AES Senior Projects: Best Practices for Project-based Courses

advertisement

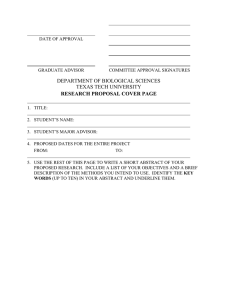

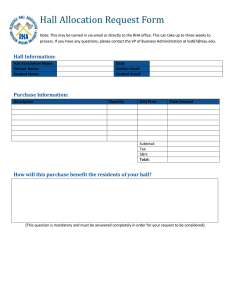

AES Senior Projects: Best Practices for Project-based Courses James A. Nabity, PhD Associate Professor, Aerospace Engineering Sciences Aerospace Ventures Workshop 25 January 2016 Course Objectives • Provide a Capstone Experience to seniors • Integrate technical knowledge from previous courses • Learn and practice professional skills in a team environment • Exercise and refine technical skills • Acquire and apply new knowledge • Provide an engineering solution • Learn Systems Engineering methods and skills employed in industry 2 Transition from Student to Professional • Two-semester course requiring industry/government sponsorship (non-ITAR / no IP) • Self-directed teams w/ 8-10 students - Quality teamwork is essential • No one knows the “answers”; its up to the team to: • Understand the project needs • Seek out advice/help/knowledge/information • Apply engineering principles/tools/reasoning to make (and support) sound design decisions • Benefit from the Systems Engineering methods taught in this course • Faculty advisors • Coach two teams during design development • Part of review board to evaluate presentations and reports 43 The Projects Advisory Board (PAB) James Nabity (Course Coord.) Ryan Starkey (Team Advisor) Bob Marshall (Team Advisor) Matt Rhode (Machine Shop Supervisor) Jelliffe Jackson (Team Advisor) Bobby Hodgkinson (Elect./Mech. Shop) Joe Tanner (Team Advisor) Trudy Schwartz (Electronics Shop Supervisor) 4 Design Process and Course Milestones Project Definition Document (PDD) - wk 2, 3 Concept Definition Document (CDD) - wk 5 ANALYZE CONCEPTS FOR FEASIBILITY Preliminary Design Review (PDR) – wk 8, 9 DETAILED SYSTEM DESIGN DEFINE PROBLEM DEVELOP CONCEPTS Project Final Report (PFR) – wk 17 Spring Final Review (SFR) – wk 15, 16 FUNCTIONAL & MODEL VALIDATION REQUIREMENTS VERIFICATION Test ANALYZE TEST DATA DEVELOP Readiness CONCLUSIONS Review (TRR) – wk 8 Critical Design Review (CDR) - wk 15, 16 Fall Final Report (FFR) - wk 17 ORDER/BUILD PARTS ASSEMBLE Manufacturing Status Review SYSTEM, UNIT TESTING (MSR) – wk 4 5 Required Project Elements • All projects must have • • • • • A Mechanical/aerodynamic/thermal design component (> 25%) An Electrical/optical/radio design component (> 25%) A Software/firmware design component (> 25%) Functional objectives that can be prototyped and tested Engineering models that predict performance and can be validated with prototype testing • Be careful to evaluate design content separately from purchasing, building, and testing aspects Components Lowest weight Highest weight M, E, S 25% 50% 6 Lecture Topics • General topics: course overview, project descriptions, ITAR, ethics in engineering, presentation skills, surviving design reviews, readiness levels • Project Management*: project planning, organizing team meetings, team roles / lead positions, work breakdown structure, fire & safety, finance / travel • Systems Engineering*: project / concept definition, requirements development & flowdown, critical project elements, trade studies, risk assessment / prioritization, Failure Modes & Effects Analysis (FMEA) • Technology-driven: power feasibility, electronics, sensors, processors, manufacturing, measurements & uncertainty, data presentation * Most important to project success 7 Grading • Each assignment gets a team grade; Notebooks are the only exception • PAB discusses team grades on all major assignments to ensure uniformity across projects • Team members are differentially graded within each project according to: • Peer and self evaluations (twice per term: at MSR and SFR) • Advisor evaluations • Discussions among the whole PAB • Customer input • Grading scale is absolute, based on performance with respect to assignment objectives. (See syllabus for more info.) 8 Multi-disciplinary Projects (AY15/16) • AFRL - Recuperated Turbine Engine • Aurora Flight Sciences - UAV Wing De-icing • Jet Propulsion Laboratory – Deployed FireTracker System • CU AES - Wind Tunnel Model Positioning System • Special Aerospace Services - 3D Printed Solid Motors • Ball Aerospace - NeoPod for Surface Science on Europa • Surrey Satellite - Lightweight SmallSat Structure for Deployment from the ISS • CU AES - CubeSat Attitude Control Testbed 9 MODEFLIER Demonstration of Dutch Roll End of mode excitation 5° Visibility requirement Full control reestablished 4/29/2015 University of Colorado Boulder Aerospace Engineering Sciences 10 Customers • Industry, government & academic • Course Coordinator lines up with assistance from the chair, industry outreach staff & OCG • NOI • Research contract • Define the project need • Provide financial support for the project • $5K for procurements • $15K for AES staff and shop support • Other obligations • Meet w/ the team once per week to review work & offer advice • Attend reviews (to the extent possible) 11 Lessons Learned • The course works - industry, gov’t lab, faculty assessment and student feedback • Team organization w/ diverse skills very important • Project manager; the right person matters • Effective & well-run team meetings • Poorly organized teams leave students struggling to keep up in the fast-paced course • Communication equally or more important to technical • Help from the customer most important to a good start 12 Challenges with Expected Growth • AY14/15: 88 students in Senior Projects • 10 projects (8-9 students/team) • AY15/16: 68 students • 8 projects (7-9 students/team) • AY16/17: Anticipate 107 students • Expect 10-12 projects (9-11 students/team) • Recruitment of sponsors already underway • May need a shift in paradigm to support increased enrollment • Shops near capacity in Spring semester • Major presentations (currently 5 teams/wk, should be able to fit in 6 teams/wk by eliminating a lecture) • Senior Projects room at/near capacity 13 THANK YOU! 14 Back up Slides 15 REAPER: REcuperating Advanced Propulsion Engine Redesign Model, build, implement, and verify an integrated recuperative system into a JetCat P90-RXi miniature turbojet engine for increased fuel efficiency from its stock configuration. Recuperator Inlet Compressor Customer: AFRL-WPAFB Capt. Joshua Rittenhouse Combustor Turbine Nozzle Advisor: Dr. Ryan Starkey 16 AESIR: Actuated Electromagnetic System for Ice Removal Design, build, and test a small-scale prototype of a deicing system for the Orion UAV Magnetic-actuated ice removal system Ice Carbon fiber skin • Orion designed to fly for 5 days at 20,000 ft at 65 Knots-Indicated Air Speed • Mission limited by icing conditions Customer: Aurora Flight Sciences Ellis Langford, Ed Wen Paramagnetic Material Solenoid Advisor: Joe Tanner 17 ELSA: Europa Lander for Science Acquisition Develop and integrate a communications and avionics systems with a scientific payload to fit within a 25-cm spherical Europa probe 128 kbps data transfer Europa Orbiter NeoPod 100 hr lifetime Customer: Ball Aerospace Joe Hackel Advisor: Dr. Robert Marshall 18 INFERNO: INtegrated Flight-Enabled Rover For Natural disaster Observation Design and create an aerial sensor package delivery system for future integration with a natural disaster observation system 10 minutes 0 1 2 Customer: Jet Propulsion Laboratory Barbara Streiffert 12 13 1/2 minutes Advisor: Dr. Jelliffe Jackson 19 SPAM: Solid Propellant Additive Manufacturing Design & integrate an additive manufacturing system to print Sucrose-potassium nitrate solid rocket motors Customer: Special Aerospace Services Tim Bulk Advisor: Dr. Ryan Starkey 20 FISH & CHIPS: FeatherCraft Integrated Structural Housing & Computer, Hardware Interface Processing Suite Design & build a 5 kg FeatherCraft structure for a 100 kg smallsat that: reduces structural manufacturing time and materials cost and enables launch to/from the ISS for a nadir-facing mission Design Features: • Composite materials • Woven Carbon Fiber skin • Aluminum Honeycomb Core • Low parts count • Integrate customer provided systems (propulsion, solar panels, nadir-facing payload, radiator, avionics, etc.) Advisor: Joe Tanner Customer: Surrey Satellite Technology Michael Brown 21 COMPASS: University of Colorado Model Positioning - DynAmic/Static - System Design, build, and validate a wind tunnel positioning system with minimal blockage, capable of moving a test article through four degrees of freedom: pitch, yaw, roll and plunge 1.19 m 0.76 m 0.6 m Customer: University of Colorado John Farnsworth Advisor: Dr. Jelliffe Jackson 22 STAR: Satellite Testbed for Attitude Response Design & build a testbed for preflight verification of CubeSat functionality; Supports the QB50 project Matlab Simulation Interface Board Sun Sensor Calibration Customer: University of Colorado Scott Palo Customer ADCS ADCS Verification Advisor: Dr. Robert Marshall 23