only slight buoyancy which would position the array to have maximum deflection resulting in maximum power generation as a wave moves from rear to forward across the array. Reliability and Affordability Many piezoelectric ceramics and crystals are proprietary and would influence the cost of the apparatus. Additional costs in the form of royalties from patents may have to be paid. But the apparatus is simple and scalable to an application. This scalability is key to offsetting the costs required to compete with large fossil fuel power plants. 6.2.4. Efficiency Calculations wind and solar power systems.pdf – has HPEG concept, estimate 2% efficiency. 6.3. Energy Storage and Transmission Considerations 1.1.1. Fly-Wheels Flywheels store energy through accelerating a rotor up to a high rate of speed and maintaining the energy in the system as kinetic energy. The flywheel releases its energy by reversing the charging process and slowing down. A flywheel can be designed to either release a large amount of energy in a very short period, or a small amount of energy over a longer period. Flywheels also may be divided into two main types, low speed and high speed. Distributed Generation--The power generation technologies available today, such as microturbines, wind power, and diesel or natural gas generators, are not capable of replicating the power quality available through the existing power grid by themselves. By complementing these systems with a flywheel, the power quality of the system is increased as ride through during start up and voltage sag problems are both corrected. Flywheels can instantly absorb power when demand drops and deliver power when demand rises, allowing the distributed generation device to catch up with the load a few seconds later. This is called Load-Following. Renewable energy sources, especially wind, suffer from intermittency that can be reduced through the use of flywheels. Through incorporating the flywheel-based energy storage unit into the installation of the wind turbines, three problems can be addressed: to stabilize the frequency variations stemming from the turbines, to capture excess energy from short-term wind gusts and to eliminate the need for spinning/standby generator reserve due to the introduction of the wind turbines. 1.1.2. Ultra Capacitors Conventional capacitors have enormous power but store only tiny amounts of energy. Supercapacitors offer a unique combination of high power and high energy. Supercapacitors are capable of very fast charges and discharges, and are able to go through a large number of cycles without degradation. Supercapacitors: Can be charged and discharged almost an unlimited number of times Can discharge in matters of milliseconds or as long as tens of seconds or several minutes Can be charged in seconds to minutes High power density Do not release any thermal heat during discharge There is no danger of overcharging; when fully charged the ultracapacitor simply quits accepting a charge Are not affected by deep discharges as are chemical batteries Have a long lifetime, which reduces maintenance costs; anecdotal evidence suggests that they lose about 80% of their storage capacity after 10 years, with a lifetime estimated to be 20 years The DC-DC round-trip efficiency is 80%-95% in most applications Operating temperature range as great as between -50C and 85C, capacity increases as temperature decreases below the rating temperature They do not release any hazardous substances that can damage the environment 1.1.3. Transmission Lines 1.1.4. Other 2. RESULTS / DISCUSSION…………………………………………………………..6 2.1. Near Shore Piezoelectric Converter The overall amount of energy gained would depend upon the efficiency of the converter used and the location and intensity of waves. 2.2. Comparison to Alternatives 2.2.1. Efficiency 2.2.1.1. Other near shore devices 2.2.1.2. Power Plants 2.2.2. Costs In the generation of electricity from fossil fuels as a resource for public consumption in the form of a utility there rises two forms of externalities: Cost and Benefit. Cost externalities, defined in Managerial Economics (Keat), are defined as an unaccounted for cost that the producer does not always have to pay as part of production. Benefit Externalities are costs that are not compensated. In fossil fuel electricity generation cost externalities come in forms such as pollution and potentially climate change (Riversedge). These types of externalities are very difficult to evaluate due to their nature. It is difficult to measure the extent of pollution from electricity generation and its effects on nature other than observing obvious symptoms from general pollution such as acid rain, carbon dioxide increase/global warming, and chemical invasion in drinking water and attempting to apply a ratio based on the global fossil fuel consumption and making estimates (Fossil). Additional costs abound with fossil fuel energy generation. Costs such as purchase of the fossil fuel natural resources, shipment to an electric plant, and waste heat through inefficiencies in the transformation of the fuel to electricity all add to the overall costs of the end product. Externalities, like fossil fuel pollution, and these extra costs can be overcome either through government regulation and credits/taxes (Keat pg. 526), by expensive technology, or through utilizing alternative energy forms that do not result in these extra externalities or costs, such as near shore wave energy. Near shore wave energy generation, one form of alternative energy, can create usable energy in the form of electricity efficiently, renewably, and competitively as compared to fossil fuels and other alternative fuels. To understand the economics of various alternative energies we can refer to Twidell’s Renewable Energy Resources, Ch. 13 which evaluates various different energy forms (i.e. wind, water waves and hydro, solar, etc.) for total lifecycle cost and considerations for use. I will summarize that here for the purposes of this paper and focus particularly on wave energy. To understand the cost of a technology you need to evaluate various factors. These include understanding Initial Capital required to start up, Interest during construction, Refurbishing and replanting during the life of the equipment, Decommissioning Costs, Operation and Maintenance Costs, Resource Availability, Plant (equipment) availability, Life of the equipment, Break-even Costs, Rated Performance, Rate of Return, and other miscellaneous costs. Ideally though what matters most is efficiency; do you get the most out of what you put into the machine? This will help determine how you will meet these other factors. As referenced in (Muller) Table 1, other key challenges should be evaluated as well. TABLE 1: Summary of Key Challenges and Priority Advances for Marine Renewables (ref. Mueller, M., and R. Wallace. "Enabling Science and Technology for Marine Renewable Energy, pg. 4378) We can compare each of these categories between fossil fuel energy generation and ocean wave generation: Predictability – The energy amounts that can be extracted from fuels are well understood and finite. From (Bioenery) • Barrel of oil equivalent (boe) = approx. 6.1 GJ (5.8 million Btu), equivalent to 1,700 kWh. • Natural gas: HHV = 1027 Btu/ft3 = 38.3 MJ/m3; LHV = 930 Btu/ft3 = 34.6 MJ/m3. Therm (used for natural gas, methane) = 100,000 Btu (= 105.5 MJ) Wave devices currently are designed usually to take advantage of a specific feature of waves (up/down motion, driving force, combination) (Mueller). Additionally, a near shore device would have to take into account the changing shoreline/environment which makes it an increasingly difficult area to predict wave energy output and design a device to extract it. Manufacturability – Modern fossil fuel power plants have been around for many years and the designs are well established. Wave power generation devices, on the other hand, have only been around for approx. 50 years and are still being developed. The difficulty in wave power generation is that they have to be designed to work in an unpredictable, caustic environment; waves are not constant and vary in intensity and salt water corrodes many materials. Installability and Survivability – Large fossil fuel power-plants are expensive and take up a lot of space. Once built they last for years and years with regular maintenance. Some of the oldest still operating coal power-plants in the US were built in 1921 (http://wiki.answers.com/Q/What_is_the_lifespan_of_a_coal_fired_power_plant). Ocean wave power plants require installation too. Usually they are either designed to be moored to the ocean floor or attached to another stable vessel or construction to keep them from floating away. This leads to difficulties such as ocean depths, potential to loose your device if the attachment breaks, etc. From (Harris); then there are environmental issues. Placing large man-made structures in the oceans will clearly have some effect on marine life. Tidal barrages present perhaps the biggest challenges. Machinery in these structures can kill fish and impede their migration to spawning areas. Barrages also interfere with the normal flushing of silt and other dissolved pollutants. This affects water quality, which in turn affects bird and fish life. Some of the major concerns associated with ocean power are variable intensity, limited survivability of equipment, navigation and sea-space concerns, and release of lubricants. Operability – (Fossil) Typical thermal efficiency for electrical generators in the industry is around 33% for coal and oil-fired plants, and up to 50% for combined-cycle gas-fired plants. Plants designed to achieve peak efficiency while operating at capacity will be less efficient when operating off-design (i.e. temperatures too low.) Ocean wave generators will have a variable output due to the variation of the wave input. Therefore they have to be designed to be attuned to efficiently extract energy from a range of wave inputs and selectively installed in locations that have that average range. If waves are applied as inputs that are too big, they risk damaging the device. Too small and you may not get enough energy out. “Wave direction, period, spectral content and groupiness also vary. The statistics of the wave climate are fundamental influences on cost-efficient design, energy production and survival” (Mueller). Some wave machinery have already extremely high efficiencies (Salter Duck - ~81% in controlled experiments - Wave Power). This shows that with the right technology and application in a specific spectrum of waves you should be able to compete with fossil fuel plants. Reliability and Affordability – From (Meyer), “It has been estimated that improving technology and economies of scale will allow wave generators to produce electricity at a cost comparable to wind-driven turbines, which produce energy at about 4.5 cents kWh. For now, the best wave generator technology in place in the United Kingdom is producing energy at an average projected/assessed cost of 7.5 cents kWh.” Additionally, the ocean wave “fuel” is essentially free and renewable and won’t run out but it is an unpredictable fuel. (Meyer) “In comparison, electricity generated by large scale coal burning power plants costs about 2.6 cents per kilowatt-hour. Combined-cycle natural gas turbine technology, the primary source of new electric power capacity is about 3 cents per kilowatt hour or higher. It is not unusual to average costs of 5 cents per kilowatt-hour and up for municipal utilities districts.” Additionally, fossil fuel is generally considered a finite resource. As current resources are depleted, if the demand stays stable, the price would be expected to increase. The cost to transmit energy via power lines needs to be considered as well. “Above ground lines cost around $10 per foot and underground (and submerged) lines cost in the range of $20 to $40 per foot” (Electric) for installation plus yearly maintenance. “Long-distance transmission of electricity (thousands of kilometers) is cheap and efficient, with costs of US$0.005–0.02/kWh… transmission and distribution losses in the USA were estimated at 6.6%.”(Electric). This makes a strong case for using near shore energy generation (with-in 1 mile of the shore line) as opposed to off shore (>1 mile from the shoreline) as there is less initial cost involved with installation and less required maintenance. Additionally, less transmission cable leads to better overall efficiency. 2.3. Environmental Impact . If carbon based plants cost 2 to 5 cents per kwh, and near shore plants 8 cents, then surely a large portion of the difference could be made up by forcing the former to pay their environmental carrying costs. take account of near shore: a) catastrophic weather damage, b) esthetic pollution (important to some), c) storability of energy. The latter is important because if the facility were located near to a large city, to lessen transimission costs (as you recommend), then the degree to which this could replace carbon-based sources depends on storability. Complete replacement would be impractical if there were not adequate storability. 2.4. Global Trends 3. CONCLUSION……………………………………………………………………….7 3.1. Conclusions Waves are excellent sourced of energy, are a natural resource, and are renewable. Waves in shallow water are one of the best ways to capture this energy as this is when the wave energy is at its maximum. Wave energy can be categorized in both potential and kinetic, where the potential energy is a factor of the wave amplitude and displacement and the kinetic energy is a factor of the translation of the particles. These energies can be captured using opposing forces such as drag and buoyancy. How much energy is captured depends upon a number of factors: wave translation, wave height, the number of waves in a set period, the type of converter used and its efficiency of capturing both the potential and kinetic wave energy. A near shore wave energy apparatus should be able to compete with a fossil fuel power plant. This is because it would not generate the cost externalities that a fossil fuel plant does (in the form of pollution), it uses “free” fuel in the form of renewable ocean waves, and through proper engineering and manufacturing can have a low initial cost to build and install. Returning to figure 1, a fossil fuel plant would operate at MCs while a wave energy plant could operate at MCp for these reasons. In a higher level comparison where the output energy of a fossil fuel plant is equal to a near shore wave energy plant these lower costs would enable the near shore wave plant to ultimately make higher revenue over the life of the plant. 3.2. Recommendations 3.2.1. Improvements 3.2.2. Considerations 3.2.3. Future Research 4. REFERENCES / BIBLIOGRAPHY………………………………………………..10 5. APPENDICES……………………………………………………………………....11 5.1. List of Symbols 5.2. Definitions 5.2.1. Wave Shoaling - In fluid dynamics, wave shoaling is the effect by which surface waves entering shallower water increase in wave height (which is about twice the amplitude). It is caused by the fact that the group velocity, which is also the waveenergy transport velocity, decreases with the reduction of water depth. Under stationary conditions, this decrease in transport speed must be compensated by an increase in energy density in order to maintain a constant energy flux. Shoaling waves will also exhibit a reduction in wavelength while the frequency remains constant. In shallow water and parallel depth contours, non-breaking waves will increase in wave height as the wave packet enters shallower water. This is particularly evident for tsunamis as they wax in height when approaching a coastline, with devastating results. 5.2.2. 5.3. Basic Wave Equations and Theory The following explanation of wave theory is taken from (Meadows) so we can understand the basics behind ocean waves. Wave formation, motion, and energy can be described as follows and viewed in Figure 1. – Wave Basics: Figure 1. – Wave Basics The wave height, H, is the vertical distance between its crest and leading trough. Wavelength, L, is the horizontal distance between any two corresponding points on successive waves and wave period is the time required for two successive crests or troughs to pass a given point. The celerity of a wave C, is the speed of propagation of the waveform or how fast it travels (phase speed), defined as C = L/T, where T = time. It is of note that waves entering shallow-water begin to show a net displacement of water (visible wave) in the direction of propagation and are classified as translational in their movement. The equilibrium position used to reference surface wave motion, (still water level, SWL) is z = 0 and the bottom is located at z = –d. Small-Amplitude Wave — Properties The equation for the free surface displacement of a progressive wave is The expression relating individual wave properties and water depth, d, to the propagation behavior of these waves is the dispersion relation, sigma2, where g is the acceleration of gravity. (1) From this equation (1) and the definition of celerity (C) it can be shown that and (2a, 2b) The hyperbolic function tanh kd approaches useful simplifying limits of 1 for large values of kd (deep water) and for small values of kd (shallow water). Applying these limits results in expressions for shallow water where (3) which shows that wave speed in shallow water is dependent only on water depth. Some useful functions for calculating wave properties at any water depth, from deep water wave properties reference in Meadows, are . (4) Values of d/L can be calculated as a function of d/Lo by successive approximations using . (5) Particle Motions The horizontal component of particle velocity, u, beneath a wave is . (6) The corresponding acceleration, ax, is . (7) The vertical particle velocity, w, and acceleration, az, are respectively (8) and . (9) It can be seen from eqns. (6) and (8) that the horizontal and vertical particle velocities are 90 deg. out of phase. Extreme values of horizontal velocity occur in the crest in the direction of wave propagation, and the trough in the direction opposite to the direction of wave propagation while extreme vertical velocities occur mid-way between the crest and trough, where water displacement is zero. The u and w velocity components are at a minimum at the bottom and both increase as distance upward in the water column increases. Maximum vertical accelerations correspond to maximum in horizontal velocity and maximum horizontal accelerations correspond to maximum in vertical velocity. Figure1 provides a graphic summary of these relationships. The particle displacements can be obtained by integrating the velocity with respect to time and simplified by using the dispersion relationship to give a horizontal displacement (10) and vertical displacement (11) where (xo, zo) is the mean position of an individual particle. Pressure Field The pressure distribution beneath a progressive water wave is given by the following form of the Bernoulli Equation (12) where is fluid density and Kp, the pressure response coefficient, is which will always be less than 1, below mean still water level. gz is the hydrostatic pressure and g Kp(z) v is the dynamic pressure term. This dynamic pressure term accounts for two factors that influence pressure, the free surface displacement and the vertical component of acceleration. A frequently used method for measuring waves at the coast is to record pressure fluctuations from a bottom-mounted pressure gage. Isolating the dynamic pressure (PD) from the recorded signal by subtracting out the hydrostatic pressure gives the relative free surface displacement (13) where Kp(–d) = 1/cosh kd. It is necessary, therefore, when determining wave height from pressure records to apply the dispersion relationship to obtain Kp from the frequency of the measured waves. It is important to note that Kp for short period waves is very small at the bottom (–d), which means that very short period waves may not be measured by a pressure gage. Wave Energy Progressive surface water waves possess potential energy from the free surface displacement (vertical) and kinetic energy from the water particle motions (translational). From linear wave theory it can be shown that the average potential energy per unit surface area for a free surface sinusoidal displacement, restored by gravity, is (14) Likewise the average kinetic energy per unit surface area is (15) and the total average energy per unit surface area is . The unit surface area considered is a unit width times the wavelength L so that the total energy per unit width is (16) The total energy per unit surface area in a linear progressive wave is always equi-partitioned as one half potential and one half kinetic energy. Energy flux is the rate of energy transfer across the sea surface in the direction of wave propagation. The average energy flux per wave is where (17, 18) and Cg is the group speed defined as the speed of energy propagation. In deep water n = 1/2 and in shallow water n = 1 indicating that energy in deep water travels at half the speed of the wave while in shallow water energy propagates at the same speed as the wave. Wave Breaking Waves propagating into shallow water tend to experience an increase in wave height to a point of instability at which the wave breaks, dissipating energy in the form of turbulence and work done on the bottom. Breaking waves are classified as: spilling breakers generally associated with low sloping bottoms and a gradual dissipation of energy; plunging breakers generally associated with steeper sloping bottoms and a rapid, often spectacular, “explosive” dissipation of energy; and surging breakers generally associated with very steep bottoms and a rapid narrow region of energy dissipation. A widely used classic criteria applied to shoaling waves relates breaker height, Hb, to depth of breaking, db, through the relation . (19) However, this useful estimate neglects important shoaling parameters such as bottom slope (m) and deepwater wave angle of approach ( o). Meadows4 uses the following to solve for breaker depth (db), distance from the shoreline to the breaker line (xb) and breaker height (Hb) as (20) and (21) where m = beach slope and K = Hb /db The author makes note that wave breaking is still not well understood and caution is urged when dealing with engineering design in the active breaker zone. TABLE 1: Wave Formulas4 5.4. Piezoelectric Energy Equations 5.5. Other References Density of everyday substances (in g/cm3) Water Vinegar Ice Salt Water Milk(Skim) 1.00 0.78 3 0.92 1.03 3 1030 kg/m 0.037 lb/in 64.3 lb/ft 1.033 3 Rubber, hard 1.2(103 kg/m3) 1.2 g/cm3 74 (lb/ft3) Rubber, soft commercial 1.1(103 kg/m3) 69 (lb/ft3) Rubber, pure gum 0.91 - 0.93(103 kg/m3) 57 - 58(lb/ft3) Density of Silicone: 0.968 to 1.29 grams per cubic centimeter for the silicone most people think of (implants). That's 60 to 80 lbs per cubic foot. For comparison, water has a specific gravity of 1, or about 62.4 lbs per cubic foot. Also for comparison, there are about 7.5 gallons in 1 cubic foot. A gallon of water weighs about 8.3 lbs. Mechanical Properties Name: Butadiene Rubber Ethenepropenediene Rubber Natural Rubber Styrenebutadiene Rubber Nitrile Rubber Young's modulus Mpa Tensile strength MPa Elongation % Thermal expansion e-6/K Physical Properties Thermal conductivity W/m.K Glass temperature °C Service temperature °C Density kg/m 3 NA 10-15 200-400 6.5-6.6 0.25-0.25 -100 - -50 -70 - 70 900 - 1000 Technical general purpose rubber as 1.4-polymerisation product of polybutadiene with dominating cis-config be equal to polybutadiene in general as produced throughout Europe. The strenght, heat buildup and wear r addition of 25% carbon black. Butadiene rubber is almost exclusively applied as a neccesary component of ru strongly the wear resistance. 2-10 10-20 250-500 NA 0.26-0.26 -55 -40 - 65 Production of 1 kg product including mixing and vulcanisation. Flexible, weather-resistant. 1-5 20-30 750-850 6.7 0.13-0.42 Incineration 45,2 MJ/kg. Moderate injection mouldability. -70 -50 - 85 860 910 - 930 2-10 10-25 250-700 6.7 0.2-0.25 -65 - -50 -30 - 70 940 Copolymer of Styrene and Butadiene in a 23/77% ratio mixture reinforced with 30% carbonblack. Average da Copolymerisation data assumed equal to the polymerisation process of the components. Oxidation-, water-, resistance against organic solvents and mineral oil. 2-5 10-20 200-500 NA NA -40 - -20 -35 - 110 1000 Copolymer of Acrylonitrile and Butadiene in a 30/70% ratio mixture. Average data from the European indust assumed equal to the polymerisation process of the components. Permeability for gasses is poor. Oil resistan (90%) of all rubbers. Very good resistance against oil and other organics. 5.6. List of wave energy converters Table A gives an overview of the existing energy conversion devices for near-shore to offshore and offshore situations both operational and those in advanced stages of development. Main information sources are Wave Energy Conversion by John Brooke in 2003 and the assessment on Offshore Wave Energy Conversion Devices of the Electricity Innovation Institute by Mirko Previsic from June 2004. The devices are split between the different conversion techniques and small pictures give an indication of their functioning. Definition of 'operational' energy conversion devices and 'advanced stage of development' by John Brooke: "The operational category comprises full-scale devices, chiefly prototypes, that are currently operating (or have operated) where the energy output is utilized for the production of energy or other purpose; also includes full-scale devices at an advanced stage of construction." The advanced-stage-development category comprises: (a) devices of various scales including fullscale, that have been deployed and tested in situ for generally short periods, but where the energy output has not been utilized for the production of electricity or other purpose (in most cases plans call for such devices to be further developed and deployed as operational wave energy systems); and (b) full-scale devices planned for construction where the energy output will be utilized for the production of electricity or other purpose." Classification of basic energy conversion principles: A Heaving or pitching bodies B Oscillating water column C Pressure devices D Surging-wave energy converters E Particle motion converters F Overtopping devices 5.7.