Trends in U.S. Poultry Housing for Energy Conservation

Trends in US Poultry Housing for Energy Conservation

John W. Worley

Associate Professor

University of Georgia

1

Co-authors

• Mr. Michael Czarick

– Biological and Agricultural Engineering

– University of Georgia

• Dr. Brian Fairchild

– Poultry Science

– University of Georgia

2

Overview

• Background

• Energy Saving Technologies

• Survey Results

• Conclusions - Needs

3

Growth in Broiler Production in

Southeastern US

4

• Reasons for regional growth

– Low-cost land, labor, and housing

– Synergy with cow-calf operations –

Restoration of depleted crop lands

• Low-cost housing meant:

– Natural Ventilation

– Cheap construction

– Little or no insulation or powered ventilation

5

Evolution of birds and housing

• Improvements in genetics and nutrition

• Improvements in buildings

• Better buildings necessary for better bird performance

6

Energy efficiency

• Has always been considered

• Low historic energy prices

• Recent changes

• Energy now on “Front Burner”

7

Objectives

• Quantify expected energy savings from eight technologies (per house)

• Determine present and projected adoption rate by industry (poll)

• Estimate potential energy savings attributable to these technologies

(sample and industry-wide)

8

Energy Saving Technologies

• Tunnel Ventilation

– Allows greater bird densities and improves bird performance

– No energy savings recognized in this report

9

Energy Saving Technologies

• Electronic Controllers

– Tighter control of desired temperature

– Improved bird environment and performance

– No energy savings recognized in this report

Heaters

Exhaust

Fans

10

Energy Saving Technologies - Gas

• House Tightness

– Allows control of entering air (winter conditions)

– Curtain Flaps – one example of tightening

– O.1” static pressure with one 48-inch fan

– Projected 15% gas savings

11

Energy Saving Technologies - Gas

• Solid Walls

– Reduces leaks and conductive heat flow

– Savings depend on size of opening and R-value of solid wall

– Can be solid wall on both sides or North side

– Projected 15% gas savings

12

Energy Saving Technologies - Gas

• Circulation Fans

– Reduces heat stratification

– Increases bird comfort while reducing gas consumption

– Savings depend on type of heat and management

(10 to 30%)

– Projected 20% gas savings

13

Energy Saving Technologies - Gas

• Litter Treatments

– Reduce pH of litter

– Reduces ammonia emissions

– Reduces required ventilation during brooding

– Projected 20% gas savings

14

Energy Saving Technologies - Gas

• Wider Houses

– Reduces exposed wall area per bird

– Usually thicker walls (increased R value)

– 50 ft wide or wider

– Projected 15% gas savings

15

Energy Saving Technologies -

Electricity

• High efficiency exhaust fans

– Combination of efficient motors and housing

– Cone exhaust is indicator of efficiency

– Projected 15% savings based on EER improvement from 19 to 22 (Typical range of 16 to 24 for poultry ventilation fans)

16

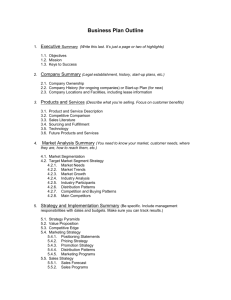

Summary of Expected Savings

Technology

House Tightness

Solid Walls

Circulation Fans

Litter Treatments

Wider Houses

Hi-Eff. Exhaust Fans

Estimated %

Savings

15% (gas)

15% (gas)

20% (gas)

20% (gas)

15% (gas)

15% (electric)

Note: Gas savings are multiplicative, not additive

17

Survey Results

• Sent survey to 20 complexes in GA, SC, and AL

• Received 11 replies (all from GA)

• Replies represent 806 million broilers per year

– 64% of production in Georgia

– 9.5% of total US production

• 6218 houses (projected 6418 by 2010)

18

Adoption Rates of Energy Saving

Technologies

100%

90%

80%

70%

60%

50%

40%

30%

20%

10%

0%

Tu nn el

C on tro

S oli lle r

C d W irc all

. F

H i E an s ff F

Lit te an s

W id r T rt.

e

Tig ht

Total

2010

2004

19

Gas Saved (million gallons)

40

30

20

10

0

So lid

W all s

C irc

. F an s

Lit te r T rt.

W id e

Tig ht

2004 Projected 2010 Total Potential

20

Electrical Energy Saved

(million kWh)

400

300

200

100

0

High Eff.

Fans

2004 Projected 2010 Total Potential

21

Conclusions

• Energy savings is recognized by the industry as important

• Technologies have had varying degrees of acceptance

• The need for education and further demonstration of technologies still exists

• Circulation fans, hi-eff. exhaust fans, and wider housing show the greatest potential for future savings

22