Canon City (Colorado) Dam Remedial Project

advertisement

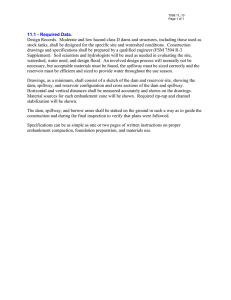

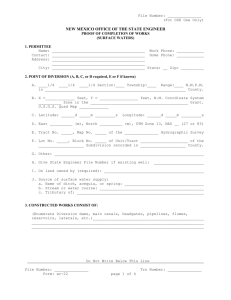

Case Study Colorado PL566 Remedial Assistance Project Frank Riggle Colorado Assistant State Conservationist Water Resources The Dam Built with PL-566 in 1971 Flood Control Crest to reservoir: 30’ Structural Height: 70’ Structure length: 490’ Holes Intelligent Rodents??? Accelerating Problem Holes along crest increased in the past 4-5 years Colorado State Engineer’s inspection started in 1991 NRCS State Engineer’s review mid 1990s Northern Plains Engineering Team Review 1/2004 Breach Order Because of the worsening condition of the dam and a concern with dam safety: The Colorado State Engineer issued the sponsors a breach order in March 2004 OPTIONS ??? Met with sponsors and State Engineer Discussed needs and strategy Initiated Formal Engineering Investigation Why is the dam cracking? Extended drought? Poor operation and maintenance? Poor construction? Engineering and design oversight? Investigation Investigation Engineering Team included members from Colorado, Texas, and Nebraska Site Visit - Visual Examination Excavated Exploration Trenches Interviews with NRCS State Engineer, former NRCS District Conservationist, and Colorado State Dam Safety Engineer about involvement during construction Examination of construction drawings, job diaries, soil engineering report, geology report, drill logs, profile and cross section drawings, ½” – 3” diameter holes became evident in early 1980’s, and are considerably larger today View of embankment with sink hole in foreground, shows developing pattern of holes along crest. Site Survey/Excavation Holes, cavities, and cracks of significant size observed Located in a line along the crest Lined up in three distinct areas perpendicular to axis of dam Lines of holes were on either side of principal spillway, and the third close to auxiliary spillway Virtually all holes located on upstream half of embankment Test pit dug over hole shows crack at depth Bucket width approximately two-feet Yellow soil is paint used to reveal crack while digging. Emergency Action Plan Breach Inundation Study NOAA Monitor precipitation Monitor dam when rainfall >2” Reverse 9-1-1 Brief County and City Emergency Staff How Many Engineers Does it Take……?? EMBANKMENT AS RESERVOIR FILLED Horizontal Crack Transverse Cracks Transverse Crack Transverse Crack The filter has not been contaminated with piped soil material. Engineer’s Report Cause of cracking/cavities differential settlement of upstream embankment and at the steep abutments and principal spillway along upstream edge of cutoff trench Holes and cavities are surface expressions of cracks in compacted earthfill Transverse cracks represent the most serious concern regarding safety of dam Responsibility for problem can be attributed primarily oversights and/or misjudgments during design, and construction of original embankment Underestimating collapse potential of sandy alluvium Decision to locate cutoff trench on dam centerline instead of near the upstream toe RESTORED EMBANKMENT Current Activities Draft environmental assessment Interagency review Copies of draft to affected landowners Final draft designs to Fort Worth for review Questions ???