Supply Chain Management in Textile and Supplier Performance Evaluation

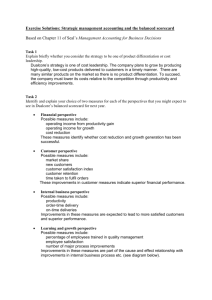

advertisement

10th Global Conference on Business & Economics ISBN : 978-0-9830452-1-2 Supply Chain Management in Textile and Supplier Performance Evaluation Mehmet Tanyas Faculty of Economics and Administrative Sciences, Maltepe University, Turkey Cevza Candan Textile Engineering Faculty, Istanbul Technical University, Turkey Kadir Cesur* Textile Engineering Faculty, Istanbul Technical University, Turkey ABSTRACT In this study, supply chain management is described and importance of well managed supply chain management is indicated. Performance, performance evaluation and supplier selection and performance evaluation methods are clarified. As a performance evaluation technique, Balanced Scorecard system is described in detail and financial, customer, internal process, and “learning and development” perspectives are defined. The application of the system to a Global Sourcing Office which is mainly processing in textile business is also demonstrated. Analytical Hierarchy Process which is also a performance evaluation method, is on the other hand employed to determine the importance weight of the performance evaluation metrics. Finally, unlike the previous studies, balanced scorecard is used as a supplier evaluation tool in this work and furthermore the supplier evaluation system in a supply chain perspective is investigated. 1. INTRODUCTION There has been a remarkable interest in supply chain management (SCM) related research in the last twenty years because of its potential to improve the efficiency and reduce of the costs. Sengupta and Turnbull (1996) mentioned that organizations have noticed that effectively streamlining the supply chain can improve their customer service levels dramatically, reduce October 15-16, 2010 Rome, Italy 1 10th Global Conference on Business & Economics ISBN : 978-0-9830452-1-2 excess inventory in the system and cut excess costs from the network of the organization. In recent years, the considerable attention among researchers regarding how to make the integration of supply chain is possible. However, Christopher and friends (2006) indicated that there are no supply chain (SC) strategies that are applicable to all types of products and markets. One component of SCM that had until recently been relatively neglected was that of supply chain performance measurement. According to Fawcett and Clinton (1996b), an effective measurement system provides the basis to understand the system, influences behavior throughout the system and provides information regarding the results of system efforts to supply chain members and outside stake holders. As a part of SCM performance measurement throughout the international purchasing strategy, the performance evaluation of suppliers has big affects on customer satisfaction for the goods or services that they have taken. According to Kannan and Tan (2002), there has been a shift in manufacturing companies away from vertical integration toward smaller, leaner organizations which leads to greater dependence on suppliers and increase the need to effectively manage suppliers. It leads the companies to create meaningful supplier performance assessment in a SCM manner. There has been a special attention on performance evaluation systems and mechanisms and many researchers studied on this subject. Hinkle and friends (1969) offered categorical method as a simple and basic supplier performance measurement system while Timmerman (1986) indicated linear averaging method as a more subjective and details system. Total cost based supplier performance evaluation was also investigated by Timmerman (1986). Apart from these basic performance evaluation systems, Cooper and friends (2004) studied on data envelopment analysis, Pan (1989) on linear programming models, Mummalaneni (1996c) on statistical models October 15-16, 2010 Rome, Italy 2 10th Global Conference on Business & Economics ISBN : 978-0-9830452-1-2 and Talluri (2002b) on game models. Analytical hierarchy process (AHP) is also another method to determine relative weights of performance evaluation which was studied by Hu (2009). There has been discussion on supplier performance evaluation metrics as well. Dickson (1966) was the first who studied on performance evaluation criteria, mentioned that cost, quality and delivery performance are the most important supplier evaluation metrics. According to Talluri (2002b), many other researchers indicated that cost, quality and delivery performance are the key performance evaluation metrics. In the study of Kannan (2002), it is mentioned that the performance metrics vary according to the type of purchasing and, by literature review and survey research 30 performance metrics were determined and their importance in buying environment was evaluated. He pointed out that the results of the survey research is parallel with previous studies. The previous studies mainly focused on performance evaluation techniques and performance evaluation criteria to evaluate supplier performance. Literature survey showed that there is a lack of research on establishing supplier performance evaluation system on a wider scale from supply chain perspective by using Balanced Scorecard method. Different from previous researches, the supplier performance evaluation system is created starting from company structure and its strategic targets and previously used performance evaluation techniques are adopted for the application. In our paper, Balanced Scorecard is employed as a tool to create a supplier performance measurement system for a global sourcing office which supplies textile products to an international retail company. Initially, the performance evaluation system is was created in a whole aspect using balanced scorecard. Then, performance evaluation metrics were defined and AHP was used to determine the weighted importance of these performance metrics. Finally, the October 15-16, 2010 Rome, Italy 3 10th Global Conference on Business & Economics ISBN : 978-0-9830452-1-2 application of the performance evaluation system to a global textile sourcing company was discussed. 2. ANALYTICAL HIERARCHY PROCESS The AHP method, introduced by Saaty (1980), expresses how to establish the priority of a set of alternatives and the relative importance of criteria in a multiple criteria decision making problem, and has been extensively discussed in a variety of aspects. The consideration area of AHP is not only the qualitative but also quantitative approaches. According to Saaty (1995), the AHP process is based on three principles of methodical process: constructing hierarchies, establishing priorities and reasonable consistency. 2.1 Structuring Hierarchies The first step in AHP is to work on the decision problem in order to decompose it and then try to build a hierarchical structure from the criteria or sub criteria. According to Saaty (1990), decision maker should be careful with the structuring hierarchy. In order to do this, the structure should present the problem in a best way, all sides of the factors that affect the problem should be considered, all the information sources that might help the solution should be considered and all the participators who will be in the problem process should be defined. 2.2 Setting Priorities The second step in using AHP is to set the priorities and weights for each element. The elements of each level of the hierarchy are rated using the pair wise comparison approach. Hu (2009) stated that AHP provides unique features for criteria weight and subjective evaluations by pair wise comparison and the 1-9 ratio scale in Table 1. October 15-16, 2010 Rome, Italy 4 10th Global Conference on Business & Economics ISBN : 978-0-9830452-1-2 Table 1. Saaty’s 1-9 scales for pair wise comparison in AHP Importance intensity 1 3 5 7 9 2,4,6,8 Definition Equal importance Moderate importance of one over another Strong importance of one over another Very strong importance of one over another Extreme importance of one over another Intermediate values The actors’ comparative decisions between the paired goals build the basic pair wise comparison according to the relative importance of one goal to another. Paired comparisons are asked to the respondents in order to define which goal or criteria in the pair are more important to him/her. Saaty’s scale of measurement for the paired comparisons uses the verbal comparisons into numerical value of the scale as in Table 1. After all criteria have been compared with the priority scale pair by pair, a paired comparison matrix is formed (1). (1) Let C1, C2, …,Cn be the set of elements, while aij represents a judgment on a pair of elements C1, Cn . In matrix A , aii =1 and aji = 1/ aij , i, j =1, 2,…, n . The relations between weights Wi and judgments aij are simply given by Wi/ Wj = aij (for i, j =1, 2,…, n ). 2.3 Consistency According to Saaty, consistency is not guaranteed in any measurement type. Errors in judgment are common; therefore, the consistency ratio (CR) is used to measure the consistency in pair wise comparisons (1990). He proved that for common matrix, the largest eigen value is equal to the size of comparison matrix. October 15-16, 2010 Rome, Italy 5 10th Global Conference on Business & Economics ISBN : 978-0-9830452-1-2 Consistency Index (CI) and CR are calculated as below: (2) (3) RI denotes the average consistency index and If CR ≤ 0.1, the estimate is accepted. 3. BALANCED SCORECARD The balanced scorecard is a strategic planning and management system. It was originated by Robert Kaplan and David Norton (1996d) as a performance measurement framework that added strategic non-financial performance measures to traditional financial metrics to give managers and executives a more balanced view of organizational performance. According to Kaplan and Norton (1996d), the balanced scorecard is a management system (not only a measurement system) that enables organizations to clarify their vision and strategy and translate them into action. It provides feedback around both the internal business processes and external outcomes in order to continuously improve strategic performance and results. When fully deployed, the balanced scorecard transforms strategic planning from an academic exercise into the nerve center of an enterprise. Kaplan and Norton (1996d) stated that the balanced scorecard retains traditional financial measures. But financial measures tell the story of past events, an adequate story for industrial age companies for which investments in long-term capabilities and customer relationships were not critical for success. These financial measures are inadequate, however, for guiding and evaluating the journey that information age companies must make to create future value through investment in customers, suppliers, employees, processes, technology, and innovation. October 15-16, 2010 Rome, Italy 6 10th Global Conference on Business & Economics ISBN : 978-0-9830452-1-2 The balanced scorecard suggests that we view the organization from four perspectives which are financial, customer, business process and learning and improvement perspectives. 3.1 The Financial Perspective Kaplan and Norton do not disregard the traditional need for financial data. Timely and accurate funding data will always be a priority, and managers will do whatever necessary to provide it. In fact, often there is more than enough handling and processing of financial data. With the implementation of a corporate database, it is hoped that more of the processing can be centralized and automated. But the point is that the current emphasis on financials leads to the "unbalanced" situation with regard to other perspectives. There is perhaps a need to include additional financial-related data, such as risk assessment and cost-benefit data, in this category. 3.2 The Customer Perspective Recent management philosophy has shown an increasing realization of the importance of customer focus and customer satisfaction in any business. These are leading indicators: if customers are not satisfied, they will eventually find other suppliers that will meet their needs. Poor performance from this perspective is thus a leading indicator of future decline, even though the current financial picture may look good. In developing metrics for satisfaction, customers should be analyzed in terms of kinds of customers and the kinds of processes for which we are providing a product or service to those customer groups. 3.3 The Internal Process Perspective This perspective refers to internal business processes. Metrics based on this perspective allow the managers to know how well their business is running, and whether its products and services conform to customer requirements. These metrics have to be carefully designed by those who October 15-16, 2010 Rome, Italy 7 10th Global Conference on Business & Economics ISBN : 978-0-9830452-1-2 know these processes most intimately matching with company’s unique missions. These are not something that can be developed by outside consultants. 3.4 The Learning and Development Perspective This perspective includes employee training and corporate cultural attitudes related to both individual and corporate self-improvement. In the current climate of rapid technological change, it is becoming necessary for employees to be in a continuous learning mode. Metrics can be put into place to guide managers in focusing training funds where they can help the most. In any case, learning and growth constitute the essential foundation for success of any organization. Kaplan and Norton (1996d) emphasize that 'learning' is more than 'training'; it also includes things like mentors and tutors within the organization, as well as that ease of communication among employees that allows them to readily get help on a problem when it is needed. It also includes technological tools. 4. THE CASE STUDY The performance evaluation system which is based on balanced scorecard was applied to a global sourcing office of an international retail company. Before the application of a structured performance evaluation system, the performance of the global sourcing office and suppliers have been evaluated subjectively. However, the sourcing office which is located in Turkey has been continiously improving its business activities and supply chain structure. As a result of that, there has been a need for more objective, quantitative and structured performance evaluation system for the office performance as well as its suppliers performances. During the application of the office and supplier performance evaluation system, the office manager and the department managers involved in a structuring the balanced scorecard system. Also, all the employees took part in a performance evaluation criteria’s importance weight with October 15-16, 2010 Rome, Italy 8 10th Global Conference on Business & Economics ISBN : 978-0-9830452-1-2 the help of AHP method. While establishing the supplier performance evaluation system in the “supply chain management” perspective, it was decided that the performance in the office organisation should be established first. This enabled to determine the strategic targets much better and the measurement criteria in each perspective of the balanced scorecard in a more structured and strategical way. Under this topic, the company structure will be introduced initially. Then the design of the performance evaluation system will be described at the office level. Finally, the performance evalutaion system established for the supplier performance measurement will be discussed. 4.1 The Company Being part of an international retail company, the global sourcing office was established in Turkey for mainly supplying textile products to its stores located in all over Europe. The global sourcing office is structured in accordance with the type of products and thus its departments are divided into categories such as home textiles, underwear, hosiery and outwear, etc. in terms of business and product development section. For production, quality and sustainability of the production, there is a separate department which promotes product development in parallel with company requirements and specifications. 4.2 The Performance Evaluation System Design for the Office In order to be able to establish a performance evaluation system throughout a whole supply chain, first the office mission and vision needed to be clarified so as to define strategical targets and also measurement criteria. The mission was described as being the preferred sourcing office for the company branded products and vision was described as to increase the volume of the business up to 50% by 2012 . According to the mission and vision, the strategical targets were October 15-16, 2010 Rome, Italy 9 10th Global Conference on Business & Economics ISBN : 978-0-9830452-1-2 described for each perspective of the balanced scorecard which are financial, customer, business process and learning and development perspective. In accordance with the strategical targets for each perspective, the performance metrics were determined by the department and office managers. In order to create a more objective and reliable performance measurement system, quantitative metrics were used as much as possible. Consequently, the strategic targets and performance evaluation metrics in accordance with the balanced scorecard frame is presented in Table 2. Table 2. The strategic targets and performance metrics in accordance with balanced scorecard. Balanced Scorecard Perspectives Strategical Targets Financial Perspective - Increase of income and its type of combination - Decrease of costs and increase of efficiency Customer Perspective - Customer satisfaction - Customer sustainability Internal Process Perspective - Strong supplier relations - Strong customer relations - Efficient product follow up Learning and Development Perspective - Continuous improvement of the employees - New product or system development - Development of suppliers October 15-16, 2010 Rome, Italy Performance Criteria - Turnover - Shipment quantity - General expenses - The cost of third party service providers - On time deliveries - Right quantity deliveries - Product diversity - Fast and accurate product development - Product quality level - Technical, social and environmental audits - Supplier visits - Customer visits - Accurate information input - Accurate order creation - Fast logistic operations - The amount of the external trainings - The amount of the internal meetings and trainings - The achievement of new working methods - Usage of new information technologies - New product developments - The training of suppliers 10 10th Global Conference on Business & Economics ISBN : 978-0-9830452-1-2 In order to determine the relative importance of the performance criteria, AHP was used by pairwise comparison of the criteria. According to the survey within the employees at the global sourcing office, the qualitative pairwise comparison of the pre-determined criteria was made and with the help of the computer programme Super Decisions which is operating on the logic of AHP, the importance weights of the criteria for each balanced scorecard perspective were calculated. The pairwise comparison in AHP model for financial perspective is shown in Table 3. Table 3. The comparison table of office performance in financial perspective by using AHP. 1=Equally important 3=Medium level important 5= Important 7=Very Important 9=Extremely Important 9 8 7 6 5 4 3 2 1 2 3 4 5 6 7 8 9 Turnover Turnover Shipment quantity General expenses The cost of third party service providers General expenses The cost of third party service providers The cost of third party service providers Turnover Shipment quantity Shipment quantity General expenses For obtaining general performance evaluation results the evaluation metrics should have been transformed into measurable and comparable numbers. Therefore, normalization and aggregation method which was employed by Lohman and friends in their study was utilized (2004). The normalization method is based on a linear 0-10 scale. It appeals to one’s imagination and makes readability and interpretation of actual metric values very easy. Two steps need to be taken for normalizing the metric scores. 1. Set performance targets: The target is the starting point for defining the metric score range that corresponds with the 0-10 scale. October 15-16, 2010 Rome, Italy 11 10th Global Conference on Business & Economics ISBN : 978-0-9830452-1-2 2. Normalisation scores to a 0-10 scale: A target will lie somewhere between 0 and 10. Since consistency is recommended when using a normalised scale, the values 0-10 should always have a same meaning, regardless the metric observed. In our system, the score 8 corresponds to the target. This means that if the target is hit, the metric gets a score of 8 or higher. After normalization of the results each performance criteria, the scores for each balanced scorecard perspective were calculated. The results are given in Table 4. Table 4. The relative importance of the performance metrics and scores in office level. Perspective Strategic Performance Criteria Turnover Shipment quantity Financial General expenses Perspective The cost of third party service providers On time deliveries Right quantity deliveries Product diversity Customer Product quality level Perspective Fast and accurate product development Technical, social and environmental audits Supplier visits Internal Customer visits Process Accurate information input Perspective Accurate order creation Fast logistic operations The amount of the external trainings The amount of the internal meetings and trainings Learning and The achievement of new working Development methods Perspective Usage of new information technologies New product developments The suppliers’ training October 15-16, 2010 Rome, Italy 12 Importance Weight 55,0% 9,0% 18,0% Results 5,9 6,1 10,0 18,0% 10,0 28,0% 15,0% 15,0% 28,0% 6,9 9,2 7,2 7,2 9,0% 8,5 5,0% 8,8 9,0% 9,0% 27,3% 27,4% 27,3% 25,0% 4,5 6,0 6,0 7,2 9,2 3,2 25,0% 2,7 12,5% 7,2 12,5% 6,0 12,5% 12,5% 10,0 3,2 Perspective Result 7,4 7,9 7,1 4,8 10th Global Conference on Business & Economics ISBN : 978-0-9830452-1-2 As a final performance score of the office, the importance weights of each perspective was taken from the study of Norton (2000). He mentioned that in an ideal scorecard, the importance weight for each perspective should be as 22% for financial, 22% for customer, 34% for internal process and 22% for learning and development perspectives. By using lineer averaging method of the scores of the perspectiveds the final score for office performance was calculated and displayed in Table 5. Table 5. The office level general performance figures. Total Performance Scorecard Financial Perspective Customer Perspective Internal Process Perspective Learning and Development Perspective Total Weight 22% 22% 34% 22% 100% Target Score 8 8 8 8 8 Result 7,4 7,9 7,1 4,8 7,5 After any performance evaluation, both the actions taken for the results which are below the target set and the further development of an achived target are equally important since these will guaarantee continious improvement. The results of the office performance in 2009 were below the target in all perspectives. Learning and development perspective was especially much lower the target due to the financial turmoil all over the world. Most of the trainings were cancelled for financial reasons and this had a positive effect on financial perspective. However, lack of training might lead to loose of motivation, worse operation performance, and decrease in other perspectives in long term. The financial target was below the target as well due to decrease in order quantities. Considering the global economic crisis, the score was regarded as acceptable. The customer perspective score was acceptable but there were problems with “on time” deliveries. By supplier trainings, and by focusing on production follow-up more, it was believed that the results could be improved. October 15-16, 2010 Rome, Italy 13 10th Global Conference on Business & Economics ISBN : 978-0-9830452-1-2 4.3 The Supplier Performance Evaluation System Design The global sourcing office is working with various textile suppliers in terms of product type, company structure, and capacity. The suppliers’ internal processes differ from each other even for the same product group. Some of the suppliers have integrated capacity from spinning, weaving or knitting, dying or printing to clothing. Some of them, on the other hand are only doing the packaging process by using subcontractors in each process. Because of that variation seen in the suppliers, the performance evaluation system which would be selected for textile suppliers should have been as flexible as possible and the criteria however could have been applied to all suppliers. Bearing the aspects given above on mind, for suppliers the performance evaluation system was based on the level performance evaluation of the global sourcing office. In parallel with the mission, vision, strategic targets and performance criteria for office, the structure of the suppliers’ performance evaluation system was established. Balanced scorecard was used as a base for supplier performance evaluation and it should be emphasized that our study differed from the previous studies in that sense particularly. While defining the performance metrics for the evaluation of the suppliers, the structure of textile was also taken into consideration and thus some of the metrics like flexibility, fast product development, the capability of the customer representative were added to the criteria. Similar with the office level, the strategic targets and evaluation parameters for supplier performance evaluation was mainly decided by the department and office managers. The strategic targets and performance criteria for suppliers are described in Table 6. October 15-16, 2010 Rome, Italy 14 10th Global Conference on Business & Economics ISBN : 978-0-9830452-1-2 Table 6. The strategic targets and performance metrics for suppliers. Balanced Scorecard Perspectives Strategical Targets Financial Perspective - Increase of income and it’s type of combination - Decrease of costs and increase of efficiency - Financial Strength Customer Perspective Business Process Perspective Learning and Development Perspective Performance Criteria - Customer satisfaction - Customer sustainability - Strong customer relations - Efficient internal communication - Continuous improvement of the employees - Development of capacity, capability and flexibility - Turnover - The cost of third party service providers - The financial situation - Price - On time deliveries - Right quantity deliveries - Product quality - Technical, social and environmental audit results and certificates - Technical capabilities - Meetings and office visits - Fast product development and pricing - Flexibility - Internal communication level - The capability of merchandiser - Quality systems - The consistency of order follow up system - Customer focus trainings - New working methods or systems - Capacity increase and new technologies - Experience Similar with the office performance evaluation, the importance weights of each criteria for supplier performance were determined by the pairwise comparison with AHP method as well as Super Decisions computer programme. After that, normalization and aggregation were applied to the criteria in order to have the same numeric comparison for the criteria within a 0-10 scale. The target value for each criteria was found out to be 8 as in the office performance evaluation. Having the same target value provides a general approach for general understanding of the results. Like the office performance evaluation, the importance weights of each perspective was taken from the study of Norton (2000). October 15-16, 2010 Rome, Italy 15 10th Global Conference on Business & Economics ISBN : 978-0-9830452-1-2 An example for the supplier performance evaluation results for each perspective and general performance result is given in Table 7 and Table 8. Table 7. An example for a supplier performance evaluation for each perspective. Perspective Strategic Performance Criteria Turnover Financial The cost of third party service Perspective providers The financial situation Price On time deliveries Right quantity deliveries Customer Product quality Perspective Technical, social and environmental audit results and certificates Technical capabilities Meetings and office visits Fast product development and Internal pricing Process Flexibility Perspective Internal communication level The capability of merchandiser Quality systems The consistency of order follow up system Learning and Customer focus trainings Development New working methods or systems Perspective Capacity increase and new technologies Experience Importance Weight 65,0% Results Perspective Result 6,0 23,0% 9,2 6,9 12,0% 4,0% 25,0% 25,0% 28,0% 7,0 7,0 9,2 9,0 8,2 8,8 8,0% 9,0 13,0% 5,0% 9,0 3,2 28,0% 9,0 29,0% 15,0% 15,0% 8,0% 7,0 8,3 9,0 10,0 30,0% 6,4 8,0% 16,0% 7,0 7,0 30,0% 7,3 16,0% 10,0 8,1 7,4 Table 8. An example of a supplier’s general performance. Total Performance Scorecard Financial Perspective Customer Perspective Internal Process Perspective Learning and Development Perspective Total October 15-16, 2010 Rome, Italy Weight 22% 22% 34% 22% 100% 16 Target Score 8 8 8 8 8 Result 6,9 8,8 8,1 7,4 7,8 10th Global Conference on Business & Economics ISBN : 978-0-9830452-1-2 The results for all suppliers evaluation and the average value are mentioned in Figure 1. GLOBAL SOURCING OFFICE SUPPLIER EVALUATION FORM SUPPLIER TEXTILE FINANCIAL PERSPECTIVE CUSTOMER PERSPECTIVE INTERNAL PROCESS PERSPECTIVE LEARNING AND DEVELOPMENT PERSPECTIVE DEPT NAME Turnover The cost of third party service providers The financial situation SCORE Price On time deliveries Right quantity deliveries Product quality Technical, social and enviromental audit results and certificates Technical capabilities SCORE Meetings and office visits Fast product development and pricing Flexibility Internal communication level The capability of merchandiser Quality systems SCORE New working methods or systems Capacity increase and new technologies Experience SCORE TOTAL SCORE 61, 65 A B 8,3 9,1 10,0 10,0 9,0 9,5 8,8 9,3 8,0 8,0 8,2 9,1 8,4 8,7 10,0 9,0 6,5 4,5 9,0 9,0 8,7 8,5 9,0 8,0 9,0 8,0 8,0 9,0 9,0 8,0 9,0 8,0 9,5 9,0 8,8 8,4 9,0 9,0 9,0 8,0 10,0 9,0 9,0 8,0 10,0 8,0 9,3 8,5 8,9 8,6 67 C 10,0 8,8 9,0 9,6 8,0 8,5 10,0 10,0 7,5 9,0 9,2 8,0 8,0 7,0 9,0 8,0 9,0 7,9 8,0 7,0 7,5 8,0 7,0 7,7 8,5 67 D 7,9 8,5 9,0 8,2 8,5 6,1 9,9 10,0 4,5 9,0 8,4 9,0 9,0 8,0 8,0 10,0 8,0 8,6 8,0 8,0 9,0 9,0 9,0 8,6 8,5 67 E F 10,0 9,6 0,0 9,7 9,5 9,0 7,6 9,5 8,0 8,0 6,7 8,3 9,3 10,0 10,0 9,0 4,5 4,5 9,0 9,0 8,4 8,7 8,0 8,0 8,0 7,0 9,0 8,0 10,0 7,0 8,0 6,0 10,0 9,0 8,8 7,4 10,0 8,0 8,0 8,0 8,0 7,0 9,0 8,0 7,0 10,0 8,7 8,2 8,4 8,3 67 G 6,8 3,1 9,0 6,2 8,0 7,7 9,8 10,0 5,5 8,0 8,7 9,0 9,0 9,0 9,0 10,0 8,0 9,1 8,0 8,0 9,0 8,0 10,0 8,5 8,2 65 H 3,5 10,0 9,0 5,7 7,0 9,0 8,9 9,0 6,5 8,0 8,6 8,0 9,0 8,0 9,0 10,0 9,0 8,8 9,0 9,0 10,0 9,0 10,0 9,3 8,2 67 I 9,5 9,6 9,0 9,5 7,0 7,0 6,3 10,0 4,5 9,0 7,6 8,0 8,0 7,0 8,0 7,0 8,0 7,6 8,0 8,0 7,0 8,0 7,0 7,7 8,0 64 J 9,3 10,0 9,0 9,5 8,0 9,9 10,0 8,0 3,5 8,0 8,6 8,0 7,5 8,0 7,0 7,5 5,0 7,4 7,0 7,0 5,0 7,0 7,0 6,7 8,0 65 K 9,2 10,0 9,0 9,4 7,0 8,8 4,0 9,0 4,5 8,0 7,1 7,0 7,0 7,0 8,0 7,0 9,0 7,3 8,0 7,0 8,0 8,0 9,0 8,1 7,9 63 L 9,1 9,8 9,0 9,3 7,0 4,6 10,0 8,0 3,5 8,0 7,2 7,0 8,0 8,0 8,0 7,0 8,0 7,8 8,0 7,0 7,0 8,0 5,0 7,3 7,9 63 M 8,4 4,5 6,0 7,2 7,0 7,7 10,0 8,0 3,5 8,0 8,0 7,0 8,0 8,0 8,0 8,0 8,0 8,0 8,0 7,0 6,0 7,0 5,0 6,8 7,6 67 N O 9,2 10,0 1,0 10,0 8,0 6,0 7,2 9,5 7,0 5,0 6,6 10,0 8,5 10,0 10,0 9,0 3,5 3,5 9,0 6,0 8,0 8,5 8,0 6,0 7,0 7,0 7,0 7,0 7,0 7,0 8,0 6,0 8,0 5,0 7,3 6,6 8,0 6,0 7,0 5,0 7,0 5,0 8,0 5,0 9,0 7,0 7,9 5,6 7,6 7,5 65 P 7,7 10,0 8,0 8,3 7,0 5,8 5,9 10,0 3,5 8,0 7,0 7,0 8,0 8,0 7,5 7,0 7,0 7,6 7,0 8,0 5,0 7,0 7,0 6,8 7,5 67 Q 2,0 8,7 8,0 4,2 7,0 7,9 9,8 10,0 6,5 9,0 8,9 7,0 8,0 9,0 8,0 9,0 6,0 8,2 8,0 7,0 7,0 7,0 10,0 7,8 7,4 63, 64 R 9,0 9,4 7,0 8,9 7,0 4,4 6,0 8,0 3,5 7,0 6,1 8,0 8,0 7,0 7,0 7,0 6,0 7,3 7,0 6,0 5,0 5,0 7,0 6,0 7,1 63, 64 T 8,3 9,5 8,0 8,6 8,0 4,4 1,4 9,0 3,5 7,0 5,2 5,0 7,0 8,0 7,0 7,0 7,0 7,2 7,0 7,0 7,0 8,0 5,0 7,0 7,0 63, 64 U 6,6 10,0 9,0 7,7 7,0 4,0 0,0 9,0 3,5 9,0 5,0 6,0 8,0 7,5 8,0 5,0 7,0 7,2 7,0 7,0 6,0 7,0 10,0 7,3 6,8 61, 62, 63, 64, 67 W 8,4 4,7 4,0 7,0 8,0 0,0 5,4 9,0 3,5 8,0 5,2 8,0 9,0 9,0 5,0 6,0 8,0 7,8 6,0 6,0 7,0 5,0 9,0 6,3 6,8 65 X 5,8 8,5 9,0 6,8 8,5 0,0 10,0 9,0 2,5 6,0 6,1 7,0 7,0 6,0 7,0 6,0 8,0 6,6 6,0 6,0 5,0 9,0 9,0 7,2 6,7 67 Y Z 5,5 8,6 6,5 0,0 9,5 8,0 6,2 6,6 7,0 6,0 2,3 3,1 3,5 7,9 9,0 9,0 4,5 2,5 9,5 8,0 5,6 6,5 8,0 8,0 7,0 6,0 6,5 6,0 7,0 9,0 6,0 6,0 9,0 7,0 6,9 6,6 8,0 7,0 8,0 7,0 7,0 5,0 8,0 8,0 7,0 5,0 7,7 6,7 6,6 6,6 63,67 AB 1,1 6,8 7,0 3,1 7,0 4,7 9,7 8,0 4,5 8,0 7,3 8,0 9,0 8,0 8,0 8,0 7,0 8,2 7,0 7,0 6,0 6,0 9,0 6,9 6,6 67 AC 7,7 0,0 4,0 5,5 7,0 3,7 10,0 8,0 2,5 7,0 6,8 7,0 7,0 8,0 7,0 7,0 5,0 7,1 7,0 5,0 5,0 5,0 7,0 5,9 6,4 63 AD 7,6 4,8 7,0 6,9 8,0 0,0 9,3 8,0 1,5 7,0 5,7 7,0 8,0 7,0 7,0 6,0 4,0 6,9 6,0 6,0 5,0 6,0 5,0 5,7 6,4 63 AE 8,2 7,2 8,0 7,9 9,0 0,0 8,4 8,0 2,5 6,0 5,4 7,0 7,0 6,0 5,0 4,0 6,0 5,9 6,0 6,0 5,0 7,0 7,0 6,3 6,3 63 AF 0,0 7,9 7,0 2,7 7,0 4,9 8,6 9,0 3,5 7,0 7,1 7,0 7,0 8,0 7,0 8,0 7,0 7,4 7,0 6,0 5,0 7,0 5,0 6,3 6,1 67 AG 5,8 2,5 5,0 4,9 7,0 3,7 10,0 10,0 2,5 5,0 7,0 8,0 6,0 6,0 7,0 6,0 4,0 6,1 5,0 6,0 5,0 6,0 7,0 5,7 6,0 60 AH 0,0 6,5 6,0 2,2 5,0 9,0 10,0 9,0 3,5 6,0 8,3 6,0 7,0 7,0 7,0 6,0 5,0 6,6 6,0 5,0 5,0 5,0 7,0 5,6 5,8 63 AI 0,0 6,5 8,0 2,5 6,0 8,0 0,0 8,0 2,5 9,0 5,6 6,0 8,0 7,0 8,0 6,0 6,0 7,2 7,0 6,0 5,0 7,0 7,0 6,6 5,7 63, 64 AJ 1,8 10,0 6,0 4,2 6,0 5,8 8,5 7,0 1,5 6,0 6,5 7,0 8,0 7,0 4,0 5,0 4,0 6,3 5,0 5,0 5,0 5,0 5,0 5,0 5,6 63 AK 0,0 0,0 8,0 1,0 7,0 5,5 1,4 8,0 2,5 8,0 5,3 8,0 7,0 8,0 8,0 7,0 9,0 7,7 7,0 7,0 5,0 7,0 5,0 6,4 5,4 63 AL AM 0,0 0,0 8,6 0,0 8,0 8,0 2,9 1,0 7,0 7,0 0,0 0,0 0,0 10,0 9,0 8,0 4,5 2,5 8,0 6,0 3,9 5,8 6,0 5,0 7,0 8,0 7,0 7,0 7,0 8,0 7,0 6,5 8,0 6,0 7,0 7,2 7,0 7,0 7,0 6,0 5,0 5,0 7,0 7,0 5,0 5,0 6,4 6,3 5,3 5,3 63 AN 0,0 0,0 6,0 0,7 7,0 8,8 0,0 8,0 3,5 7,0 5,7 7,0 7,0 8,0 7,0 9,0 6,0 7,5 7,0 7,0 4,0 5,0 5,0 5,6 5,2 63 AO 1,2 8,4 6,0 3,5 8,0 0,0 7,4 8,0 1,5 8,0 5,3 6,0 6,0 7,0 6,0 5,0 4,0 6,0 6,0 6,0 5,0 5,0 5,0 5,4 5,1 63 AP 0,0 0,0 8,0 1,0 9,0 1,7 10,0 8,0 2,5 7,0 6,4 8,0 5,0 6,0 6,0 6,0 7,0 5,9 7,0 7,0 5,0 8,0 5,0 6,7 5,1 67 AQ 4,9 4,7 6,0 5,0 8,0 0,0 8,3 8,0 1,5 5,0 5,2 8,0 4,0 5,0 3,0 3,0 7,0 4,4 5,0 4,0 4,0 5,0 5,0 4,8 4,8 63 AR 0,0 0,0 7,0 0,8 6,0 0,0 0,0 8,0 1,5 7,0 3,3 6,0 4,0 5,0 5,0 4,0 6,0 4,7 6,0 5,0 5,0 5,0 9,0 5,9 3,8 65 AT 3,1 3,0 2,0 2,9 10,0 0,0 0,0 7,0 1,5 4,0 2,8 6,0 4,0 4,0 2,0 2,0 7,0 3,7 3,0 4,0 4,0 6,0 5,0 4,5 3,5 6,8 6,7 61, 65 62, 63, 64 60 67 64 Average 7,6 7,1 The consistency Customer focus of order follow trainings up system 7,2 Figure 1. The supplier performance evaluation list in global sourcing office From these results, it may be seen that 10 out of 46 suppliers were above the target whereas 12 suppliers took a score below 6,0 which was not a good performance. It should also be noted that 10 suppliers out of 46 were located out of Turkey. The results suggested that it was necessary to make investment on the development of the suppliers outside Turkey and to organise trainings. On the other hand, the management decided to phase out the worst 4 suppliers in terms of performance. It was seen that they did not show the development expected and there was a risk for the customer perspective of the office. 5. CONCLUSION This study designed the performance evaluation system in a textile global sourcing office using Balanced Scorecard method. Its primary contribution is the development of a supplier October 15-16, 2010 Rome, Italy 17 10th Global Conference on Business & Economics ISBN : 978-0-9830452-1-2 performance evaluation system by adopting AHP into Balanced Scorecard within a supply chain perspective. Although the balanced scorecard approach takes considerable thought to develop an appropriate scorecard, the structure of balanced scorecard is available for textile business with its flexibility to adopt to the different demands and conditions. In order to create the supplier performance evaluation system, we first started with the base and accordingly established an organisational performance evaluation. This brought the advantage to clarify the vision, mission and strategic targets of the organisation as well as the demands from the suppliers. After clarification of the demands and criteria by using balanced scorecard, AHP method was used to determine the importance weights of the criteria by pairwise comparisons. After that, the results for each criteria has trassferred into 0-10 scale numeric velues according to the lineer scaling of the target, possible minimum or maximum resulst and final results. The system provided detailed information about the performance results and enabled to figure out the bottlenecks in terms of finance, customer, internal process and learning and development perspectives. So that, it would be possible to focus on the critical points for further development by corrective actions. References Christopher, M.C., Peck, H. & Towill, D.R. (2006) “A taxonomy for selecting global supply chain strategies” International Journal of Logistics Management, 17, 277-87. Cooper, W. W., Seiford, L. M.& Zhu, J., (2004) “Handbook on Data Envelopment Analysis” Kluwer Academic Publishers Dickson, G. (1966), “An Analysis of Vendor Selection Systems and Decisions”, Journal of Purchasing, 2, 28-41 October 15-16, 2010 Rome, Italy 18 10th Global Conference on Business & Economics ISBN : 978-0-9830452-1-2 Fawcett, S.E. & Clinton S.R (1996b) “Enhancing Logistics Performance to Improve the Competitiveness of Manufacturing Organizations” Production & Inventory Management Journal, 37, 40-46. Hu, Y. (2009) “Supplier Selection Based on Analytic Hierarchy Process and Grey Relational Analysis”, ISECS International Colloquium on Computing, Communication, Control, and Management, 607-610. Kannan, V.R. & Tan, K.C., (2002) “Supplier Selection and Assessment: Their Impact on Business Performance” The Journal of Supply Chain Managament, 38, 11-18. Kaplan R..S & Norton D.P (1996d), “The Balanced Scorecard: Translating Strategy into Action” Harward Business School Press, Boston. Lohman, C., Fortuin, L. & Wouters, M. (2004) “Designing a Performance Measurement System: A Case Study” European Journal of Operational Research, 156, 267-286. Mummalaneni, V. Dubas, K.M. & Chao, C., (1996c) “Chinese Purchasing Managers' Preferences and Trade-offs in Supplier Selection and Performance Evaluation" Industrial Marketing Management, 25, 115-124. Norton, D.P., 2000 “Beware: The Unbalanced Scorecard”, Balanced Scorecard Report” C: II, No:2, 2000, s.13-14 Saaty, T.L. (1980), “The Analytic Hierarchy Process: Planning, priority setting, resource allocation”, Mc Graw-Hill International Book Co., New York Saaty, T.L. (1990), “Multicriteria Decision Making: The Analytic Hierarchy Process”, RWS Publications, Pittsburg Saaty, T.L. (1995), “Decision Making for Leaders”, RWS Publications., Pittsburg October 15-16, 2010 Rome, Italy 19 10th Global Conference on Business & Economics ISBN : 978-0-9830452-1-2 Sengupta, S. and Turnbull, J. (1996), “Seamless Optimization of the Entire Supply Chain”, IEE Solutions, 28, 28-33. Talluri, S. (2002b) “A buyer-seller game model for selecting and negotiation of purchasing bids” European Journal of Operational Research, 143, 171-180 Timmerman, E., (1986), “An Approach to Vendor Performance Evaluation” Journal of Purchasing and Materials Management, 143, 171-180. October 15-16, 2010 Rome, Italy 20