Comet Aircraft.doc

advertisement

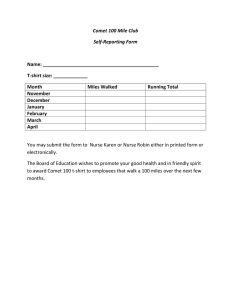

4A6(1) Structural Design Group 6 The de Havilland Comet Fatigue Failure Background In September 1946, Sir Geoffrey de Havilland began design work, under the direction of Ronald Bishop, for the Comet. It was the world’s first turbojet powered airliner, and with four de Havilland Ghost 50 turbofan engines, of 22kN thrust, it would fly at double the then cruising altitude of 12.2 km. The Comet was the first aircraft to use hydraulically actuated controls, to use high pressure refuelling and to have a highly pressurised, and air-conditioned, cabin. De Havilland also pioneered glued skin panels (‘Redux’ panels) to keep the weight of the aircraft down. The Comet could carry 36 passengers, with a cruising speed of 725 km/h and a range of 4000km. The de Havilland Comet 1 (G-ALYP) On the 27th July 1949, the DH 106 Comet flew for the first time. This was the first prototype flight but still 16 aircraft had already been signed for, 14 to British Overseas Airways Corporation and 2 to the Ministry of Supply, and a production line set up. This was a huge managerial risk to take as any alterations to the design from now on would be costly to implement. After 3 years of testing, the first passenger flight took off from London for Johannesburg in May 1952. The flight time was cut from 40 hours to 23, and due to the pressurised cabin the plane was able to fly above storms, hence providing a much quieter, smoother flight. In its first year of operation the Comet carried 28,000 passengers and travelled over 104 million miles. 4A6(1) Structural Design Group 6 The Problems Begin However the success was soon to be outlived, on the 26th October 1952 the first accident occurred while departing from Ciampino airport in Rome. Luckily there were no fatalities and the incident was blamed on poor pilot handling of the aircraft, however it seems de Havilland knew there could be a problem with the aircraft during take-off but were relying on the pilot’s skill to overcome this. Following this, on the 3rd March 1953 a new Comet 1A (CF-CUN) was being delivered and failed to gain altitude on take-off from Karachi, Pakistan. The plane collided with a bridge and caught fire, killing 11 crew members and others on board. It had been loaded to almost the maximum permissible weight but a flaw in the design was also found, it was discovered that during a steep ascent a large area of the wing lost its lift. A design review followed this and the leading edge of the wing was re-profiled, to provide greater lift, and a wig fence was added, to control spanwise flow. By May 1953, de Havilland had firm orders for 50 Comets and was negotiating 100 more. The first fatal accident involving passengers was on 2nd May 1953. A Comet 1 (GALYV) broke up, mid-air, 50km from Calcutta. The crash was attributed to excessive stresses in the airframe due to a tropical storm, but subsequent accidents indicated a weak structure was the more likely cause. On the 8th January 1954 one of the most serious accidents occurred, Comet GALYP, bound for London, exploded in good weather ascending from Rome to 8200m and crashed into the sea near Elba. All 35 passengers died. The fleet was grounded and an investigation began and the Royal Navy started to recover the aircrafts remains. The results of the investigation led to a design review, in which “modifications [were] embodied to cover every possibility that imagination [had] suggested as a likely cause of the disaster”; shields were installed between the engines and the fuel tanks, smoke and fire detectors were installed and the fuel lines were reinforced. On the 23rd March 1954 the fleet re-entered service. In less than a month, on 8th April 1954 Comet G-ALYY ran into difficulties 30 mins into flight while ascending towards 10.6 km. The wreckage was found in the sea near Naples and the fleet was grounded once more. A full investigation by the Royal Aircraft Establishment (RAE), under the direction of Sir Arnold Hall at Farnborough, began and a court enquiry was established. The result of which was that the plane suffered a catastrophic explosion of the fuselage and the Comets were withdrawn from service. On 12th April 1954 the Ministry of Transport and Civil Aviation removed the certificate of airworthiness. The square windows of the Comet 1 were redesigned as oval for the Comet 2, and the skin sheeting was thickened slightly. The remaining Comet 1s and 1As were either scrapped or the windows modified. But the Comet did not resume commercial airline service until 1958, when the Comet 4 was introduced (with better engines, greater fuel capacity, and a lengthened cabin for additional passengers) and became the first airliner to enter transatlantic service. 4A6(1) Structural Design Group 6 However, the 4 year hiatus gave other aircraft manufacturers the opportunity to profit from de Havilland’s hard-learned lessons The rival Boeing 707 and Douglas DC-8 had claimed the bulk of the market and only about 90 Comets ever reached the commercial market. Had the Comet not been plagued by a fatal design flaw, Britain might well still dominate commercial aviation today. The Reasons Investigators at the RAE examining the Comet G-ALYP carefully studied the cabin pressurisation by loading a full-size Comet into a water tank, and repeatedly pressurising and depressurising it, to simulate cabin loading at 35,000 ft, for a period of 9000 hours. When the tank was drained, a crack was located in the fuselage. This was a fatigue crack due to stress concentrations at the rear ADF window cut-out of 315MPa around the window and 70MPa at bolt positions. The stresses around pressure cabin apertures were higher than anticipated, especially around sharp cornered windows. When these cracks reached a critical length they would rapidly increase in size causing a rapid depressurisation of the cabin resulting in an explosion that would destroy the aircraft. The problem was exacerbated by the punch rivet construction technique used. The windows had been engineered to be glued and riveted, but had been punch riveted only. The imperfect nature of the hole created by punch riveting may have caused the start of fatigue cracks around the window. G-ALYU Fuselage failure – inside G-ALYU Fuselage failure - outside The technology introduced was cutting edge and with all new technology there are risks involved with entering unfamiliar territory. There were new load cases and failure modes to be analysed and new theories had to be developed to deal with all of this. There was also a possible mis-match between service loads and fatigue test procedure, a possible contribution from out-of-plane bending loads (bi-axial stresses). Finally, a poor configuration due to wing roof engine placement, affecting the updating potential, posing a possible fire hazard and affecting the structural integrity in case of engine disintegration. 4A6(1) Structural Design Group 6 The Results The lessons learnt from the Comet disasters, led to the revision of the safe loading strength requirements of airliner pressure cabins; even though the Comets had been designed in excess of current requirements, 2.5P as opposed to 1.33P (where P is the cabin proof pressure), they had still failed. The design of the different elements in the cabin was revised to eliminate the sharp corners which concentrated the stresses; hence the reason plane windows have rounded corners. Full- scale testing of aircraft structures was implemented and attention was drawn to detection of and the critical size for fatigue cracks in aircraft structures, with the concept of ‘one-bay’ crack tolerance in fuselage properly formulated. Finally, thanks to the pioneering experiments at Farnborough a better understanding of fatigue testing was established, by accurately matching service and test loads. References: “Structures or why things don’t fall down”, J.E. Gordon “Fatigue Failure of the de Havilland Comet”, P.A. Whitney www.tech.plym.ac.uk/sme/Interactive_Resources/tutorials/FailureCases/sf2.html http://aerospaceweb.org/aircraft/jetliner/comet/ http://en.wikipedia.org/wiki/De_Havilland_Comet#Production_and_service_summary